Académique Documents

Professionnel Documents

Culture Documents

Technical Schedule

Transféré par

Anshuman AgrawalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Schedule

Transféré par

Anshuman AgrawalDroits d'auteur :

Formats disponibles

TECHNICAL SCHEDULE

Tender Specification No. MPPGCL/Tender No.5846.

Due on : 13.02.2017

NIT No: 132

Sub:- Supply & installation of one number 4200 LPH Capacity Trolley Mounted FRF Oil

Purification System having Ion Exchange Plus Vacuum Dehydration Technology along

with 3 stage Filtration for 500 MW Units of SGTPS, Birsinghpur.

I. FRF Oil Purifier System Technical Specification :

FRF Oil Purifier System shall be having Ion Exchange Plus Vacuum Dehydration

Technology along with 3 stage filtration and capability to reduce Total Acid Number

(TAN) to 0.1 mg KOH/gm (minimum) and should reduce water content to 0.08%

Wt.(800 ppm) and it should conform to oil cleanliness level as per NAS1638 (SAE

Class-3) ,Solid Particle cleanliness level to be achieved - NAS 5.

S.N Particulars Remarks

A Procurement of FRF Purifier for 500 MW

BHEL make Steam Turbine having

reservoir volume 15000 Liters confirming

to System temperature below 70o C.

Ion Exchange & Vacuum Dehydration

Technology along with 3 stage filtration.

OEM Specifications of TAN ( < 0.1 mg

KOH/gm),Electrical Resistivity ( >50 Mega

Ohm Mtr.) & Particulates Distribution <

15/12 ( as per ISO 4406) should be

achieved.

Should have capability to reduce TAN to

0.1 mg KOH/gram (minimum) & should

reduce water content to 0.08% Wt (800

ppm).

Should confirm to oil cleanliness level as

per NAS 1638 (SAE Class-3 ). Solid

particle cleanliness level to be achieved -

NAS 5.

FRF Fluid Flow Rate 70 LPM

Inlet Pressure to purifier ( required pump 1.5 bar (G)

shall be in scope of bidder)

Water removal capacity Moisture removal should be 100%

of free water as such as 90% of

dissolved water.

Fluid Temperature (+) 10% to 70%

Fluid Viscosity 700 cSt (Maximum )

Filter 3 stage filtrationmodule of 10,6 &

3 micron in series. Filter should

be high efficiency stress resistant

technology inorganic fibers

impregnated bonded with epoxy

resins with polymer end caps and

antistatic design.

Filter Beta Ratio >1000

Filter Micron Rating & Beta Ratio As per ISO-16889 & Cyclic

Certification & Testing :- Stabilization Test to determine filter

rating under stress conditions as per

SAE ARP 4205.

Oil Conditioning Purifier Type Portable & Trolley Mounted.

Inlet & Outlet connections with required Size & length to be confirmed by

Hoses from Counter Flanges at ends bidder from site.

Vacuum Dehydrator Operating Vacuum. (-) 0.6 bar (G) to (-) 0.9

Bar (G) (adjustable)

Normal Operating Vacuum (-) 0.8 bar (G)

Vacuum Pump To be of internationally reputed

make.

Gas removal Capability 100% of free & entrained gases

and upto 80% of dissolved gases.

Power Supply 415 Volt AC,3 Phase,50 Hz

Control Circuit 24V DC.

Total Motor Power To be submitted by bidder.

Differential Pressure Indicator Visual differential pressure

indicator (spring operated ).

Standard & Compliance To comply with all applicable EC

directions & bears CE Mark.

B Spares for Oil Purifier Module

i) High Efficiency Polishing Filter 5 Nos.

Element 3 Micron Absolute, Beta

Ratio =1000

ii) High Efficiency Polishing Filter 5 Nos.

Element 6 Micron Absolute, Beta

Ratio =1000

iii) High Efficiency Polishing Filter 5 Nos.

Element 10 Micron Absolute, Beta

Ratio =1000

iv) Air Breather 2 Nos.

v) WBA Resin Elements 7 Nos.

vi) Gaskets for Filters 5 Set of each type

vii) Recommended spares for Vacuum To be submitted by bidder

Pump

C Cleanliness Oil Monitoring System,

Portable Cleanliness Trend monitor along 1 Set

with TAN Titration Kit & Moisture Titrator.

Remarks:- Trend Monitor directly should

give the cleanliness level reading in

NAS/ISO/SAE Standards. In addition

to cleanliness level it should also

provide the viscosity, temperature

moisture & water saturation (optional).

It should be compatible for Off-line as

well as On-line use.

D Material of Construction : All wetted parts

of the machine (which will be in contact

with FRF) should be compatible with FRF.

Compatibility proof to be submitted. All

pipelines should be of stainless steel SS

316 non-magnetic. All seals should be of

Viton. At no place rubber /asbestos

should be used for sealing. All flexible

hoses should be Teflon.

E Machine should have ball valve provision

to bypass ION Exchange and /or

Vacuum De-hydration System as and

when required. Also the ION Exchange

should have provision of charging/

isolation of resin cartridge individually.

F The bidder should provide the following

machine characteristic certificates:-

1) Flow Rate of Machine.

2) Filter Element contamination Holding

vs Differential Pressure.

3) Micron Rating vs Beta Ratio

4) Filtration ratio vs Time.

G O&M Manuals, GA drawings, P&ID,

Electrical Circuit Drawings & other related

technical documents should be submitted

in 3 sets.

All necessary tools & tackles should be

provided.

II. Other terms & conditions :

1. Prices : The offered prices shall remain FIRM during entire execution of the order.

No price variation formula will be accepted.

2. Validity : Offer shall be kept valid for 6 (six) months from the date of opening.

3. Delivery Period : The ordered Purifier System /spares will be supplied in one lot within

8 months from the date of order. Part supply is not acceptable.

4. Payment Term:

(a) For Supply : 90% payment towards basic value of Purifier System / Spares shall be

made after receipt of material in good condition at Power Station Store against MRC

within 45 days or on turn as per queue whichever is later. Balance 10% payment

along with full taxes & duties and other charges shall be released after installation

and successful trial run of Oil Purifier System.

(b) For Installation: Full payment towards installation charges shall be made within 45

days or on turn as per queue whichever is later after successful trial run of Oil

Purifier System.

5. Other terms & conditions : Other terms & conditions are stipulated in General Tendering

Condition of Contract Booklet attached with tender specification shall be applicable in

toto.

(S. Chauhan)

Superintending Engineer (P&W)

O/o Executive Director (MM)

MPPGCL, Jabalpur

Vous aimerez peut-être aussi

- B-T1a B-T1C: Slope 1:250 Slope 1:250Document1 pageB-T1a B-T1C: Slope 1:250 Slope 1:250Anshuman AgrawalPas encore d'évaluation

- WssDocument6 pagesWssAnshuman AgrawalPas encore d'évaluation

- WDWDDocument5 pagesWDWDAnshuman AgrawalPas encore d'évaluation

- SwwswsDocument7 pagesSwwswsAnshuman AgrawalPas encore d'évaluation

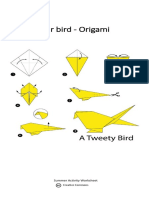

- 22032020071234summer Activity Sheet Day 2 PDFDocument6 pages22032020071234summer Activity Sheet Day 2 PDFAnshuman AgrawalPas encore d'évaluation

- 171Document2 pages171jayshah_26Pas encore d'évaluation

- WwsDocument7 pagesWwsAnshuman AgrawalPas encore d'évaluation

- 22032020071234summer Activity Sheet Day 2 PDFDocument6 pages22032020071234summer Activity Sheet Day 2 PDFAnshuman AgrawalPas encore d'évaluation

- DsdsDocument2 pagesDsdsAnshuman AgrawalPas encore d'évaluation

- DsdsDocument2 pagesDsdsAnshuman AgrawalPas encore d'évaluation

- DsdsDocument2 pagesDsdsAnshuman AgrawalPas encore d'évaluation

- 171Document2 pages171jayshah_26Pas encore d'évaluation

- 171Document2 pages171jayshah_26Pas encore d'évaluation

- 171Document2 pages171jayshah_26Pas encore d'évaluation

- Gulf Synthetic Gear Oil 320 PDFDocument6 pagesGulf Synthetic Gear Oil 320 PDFAnshuman AgrawalPas encore d'évaluation

- 7 Marketing Strategies of India Automobile CompaniesDocument6 pages7 Marketing Strategies of India Automobile CompaniesSandeep Kaur SraPas encore d'évaluation

- 171Document2 pages171jayshah_26Pas encore d'évaluation

- FedfefDocument2 pagesFedfefAnshuman AgrawalPas encore d'évaluation

- DsdsDocument2 pagesDsdsAnshuman AgrawalPas encore d'évaluation

- 171Document2 pages171jayshah_26Pas encore d'évaluation

- Award of Contract (AOC) : For and On Behalf, Tender Inviting Authority, Indian Oil Corporation LimitedDocument1 pageAward of Contract (AOC) : For and On Behalf, Tender Inviting Authority, Indian Oil Corporation LimitedAnshuman AgrawalPas encore d'évaluation

- 10 NA 1000054791 20 NA: Quoted/Not Quoted Table - Do Not Mention Any Prices in This SheetDocument3 pages10 NA 1000054791 20 NA: Quoted/Not Quoted Table - Do Not Mention Any Prices in This SheetAnshuman AgrawalPas encore d'évaluation

- Annexure 5 Exceptions To Bid Terms and Conditions/ Compliance StatementDocument1 pageAnnexure 5 Exceptions To Bid Terms and Conditions/ Compliance StatementAnshuman AgrawalPas encore d'évaluation

- Hindustan Aeronautics Limited Sukhoi Engine Division, KoraputDocument1 pageHindustan Aeronautics Limited Sukhoi Engine Division, KoraputAnshuman AgrawalPas encore d'évaluation

- SsDocument2 pagesSsAnshuman AgrawalPas encore d'évaluation

- Astron Garden Special: Your Confirmed Booking atDocument2 pagesAstron Garden Special: Your Confirmed Booking atAnshuman AgrawalPas encore d'évaluation

- SDocument2 pagesSAnshuman AgrawalPas encore d'évaluation

- WWDocument2 pagesWWAnshuman AgrawalPas encore d'évaluation

- GDocument1 pageGAnshuman AgrawalPas encore d'évaluation

- SJHJDocument38 pagesSJHJAnshuman AgrawalPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- X-Ray Pipeline CrawlerDocument4 pagesX-Ray Pipeline CrawlerBala SingamPas encore d'évaluation

- HMC Internship ReportDocument40 pagesHMC Internship ReportAitazaz Ahsan0% (1)

- Tunnelling in Soft GroundDocument19 pagesTunnelling in Soft Groundiman safiyaPas encore d'évaluation

- Phenolic Pro Filing of Portuguese Propolis by LC - MS Spectrometry: Uncommon Propolis Rich in Flavonoid GlycosidesDocument10 pagesPhenolic Pro Filing of Portuguese Propolis by LC - MS Spectrometry: Uncommon Propolis Rich in Flavonoid GlycosidesBanuraspatiPas encore d'évaluation

- Effect of Eccentricity On Analysis and Design of Isolated FootingsDocument18 pagesEffect of Eccentricity On Analysis and Design of Isolated Footingsप्रभु नाथ सिंहPas encore d'évaluation

- Wl2000it Brochure ENGDocument2 pagesWl2000it Brochure ENGSantos RodriguezPas encore d'évaluation

- Ampho 149Document18 pagesAmpho 149Luis Andre SilvaPas encore d'évaluation

- Fsall-10 ME 3333 Thermodynamics Exam-1Document2 pagesFsall-10 ME 3333 Thermodynamics Exam-1dillydotPas encore d'évaluation

- Section 9 Introduction To Welding ProcessesDocument16 pagesSection 9 Introduction To Welding ProcessesS GoudaPas encore d'évaluation

- HoneywellDocument2 pagesHoneywellzenerdiodePas encore d'évaluation

- Stress Strain Curve ExplanationDocument8 pagesStress Strain Curve ExplanationGptc Chekkanurani0% (1)

- I - Grades & Materilas InfoDocument32 pagesI - Grades & Materilas InfoEswara ReddyPas encore d'évaluation

- Philippine National StandardsDocument30 pagesPhilippine National StandardsJonathan Pascua CamachoPas encore d'évaluation

- Sierra Megonnell and Kyle Lovisone ExpDocument1 pageSierra Megonnell and Kyle Lovisone Expapi-528179516Pas encore d'évaluation

- HNDBK For Calculation of Nuclear Reaction DataDocument166 pagesHNDBK For Calculation of Nuclear Reaction DatadelhiprashantPas encore d'évaluation

- Target Iit-Jee: DATE: 12-12-2014Document8 pagesTarget Iit-Jee: DATE: 12-12-2014asuhassPas encore d'évaluation

- FloPro SFDocument4 pagesFloPro SFLoganBohannonPas encore d'évaluation

- Electrochemistry Part 1Document19 pagesElectrochemistry Part 1Jenny ArutaPas encore d'évaluation

- 1.principles of Chemistry, E. ElectrolysisDocument7 pages1.principles of Chemistry, E. ElectrolysisDr.AndrewMatovuPas encore d'évaluation

- Mitsubishi AcDocument28 pagesMitsubishi AcZeeshanPas encore d'évaluation

- Application of Hydrocolloids in The Beverage Industry - Dedi FardiazDocument35 pagesApplication of Hydrocolloids in The Beverage Industry - Dedi FardiazbanakhoiriPas encore d'évaluation

- Sand To Silicon 22nm VersionDocument18 pagesSand To Silicon 22nm VersionDavid Rubio SaezPas encore d'évaluation

- Prime Cut MsdsDocument2 pagesPrime Cut MsdsMarvin BarahonaPas encore d'évaluation

- Thermal Physics Assignment 2013Document10 pagesThermal Physics Assignment 2013asdsadPas encore d'évaluation

- Grundfos Pompa PDFDocument9 pagesGrundfos Pompa PDFAnastasia Lova DiantoroPas encore d'évaluation

- Abs 0678Document11 pagesAbs 0678Jorge OrtegaPas encore d'évaluation

- ISA - 75.01.01.2012 - Flow Capacity - Sizing Equations For Fluid FlowDocument70 pagesISA - 75.01.01.2012 - Flow Capacity - Sizing Equations For Fluid FlowCarlos Ramos100% (1)

- 11.7 States of Matter PhET LabDocument2 pages11.7 States of Matter PhET LabCoacytTucumanPas encore d'évaluation

- Shubharambh Banquets HL - All Halls 26-5-2017Document5 pagesShubharambh Banquets HL - All Halls 26-5-2017calvin.bloodaxe4478Pas encore d'évaluation

- Lip SealDocument31 pagesLip SealVineet ThapliyalPas encore d'évaluation