Académique Documents

Professionnel Documents

Culture Documents

Xaa610bb GL en

Transféré par

jamesTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Xaa610bb GL en

Transféré par

jamesDroits d'auteur :

Formats disponibles

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 1/24

AMCB2

Guide lines

Xizi Otis Elevator Co., Ltd

No: XAA610BB_GL_EN

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 2/24

PC Record

Zhang

Edit Xia yongjie Check Liu Zubin Auth. Qian Xinhui Appr.

Hongbing

Dept. PDC Dept. PDC Dept. EC Dept. PDC

Date 2006-7-5 Date 2006-7-5 Date 2006-7-5 Date 2006-7-5

AUTH. PC-LS0010-2006

Component Version

Name Hardware Software

AMCB2 1.0 3.5

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 3/24

Modification Record:

No PC Content Date Signature

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

This work and the information it contains are the property of Xizi Otis Elevator Company (XOEC). It is delivered to others on

the express condition that it will be used only for, or on behalf of, XOEC; that neither it nor the information it contains will be

reported or disclosed, in whole or in part, without the prior written consent of XOEC, and that on demand it and any copies will

be promptly returned to XOEC.

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 4/24

Contents

1 General..................................................................................................................................3

2 Top view of AMCB2:...............................................................................................................3

2.1 LCD display ..................................................................................................................3

2.1.1 Monitor...........................................................................................................................3

2.2 Operate Keys ................................................................................................................3

2.3 Pin Assignments............................................................................................................3

3 Run sequence........................................................................................................................3

3.1 Inspection Run...............................................................................................................3

3.2 Normal run.....................................................................................................................3

3.3 Correct run.....................................................................................................................3

3.4 Learning run..................................................................................................................3

3.5 NTSD protection run......................................................................................................3

4 Parameters list introduce.......................................................................................................3

4.1 System parameter F0....................................................................................................3

4.2 Parameters of run curveF1~F6.....................................................................................3

4.3 Related parameters about floor, speed and so on........................................................3

4.4 The parameters about adjustment of leveling position.................................................3

4.5 The parameters of adjusting load weighting device......................................................3

4.6 Parameters about adjusting the brake delay:................................................................3

5 Other function parameters.....................................................................................................3

6 Troubleshooting.....................................................................................................................3

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 5/24

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 6/24

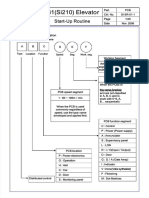

General:

AMCB2 board is used to the OH-CON4421/3 control system of XOEC, and those systems

used in XO-STAR and OH5000 elevators.

The board is a bridge between the OTIS LCBII control board and general inverter. It receives

the V codes form LCBII, and then switches the V codes to run command and speed curve to

drive. It also monitors the inverter status, and sends DS (drive statue) codes to LCBII

System is shown below:

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 7/24

`

Top view of AMCB2:

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 8/24

`

1.1 LCD display

the display of AMCB2 has three interfaces: monitor, menu and trouble (only display when

the fault happens).

1.1.1 Monitor

the Monitor interface shows the car current position and speed of car.

1.1.2 Menu

The Menu interface shows two menus: F menu, P menu.

The F menu is function parameters, the basic parameter of elevator run like speed curve,

contract speed and inspection speed and so on are in this menu;

The P menu is position parameters, all hoistway learning parameters are saved in it. For

example: all landing position, 1LS/2LS position, the length of vane and distance of two top of

car sensors.

1.1.3 Trouble

The trouble menu shows the entire fault, it will be automatically display when the fault

happened. The faults include encoder fault, inverter fault and contactor fault etc.

The below table are three interface:

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 9/24

1.2 Operate Keys

There are 5 operate keys under the displayer, it is used:

Modify the parameters of F menu, switch P/F menu each other

Name Function

Used to go up one level in menu navigation;

Esc Used to escape out of parameters edit or selection with no

change.

Scroll digits in parameters edit mode;

Shift

P menu and F menu exchange

Used to scroll up menu items in menu navigation; Added the

+ value in

Parameters edit mode

Used to scroll down menu items in menu navigation;

-

Reduced the value in Parameters edit mode

Used to enter the selected parameter or parameter value after

Enter

editing.

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 10/24

`

1.3 Pin Assignments

The AMCB2 is applicable for two Drive Types; when it uses different drives, some terminals

assignment will be different.

Plug JP1 1 2 3 4 5 6 7 8

Signal A+ A- B+ B- GND A B 0V

type In In In In In In In In

Volt. garde 5Vdc 24Vdc

Function Encoder signal

Encoder signal input(line driver input)

(complementary)

JP1-1~5: used to input line driver encoder signal; e.g.: EXP-E of SIEI drive;

JP1-6~8: use to input complementary encoder signal; e.g.: PG-B2 of YASKAWA drive.

Plug JP2 1 2 3 4 5

Signal DFC INS INVF SW BY

type In In In In In

Volt. garde 19.2~40Vdc

Door full Inspection run Enable Enable

Function Drive fault

close contact brake

or relay

Plug JP3 1 2 3 4

Signal 1LV 2LV 1LS 2LS

Type In In In In

Volt. garde 19.2~40Vdc

Up Down 1 limit SW 2 limit SW

Function sensor sensor

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 11/24

Plug JP4 1 2 3 4 5

DRIVE=0 LWS LNS 50L 25L ANS

Signal

DRIVE=2 SW FBK LNS 50L 30L BY FBK

Type In In In In In

Volt. garde 19.2~40Vdc

DRIVE=0 100% 80% 50% 25% 10%

Function

DRIVE=2 SW FBK 80% 50% 30% BY FBK

Plug JP5 1 2 3 4 5

Signal V1 V2 V3 V4 DO

Type IN IN IN IN IN

Volt. garde 24Vdc

Enable

Function Velocity codes

DO

relay

The input of velocity codes are coded as described below:

Mode Function V4 V3 V2 V1

WT wait 0 0 0 0

ST stop 1 1 1 1

IR-U Inspection run up 0 1 0 0

Inspection run

IR-D 0 1 0 1

down

FR-U Normal run up 0 1 1 0

FR-D Normal run down 0 1 1 1

RL-U Relevel run up 1 0 1 0

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 12/24

`

Relevel run

RL-D 1 0 1 1

down

SD Slow down 1 1 1 0

(Not allowed)

-

Plug JP6 1 2 3 4

Signal 30VDC 30VDC 0V 0V

Type In In In In

Volt. garde 24~40Vdc

Function Power supply

Plug JP7 1 2 3 4 5 6 7 8

Signal DO Relay BY Relay SW Relay

Type Out Out Out

Volt. garde 24Vdc 5A\110/220Vac 5a

Function Door open relay Brake relay contactor

Plug JP8 1 2 3 4 5 6

Signal DS1 DS2 DS3 IP 1LV 2LV

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 13/24

`

Type Out Out Out Out Out Out

Volt grade 24Vdc 100mA

Function Up Down

Drive status codes IP

sensor sensor

signal signal

DS(Drive status)

DS3 DS2 DS1 Remark

0 0 0 Drive fault

0 0 1 Speed > 0.3m/s,

0 1 0 Normal run

1 0 0 Learn run

1 1 0 speed<0.3m/s

1 1 1 stop

other -

Plug JP9 1 2 3 4 5 6 7 8

Signal ENA FWD REV LZ COM VREF VTOQ 0V

Type Out Out Out Out Out Out Out Out

Volt

24Vdc 100mA 0~10Vdc 20mA

grade

Velocity

Landing Com of LWD analog

Function Enable Forward reverse Analog Com

zone output output

output

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 14/24

`

2 Run sequence

2.1 Inspection Run

If the JOG (inspection) is activated, the AMCB2 is in the inspection mode.

AMCB2 output the Enable and Start (FWD/REV) signals according V code; and after

the BY signal is activated, the AMCB2 start to output the speed curve.

in inspection run mode, the IP signal will never be activated

when the lift start to inspection run, the AMCB2 change the DS codes form 111 to 010 to

LCBII; when the lift stop to run, the Enable and Start signals is off and DS codes

change to 111 to LCBII.

When the lift is in inspection run mode, and If Enable or Start is off, the lift stop

immediately

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 15/24

`

2.2 Normal run

AMCB2 should send the IP signal to LCBII before the lift reach the deceleration point.

LCBII will count the floor number according to received IP signal during normal run, and

if the next floor is stop floor, the LCBII will send the slow down (V codes) to AMCB2,

AMCB2 will slow down followed according to curve and stop.

When the run speed is less than the door open speed threshold, AMCB2 will sent the

DS codes (DS1=1, DS2=1, DS3=0) to LCBII.

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 16/24

`

2.3 Correct run

When the AMCB2 or the LCBII lose the position, the lift enters the correct run mode.

if AMCB2 lose the position, the lift run at half normal speed; and if only the LCBII lose

the position, the lift run at normal speed.

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 17/24

`

2.4 Learning run

When the lift start to learn run, the car run to DZ of bottom floor with normal speed, then

car run up with learning speed, and finished when the car get DZ of top floor.

After finished the learning run, the lift return to normal mode automatically

By learning run, AMCB2 get the floor position and 1LS/2LS position, you can find those

in P menu.

the speed of learning is same with inspection run

AMCB2 do not sent the IP signal to LCBII in the course of learning run

During the learning run, if let JOG to 1, the car quit the learning.

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 18/24

`

2.5 NTSD protection run

If the car hit the 1LS or 2LS at contract speed, the lift will be forced to perform an NTSD

slowdown.

3 Parameters list introduce

3.1 System parameter F0

Number Value LCD Display Description

Enter password, the initialize

F0 F01 Enter password password: 1234

Function F02 Change password Change password

Set to 3, the terminal of

F03 Velocity Analog will output

10vdc

Set to 4, lift will be enter learn

F04 Shaft learning mode

Initialize the parameters

F05 Reset parameter

The initialize password of AMCB2 is 1234; allowed to modify the parameters of F menu

after affirming the password every time power on.

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 19/24

In order to ensure velocity display of AMCB2 and drive are the same, the gain and

offset tune of velocity analog should be done before the car to normal run

Before car to normal run, the hoistway learning run should be done; and before start to

hoistway learning run, the blew items should be conformed:

the parameter of F24 should set to 0

the inspection switch is on normal position

and then set F0 to 4, the car start to hoistway learning run, after finished the hoistway

learning, the F0 set to 1 automatically

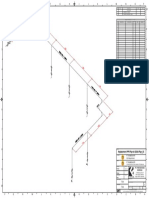

3.2 Parameters of run curveF1~F6

Number Display Description Range Unit

F1 Acceleration Sets the 200~1200 mm/s^2

acceleration

speed

F2 Deceleration Sets the 200~1200 mm/s^2

deceleration

speed

F3 Acceleration T0 S-curve 500~1500 ms

F4 Acceleration T1 characteristic 500~1300 ms

F5 Deceleration T2 time T0~T3 500~1300 ms

F6 Deceleration T3 500~1500 ms

The AMCB2 can set respectively the acceleration time and deceleration time; and the

S-curve characteristic time also can be set respectively for beginning acceleration,

ending acceleration, beginning deceleration and ending deceleration.

the relation between F1~F6 is shown below:

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 20/24

3.3 Related parameters about floor, speed and so on

Number Display Description Range Unit

F7 Floor number the floor number 2~32 floor

Set lift contract

F8 Rated speed 200~2500 mm/s

speed

Set the number

F9 Encoder pulse 100~10000 PPR

of encoder pulse

Set the motor

F10 Motor rated RPM rated RPM 50~5000 RPM

F11 Inspection speed Inspection speed 0~500 mm/s

F12 Open door Set ADO speed 0~300 mm/s

F13 speed

Stop speed Stop speed 0~150 mm/s

Set the RLV

F14 Releveling speed speed 10~100 mm/s

Normal speed

F26 Setanalog speed gain 50~100 %

F27 Startup speed Startup speed 0~30 mm/s

F28 Startup time Startup time 0~1000 ms

F7: the floor number, set according to the number of vane of DZ.

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 21/24

F8: contract speedF11: inspection and hoistway learn speed; F12: the speed of

sending the LZ signal; F13: stop speed; F14: The speed of RLV.

F9: the number of encoder pulses, when the pulses that the AMCB2 received is division

output, the set F9 to encoder pulse/division ratio. E.g.:

the encoder pulses is 1024, set the division ratio(set by drive) to 4, you should set the

F9 to 256(1024/4)

F10: the motor RPM when the lift is running with contract speed.

F26: the rated speed gain, the output speed of AMCB2 is F26XF8

F27/F28: the startup speed and startup time, you can set the two parameters to improve

the start performance(usually set F27 to 4mm/s, F28 to 300ms)

3.4 The parameters about adjustment of leveling position

Number Display Description Range Unit

Upward leveling

F15 Upward adj offset 0~200 mm

Downward leveling

F16 Downward adj offset 0~200 mm

F25 Level delay Level delay offset 0~200 mm

Before the adjustment of leveling, it should be sure that the leveling indicator plate of

door zone has been mechanically adjusted before performing electrical leveling

adjustment, and the car can run with high speed

The car is half-loaded.

Move downwards and record the error of leveling of each floor, adjust F16 Downward

Adj. according to the average value of the error.the value of F16 Downward Adj

should be reduced if the elevator overshoots the switches, if not, it should be

increased.

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 22/24

Move upwards and record the error of leveling of each floor, adjust F15 Upward Adj.

according to the average value of the error.the value of F15 Downward Adj should be

reduced if the elevator overshoots the switches, if not, it should be increased.

3.5 The parameters of adjusting load weighting device

Number Display Description Range Unit

Vpre-torque Output volt when

F17 100 load 900~1000 10mV

100%

Output volt when

F18 Vpre-torque 80% 80 load 700~900 10mV

Output volt when

F19 Vpre-torque 50% 50 load 350~750 10mV

Output volt when

F20 Vpre-torque 25% 25 load 150~400 10mV

Output volt when

F21 Vpre-torque 10% 10 load 50~150 10mV

DRIVE=0(SIEI Inverter)

The AMCB2 can connect 5 load weighting switches most, when the relevant switches

is activated, the AMCB2 will output relevant voltage by LWD analog output (terminal

JP9-7 and JP9-8), the relation between the switches and output voltage as below:

Switch ANSS 25L 50L LNS LWS

Output ovlt (10%) (25%) (50%) (80%) (100%)

F21(0.5V1.5V) X X X X

F20)1.5V4V) X X X

F19(3.5V7.5V) X X

F18(7V9V) X

F17(9V-10V)

Note: :the switch is on; X: the switch is off : Neglect the status of switch

DIRVE=1(YAKAWA Inverter)

the AMCB2 is only permitted to connect 3 load weighting switched(25L,50L,80L).

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 23/24

F17~F21 used to adjust the output voltage when the relevant switch is on

3.6 Parameters about adjusting the brake delay:

Number Display Description range Unit

Brake delay time

F22 Brake delay1 when the lift start 0~2000 ms

to run delay time

Brake

F23 brake delay2 when the lift stop 0~3000 ms

to run

F32 Brake delay3 0~700 ms

4 Other function parameters

Numbe

Display Description range Unit

r

0: forbid normal run, inspection and

F24 Run enable Enable normal

learn run is permitted

run

1:normal run is permitted

0: SIEI drive

F29 Invert Type Drive type 1: vacant

2: YASKWAW

0: with LZ

F30 Disable LZ Disable LZ

1:without LZ

0: without brake switch

F31 Brake SW Brake switch

1: brake switch type is NO

type type 2: brake switch type is NC

F33 DDP time Run timeout s

1~45

protection

F34 ZS Deceleration 100~900 mm/s^2

Deceleratio of correct run

Unpublished Work Copyright XIZI OTIS Elevator Company

No: XAA610BB_GL_EN

AMCB2

Date: 04/07/2006

Guide Lines Page: 24/24

`

5 Troubleshooting

there are only 6 faults that can be shown in displayer; the faults table is followed:

Display Meaning Probable cause Corrective action

Drive has not output signal Deal with the drive

Inerter Fault Inverter fault of DRIVE OK fault

The wiring of it is incorrect Fix the wiring

The wiring of drive to Fix the wiring

Encoder Fault Encoder fault AMCB2 is incorrect Check the signal

Noise interfere noise

The sensor is damaged Replace the sensor

Level Fault Level fault The sequence of two Change the wiring

sensors is reverse JP3-1 and JP3-2

Contactor Replace the

The contactor is damaged

CNT fbk Fault feedback fault contactor

The wiring of it is incorrect

(DRIVE=2) Fix the wiring

Brake feedback

Brake relay is damaged Replace the relay

BY fbk Fault fault

The wiring of it is incorrect Fix the wiring

(DRIVE=2)

Check the value

The value is too small

DDP timeout: DDP protection Check the

Machine is not run

mechanical system

Unpublished Work Copyright XIZI OTIS Elevator Company

Vous aimerez peut-être aussi

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideD'EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideÉvaluation : 4 sur 5 étoiles4/5 (9)

- ACD2 Elevador XIzi ACD2-MRL - SUR - EN PDFDocument93 pagesACD2 Elevador XIzi ACD2-MRL - SUR - EN PDFIván Sulbaran100% (2)

- MCS LCB II List of ParametersDocument26 pagesMCS LCB II List of ParametersMalik AsifPas encore d'évaluation

- Otis Door Drive User ManualDocument34 pagesOtis Door Drive User ManualRoyal Akash100% (8)

- 11 1 ControlDocument166 pages11 1 ControlFabian Virgili67% (3)

- OTIS Elevator Fault Code: LCB-2, TCBC and GECB Board Faults - Elevatorvip - Com - 1627641777743Document5 pagesOTIS Elevator Fault Code: LCB-2, TCBC and GECB Board Faults - Elevatorvip - Com - 1627641777743Aluko Damilare MosesPas encore d'évaluation

- Gecs With Mesd: Service Tool ManualDocument51 pagesGecs With Mesd: Service Tool ManualAidolan Ulrich86% (7)

- ZXK-CAN3200 User Manual V1 - 0Document109 pagesZXK-CAN3200 User Manual V1 - 0chronos00_78847011578% (9)

- Otis+Elevator+Fault+Code+Lcb 2+Tcbc+Gecb+BoardDocument3 pagesOtis+Elevator+Fault+Code+Lcb 2+Tcbc+Gecb+BoardMohammed Qaid AlathwaryPas encore d'évaluation

- Escalera Otis 2.compressedDocument11 pagesEscalera Otis 2.compressedatom2013xd75% (4)

- SIGMA LG OTIS Di1 Si210 SPEC Table Programacion PDFDocument30 pagesSIGMA LG OTIS Di1 Si210 SPEC Table Programacion PDFQuyết83% (6)

- OH-CON4423 Adjust Training ManualDocument49 pagesOH-CON4423 Adjust Training ManualJuanmanuel Barroyeta100% (4)

- DO3000 InstructionsDocument38 pagesDO3000 InstructionsMoh Asat Dullah100% (3)

- MCS 220Document1 pageMCS 220Taha Alkibsi100% (3)

- Parameter List MCS - RCB2Document34 pagesParameter List MCS - RCB2FazilPas encore d'évaluation

- Acd4 MRLDocument66 pagesAcd4 MRLRafael BrunoPas encore d'évaluation

- 799all (GECB) (001-173) PDFDocument173 pages799all (GECB) (001-173) PDFtu_negro_luis100% (5)

- Otis Sigma Codigo de ErroresDocument57 pagesOtis Sigma Codigo de ErroresMaury Tabares100% (1)

- Di1 (Si210) Elevator: Start-Up RoutineDocument34 pagesDi1 (Si210) Elevator: Start-Up RoutineQuyết50% (2)

- SIGMA iAstar-S8 Integrated ControllerDocument143 pagesSIGMA iAstar-S8 Integrated ControllerJaydi Zambrano100% (3)

- LBII ParametrosDocument37 pagesLBII ParametrosPolinho Donacimento100% (1)

- Dbss - HSDD - Startup Routine: Field Component ManualDocument25 pagesDbss - HSDD - Startup Routine: Field Component ManualМихаил100% (1)

- Mitsubishi Elenessa Encoder CalibrationDocument6 pagesMitsubishi Elenessa Encoder CalibrationGutmonarchPas encore d'évaluation

- SVT GreskeDocument17 pagesSVT GreskePeter100% (6)

- OTIS ACD RELEASE1 DAA21290AL电气原理图Document75 pagesOTIS ACD RELEASE1 DAA21290AL电气原理图Jms Quintero100% (1)

- 02 MUSE ACD3 T&C WiringDocument15 pages02 MUSE ACD3 T&C WiringMoises PerelloPas encore d'évaluation

- MCS - LCB II List of ParametersDocument25 pagesMCS - LCB II List of ParametersEneko Diaz De Lezana100% (5)

- Xba26201al SVT Manual EsDocument37 pagesXba26201al SVT Manual EsPolinho Donacimento100% (2)

- DSS Installation Manual Rev2 ENGDocument29 pagesDSS Installation Manual Rev2 ENGReynold Suarez80% (5)

- 506NCE DAA26200R - SUI - 090713 - Start-UpDocument8 pages506NCE DAA26200R - SUI - 090713 - Start-UpPolinho Donacimento0% (1)

- Basic Data Lbii Basic Data LB Ii - 1997!02!17Document29 pagesBasic Data Lbii Basic Data LB Ii - 1997!02!17Polinho Donacimento67% (3)

- User Manual For Ds Product (Ver1.3)Document56 pagesUser Manual For Ds Product (Ver1.3)thanhhung_hyPas encore d'évaluation

- IRIS1NV Manual PDFDocument131 pagesIRIS1NV Manual PDFVilla Robert Ramoa92% (13)

- FSD GAA30782GAA Feature and Set Up Description - 2014-05-23 - PDFDocument183 pagesFSD GAA30782GAA Feature and Set Up Description - 2014-05-23 - PDFQuang Pham Duy100% (1)

- Start Up Routine: Field Component ManualDocument12 pagesStart Up Routine: Field Component Manualihwisso100% (5)

- DCSS5 Guide LineDocument37 pagesDCSS5 Guide LineJavier Martínez100% (4)

- Sigma LG Otis Di1 Si210 PCB - CompressDocument49 pagesSigma LG Otis Di1 Si210 PCB - Compressalaa suhailPas encore d'évaluation

- Defauts Mitsubishi VFGLCDocument8 pagesDefauts Mitsubishi VFGLCAnderley Quintero80% (5)

- Ovf20cro AdtDocument49 pagesOvf20cro AdtAriel Ariel83% (6)

- Drawing 300 VF PDFDocument51 pagesDrawing 300 VF PDFAnonymous EstxH7100% (1)

- Otis TCBC Service Tool ManualDocument55 pagesOtis TCBC Service Tool ManualІван Кравчук100% (2)

- KDL16 Parameter List 972483D01: The Document Id of This Sheet Must Match With The Id Reported by UI Menu 6 - 0Document3 pagesKDL16 Parameter List 972483D01: The Document Id of This Sheet Must Match With The Id Reported by UI Menu 6 - 0Александр ЕгоровPas encore d'évaluation

- Otis 300vf FaultDocument3 pagesOtis 300vf FaultMohammed Qaid AlathwaryPas encore d'évaluation

- Xaa610bb GL enDocument24 pagesXaa610bb GL enchalogdPas encore d'évaluation

- Troubleshooting Si210 Elevator Control Panel TCD CodesDocument110 pagesTroubleshooting Si210 Elevator Control Panel TCD CodesQuang Pham Duy100% (1)

- Otis Mcs 220c Gen2Document96 pagesOtis Mcs 220c Gen2krp85734982% (49)

- SPMDCBDocument24 pagesSPMDCBSyed iliyas100% (3)

- EZ 2/3/5 SERIES: Parts ListDocument120 pagesEZ 2/3/5 SERIES: Parts ListNma ColonelnmaPas encore d'évaluation

- ALL-T Parts ListDocument9 pagesALL-T Parts ListDBKPas encore d'évaluation

- MotorDocument1 pageMotorfran reyPas encore d'évaluation

- OL SMM-055-ODE - Requistion Form (Ver 04)Document1 pageOL SMM-055-ODE - Requistion Form (Ver 04)wendy pramonoPas encore d'évaluation

- Adswed PDFDocument1 pageAdswed PDFNgô MạnhPas encore d'évaluation

- Articulacion 745CDocument2 pagesArticulacion 745CAngel ContrerasPas encore d'évaluation

- SM-G570M: Samsung Confidential Samsung ConfidentialDocument9 pagesSM-G570M: Samsung Confidential Samsung Confidentialvinh tuanPas encore d'évaluation

- Dimensional Drawing of FlowmeterDocument3 pagesDimensional Drawing of FlowmeterlatasharmaPas encore d'évaluation

- Replacement PPR Pipe To SS304 Pipe - CK: Material ListDocument1 pageReplacement PPR Pipe To SS304 Pipe - CK: Material ListSyach FirmPas encore d'évaluation

- Hammer Strength HDT-MAB Assembly ManualDocument8 pagesHammer Strength HDT-MAB Assembly ManualRida DahmounPas encore d'évaluation

- C-Chart For Constant Sample Size: 18 Samples Are Controlled and Nonconformities Are CountedDocument2 pagesC-Chart For Constant Sample Size: 18 Samples Are Controlled and Nonconformities Are Countedamrt3505Pas encore d'évaluation

- Installation Instructions: Single Lever & Dual Control Bathroom FittingsDocument2 pagesInstallation Instructions: Single Lever & Dual Control Bathroom Fittingsirina_petresscuPas encore d'évaluation

- Circuit diagram of an SN74LS247 integrated circuitDocument1 pageCircuit diagram of an SN74LS247 integrated circuitFrancis GuilbaultPas encore d'évaluation

- 2016 EscalatorCatalog 161005Document13 pages2016 EscalatorCatalog 161005Lloyd R. PoncePas encore d'évaluation

- Ssvf5 Summary of Error CodeDocument1 pageSsvf5 Summary of Error CodejamesPas encore d'évaluation

- Architect's and Consultant's Specification Guide: Otis Elevator CompanyDocument12 pagesArchitect's and Consultant's Specification Guide: Otis Elevator CompanyjamesPas encore d'évaluation

- Architect's and Consultant's Specification Guide: Otis Elevator CompanyDocument12 pagesArchitect's and Consultant's Specification Guide: Otis Elevator CompanyjamesPas encore d'évaluation

- Diagrama Electrica Escalera SLDocument23 pagesDiagrama Electrica Escalera SLjames100% (1)

- OH1000 BrochureDocument6 pagesOH1000 BrochurejamesPas encore d'évaluation

- WD DW 05 PDFDocument2 pagesWD DW 05 PDFjamesPas encore d'évaluation

- Otis Acd2 MRL: Field Installation ManualDocument9 pagesOtis Acd2 MRL: Field Installation Manualjames100% (3)

- Hydraulic Elevator Thyssenkrupp ElevatorsDocument187 pagesHydraulic Elevator Thyssenkrupp Elevatorshmbx100% (3)

- 7502.9028 Manual Dover DMC I For 32bit Windows Rev11Document87 pages7502.9028 Manual Dover DMC I For 32bit Windows Rev11jamesPas encore d'évaluation

- Cs15 Gas Tank Cleaning Degassing 1997Document12 pagesCs15 Gas Tank Cleaning Degassing 1997kirandevi1981100% (2)

- Pure Chem p2 - 26pgDocument26 pagesPure Chem p2 - 26pgJhomer CrespoPas encore d'évaluation

- TAIL Project NewsletterDocument9 pagesTAIL Project NewsletterAbdul R. MustaphaPas encore d'évaluation

- Solve Process Problems Quickly with Simulation TrainingDocument6 pagesSolve Process Problems Quickly with Simulation TrainingAnonymous qPt2MHzXTPas encore d'évaluation

- Hoisting Systems ExplainedDocument21 pagesHoisting Systems Explainedsparda94Pas encore d'évaluation

- The Properties of WaterDocument6 pagesThe Properties of WaterannisyaPas encore d'évaluation

- Software TestingDocument3 pagesSoftware TestingDr. P. N. Renjith Associate Professor - CSEPas encore d'évaluation

- T REC K.Sup16 201905 I!!PDF E PDFDocument24 pagesT REC K.Sup16 201905 I!!PDF E PDFMark LionPas encore d'évaluation

- ESD 18-91-067 - Instruction Manual and Parts List - Ed. 305Document208 pagesESD 18-91-067 - Instruction Manual and Parts List - Ed. 305Centrifugal SeparatorPas encore d'évaluation

- d-Copia3500MF 4500MF 5500MFsmY113351-4Document1 051 pagesd-Copia3500MF 4500MF 5500MFsmY113351-4ctecisbPas encore d'évaluation

- Shop Manual WA380-3LE SN A50001Document758 pagesShop Manual WA380-3LE SN A50001Eliecer godoy100% (2)

- Theory of Metal Cutting-Module 1Document116 pagesTheory of Metal Cutting-Module 1rejeesh_rajendranPas encore d'évaluation

- Standard For Safety UL ADocument49 pagesStandard For Safety UL ANhất NgônPas encore d'évaluation

- Premium Swab Rigs Since 1925Document8 pagesPremium Swab Rigs Since 1925fabricio3fabricio-1Pas encore d'évaluation

- Plant Cost EstimationDocument49 pagesPlant Cost EstimationAlpianto100% (1)

- 2020 Can Am Off Road - Apache Track Kits Leaflet - enDocument7 pages2020 Can Am Off Road - Apache Track Kits Leaflet - enNicolas VillamayorPas encore d'évaluation

- Transmission ErrorDocument7 pagesTransmission ErrorTapas JenaPas encore d'évaluation

- Grouting in Rock TunnellingDocument161 pagesGrouting in Rock TunnellingOanaPas encore d'évaluation

- MEITRACK MVT100 User Guide V2.4Document19 pagesMEITRACK MVT100 User Guide V2.4MeitrackPas encore d'évaluation

- Human-Environment InteractionDocument3 pagesHuman-Environment Interactionapi-299100358Pas encore d'évaluation

- PilotstarD AP02-S01 Mar09Document168 pagesPilotstarD AP02-S01 Mar09Dharan NarayananPas encore d'évaluation

- Axle, Front - Differential and Carrier - Jee0123251Document3 pagesAxle, Front - Differential and Carrier - Jee0123251Husi NihaPas encore d'évaluation

- Physical and Rheological Properties of Modified Sulfur Asphalt BinderDocument8 pagesPhysical and Rheological Properties of Modified Sulfur Asphalt Binderramesh naikPas encore d'évaluation

- Iso Dis 20283-4 2011Document27 pagesIso Dis 20283-4 2011Ricardo RamirezPas encore d'évaluation

- GDCF 2 240 - 2nd - 01 10Document2 pagesGDCF 2 240 - 2nd - 01 10edgardomichligPas encore d'évaluation

- Corrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsDocument1 pageCorrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsAsma Sed100% (1)

- BRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualDocument28 pagesBRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualLuis Daniel ContrerasPas encore d'évaluation

- NASA ERAST Program Develops High-Altitude UAVsDocument17 pagesNASA ERAST Program Develops High-Altitude UAVsEgz AguilarPas encore d'évaluation

- AGA-3 Comparison Normal BetaDocument12 pagesAGA-3 Comparison Normal BetahailriqPas encore d'évaluation

- BPUT Colleges ListDocument7 pagesBPUT Colleges ListhirenPas encore d'évaluation