Académique Documents

Professionnel Documents

Culture Documents

Brochure FPE Sale Straight Tunnel Freezer 2009

Transféré par

Aries RezpectorCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Brochure FPE Sale Straight Tunnel Freezer 2009

Transféré par

Aries RezpectorDroits d'auteur :

Formats disponibles

PATKOL

Public Company Limited

IQF Freezer

Product Information

Straight Tunnel

Freezer

Feat ur es

Simple and continuous processing for various products

Minimum maintenance and operating costs

High efficient freezing with top down flow in pressure tunnel

Simple layout for increasing productivity

Easy maintenance and cleaning

Hygienic design

Capable for both for chilling and freezing

Automatically control PATKOL 40 yrs.

28 NOV. 2005

T&D/FST/P1/200605/16

QUALITY WITH SERVICE

PATKOL Straight Tunnel Freezer is the standard

freezer of single mesh belt conveyer with continuous

process, which can freeze up to more than a ton per hour.

It is constructed on the GMP and HACCP standards for

food industry. It is a more efficient and cost effective

freezer, yielding the benefits of high quality product and

low operating cost.

Temperature

Straight tunnel freezer is suitable for freezing a wide

range of products such as seafood, meat product, fried

product, vegetable, fruit, bakery, ready-to-eat meal and

other products. There are two options of standard freezer;

one composed of normal coil for common products (inlet

Conventional Tunnel Freezer

temperature of the product is not high), the other with Pressure Tunnel Freezer

heavy duty coil, suitable for high temperature product

(warm or hot products). Freezing Time

Bakery Shrimp & Seafood Poultry Meat Product Fruit & Vegetable

Operation Sanitary Hygiene

Performance of the freezer is based on the ventilation The straight tunnel freezer enables completely open

of cool air on the top surface of product in top down flow up for cleaning. With stainless steel structure, manu-

within pressure tunnel. The top down flow in pressure factured under GMP and HACCP standards, one can

tunnel give high efficiency in freezing for elevated product assures that is need for sanitary and hygiene.

quality. The system is suitable for both food chilling and This freezer is designed to allow full visual inspection

freezing manufacturing process, in order to gain best of all surfaces, which would reduce the risk of invisible

quality products. and undesired hygienic hazards.

Top Down Flow Standard

In Pressure Tunnel Main Components

PATKOL Straight Tunnel Freezer is designed with top PATKOL Straight Tunnel Freezer is assembling from

down flow within pressure tunnel, giving higher efficiency high quality materials. It is consisted of conveyor mesh

than the normal flow direction. When the product is belt, main structure, evaporator unit, fan, and insulation

freezed in pressure tunnel, freezing time of product is enclosure.

decreased significantly as heat transfer area of product in High quality stainless steel wire mesh belt is used in

pressure tunnel increases and air velocity between product conveying in freezing process. All parts are made

products is very high. from stainless steel materials. High performance freezer's

fans allowing sufficient air flow.

Conventional Flow Pressure Tunnel Flow

Moreover, the rigid foamed polyurethane, the most

High air

velocity

effective heat-insulating material, is used as insulation

enclosure, giving high strength and durability of the

freezer room.

High heat removal

surface area

Slow Freezing Fast Freezing

PATKOL

P r o d u c t In fo r m a ti o n

Straight Tunnel Freezer

L W

H

PRODUCT

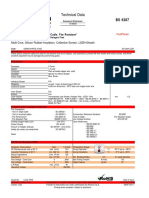

External Dimension (mm) Effective Effective Fan Fan Motor Product

Model Capacity

Length Belt Width (QTY.) (HP) (kg/h)

W L H

FST-1AP-04 3,600 5,600 3,300 4,000 1,850 3 5 250

FST-1AP-08 3,600 9,600 3,300 8,000 1,850 6 5 500

FST-1AP-12 3,600 13,600 3,300 12,000 1,850 9 5 750

FST-1AP-16 3,600 17,600 3,300 16,000 1,850 12 5 1,000

FST-1AP-20 3,600 21,600 3,300 20,000 1,850 15 5 1,250

Remark : This above specifications are changeble as require by customer Unit in mm

The length does not include infeed and outfeed zones

Product capacity is based on cooked shrimp product, inlet and outlet temperatures are +10oC and -20oC, respectively.

PAT K O L

Straight Tunnel

Customer Freezer

Reference

Customer : Pisittichai Internation Customer : S&P Syndicate

Application : Vegetable and Fruit Pisittichai Application : Butter Pound Cake

Capacities : 400 kg/hr Capacities : 500 pieces/hr

Customer : Thaveevong Industry Customer : Mycom (Thailand)

Application : Surimi and Tofu Application : Shrimp Frozen Industry

Capacities : 400 kg/hr Capacities : 500 kg/hr

After Sale

Service

Presently, PATKOL has many customers both

domestic and international, for various products

using our straight tunnel freezer. Optimums after

sale service and customer-driven production

process have been instrumental in ensuring high

customers' satisfactions.

In addition, PATKOL Food Technical and

Development specialists are ready to test the IQF

T&D-FST-P4-2006/04/26

product in our laboratory; design and fabricate

the freezer system to suit each kind of product.

PATKOL Public Company Limited

PATKOL

348 Chalermprakiat Rama 9 Road, Nongbon, Pravate, Bangkok 10250, Thailand

Tel : (66) 2328 1032-49 Fax : (66) 2328 1245, (66) 2328 1058

website : www.patkol.com e-mail : sales@patkol.com Quality With Service

Since 1965

Vous aimerez peut-être aussi

- Desiccant Dehumidifier FLi Jr. SeriesDocument2 pagesDesiccant Dehumidifier FLi Jr. Seriesroger_shPas encore d'évaluation

- Bahir Dar Uniiversity: Bahir Dar Institute of Technology (Bit) Faculty of Mechanical and Industrial EngineeringDocument10 pagesBahir Dar Uniiversity: Bahir Dar Institute of Technology (Bit) Faculty of Mechanical and Industrial Engineeringabdulber kedirPas encore d'évaluation

- MPR-161D (H) MPR-311D (H) Pharmaceutical Refrigerators: Compact and Large CapacityDocument2 pagesMPR-161D (H) MPR-311D (H) Pharmaceutical Refrigerators: Compact and Large Capacityfelix bazanPas encore d'évaluation

- Agitated Thin Film Dryer Manufacturer-CentPro EngineeringDocument6 pagesAgitated Thin Film Dryer Manufacturer-CentPro EngineeringAbhay RoyPas encore d'évaluation

- AAHE HEPA HousingDocument2 pagesAAHE HEPA HousingBANGUN RAHMAT TEKNIKPas encore d'évaluation

- Report On Fluidised Bed DryerDocument6 pagesReport On Fluidised Bed DryerDinesh DineshPas encore d'évaluation

- Tray Drying ChamberDocument4 pagesTray Drying ChamberParveen SharmaPas encore d'évaluation

- Electrolux rbf1016 Manual de UsuarioDocument3 pagesElectrolux rbf1016 Manual de UsuarioMichell Jaimes RodriguezPas encore d'évaluation

- Conservation Vent (Pressure & Vacuum)Document8 pagesConservation Vent (Pressure & Vacuum)Mustafa PardawalaPas encore d'évaluation

- WP PPR - Thermopipe SubmittalDocument36 pagesWP PPR - Thermopipe SubmittalMohammad Rashad BarakatPas encore d'évaluation

- Compact Air Conditioner Series - PC-KMADocument18 pagesCompact Air Conditioner Series - PC-KMAElisif DeFairPas encore d'évaluation

- Tray Drying ChamberDocument4 pagesTray Drying ChamberAcmas IndiaPas encore d'évaluation

- Petra PPH PDFDocument42 pagesPetra PPH PDFStepanusKukuhKurniadi61% (18)

- 1/4ton To 2ton Air Cooled Small Water Chiller: Product IntroductionDocument5 pages1/4ton To 2ton Air Cooled Small Water Chiller: Product IntroductionTitan KPas encore d'évaluation

- 2024 Brochure DRYPOINT XHDocument8 pages2024 Brochure DRYPOINT XHpeoplesrobinhoodPas encore d'évaluation

- York Standard Efficiency Screw Chiller With VSDDocument12 pagesYork Standard Efficiency Screw Chiller With VSDferdinand lai100% (1)

- 3119-600series Rev2 0912 LRes PDFDocument8 pages3119-600series Rev2 0912 LRes PDFAlper Emrah SakalsızPas encore d'évaluation

- PKGP PRC006 en - 03012009Document16 pagesPKGP PRC006 en - 03012009jm7711728Pas encore d'évaluation

- Tetra Pak Indirect UHT Unit PFF SSHE - PDDocument4 pagesTetra Pak Indirect UHT Unit PFF SSHE - PDLotfi JeffaliPas encore d'évaluation

- Iqf Tunnel Freezer, 1000kg Per Hour CapacityDocument12 pagesIqf Tunnel Freezer, 1000kg Per Hour CapacityEric WangPas encore d'évaluation

- Multipass Belt Tunnel FreezerDocument11 pagesMultipass Belt Tunnel FreezerAbas S. AcmadPas encore d'évaluation

- CFT Brochure NEWDocument20 pagesCFT Brochure NEWRahul KhannaPas encore d'évaluation

- Panwater PET 300 & 400 FC Series Cooling Towers PDFDocument4 pagesPanwater PET 300 & 400 FC Series Cooling Towers PDFkingathur26681Pas encore d'évaluation

- Types of Freezers and Its PrincipleDocument19 pagesTypes of Freezers and Its PrincipleRamya RPas encore d'évaluation

- Free Standing - Korea - R410a - CARRIERDocument13 pagesFree Standing - Korea - R410a - CARRIERWarish AliPas encore d'évaluation

- Bts Brochure Air-Cooled-Chillers YgweDocument12 pagesBts Brochure Air-Cooled-Chillers Ygwetarakoranga71Pas encore d'évaluation

- Thosiba TurbinesDocument16 pagesThosiba Turbinesilusee100% (1)

- A Flooded Screw ChillerDocument29 pagesA Flooded Screw ChillerDiêm Công Việt100% (3)

- 5l Glass FermenterDocument17 pages5l Glass FermenterRobert Jahirzinho Machaca MamaniPas encore d'évaluation

- Air WashersDocument7 pagesAir WashersimshubhamlackPas encore d'évaluation

- AwshcDocument9 pagesAwshcEduardo RivasPas encore d'évaluation

- Case Study - AsurionDocument9 pagesCase Study - AsurionItanPas encore d'évaluation

- Aqualogic Toplotne PumpeDocument28 pagesAqualogic Toplotne PumpeAnonymous WNKDboSFlPas encore d'évaluation

- BSC CatalogueDocument7 pagesBSC CatalogueNeeraj MehtaPas encore d'évaluation

- Kahl Extruder Type Oee 25 NG For Fish Feed and PetfoodDocument2 pagesKahl Extruder Type Oee 25 NG For Fish Feed and PetfoodMercyclara IgwePas encore d'évaluation

- Airsys P SC Medicool Brochure Mk2Document11 pagesAirsys P SC Medicool Brochure Mk2Anonymous mqsR6k1q6Pas encore d'évaluation

- KAHL ExtrudeurDocument2 pagesKAHL ExtrudeurAhmed Lamine AZZOUZPas encore d'évaluation

- Rlc-Svu02c-E4 0106Document12 pagesRlc-Svu02c-E4 0106Elias GarciaPas encore d'évaluation

- Fluid Bed Dryer PDFDocument5 pagesFluid Bed Dryer PDFAwalunisa IstiqomahPas encore d'évaluation

- Pizza Prep Table Pizza Prep Table: More Durable, Efficient, BeautifulDocument2 pagesPizza Prep Table Pizza Prep Table: More Durable, Efficient, BeautifulJorgePas encore d'évaluation

- Pultruded FRP Cooling TowersDocument14 pagesPultruded FRP Cooling TowersA.Subin Das100% (1)

- Inha CatalogueDocument16 pagesInha CatalogueJorge ValenciaPas encore d'évaluation

- Conservation Vent (Pressure & Vacuum)Document8 pagesConservation Vent (Pressure & Vacuum)Bureau VeritasPas encore d'évaluation

- LU VE Group Commercial Coolers PDFDocument34 pagesLU VE Group Commercial Coolers PDFmoran sahpiroPas encore d'évaluation

- Product Data: Fv4C Performancet Series Fan Coil Sizes 002 Thru 006Document18 pagesProduct Data: Fv4C Performancet Series Fan Coil Sizes 002 Thru 006John doPas encore d'évaluation

- STM Folder Blow Moulding Machines A4 ENG 2018 Opt 1Document16 pagesSTM Folder Blow Moulding Machines A4 ENG 2018 Opt 1Jauhari Mohd SeranPas encore d'évaluation

- Catalog Display MerchandisersDocument76 pagesCatalog Display MerchandisersAna GuijarroPas encore d'évaluation

- Vertical Deep Freezer India Suppliers and ManufacturersDocument3 pagesVertical Deep Freezer India Suppliers and Manufacturerssaurabh_acmasPas encore d'évaluation

- Static Blower: FDN-H Series FGN-H SeriesDocument7 pagesStatic Blower: FDN-H Series FGN-H SeriesAung Thiha SoePas encore d'évaluation

- Vertical Pellet Cooler LiteratureDocument6 pagesVertical Pellet Cooler LiteratureMusheer BashaPas encore d'évaluation

- Fmaxx Guide Specifications & Company QualificationsDocument4 pagesFmaxx Guide Specifications & Company Qualificationsthinesh karthikeyanPas encore d'évaluation

- Mann+Hummel Protec GMBH: ConveyingDocument8 pagesMann+Hummel Protec GMBH: ConveyingMUHAMMAD SHARIFPas encore d'évaluation

- Freeze Dryer 20Document3 pagesFreeze Dryer 20Shrini TamaskarPas encore d'évaluation

- OPFLOCooler Lit 2012Document6 pagesOPFLOCooler Lit 2012Bảo Phan HoàiPas encore d'évaluation

- GRN Brochure 2023 R4Document8 pagesGRN Brochure 2023 R4malennyPas encore d'évaluation

- Air Cooling System DPDocument10 pagesAir Cooling System DPDPSHARMAPas encore d'évaluation

- Contherm Max Scraped Surface Heat ExchangerDocument2 pagesContherm Max Scraped Surface Heat ExchangerManoj Kumar LalPas encore d'évaluation

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Comfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаDocument28 pagesComfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаJohn SmithPas encore d'évaluation

- 100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesDocument3 pages100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesPazhamalairajan KaliyaperumalPas encore d'évaluation

- Super End ChipperDocument14 pagesSuper End ChipperalphatoolsPas encore d'évaluation

- API 600 Trim No.Document19 pagesAPI 600 Trim No.SUBHASISH BHATTACHARYYAPas encore d'évaluation

- Bulletin 446 - 1/06 - Alumina Loading Problems - Western AustraliaDocument2 pagesBulletin 446 - 1/06 - Alumina Loading Problems - Western Australialevent364Pas encore d'évaluation

- HD465.605-7 Field AssemblyDocument72 pagesHD465.605-7 Field Assemblysoelist teoPas encore d'évaluation

- Dokumen - Tips - Caterpillar d6 Dozer Manual d6b Crawler Tractor Ritchiewiki Caterpillar d6bDocument5 pagesDokumen - Tips - Caterpillar d6 Dozer Manual d6b Crawler Tractor Ritchiewiki Caterpillar d6bjuane27Pas encore d'évaluation

- Epoxy CuringDocument8 pagesEpoxy CuringUrban Renewal Development100% (1)

- Color Changing Cylinder Universal Indicator and Dry IceDocument2 pagesColor Changing Cylinder Universal Indicator and Dry Iceapi-354141486Pas encore d'évaluation

- Partition ManualDocument42 pagesPartition ManualAnonymous SblBDN0Pas encore d'évaluation

- Xfmea MfmeaDocument6 pagesXfmea Mfmeabojanmarkovic88Pas encore d'évaluation

- UNF ThreadDocument4 pagesUNF ThreadMUUTHUKRISHNANPas encore d'évaluation

- Boge Up To 300kw - PDFDocument12 pagesBoge Up To 300kw - PDFparsmessengerPas encore d'évaluation

- DSE501 Data Sheet PDFDocument2 pagesDSE501 Data Sheet PDFChristopher100% (3)

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaPas encore d'évaluation

- Drveni Zidovi PDFDocument35 pagesDrveni Zidovi PDFMartinJankovićPas encore d'évaluation

- Industrial Training Report 18se02ch014Document9 pagesIndustrial Training Report 18se02ch014Alis Navadiya0% (1)

- Zinc and Tin Alloy Wire Used in Thermal Spraying For Electronic ApplicationsDocument4 pagesZinc and Tin Alloy Wire Used in Thermal Spraying For Electronic ApplicationsBang AnPas encore d'évaluation

- Fabric Inspection Under 4Document5 pagesFabric Inspection Under 4texcons677150% (2)

- A Method of Approximate Tool Wear Analysis in Cold Roll FormingDocument6 pagesA Method of Approximate Tool Wear Analysis in Cold Roll FormingAly MahdyPas encore d'évaluation

- MEG (Monoethylene Glycol)Document3 pagesMEG (Monoethylene Glycol)Lakshman NaikPas encore d'évaluation

- Strength of Materials StressDocument5 pagesStrength of Materials StressMarianne Lou PalomarPas encore d'évaluation

- Cleaning and Sanitizing: Concentration - The Presence of Too Little Sanitizer Will Result in An InadequateDocument3 pagesCleaning and Sanitizing: Concentration - The Presence of Too Little Sanitizer Will Result in An InadequateRhodaCastilloPas encore d'évaluation

- MBX - Amoladora Quita OxidoDocument6 pagesMBX - Amoladora Quita OxidoomarPas encore d'évaluation

- ABS Under 90m - Part 4Document356 pagesABS Under 90m - Part 4blindstrom42Pas encore d'évaluation

- Zinc Flake Technology-Technical PDFDocument1 pageZinc Flake Technology-Technical PDFKalyan DhakanePas encore d'évaluation

- IGCSE Chemistry DefinitionsDocument5 pagesIGCSE Chemistry DefinitionsTanmay Karur100% (1)

- Ansys Tutorial 3Document4 pagesAnsys Tutorial 3deathesPas encore d'évaluation

- RF Series-Catalog 3800 - SectionADocument3 pagesRF Series-Catalog 3800 - SectionAStefan DinuPas encore d'évaluation

- S2 G 460 - TDS PDFDocument3 pagesS2 G 460 - TDS PDFWawanDarmawanPas encore d'évaluation