Académique Documents

Professionnel Documents

Culture Documents

Specification Description Design Code Content

Transféré par

sushant_jhawerDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Specification Description Design Code Content

Transféré par

sushant_jhawerDroits d'auteur :

Formats disponibles

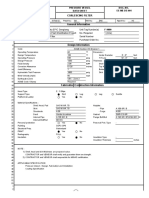

SPECIFICATION VESSELS AND TANKS

DESCRIPTION SEAL POT TYPE VERTICAL JACKETED TANK

DESIGN CODE ASME SEC VIII DIV - I EQUIP NO. V - 118

CONTENT

CAPACITY

WORKING (LITER) 80

SERVICE DATA TOTAL (LITER) 100 SHELL JACKET

NORMAL / MAX OPERATING PRESS Kg / cm2) 5.5 5.5

NORMAL / MAX OPERATING TEMP (C) 50

DESIGN PRESSURE (Kg/cm2) 7 7

DESIGN TEMPERATURE ( C) 100

SHELL CLOSURE TYPE (TOP) Dished

SHELL CLOSURE TYPE (BOTTOM) Dished

CORROSION ALLOWANCE mm 3 2

DESIGN DATA JOINT EFFICIENCY 0.7 0.7

RADIOGRAPHY (%) Nil Nil

STRESS RELIEVE Nil Nil

TEST PRESSURE (HYDRO / PNEU) (Kg/cm2) 10 10

WELDING PROCEDURE SMAW

SUPPORT ARRANGMENT 3 Nos of legs

SHELL IS 2002/SA 515 GR70NOZZLE SA 106 GR C FLANGE SA 105 GR C

MATERIAL OF JACKET IS 2002/SA 515 GR70 NOZZLE SA 106 GR C FLANGE SA 105 GR C

CONSTRUCTION SHELL CLOSURE IS 2002/SA 515 GR70 JACKET CLOSURE IS - 2002

SUPPORTS ISMA - 75 BOLTS & NUTS High Tensile GASKET CAF

SHELL 500 420

DIMENSIONS

JACKET 550 350; Leg Length: 750

PAINTING Two Coats of Red Oxide Primer on exterior

INSULATION CLEATS, RINGS Required

OTHERS INSPECTION

OTHER ACCESSORIES BY VENDOR Name Plate, Lifting Lugs, Earthing Boss

NOZZLES SCHEDULE

NOZZLE SERVICE FLANGE NOZZLE NECK NOM SIZE

REMARKS

NO QTY STD RTG TYPE SCH PROJ (mm)

N1 1 Hot Water In ASA 150 RF 40 200 25

N2 1 Hot Water Out ASA 150 RF 40 200 25

N3 1 Jacket Vent ASA 150 RF 40 200 25

N4 1 Process Inlet ASA 150 RF 40 200 50

N5 1 Process Outlet ASA 150 RF 40 200 50

N6 1 Spare ASA 150 RF 40 200 50

N7 1 Vent ASA 150 RF 40 200 25

N8 1 Earthing Clip 50 50 6

N9 1 Hand Hole ASA 150 RF 40 200 200

Vous aimerez peut-être aussi

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Vacuum Catch PotDocument1 pageVacuum Catch Potsushant_jhawerPas encore d'évaluation

- Air Surge VesselDocument1 pageAir Surge Vesselsushant_jhawerPas encore d'évaluation

- Cyano Inters ReceiverDocument1 pageCyano Inters Receiversushant_jhawerPas encore d'évaluation

- Specification Description Design Code ContentDocument1 pageSpecification Description Design Code Contentsushant_jhawerPas encore d'évaluation

- Graesser ExtractorDocument1 pageGraesser Extractorsushant_jhawerPas encore d'évaluation

- Er89-196 MHF 50Document1 pageEr89-196 MHF 50Gabriel VejarPas encore d'évaluation

- Acetaldehyde Storage TankDocument2 pagesAcetaldehyde Storage Tanksushant_jhawerPas encore d'évaluation

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelPas encore d'évaluation

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiPas encore d'évaluation

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Document3 pagesEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasPas encore d'évaluation

- ER89-187-2 CL 9002 VacDocument1 pageER89-187-2 CL 9002 VacGabriel VejarPas encore d'évaluation

- 8) Tss-Glycol Surge DrumDocument1 page8) Tss-Glycol Surge DrumKiran KumarPas encore d'évaluation

- Neutral Oil Extractor - FFTDocument1 pageNeutral Oil Extractor - FFTsushant_jhawerPas encore d'évaluation

- Technical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKDocument7 pagesTechnical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKAshok reddyPas encore d'évaluation

- Strainer Class 125 Iron: Y-Pattern - Bolted Cover - Blow-Out-Plug Stainless Steel (304) ScreenDocument1 pageStrainer Class 125 Iron: Y-Pattern - Bolted Cover - Blow-Out-Plug Stainless Steel (304) Screenthilina lakhithaPas encore d'évaluation

- General Spec Sheets of All InstrumentsDocument32 pagesGeneral Spec Sheets of All InstrumentsArslan NisarPas encore d'évaluation

- Documento - MX Comp1Document10 pagesDocumento - MX Comp1Mangesh BanalePas encore d'évaluation

- 1A P220 WHD Data Sheet PDFDocument5 pages1A P220 WHD Data Sheet PDFAhmed MusallamPas encore d'évaluation

- Vessel Data SheetDocument1 pageVessel Data Sheetaryo93100% (1)

- MDS Diesel TankDocument2 pagesMDS Diesel TankrifkynetPas encore d'évaluation

- Activated Carbon Filter VesselDocument5 pagesActivated Carbon Filter VesselShaaban NoamanPas encore d'évaluation

- PI Shoe Guide Anchor Support StandardsDocument40 pagesPI Shoe Guide Anchor Support StandardsKarun NayyarPas encore d'évaluation

- Plate Fabricated Pipe Calculation Sample PDFDocument4 pagesPlate Fabricated Pipe Calculation Sample PDFSakthi VelPas encore d'évaluation

- Wet Beta Gamma Picoline TankDocument1 pageWet Beta Gamma Picoline Tanksushant_jhawerPas encore d'évaluation

- FP1.0 Engineering Data A-C Pumps 8100Document12 pagesFP1.0 Engineering Data A-C Pumps 8100Christian FernandezPas encore d'évaluation

- Data Sheet Basket Filter-ATF R1Document3 pagesData Sheet Basket Filter-ATF R1Suaib VCSPas encore d'évaluation

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Document55 pagesG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHPas encore d'évaluation

- Compress CalculationDocument106 pagesCompress CalculationKrupal Patel100% (1)

- Instruction Manual FOR Air ReceiverDocument49 pagesInstruction Manual FOR Air ReceiverMehmet AGAGÜNDÜZPas encore d'évaluation

- Brocure FDB 407 40 - 150Document1 pageBrocure FDB 407 40 - 150mandahandriPas encore d'évaluation

- 1) Tss-Still Column Reboiler, Rev.ADocument1 page1) Tss-Still Column Reboiler, Rev.AKiran KumarPas encore d'évaluation

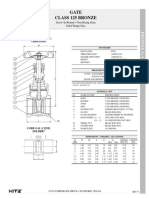

- Gate Class 125 Bronze: CODE # 40 (AK125E) ThreadedDocument1 pageGate Class 125 Bronze: CODE # 40 (AK125E) Threadedthilina lakhithaPas encore d'évaluation

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirPas encore d'évaluation

- CHECK VALVES - 1500 - Bolted Cover - SWDocument1 pageCHECK VALVES - 1500 - Bolted Cover - SWShayan Hasan KhanPas encore d'évaluation

- FD Fan Discharge DuctDocument5 pagesFD Fan Discharge Ductzakir84md3639Pas encore d'évaluation

- Heat Exchanger Datasheet, PDFDocument1 pageHeat Exchanger Datasheet, PDFWinsonLimHuiWahPas encore d'évaluation

- Pressure Drop Calculation For Fan (Exf-Bsc-01)Document8 pagesPressure Drop Calculation For Fan (Exf-Bsc-01)ibnrafeeqPas encore d'évaluation

- Instrument Data Sheets: Revision HistoryDocument9 pagesInstrument Data Sheets: Revision Historyerik masongPas encore d'évaluation

- VB 537 Ag BR: FiguraDocument1 pageVB 537 Ag BR: FiguraMaffone NumerounoPas encore d'évaluation

- Datasheet - 5 IEU X 1950 X S135 X R2 31.5 FT - 658 X 312 X TSDS50 X 135 Ksi SMYS - 14 Box 11 Pin - HB Box - 60 70 MUT - 1.0 FF and 1.15 FF - TSC DP Web Site 1Document2 pagesDatasheet - 5 IEU X 1950 X S135 X R2 31.5 FT - 658 X 312 X TSDS50 X 135 Ksi SMYS - 14 Box 11 Pin - HB Box - 60 70 MUT - 1.0 FF and 1.15 FF - TSC DP Web Site 1oscar0% (1)

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasPas encore d'évaluation

- Data Sheet Basket Filter-ATF R2Document4 pagesData Sheet Basket Filter-ATF R2Suaib VCSPas encore d'évaluation

- Bolts ConnectionDocument3 pagesBolts Connectionrizwanjawaid.meenaPas encore d'évaluation

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasPas encore d'évaluation

- FPS 100 Informacion ExtraDocument1 pageFPS 100 Informacion ExtraLuis Daniel Aguirre RuizPas encore d'évaluation

- Tank Shell Design - LATESTDocument12 pagesTank Shell Design - LATESThgagPas encore d'évaluation

- Class 125 Bronze: Butterfly Valves - 200 PsiDocument1 pageClass 125 Bronze: Butterfly Valves - 200 Psithilina lakhithaPas encore d'évaluation

- Air Receiver DesignDocument3 pagesAir Receiver DesigngksakthiPas encore d'évaluation

- Hydroseal Valves Legacy SeriesDocument16 pagesHydroseal Valves Legacy SeriesJuan David Alvarez CastroPas encore d'évaluation

- Mod. XXXXX: Ball Valve 2 PC Full Port 1000 Psi Cf8M (316) Threaded NPTDocument1 pageMod. XXXXX: Ball Valve 2 PC Full Port 1000 Psi Cf8M (316) Threaded NPTpitbullrelax11Pas encore d'évaluation

- 2A P220 Accumulator Process Data Sheet PDFDocument3 pages2A P220 Accumulator Process Data Sheet PDFAhmed MusallamPas encore d'évaluation

- Collicutt Hanover: Ltd. 7550 Ednar Industrial Drive Red Deer, Alberta T4P 3R.2 BP Canada Chemical Comdany, P.O. BP JoifreDocument2 pagesCollicutt Hanover: Ltd. 7550 Ednar Industrial Drive Red Deer, Alberta T4P 3R.2 BP Canada Chemical Comdany, P.O. BP Joifrerajindo1Pas encore d'évaluation

- Pipe Class 43 ADocument1 pagePipe Class 43 AAli RaheemPas encore d'évaluation

- Series 4030: SubmittalDocument2 pagesSeries 4030: SubmittalPSC RFQPas encore d'évaluation

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 pagesTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoPas encore d'évaluation

- M19-Air ReservoirDocument26 pagesM19-Air ReservoirAlexPas encore d'évaluation

- FRP FRP FRP FRP: Cooling Tower Cooling Tower Cooling Tower Cooling Tower Cooling TowerDocument35 pagesFRP FRP FRP FRP: Cooling Tower Cooling Tower Cooling Tower Cooling Tower Cooling TowerAhmed KhattabPas encore d'évaluation

- Dual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032Document1 pageDual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032thilina lakhithaPas encore d'évaluation

- Edoc - Pub - Fire Hydrant Pump CalculationDocument3 pagesEdoc - Pub - Fire Hydrant Pump Calculationsushant_jhawerPas encore d'évaluation

- Edoc - Pub - Foundation Design Philosophy For Rotating EquipmenDocument8 pagesEdoc - Pub - Foundation Design Philosophy For Rotating Equipmensushant_jhawerPas encore d'évaluation

- Deliverables List Feed Vs Detail EngineeringDocument9 pagesDeliverables List Feed Vs Detail Engineeringsushant_jhawer100% (5)

- Concrete FDN Insp. Checklist Rev1 On 26-12-2012Document1 pageConcrete FDN Insp. Checklist Rev1 On 26-12-2012sushant_jhawerPas encore d'évaluation

- Steam Control and Condensate Drainage For Heat Exchangers: GeneralDocument6 pagesSteam Control and Condensate Drainage For Heat Exchangers: Generalsushant_jhawerPas encore d'évaluation

- Rotary Dryer CalculationDocument5 pagesRotary Dryer Calculationsushant_jhawer100% (2)

- Dennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale OperationsDocument25 pagesDennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale Operationssushant_jhawerPas encore d'évaluation

- Heat Exchanger Failure Analysis: Case HistoryDocument1 pageHeat Exchanger Failure Analysis: Case Historysushant_jhawerPas encore d'évaluation

- Chemical Reactors and Reactions Test MethodDocument63 pagesChemical Reactors and Reactions Test Methodsushant_jhawer100% (1)

- Basic Engineering Package - Ideal ApproachDocument2 pagesBasic Engineering Package - Ideal Approachsushant_jhawerPas encore d'évaluation

- Design of Pressure Drop Flow MeterDocument6 pagesDesign of Pressure Drop Flow Metersushant_jhawerPas encore d'évaluation

- Green Field Building-ConstructionDocument7 pagesGreen Field Building-Constructionsushant_jhawerPas encore d'évaluation

- Control Valve PartDocument4 pagesControl Valve Partsushant_jhawerPas encore d'évaluation

- Multi AgitatorDocument9 pagesMulti Agitatorsushant_jhawerPas encore d'évaluation