Académique Documents

Professionnel Documents

Culture Documents

Air Compressor Risk MG T Form

Transféré par

Fateh AliyaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Air Compressor Risk MG T Form

Transféré par

Fateh AliyaDroits d'auteur :

Formats disponibles

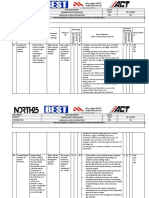

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: April 2011 Page Number: 1 of 8

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

1. Hazard Management Details General

Plant/Equipment Item: AIR COMPRESSOR (Mobile) Make/Model No.: Serial No.:

School / Work Location: Region:

Name of Person(s) Conducting Activity: Date Conducted:

Description of Use: Summary of Key Risks:

(refer to appropriate subsections)

An air compressor takes in air at atmospheric

pressure and compresses it to a higher Impact and cutting

pressure.

Pressurised content

Common uses for air compressors is to supply Electricity

high-pressure air for conveying, paint Ergonomics

spraying, inflating tyres, cleaning, pneumatic

tools etc. Noise

Slips/trips/falls

2. Documentation

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: April 2011 Page Number: 2 of 8

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Relevant Legislation/Standards Y/N Comments

Is plant required to be registered? Y N

Is a user license required? Y N

Key reference material? AS 4343Pressure equipment - Hazard levels

AS/NZS 3760 In service safety inspection and testing of electrical equipment

Plant Documentation Y/N Comments

Are operators manuals accessible? Y N

Is this a restricted use item? Y N

Does this item require safe use documents/test? Y N

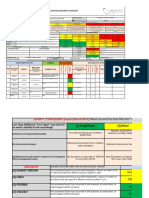

3. Hazard Identification

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ENTANGLEMENT

Can anyones hair, clothing, gloves, cleaning brushes,

Y N

tools, rags or other materials become entangled with

moving parts of the plant or materials?

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

IMPACT AND CUTTING INJURIES Strike with uncontrolled hose or Ensure air compressor is operated

Can anyone be crushed/cut/struck etc. due to: coupling. and maintained in accordance with

Material falling off the plant? manufacturers instructions.

Y N

Uncontrolled/unexpected movement of plant/load? Y N Moderate Possible Medium

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: April 2011 Page Number: 3 of 8

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected Risk Assessment Description of Risk Control Measures

Lack of capacity to slow, stop or immobilise plant? Y N

The plant tipping or rolling over? Y N

Parts of the plant disintegrating or collapsing? Y N

Contact with moving parts during testing,

inspection, operation, maintenance, cleaning or Y N

repair?

Being thrown off or under the plant? Y N

Contact with sharp or flying objects? (e.g. work

Y N

pieces being ejected)

The mobility of the plant? Y N Moderate Possible Medium

Inappropriate parts and accessories being used? Y N

Other Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SHEARING

Can anyones body parts be sheared between two

Y N

parts of plant, or between a part of the plant and a work

piece or structure?

PRESSURISED CONTENT Moderate Possible Medium Damaged hoses and Ensure air compressor is operated

Can anyone come into contact with fluids or gases accessories may cause blow and maintained in accordance with

Y N

under high pressure, due to plant failure or misuse of out. the manufacturers instructions.

the plant?

ELECTRICITY Damaged or frayed electrical Operator to check for damaged

Can anyone be injured or burnt due to: cords pose an electrical hazard. electrical cords prior to use.

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: April 2011 Page Number: 4 of 8

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

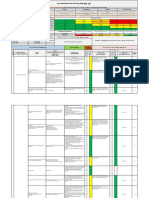

Hazards Inspected Risk Assessment Description of Risk Control Measures

Live electrical conductors? (e.g. exposed wires) Y N

Ensure equipment is serviced on a

Working in close proximity to electrical conductors? regular basis, tested and tagged,

Y N and appropriate isolation

procedures (e.g. lock out tags) are

Access to electricity?

Y N in place.

Damaged or poorly maintained electrical leads, Major Unlikely Medium

Y N

cables or switches?

Water near electrical equipment?

Y N

Lack of isolation procedures?

Y N

Other

Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ERGONOMICS Moving or handling the air Ensure appropriate manual

Can anyone be injured due to: compressor may present a handling techniques are applied

Poorly designed workstation? manual handling risk. when moving or handling the air

Y N compressor.

Repetitive body movement?

Y N

Constrained body posture or the need for Moderate Unlikely Medium

Y N

excessive effort?

Design deficiency causing psychological stress?

Y N

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: April 2011 Page Number: 5 of 8

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected Risk Assessment Description of Risk Control Measures

Inadequate or poorly placed lighting?

Y N

Does the plant impact on the surrounding

workplace and create potential hazards? (Consider Y N

safe access and egress from plant, workflow and

design of the workplace)

Is the location of the plant inappropriate? (Consider

potential effects due to environmental conditions Y N

and terrain)

Other

Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

RADIATION

Can anyone using the plant, or in the vicinity of the

plant suffer injury or illness due to exposure to radiation

in the form of any of the following: Y N

infra-red radiation

ultra violet light

microwaves

NOISE Moderate Unlikely Medium The air compressor may Ensure appropriate hearing

Can anyone using the plant, or in the vicinity of the produce high levels of noise. protection is worn if working in

plant, suffer injury due to exposure to noise? Y N

close proximity to the air

compressor.

VIBRATION

Can anyone be injured or suffer ill-health from Y N

exposure to vibration?

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: April 2011 Page Number: 6 of 8

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected Risk Assessment Description of Risk Control Measures

FRICTION

Can anyone be burnt due to contact with moving parts, Y N

materials or surfaces of the plant?

SUFFOCATION

Can anyone be suffocated due to lack of oxygen, or Y N

atmospheric contamination?

CONDITION

Is a hazard likely due to the age and condition of the

Y N

plant? (Consider how hard the machine has been

worked, and whether it is used constantly or rarely).

Can anyone be injured as a result of the plant not

serviced appropriately and/or maintained in line Y N

with manufacturers recommendations?

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SLIPS/TRIPS/FALLS Poor housekeeping by allowing Ensure appropriate cleaning and

Can anyone using the plant, or in the vicinity of the the build-up of waste materials housekeeping practices are

plant, slip, trip or fall due to: or failure to immediately clean maintained to minimise the risk of a

Uneven, slippery or steep work surfaces? up spills could result in a slip slip, trip or fall.

Y N hazard.

Poor housekeeping, e.g. spillage in the vicinity?

Y N

Minor Possible Medium

Inappropriate placement of

Obstacles being placed in the vicinity of the plant? Minor Possible Medium objects (e.g. spare materials,

Y N bags etc.) in the immediate

vicinity of the equipment may

Inappropriate or poorly maintained floor or walking result in a trip hazard.

surfaces? (i.e. lack of a slip-resistant surface, Y N

unprotected holes, penetrations or gaps?)

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: April 2011 Page Number: 7 of 8

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected Risk Assessment Description of Risk Control Measures

If operating or maintaining plant at height can anyone

slip, trip or fall due to:

Use of work platforms, stairs or ladders?

Y N

Lack of guardrails or other suitable edge

Y N

protection?

Other?

Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

FIRE AND EXPLOSION

Can anyone be injured by fire? Y N

Can anyone be injured by explosion of gases,

Y N

vapours, liquids, dusts, or other substances?

TEMPERATURE/MOISTURE

Can anyone come into contact with objects at high or Y N

low temperatures?

Can anyone suffer ill-health due to exposure to

Y N

high or low temperatures?

Can anyone be injured or suffer ill-health due to

Y N

exposure to moisture?

OTHER

Can anyone be injured or suffer ill-health from

exposure to:

Chemicals? Y N

Toxic gases or vapours? Y N

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: April 2011 Page Number: 8 of 8

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected Risk Assessment Description of Risk Control Measures

Fumes/Dusts? Y N

Other? (please specify) Y N

4. Risk Assessment Signoff

Authorised By: Signature: Date:

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

Vous aimerez peut-être aussi

- RA - SandblastingDocument2 pagesRA - Sandblasting721917114 47Pas encore d'évaluation

- 49 Roofing safety-JOB PROCEDUREDocument2 pages49 Roofing safety-JOB PROCEDUREmalimsaidi_160040895Pas encore d'évaluation

- Hand-Operated Power Tool SafetyDocument2 pagesHand-Operated Power Tool SafetySanthoshKumarPas encore d'évaluation

- SOP For Tree Cutting at HPCL UNNAODocument3 pagesSOP For Tree Cutting at HPCL UNNAOamankumarPas encore d'évaluation

- Risk Assessment for Precast InstallationDocument11 pagesRisk Assessment for Precast InstallationSajid ShahPas encore d'évaluation

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaPas encore d'évaluation

- Lifting plan checklistDocument1 pageLifting plan checklistP.M.K anthPas encore d'évaluation

- Carpentry Forming Framing or Wood WorkingDocument1 pageCarpentry Forming Framing or Wood WorkingPrakash PavuralaPas encore d'évaluation

- 02-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument5 pages02-F02 HIRA-Hazard ID and Risk Assessment Form and Registershaibaz chafekarPas encore d'évaluation

- Visitor Safety BriefingDocument2 pagesVisitor Safety BriefingDoni TriatmojoPas encore d'évaluation

- Risk Assessment For Coring WorksDocument5 pagesRisk Assessment For Coring WorksFaizan Tanveer100% (1)

- Sor-Landscape-Ppe5 29 Dec. 2020Document1 pageSor-Landscape-Ppe5 29 Dec. 2020haniPas encore d'évaluation

- RA082-C Grinding - ThornliebankDocument2 pagesRA082-C Grinding - Thornliebankloveson709Pas encore d'évaluation

- Work Permit 2.13Document14 pagesWork Permit 2.13Oliva Del Rosario Sagpao100% (1)

- Permit To Work FormDocument4 pagesPermit To Work FormMohammed Shams TabrezPas encore d'évaluation

- Attachment 7 Scaffolding PermitDocument2 pagesAttachment 7 Scaffolding PermitAviects Avie JaroPas encore d'évaluation

- 04 Vehicle Check ListDocument2 pages04 Vehicle Check ListP.M.K anthPas encore d'évaluation

- MSDS Cement PDFDocument5 pagesMSDS Cement PDFHendrik SimatupangPas encore d'évaluation

- Roofing ActivitiesDocument1 pageRoofing ActivitiesMark BeebakheePas encore d'évaluation

- Coshh Assessment FormDocument6 pagesCoshh Assessment FormAfaan gani InamdarPas encore d'évaluation

- Safety Committee Minutes of MeetingDocument4 pagesSafety Committee Minutes of MeetingMichael BejigaPas encore d'évaluation

- MWR 135Document20 pagesMWR 135Philip Bautista TotanesPas encore d'évaluation

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanPas encore d'évaluation

- 2 Consequence Management ProcedureDocument10 pages2 Consequence Management ProcedureriyazaliPas encore d'évaluation

- Risk Assessment of Trees MaintenanceDocument9 pagesRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- OHS PROC 113 BarricadesDocument9 pagesOHS PROC 113 BarricadesPhillip L100% (1)

- Temporary Fencing Risk AssessmentDocument7 pagesTemporary Fencing Risk AssessmentIrfan Prima AldiPas encore d'évaluation

- RISK ASSESSMENT FOR SWRO PLANT FOUNDATION WORKDocument7 pagesRISK ASSESSMENT FOR SWRO PLANT FOUNDATION WORKabhinav djPas encore d'évaluation

- 10-F20 Fuel Driven Equipment InspectionDocument3 pages10-F20 Fuel Driven Equipment InspectionSn AhsanPas encore d'évaluation

- Method Statement for Portland Cement PlasterDocument18 pagesMethod Statement for Portland Cement Plasterlinga2014Pas encore d'évaluation

- AHA-004, Earth Work Site PrepDocument6 pagesAHA-004, Earth Work Site PrepBuddhikaPas encore d'évaluation

- Victor Scaffolding Supervisor CVDocument12 pagesVictor Scaffolding Supervisor CVvictor joePas encore d'évaluation

- Site Environmental Control ReportDocument5 pagesSite Environmental Control ReportJasonTeePas encore d'évaluation

- Permanent Facilities Storage ProtectionDocument2 pagesPermanent Facilities Storage ProtectionMOHAMMED RIYAN TPas encore d'évaluation

- Risk Assessment Record for BPGIC TerminalDocument4 pagesRisk Assessment Record for BPGIC TerminalAbdul HadiPas encore d'évaluation

- 02 - R.A. Working On ScaffoldsDocument2 pages02 - R.A. Working On ScaffoldspremPas encore d'évaluation

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- 04 JSA - Welding WorksDocument6 pages04 JSA - Welding Workssyed khaja misbhuddinPas encore d'évaluation

- Task Based Risk Assessment for Pipe Transportation and InstallationDocument2 pagesTask Based Risk Assessment for Pipe Transportation and InstallationBeyar. ShPas encore d'évaluation

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpPas encore d'évaluation

- BOW SHACKLES InspectionDocument1 pageBOW SHACKLES InspectionLwandziso DlaminiPas encore d'évaluation

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaPas encore d'évaluation

- Batching Plant Method StatmentDocument9 pagesBatching Plant Method Statmentmohamed.elkomyPas encore d'évaluation

- Oman LPG Fire Safety RequirementsDocument47 pagesOman LPG Fire Safety Requirementsadnan amal yusfarPas encore d'évaluation

- Weekly Report As of September 12Document45 pagesWeekly Report As of September 12Cesar DuriasPas encore d'évaluation

- Site Risk Register Summarizes Facility HazardsDocument4 pagesSite Risk Register Summarizes Facility HazardsvatasaPas encore d'évaluation

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesThermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghPas encore d'évaluation

- Ra For Hot Work (Welding & Cutting Works)Document3 pagesRa For Hot Work (Welding & Cutting Works)Abrar AhmedPas encore d'évaluation

- BackfillingDocument2 pagesBackfillingGyanendra Narayan NayakPas encore d'évaluation

- 10 JSA - Cable Drums InstallationsDocument6 pages10 JSA - Cable Drums Installationssyed khaja misbhuddinPas encore d'évaluation

- Company Task Renew Main Mast Equipment: a) Navigation LightDocument17 pagesCompany Task Renew Main Mast Equipment: a) Navigation LightAbid MujtabaPas encore d'évaluation

- Rel Constrotech LLP: Check List For Arc Welding MachineDocument10 pagesRel Constrotech LLP: Check List For Arc Welding MachineAkPas encore d'évaluation

- Think Before You Tip Induction Record: You Must Not You Must AlwaysDocument2 pagesThink Before You Tip Induction Record: You Must Not You Must AlwaysramodPas encore d'évaluation

- JSA - Batching Plant OperationDocument3 pagesJSA - Batching Plant OperationNisith SahooPas encore d'évaluation

- 04, Use of Hand ToolsDocument2 pages04, Use of Hand ToolsFrancis K BonfulPas encore d'évaluation

- JSa For Glass FixingDocument17 pagesJSa For Glass FixingShekh BabulPas encore d'évaluation

- 11 - Drilling Machine ChecklistDocument1 page11 - Drilling Machine ChecklistAfzal AkhtarPas encore d'évaluation

- Air Compressor Risk MG T FormDocument8 pagesAir Compressor Risk MG T Formashraf100% (1)

- LAWS OF MALAYSIA ACT 520Document73 pagesLAWS OF MALAYSIA ACT 520May OngPas encore d'évaluation

- Industy Code of Practice For Safe Working in A Confined Space 2010Document80 pagesIndusty Code of Practice For Safe Working in A Confined Space 2010Abd Rahim100% (2)

- 1) MRL-ICT-IMSP-01.01 (S) (04) Asset ManagementDocument16 pages1) MRL-ICT-IMSP-01.01 (S) (04) Asset ManagementFateh AliyaPas encore d'évaluation

- MRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestDocument1 pageMRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestFateh AliyaPas encore d'évaluation

- ENG ICOP CHC (Amendment) Part 1 2019Document66 pagesENG ICOP CHC (Amendment) Part 1 2019Fateh AliyaPas encore d'évaluation

- Industry Code of Practice For Management of Occupational Noise Exposure PDFDocument75 pagesIndustry Code of Practice For Management of Occupational Noise Exposure PDFMohd AbidPas encore d'évaluation

- Construction of Cast In-Situ Segmental Box Girder (Road, Land Bridge) Rev 05Document126 pagesConstruction of Cast In-Situ Segmental Box Girder (Road, Land Bridge) Rev 05Fateh Aliya100% (1)

- Acf-Mra-066 - SCDocument1 pageAcf-Mra-066 - SCFateh AliyaPas encore d'évaluation

- Acf-Mra-068 - UcDocument1 pageAcf-Mra-068 - UcFateh AliyaPas encore d'évaluation

- Description of NCR at Bridge 3Document7 pagesDescription of NCR at Bridge 3Fateh AliyaPas encore d'évaluation

- Acf-Mra-067 - UcDocument1 pageAcf-Mra-067 - UcFateh AliyaPas encore d'évaluation

- Acf-Mra-069 - UcDocument1 pageAcf-Mra-069 - UcFateh AliyaPas encore d'évaluation

- ECRL-S4-BR-MS-0014 Casting of T-Beam Rev 00Document74 pagesECRL-S4-BR-MS-0014 Casting of T-Beam Rev 00Fateh Aliya0% (1)

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaPas encore d'évaluation

- Acf-Mra-065 - SCDocument1 pageAcf-Mra-065 - SCFateh AliyaPas encore d'évaluation

- MMSB Consult SDN BHD / China Railway Design Corporation East Coast Rail Link Project (Ecrl)Document1 pageMMSB Consult SDN BHD / China Railway Design Corporation East Coast Rail Link Project (Ecrl)Fateh AliyaPas encore d'évaluation

- PTS - 18.03.01 HSE Committee PDFDocument16 pagesPTS - 18.03.01 HSE Committee PDFFateh AliyaPas encore d'évaluation

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaPas encore d'évaluation

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaPas encore d'évaluation

- AsdsadassadsadfwqwqwqweDocument1 pageAsdsadassadsadfwqwqwqweFateh AliyaPas encore d'évaluation

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaPas encore d'évaluation

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaPas encore d'évaluation

- Acf-Mra-065 - SCDocument1 pageAcf-Mra-065 - SCFateh AliyaPas encore d'évaluation

- Acf-Mra-062 - SCDocument1 pageAcf-Mra-062 - SCFateh AliyaPas encore d'évaluation

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaPas encore d'évaluation

- PTS - 18.03.01 HSE Committee PDFDocument16 pagesPTS - 18.03.01 HSE Committee PDFFateh AliyaPas encore d'évaluation

- PTS - 18.03.01 HSE Committee PDFDocument16 pagesPTS - 18.03.01 HSE Committee PDFFateh AliyaPas encore d'évaluation

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaPas encore d'évaluation

- Hirard - DrivingDocument2 pagesHirard - DrivingFateh AliyaPas encore d'évaluation

- 1 Crisp Projects: Erode Salem Madurai Trichy Kochi Bengaluru CoimbatoreDocument20 pages1 Crisp Projects: Erode Salem Madurai Trichy Kochi Bengaluru CoimbatoreKathir VelPas encore d'évaluation

- Fta-500 A (03-20-08) PDFDocument8 pagesFta-500 A (03-20-08) PDFOrlando Vazquez PuertaPas encore d'évaluation

- ISO/TC 46/SC 9/working Group 1Document4 pagesISO/TC 46/SC 9/working Group 1João Paulo CésarPas encore d'évaluation

- Examining Oral Communication FunctionsDocument5 pagesExamining Oral Communication FunctionsJoshua Lander Soquita CadayonaPas encore d'évaluation

- COE 107.04 Cathodic Protection Monitoring Instruments and ProceduresDocument42 pagesCOE 107.04 Cathodic Protection Monitoring Instruments and ProceduresMo'tasem Serdaneh100% (1)

- Nursing ProcessDocument88 pagesNursing ProcessGerard On LinePas encore d'évaluation

- Product Code Threaded Rod Size (R) Lenght (L) MM Pitch (MM) Minimum Proof Load (N) Microns ( ) Bundle QuantityDocument1 pageProduct Code Threaded Rod Size (R) Lenght (L) MM Pitch (MM) Minimum Proof Load (N) Microns ( ) Bundle QuantityKABIR CHOPRAPas encore d'évaluation

- Register for a WordPress account in 5 easy stepsDocument5 pagesRegister for a WordPress account in 5 easy stepsPutriPas encore d'évaluation

- Evolution of Telecommunications GenerationsDocument45 pagesEvolution of Telecommunications GenerationsSai RamPas encore d'évaluation

- Strategic Marketing Plan For Red Bull - Elvis Asiedu - Academia - Edu PDFDocument23 pagesStrategic Marketing Plan For Red Bull - Elvis Asiedu - Academia - Edu PDFThomas Diwo0% (1)

- Karl Marx AssignmentDocument1 pageKarl Marx Assignmenthanunarabella1Pas encore d'évaluation

- 38-13-10 Rev 2Document128 pages38-13-10 Rev 2Gdb HassenePas encore d'évaluation

- 3.dummy VariablesDocument25 pages3.dummy VariablesUnushka ShresthaPas encore d'évaluation

- Achieve Your Resolutions: Archana SaratDocument27 pagesAchieve Your Resolutions: Archana Saratmaria_m21Pas encore d'évaluation

- Myers Et Al - Clear and Present ThinkingDocument214 pagesMyers Et Al - Clear and Present ThinkingAEPas encore d'évaluation

- Career Paralysis (PT 1) - Five Reasons Why Our Brains Get Stuck Making Career DecisionsDocument99 pagesCareer Paralysis (PT 1) - Five Reasons Why Our Brains Get Stuck Making Career DecisionsToni ErdfeldPas encore d'évaluation

- Comparison of Unix and Dos: AssignmentDocument10 pagesComparison of Unix and Dos: AssignmentMohsin ShakoorPas encore d'évaluation

- Fire Risk Assessment FormDocument16 pagesFire Risk Assessment Formmukamat safiiPas encore d'évaluation

- #C C C$ C%C& C' C (CDocument4 pages#C C C$ C%C& C' C (CThong Chee WheiPas encore d'évaluation

- TAURI User ManualDocument23 pagesTAURI User ManualChris Sad LHPas encore d'évaluation

- GITAM Guidelines For MBA Project Work - 2018Document6 pagesGITAM Guidelines For MBA Project Work - 2018Telika RamuPas encore d'évaluation

- SAP PPM 5.0 Certification Exam TopicsDocument7 pagesSAP PPM 5.0 Certification Exam TopicsongkecanthoPas encore d'évaluation

- Fc6a Plus (MQTT)Document44 pagesFc6a Plus (MQTT)black boxPas encore d'évaluation

- EPABX User's Guide for Making Calls and Using FeaturesDocument4 pagesEPABX User's Guide for Making Calls and Using FeaturesPraveen KumarPas encore d'évaluation

- Asphalt Laboratory Manual RevDocument13 pagesAsphalt Laboratory Manual RevKurian C ChackoPas encore d'évaluation

- Microsoft Word - JOB DESCRIPTION Staff AccountantDocument2 pagesMicrosoft Word - JOB DESCRIPTION Staff Accountantanon-634050100% (3)

- Muhammad Ajmal: Electrical EngineerDocument1 pageMuhammad Ajmal: Electrical EngineerMuhammad AbrarPas encore d'évaluation

- Organizational Development and EvaluationDocument22 pagesOrganizational Development and EvaluationFransisca RosalinPas encore d'évaluation

- Summative Test in Grade 10 ScienceDocument2 pagesSummative Test in Grade 10 ScienceRomeo GabitananPas encore d'évaluation

- Planning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDocument5 pagesPlanning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDoniansyah Mai PutraPas encore d'évaluation