Académique Documents

Professionnel Documents

Culture Documents

Diode Characteristics

Transféré par

FaIz FauziCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Diode Characteristics

Transféré par

FaIz FauziDroits d'auteur :

Formats disponibles

Bangor University

Diode Characteristics

Investigating the characteristics of Silicon,

Germanium, Zener and Bangor Fabricated

Diodes

Peter Doggart

2012

School of Electronic Engineering

Diode Characteristics 2012

SUMMARY

This experiment was set up to investigate the different properties and characteristics of

several different types of diode. Each diode was investigated by plotting the I-V curve using

a Precision Source/Measurement Unit (B2902A) and a Laptop with the corresponding Quick

I-V Measurement Software installed.

Upon studying each of the I-V graphs, it was possible to calculate through graphical analysis

the cut-in voltage for each of the diodes as well as viewing the breakdown effect of a Zenner

diode. Plotting these curves also gave an opportunity to compare the characteristics of a

diode produced in the Bangor University lab compared to a mass produced component.

The results of this experiment appear to satisfy the theory behind diodes. The measured

cut-in voltage for a Silicon diode was approximately 0.6 volts, and similarly for the

Germanium diode 0.2 volts. These are both very close to the expected cut-in voltages. The

results also confirm that a Zener diode also had the expected cut-in at 0.6 volts, as well as

demonstrating clearly the reverse breakdown effect.

The Bangor fabricated diode had much less defined results. The plotted I-V curves do not

have a clear cut-in point and are not as smooth in their nature. They did, however, clearly

display that this type of diode is light intensity sensitive.

School of Electronic Engineering Page 1

Diode Characteristics 2012

CONTENTS

Summary .................................................................................................................................... 1

Introduction ............................................................................................................................... 4

Semiconductors ..................................................................................................................... 4

N/P-Type Semiconductors ..................................................................................................... 6

P-Type Semiconductors ..................................................................................................... 6

N-Type Semiconductors ..................................................................................................... 6

Diodes .................................................................................................................................... 7

Forward Bias ...................................................................................................................... 8

Reverse Bias ....................................................................................................................... 9

Zener Diodes .................................................................................................................... 10

Theoretical ............................................................................................................................... 11

The Voltage-Current Characteristic ..................................................................................... 11

Experimental ............................................................................................................................ 12

Aims...................................................................................................................................... 12

Equipment ............................................................................................................................ 12

Procedure ............................................................................................................................. 13

Familiarisation.................................................................................................................. 13

Silicon and Germanium Diodes ........................................................................................ 13

Zener Diode ...................................................................................................................... 13

Bangor Fabricated Diode ................................................................................................. 13

Results ...................................................................................................................................... 15

Resistor ................................................................................................................................ 15

Silicon Diode......................................................................................................................... 16

Germanium Diode ................................................................................................................ 17

Zener Diode .......................................................................................................................... 18

School of Electronic Engineering Page 2

Diode Characteristics 2012

Bangor Fabricated Diode ..................................................................................................... 19

Discussion................................................................................................................................. 20

Resistor ................................................................................................................................ 20

Silicon Diode......................................................................................................................... 21

Germanium Diode ................................................................................................................ 22

Zener Diode .......................................................................................................................... 23

Bangor Fabricated Diode ..................................................................................................... 24

Conclusions .............................................................................................................................. 25

Acknowledgements.................................................................................................................. 26

References ............................................................................................................................... 27

Appendix .................................................................................................................................. 28

Formulae .............................................................................................................................. 28

Rectifiers .......................................................................................................................... 28

Ohms Law......................................................................................................................... 28

Dynamic Resistance ......................................................................................................... 28

Software ............................................................................................................................... 29

School of Electronic Engineering Page 3

Diode Characteristics 2012

INTRODUCTION

SEMICONDUCTORS

The materials used in the production of diodes are semiconductors. A semiconductor in its

pure (intrinsic state) is not a good conductor or insulator of electrical current. The most

common semiconductors are Silicon and Germanium. These single element semiconductors

are characterised by atoms with a valence number 4.

Silicon (and Germanium) has 4 valence electrons. This means in its atomic structure, there

are 4 electrons in its outmost energy shell.

Figure 1 Bohr diagram of Silicon [1]

As can be seen from Figure 1, the core of the Silicon atom (excluding the valence electrons)

has:

14 Protons, giving a relative charge of +14

10 Electrons, giving a relative charge of -10

The total net change of the core is therefore +4. It is said that the valence electrons

experience an attractive force of magnitude +4.

Compare this too Copper, a common conductor.

Figure 2 Bohr diagram of Copper [2]

School of Electronic Engineering Page 4

Diode Characteristics 2012

Similar observation of a Copper atom concludes that it has:

29 Protons, giving a relative charge of +29

28 Electrons, giving a relative charge of -28

The single valence electron in copper is therefore said to experience an attractive pull of

magnitude +1.

From this simple analysis, it is clear that the valence electron in copper can gain enough

energy to become a free electron easily, due to the relatively weak attractive force holding

it around the atom and because of its large distance from the nucleus. This is why copper is

such a good conductor of electrons, as this energy is provided at room temperature.

It is also noted that the valence electrons in Silicon are held to the atom by a much stronger

attractive force. At room temperature, only several electrons in an entire Silicon crystal

would have enough energy in order to break free from their corresponding atoms to

become free electrons. This is why silicon is not a good conductor of electricity.

In a Silicon crystal, each Silicon atom is bonded to 4 others, using the 4 valence electrons in

its outer shell. However, there will always be a small number of free electrons, as the lattice

is broken down by heat energy. Only at absolute zero (0K) would there be no free electrons.

Semiconductors are known to conduct electrical current in two ways. Electrons that have

sufficient thermal energy to break from their atom (free electrons) are known as conduction

electrons. As they are free, the easily move through the semiconductor when a potential

difference is applied to it. This process in itself is responsible for the second method of

electron movement. In the covalent structure, every time an electron escapes to the

conduction band, a hole is left in the valence band where it used to be. Electrons in

neighbouring covalent bonds can move to nearby holes using a relatively tiny amount of

energy. This means that in practise, the holes in the covalent lattice are seen to move in the

opposite direction to electron flow. This is known as the hole current.

Figure 3 Electron and Hole Current in Silicon [3]

School of Electronic Engineering Page 5

Diode Characteristics 2012

In a brief comparison, this phenomenon does not occur in Copper as Copper atoms are held

together with metallic bonds. The metallic bonds in Copper consist of a sea of positive ions

which are surrounded by the delocalised electrons. The electrons move between the

positive nuclei holding the atoms together. As all the electrons are delocalised away from

the nucleus in this bonding, it accounts for the high conductivity of metals.

N/P-TYPE SEMICONDUCTORS

Pure semiconductors are known to be poor conductors. However, their conductivity can be

drastically improved by the addition of impurities into the crystal lattice. This controlled

addition is known as doping, and increases the number of current carriers available inside

the lattice. There are two types of doping practice, both are essential in the production of

diodes.

P-TYPE SEMICONDUCTORS

This involves doping the pure semiconductor with atoms that have a valence number of 3.

This means that the doping atoms only have 3 electrons in their outer shell, so when

bonded in the covalent lattice to 4 Silicon (or Germanium) atoms, a hole results, as it does

not have enough electrons to complete the bonds. Atoms of this type are called acceptor

atoms. These holes do not have a matching free electron in the crystal, therefore this

process, in a controlled manor, can be used to increase the number of holes and therefore

the conductivity of the semiconductor due to increasing hole current.

In a P-Type semiconductor, holes are the majority electron carriers. There will be a small

amount of conduction due to conduction band electrons produced when electron-hole pairs

are produced due to the thermal breakdown of the lattice. However, this is a small fraction

of the total available carriers. It is worth clarifying that these conduction band electrons are

not produced by the doping process.

N-TYPE SEMICONDUCTORS

This type of semiconductor is doped with atoms that have a valence number of 5. When

these doping atoms are introduced to the semiconductor lattice, they form covalent bonds

with 4 adjacent Silicon (or Germanium) atoms. As each bond uses 1 of the valence electrons,

there is 1 extra electron. This electron is not involved in the bonding and therefore enters

the conduction band. The number of conduction electrons added can be carefully controlled

in the doping process. A conduction electron created from the doping process does not have

a matching electron hole, as it is provided by the donor atom.

In a N-Type semiconductor, the majority of the current carriers are conduction band

electrons introduced by the doping process. A small amount of current will come from holes

generated when the lattice has thermal energy to produce electron-hole pairs.

School of Electronic Engineering Page 6

Diode Characteristics 2012

DIODES

When a semiconductor is doped so that it contains a P-Type region and an N-Type region, a

P-N junction forms at the boundary between them. This is a fundamental diode.

The P-Type region has many holes, and the N-Type region has many free electrons.

However, both regions are electrically neutral (before the P-N junctions forms), as they have

a balanced number of positive charges (protons) and negative charges (electrons).

Figure 4 Diagram showing the basic structure of a P-N junction. The depletion zone size is exaggerated for illustration purposes. [4]

In any given P-N junction, a depletion region exists between the two doped regions. This is

caused by current carrier movements across the junction:

The N-Type region loses free electrons, as they diffuse across the junction towards

the majority holes (like charges repel). This causes a build-up of positive ions on the

N-Type side of the junction, due to the imbalance between positive and negative

charges.

The P-Type region loses holes, as the electrons crossing the junction from the N-Type

region fill in the spaces. There is therefore more negative charges in the P-Type

region than positive, resulting in a layer of negative ions on the P-Type side of the

junction.

After the junction has stabilised (does not take long!) an equilibrium is established and there

is no further diffusion of electrons across the junction. This is caused by the repulsive force

the negative ions of the P-Type region, pushing electrons away from the junction.

At any given time, there is a potential difference across the depletion region known as the

barrier potential. This is caused by the layers of positive and negative ions. For current to

flow through the P-N junction, a voltage greater than that and of correct polarity, must be

applied across the junction to overcome the barrier potential.

Barrier potential in a P-N junction is dependent on a large number of variables including:

The type of semiconductor material

The degree of doping in both regions

The temperature of the junction

School of Electronic Engineering Page 7

Diode Characteristics 2012

Typical barrier potentials are 0.7 volts for Silicon and 0.2 volts for Germanium.

In a diode, the P-Type region is called the anode, and the N-Type region the cathode.

Figure 5 Diagram to show the terminals of a standard diode [5]

FORWARD BIAS

Biasing a diode means applying a DC voltage across it and is describes as forward or reverse

depending on the polarity of the applied voltage relative to the diode.

Figure 6 Diagram showing forward biasing of a diode

Figure 6 shows a diode which is being forward biased. The external voltage is VBIAS. The

resistor, RLIMIT is essential in the circuit to limit the current flowing through the diode,

preventing it from being damaged by excessive current flow. This circuit for fills the two

criteria for a diode to be forward biased:

The cathode of the diode (N-Type region) is connected to the negative side of VBIAS.

The magnitude of VBIAS is greater than the barrier potential of the diode (assuming

the diode is made from Silicon).

As this circuit is correctly forward biased current will flow around the circuit. An excess of

electrons is provided by the negative side of VBIAS which pushes electrons into the N-Type

region of the P-N junction in the diode. As like charges repel, and as they have enough

energy, the electrons are able to travel across the depletion zone into the excess of holes in

the P-Type region. The electrons do not have enough energy to stay in the conduction band,

and therefore fall to the valence band. However, they still have enough energy to travel

towards the positive terminal through the holes in the P-Type region. The electrons

eventually leave the anode of the diode, flow through the resistor and then return to V BIAS.

School of Electronic Engineering Page 8

Diode Characteristics 2012

Electrons flowing through the diode in this way cause the size of the depletion region to

shrink, as the amount of positive and negative ions at the junction decreases due to

electrons being able to cross the barrier.

As energy is required for the electrons to cross the depletion region, this causes a voltage

drop across the diode. In Silicon diodes, this is around 0.7V. A small amount of voltage is

also lost due to the dynamic resistance of the P/N-Type regions. However, this is so small it

can normally be ignored.

REVERSE BIAS

Reverse bias is the condition that prevents current from flowing backwards through a diode.

Figure 7 Diagram showing a diode that has been reverse biased

As you can see from Figure 7 above, the only difference between the forward and reverse

bias circuits shown here is the polarity of the power supply. It is worth noting that for this

circuit RLIMIT is irrelevant because almost no current flows.

Current is prevented from flowing because the depletion region (and therefore the barrier

potential) in the diode grows. This is because the excess electrons in the electron rich N-

Type region are pulled away from the P-N junction towards the positive side of VBIAS . This

causes an increase in the number of positive ions in the N-Type region. The few electrons

that are in the P-Type region (created by thermal breakdown) travel towards the N-Type

region, and are able to cross the junction as they are in the conduction band. They are then

able to travel through the small number of holes in the N-Type region towards the positive

terminal. This amounts to a tiny current known as the reverse bias current.

There will be a point, if VBIAS is large enough, that the diode will breakdown and allow

current to flow. This normally causes permanent damage to the diode so it not

recommended. The current flow is caused by the free minority electrons in the P-Type

region being accelerated due to the large potential difference across the diode. They travel

at high speed (high energy) towards the depletion region, colliding with other electrons in

the valence band and providing them with sufficient energy to enter the conduction band.

These electrons cross the depletion region and have enough energy to travel through the N-

Type region as conduction electrons. High energy electrons can knock more than one other

School of Electronic Engineering Page 9

Diode Characteristics 2012

electron into the conduction band thereby creating an avalanche effect, increasing current

dramatically.

ZENER DIODES

Zener diodes are Silicon P-N junction diodes designed to act as a normal diode but also to

allow a controlled reverse breakdown. Figure 8, below, shows the circuit symbol for a Zener

diode.

Figure 8 Circuit symbol for a Zener Diode

Zener diodes are much heavier doped than regular diodes, giving rise to a much smaller

depletion region. There are two different types of Zener diodes:

Zener breakdown (low reverse voltages) Allows reverse current due to the very

intense electric field that exists in the very narrow depletion region which is strong

enough to pull electrons from the valence band into the conduction band.

Avalanche breakdown (high reverse voltages) Have the same properties as Zener

breakdown diodes, but the avalanche effect as in a standard diode has much greater

effect.

School of Electronic Engineering Page 10

Diode Characteristics 2012

THEORETICAL

THE VOLTAGE-CURRENT CHARACTERISTIC

Theory indicates that for a p-n junction, the current I is related to the voltage V by the

equation

( )

(1)

A positive value of I means that current flows from the p to the n side. The diode is forward

biased if V is positive, indicating that the p side of the junction is positive with respect to the

n side. The symbol n is unity for germanium and is approximately 2 for silicon at rated

current. I0 is the saturation current under reverse bias.

The symbol VT stands for the volt equivalent of temperature, and is given by

(2)

At room temperature (T = 300K), VT = 26mV. [6]

School of Electronic Engineering Page 11

Diode Characteristics 2012

EXPERIMENTAL

AIMS

The aims of this experiment are to:

Become familiar with the operation of a B2902A Agilent Precision Source/Measure

Unit.

Measure the Current-Voltage characteristics of:

1. A 100 ohm resistor (for reference)

2. A silicon diode (IN4004)

3. A germanium diode (OA90)

4. A Zener diode (BZX)

5. A Bangor University fabricated diode.

Plotting the graphs for these characteristics will allow the cut-in voltages to be

measured for each diode.

View the breakdown effect of a Zener diode.

Study how light intensity affects the Current-Voltage characteristic of the Bangor

University fabricated diode.

EQUIPMENT

B2902A Agilent Precision Source/Measure Unit

o Minimum measurement resolution: 100 fA/100 nV

o Max sample rate: 50000 pts/s [7]

Samsung RV520 Laptop for data logging, connected by USB2.0

Quick I-V Measurement Software

Clips for attaching standard diodes to Measurement Unit

Accurate pin point system for attaching Bangor diodes to the Measurement Unit.

School of Electronic Engineering Page 12

Diode Characteristics 2012

PROCEDURE

FAMILIARISATION

The resistor was connected to the Measurement Unit with the clips.

Everything was checked to make sure it was connected correctly.

The Quick I-V Measurement Software was loaded and configured.

o Start voltage -2V

o Stop voltage +2V

o Increment 200 steps

The test was then run. The software automatically takes readings (to 8 decimal

places) using the Measurement Unit and plots the I-V graph.

SILICON AND GERMANIUM DIODES

Each connected in turn to the Measurement Unit with the clips.

Everything was checked to make sure it was connected correctly (diode the

correct way round).

Test was run with same configuration as with the resistor.

I-V graphs plotted.

ZENER DIODE

Connected to the Measurement Unit with the clips.

Everything was checked to make sure it was connected correctly (diode the

correct way round).

The Quick I-V Measurement Software was configured as follows:

o Start voltage -12V

o Stop voltage +2V

o Increment 200 Steps

Test was run and the I-V graph plotted.

BANGOR FABRICATED DIODE

Diode was cleaned using some cleaning paper.

Connected to the Measurement Unit via a highly accurate pin point system. (Pin

touches aluminium contact [anode], metal base underneath diode [cathode])

Everything was checked to make sure it was connected correctly (diode the

correct way round).

The Quick I-V Measurement Software was configured as follows:

o Start voltage -2V

School of Electronic Engineering Page 13

Diode Characteristics 2012

o Stop voltage +2V

o Increment 200 steps

Test was run and the I-V graph plotted.

The procedure above was then repeated with the diode in the dark covered by a

cardboard box.

The procedure above was then repeated with the diode have a very bright light

directed at it.

School of Electronic Engineering Page 14

Diode Characteristics 2012

RESULTS

RESISTOR

As expected the resistor produced a linear graph. We can verify the graph is correct by

calculating the resistance of the resistor using ohms law

(3)

Therefore, the gradient is equal to

School of Electronic Engineering Page 15

Diode Characteristics 2012

SILICON DIODE

The graph above shows the I-V characteristic for the silicon diode. As expected, it is a

straight line, of 0 current, up until the cut-in voltage, where it increases rapidly. Calculated

from the above graph using computer software, the cut in voltage is 0.668v (+/- 0.00909v).

See Appendix for information on how this was calculated.

School of Electronic Engineering Page 16

Diode Characteristics 2012

GERMANIUM DIODE

This graph shows the measured I-V characteristic for the Germanium diode. It too shows a

linear relationship between current and voltage up until the cut-in voltage. After this the

current increases rapidly, as it flows through the diode. The cut-in voltage, measured by

computer software, is 0.183v (+/- 0.015874v).

See Appendix for information on how this was calculated.

School of Electronic Engineering Page 17

Diode Characteristics 2012

ZENER DIODE

This I-V graph of the Zener diode shows both forward bias and reverse bias cut-in voltages.

Using computer software, the forward bias cut-in voltage was 0.673v (+/-0.0364v). The

reverse breakdown voltage was -10.182v (+/- 0.0364). This is the expected shape of the

graph, although the reverse breakdown voltage was not a smooth curve, most likely due to

experimental error. Unlike the other diodes, the current in the Zener diode appear to

increase linearly after the cut-in voltages.

See Appendix for information on how this was calculated.

School of Electronic Engineering Page 18

Diode Characteristics 2012

BANGOR FABRICATED DIODE

Many thanks to Alex Hoosen, Andy Rosser and Luke Allen for the experimental results for this

diode.

This graph shows the forward bias-cut in voltage for the supplied Bangor diode very clearly.

Instead of using the Quick I-V Measurement Software to plot this graph, the raw values

where taken and transferred to Microsoft Excel 2010 [9], to allow all 3 curves to be plotted

on the same graph. Careful analysis of the graph and the raw data suggests that the cut-in

voltages for the diode is 0.623v (+/- 0.02v).

The graph also shows that there must be a relationship between light intensity and current

flow (above the cut-in voltage), which will be discussed in the discussion section.

School of Electronic Engineering Page 19

Diode Characteristics 2012

DISCUSSION

RESISTOR

The experimental results from this experiment back up the well-known theory that resistors

are ohmic components at a constant temperature. The perfectly straight line provided by

the I-V graph proves that in this instance, the relationship between current and voltage is

linear and therefore purely resistive. Also, as the voltage was increased in small steps and

each measurement taken quickly, heating effect of the resistor must have been minimal.

This verifies ohms law is correct.

(3)

Doing this component first means that it is certain the experimental equipment was set up

correctly and as the value of resistance calculated from the graph matches the value of the

resistor provided, there have not been any noticeable errors created by the measurement

apparatus.

School of Electronic Engineering Page 20

Diode Characteristics 2012

SILICON DIODE

The results from the Silicon diode also support the theory behind its design. No current is

able to pass through it until the voltage across it exceeds the barrier potential of the P-N

junction. The expected value of the barrier potential for a Silicon diode is always

approximately 0.7v. From the results in this experiment, the barrier potential was measured

as 0.668v meaning a percentage error of around 4.8%. This error could be caused by a

number of different components and environmental factors during the experiment, such as

unaccounted resistance of the wires connecting the diode to the Measurement Unit and

also the temperature of the surroundings.

From the graph it can be seen that after the cut-in voltage calculated, the current increases

very rapidly, as electrons have enough energy to cross the P-N junction. However, the

voltage also continues to increase very slightly, and this is due to the internal dynamic

resistance of the semi conductive material. This means that above this point, the diode also

has resistance properties that need to be accounted for.

(4)

The graph shows that Silicon diodes have a relatively small internal dynamic resistance as

the current change after the cut-in voltage is much larger than the voltage change.

School of Electronic Engineering Page 21

Diode Characteristics 2012

GERMANIUM DIODE

The results for the Germanium diode are somewhat similar to the Silicon diode, and yet

somewhat different. The Germanium diode also does not allow any current to pass through

it until its barrier potential is reached. The barrier potential in Germanium diodes is

expected to be around 0.2v. In this experiment the measured cut-in voltage (and therefore

the barrio potential) was measured to be 0.183v giving an approximate error of 9.3%, most

likely caused by the same factors as had influenced the Silicon diode results, as they both

show lower values here than expected.

It is worth noting here the difference in the barrier potentials between the materials.

Germanium has a much lower barrier potential than Silicon. This is due to the increased

distance that the valence electrons in Germanium are away from the strong positive pull of

the nucleus. This therefore means that it takes much less energy for an electron in a

germanium diode to jump from the valence to the conduction band.

From the graph it can also be seen that after the barrier potential has been exceeded, the

current increases slower (at a lower gradient) than in the Silicon diode. This shows that

Germanium diodes have a high internal dynamic resistance, as more voltage is lost as

current increases.

School of Electronic Engineering Page 22

Diode Characteristics 2012

ZENER DIODE

Zener diodes have the interesting characteristic that they can work in an almost identical

fashion to a standard Silicon diode when forward biased, but also can be used in the

reverse-breakdown region without damaging the diode.

In this experiment the forward cut-in voltage for the diode was measured to be 0.673v

which is very similar to the value recorded by the Silicon diode. This result has an associated

percentage error of approximately 4%.

The reverse breakdown region of the diode is where the results get interesting. The Zener

diode has a clearly defined breakdown voltage, in this experiment measured as -10.182v.

The rating of the diode was -10v giving a percentage error of 1.8%. This effect is very useful,

as from diode theory we know that when the reverse breakdown voltage is reached, the

voltage remains almost constant as the current increases dramatically (due to the very low

internal dynamic resistance). It is worth noting that the reverse breakdown voltages of

Zener diodes are designed to be much lower than the reverse breakdown voltages of

regular Silicon diodes to allow engineers to take advantage of this effect.

As relatively low breakdown voltages have been used in this experiment, the breakdown

effect in the diode is predominantly Zener breakdown, which allows reverse current due to

the very intense electric field that exists in the very narrow depletion region which is strong

enough to pull electrons from the valence band into the conduction band and not avalanche

breakdown as in normal diodes.

School of Electronic Engineering Page 23

Diode Characteristics 2012

BANGOR FABRICATED DIODE

Using the Bangor fabricated diode allowed some other properties of diodes to be displayed.

As the Bangor diodes are made from Silicon, it would be expected the cut-in voltage to be

approximately 0.7. However, the measured cut-in voltage was lower, only around 0.623v

giving a percentage error of 12.4%. This is most likely caused do to impurities in the diode

which contaminated it during manufacture. Also, as the contacts needed to connect the

diode to the measurement unit where metallic pins/plates, a boundary resistance will have

been introduced as well as normal wire resistance.

The graph of results shows that dynamic internal resistance of the diode is highly dependent

on the light intensity of the surroundings. Having a high value of light intensity allows much

greater current to flow through the diode than in the dark at a given voltage. This can be

explained using wave-particle duality theory and the photo-electric effect.

It can assumed that light exists of photons, and therefore in this experiment, the higher the

light intensity the more photons hit the diode. When a photon hits the silicon, there is a

small chance that it will provide a valance electron with sufficient energy to enter the

conduction band. Therefore, it would make logical sense to assume that as more electrons

are entering the conduction band, the resistance is lowered and more current can flow.

Using equation (1), it is possible to calculate the saturation current under reverse bias for

the Bangor diode:

( )

From the results, when V = 1.75v, I = 2.07mA

Therefore I0 can be calculated as 5.01x10-18 A

School of Electronic Engineering Page 24

Diode Characteristics 2012

CONCLUSIONS

The results of this experiment show why diodes are such a critical component in designing

circuits. They have the ability to not only stop current flowing in the wrong direction (within

reasonable voltages) but also to control the current flowing in the correct direction, as even

in forward bias the current flow is voltage controlled.

It is displayed clearly that all diodes have associated cut-in voltages which are dependent on

a large number of variables, however, mainly temperature, material and degree of doping. It

has been shown that Germanium diodes have a much lower cut-in voltage than Silicon

diodes because of Germaniums atomic structure.

From theory, it is known that all diodes have a reverse saturation current caused by the

minority charge carriers in each region of the P-N junction. The calculation using results

from the Bangor diode shows that this current is normally very small and can be ignored in

the vast majority of circumstances.

All real diodes have a dynamic internal resistance due to the resistance of the material they

are made from. If they did not (an ideal diode) then the current flow could be of an infinite

value as soon as the voltage was higher than the barrier potential. The results show that

Germanium diodes have a higher internal resistance than Silicon diodes and this is caused

by Germanium atoms increased nucleus size.

Zener diodes are a special type of P-N Silicon diode that can be used for controlled reverse

breakdown, and it will not damage the diode. This is possible due to very accurately defined

doping in the material, giving rise to a very small depletion region allowing Zener

breakdown to take place.

The Bangor diode shows that diodes can be made light intensity sensitive, as photons are

able to excite the electrons in the diode (similar to increasing temperature), giving rise to an

increase in electrons that have sufficient energy to jump from the valance band to the

conduction band.

Finally, all diodes have a reverse breakdown voltage at such point current will flow

backwards through the diode. This is due to the avalanche effect, as electrons are

accelerated due to the large potential difference, and at high speed knock other electrons

into the conduction band. This normally damages the diode, if they are not designed to have

this effect.

School of Electronic Engineering Page 25

Diode Characteristics 2012

ACKNOWLEDGEMENTS

(1) The lecturers and staff at Bangor University School of Electronic Engineering, with

special thanks to Mr Roger Giddings for help in the Electronics lab and to David

Perkins for his teachings on Diodes in Circuit Design.

(2) Thomas L. Floyd for his book Electronic Devices which has been the backbone of

my understanding of diodes and other circuit design components.

(3) My partners in Electronics Lab, Mr Peter Adams and Mr Mathew Clewlow.

(4) Mr Alex Hoosen, Mr Andy Rosser and Mr Luke Allen for their Bangor Diode results.

School of Electronic Engineering Page 26

Diode Characteristics 2012

REFERENCES

Figure [1] - http://www.chemicalelements.com/elements/si.html

Figure [2] - http://www.chemicalelements.com/elements/cu.html

Figure [3] - http://hyperphysics.phy-astr.gsu.edu/hbase/solids/intrin.html

Figure [4] - http://www.evoenergy.co.uk/wp-content/uploads/2010/07/photovoltaic-cells-

pn-junction1.jpg

Figure [5] - http://upload.wikimedia.org/wikipedia/commons/8/83/Diode_pinout_en_fr.svg

Book [6] - Jacob Millman, "Microelectronics: Digital and Analog Circuits and Systems",

McGraw-Hill International Book Company, 1979

Specification [7] - http://cp.literature.agilent.com/litweb/pdf/5990-7009EN.pdf

Software [8] GNU Image Manipulation Program (GIMP) http://www.gimp.org/

Software [9] Microsoft Excel 2010 http://office.microsoft.com/en-gb/excel/

School of Electronic Engineering Page 27

Diode Characteristics 2012

APPENDIX

FORMULAE

RECTIFIERS

(1) ( )

(2)

OHMS LAW

(3)

DYNAMIC RESISTANCE

(4)

School of Electronic Engineering Page 28

Diode Characteristics 2012

SOFTWARE

The cut-in and breakdown voltages of the diodes used in this experiment were calculated

manually using the graphics produced by the Quick I-V Measurement Software.

Using the GNU Image Manipulation Program (GIMP) [8], it is possible to zoom into the

graphics at a pixel scale. Using this high, it enabled the following to be completed on each

graph:

The cut-in (or breakdown) point on each curve was zoomed in to the pixel level.

A point was placed on the line at this point.

Using the straight line tool, a perfectly straight line can be drawn from this point to

both axes.

Using the measurement tool, we can measure accurately how many pixels each

division on the graph scale is represented by.

The voltage increase per pixel is then calculated by

The distance between the cut-in line and the nearest graph scale division is then

measured.

The voltage increase for that distance is calculated by

This is then added to the nearest scale division to give the value of where the cut-in

line crosses the x-axis.

As we are measuring values to the nearest pixel, the error for each reading is +/- 1 pixel. As

we take 2 measurements in each calculation, the error in the voltage reading is

+/-

As this is always significantly larger than the error produced by the B2902A Agilent Precision

Source/Measure Unit, the error introduced by the equipment can safely be ignored.

School of Electronic Engineering Page 29

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- BK29 BetaDocument73 pagesBK29 BetaBruce A. PerreaultPas encore d'évaluation

- IEE tutorial workshop on Earthing & Bonding techniquesDocument51 pagesIEE tutorial workshop on Earthing & Bonding techniquestgkenny873491% (35)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Central Central Distributed PV Inverter PDFDocument38 pagesCentral Central Distributed PV Inverter PDFxiaowei tuPas encore d'évaluation

- Horizontal thrust block designDocument18 pagesHorizontal thrust block designAli Akl0% (1)

- AC Tank Type Test TRFRMR by HAEFELYDocument20 pagesAC Tank Type Test TRFRMR by HAEFELYmadhukarreddy2811Pas encore d'évaluation

- Switchgear and Protective DevicesDocument17 pagesSwitchgear and Protective DevicesAnonymous 5O6HavcVPas encore d'évaluation

- Project Report MECH 4313Document15 pagesProject Report MECH 4313FaIz FauziPas encore d'évaluation

- Project Report MECH 4313Document15 pagesProject Report MECH 4313FaIz FauziPas encore d'évaluation

- Alternative Fuel VehicleDocument54 pagesAlternative Fuel VehicleFaIz FauziPas encore d'évaluation

- Project ReportDocument15 pagesProject ReportFaIz FauziPas encore d'évaluation

- Sample Literature Review - 0Document9 pagesSample Literature Review - 0Sammy NLPas encore d'évaluation

- Ideal Operational Amplifier and Its CaracteristicsDocument11 pagesIdeal Operational Amplifier and Its CaracteristicsFaIz Fauzi100% (1)

- Chapter 7Document15 pagesChapter 7FaIz FauziPas encore d'évaluation

- Chapter 6 - MotakaberDocument14 pagesChapter 6 - MotakaberFaIz FauziPas encore d'évaluation

- Lectur-2 - 12 4-12 5Document23 pagesLectur-2 - 12 4-12 5FaIz FauziPas encore d'évaluation

- Lecture22 PDFDocument12 pagesLecture22 PDFFaIz FauziPas encore d'évaluation

- Chapter 2 P1Document20 pagesChapter 2 P1FaIz FauziPas encore d'évaluation

- Assignment 1.1Document3 pagesAssignment 1.1FaIz FauziPas encore d'évaluation

- Lectur-2 - 12 4-12 5Document23 pagesLectur-2 - 12 4-12 5FaIz FauziPas encore d'évaluation

- 5 Coconut Dehuskingmachine PDFDocument19 pages5 Coconut Dehuskingmachine PDFFaIz FauziPas encore d'évaluation

- Lab 1Document4 pagesLab 1FaIz FauziPas encore d'évaluation

- Ungs 2030 2016Document169 pagesUngs 2030 2016FaIz FauziPas encore d'évaluation

- Concept of Education in Islam-Syed NaquibDocument19 pagesConcept of Education in Islam-Syed Naquibjayengbaya2024100% (1)

- Rectilinear Kinematics and Constant AccelerationDocument21 pagesRectilinear Kinematics and Constant AccelerationFaIz FauziPas encore d'évaluation

- Exam Paper 2Document16 pagesExam Paper 2FaIz FauziPas encore d'évaluation

- Design and Fabrication of Coconut Fiber Removal Machine Ijariie8086Document9 pagesDesign and Fabrication of Coconut Fiber Removal Machine Ijariie8086FaIz FauziPas encore d'évaluation

- Introduction to Gear DesignDocument32 pagesIntroduction to Gear DesignbiasottopinPas encore d'évaluation

- Components of Civilizations (Slide 87)Document5 pagesComponents of Civilizations (Slide 87)FaIz FauziPas encore d'évaluation

- Lab GuideDocument5 pagesLab GuidePejuangHatiPas encore d'évaluation

- Design of Spur GearDocument39 pagesDesign of Spur GearFaIz FauziPas encore d'évaluation

- Exam Paper 1Document17 pagesExam Paper 1FaIz FauziPas encore d'évaluation

- Heat Treatment DataDocument1 pageHeat Treatment DataFaIz FauziPas encore d'évaluation

- Malfunction of Safety Features of Commercial VehiclesDocument5 pagesMalfunction of Safety Features of Commercial VehiclesFaIz FauziPas encore d'évaluation

- Stirling Final Report (AutoRecovered)Document4 pagesStirling Final Report (AutoRecovered)FaIz FauziPas encore d'évaluation

- Ethics & Fiqh For Everyday Life PDFDocument255 pagesEthics & Fiqh For Everyday Life PDFFaIz Fauzi100% (1)

- Developmentoffiqh 111219102421 Phpapp02Document82 pagesDevelopmentoffiqh 111219102421 Phpapp02FaIz FauziPas encore d'évaluation

- Ap431 Ic de Fuente Xbox Clasico V1.6Document17 pagesAp431 Ic de Fuente Xbox Clasico V1.6Eisenhower Garcia LealPas encore d'évaluation

- Extracto IEEE C37 99 Cond ExtDocument1 pageExtracto IEEE C37 99 Cond ExtPablo Poveda Rodriguez0% (1)

- P 12 PF 06Document10 pagesP 12 PF 06Lauraa IslasPas encore d'évaluation

- Visualising Magnetic FieldsDocument171 pagesVisualising Magnetic FieldshieudtqnPas encore d'évaluation

- Power Electronics-An Emerging Technology - B.K.BoseDocument8 pagesPower Electronics-An Emerging Technology - B.K.Bosegeraleao208Pas encore d'évaluation

- Water: On Ripples-A Boundary Layer-Theoretical DefinitionDocument19 pagesWater: On Ripples-A Boundary Layer-Theoretical DefinitionStereo Satin-JanePas encore d'évaluation

- BJT Amplifier SimulationDocument11 pagesBJT Amplifier SimulationNiko de LemosPas encore d'évaluation

- EasyPact MVS - MVS20N3MF2L PDFDocument3 pagesEasyPact MVS - MVS20N3MF2L PDFphongPas encore d'évaluation

- Momentum and Impulse Reading NotesDocument7 pagesMomentum and Impulse Reading NotesParvinder Bhardwaj0% (1)

- Chemical Engineering Journal: Somasekhara Goud Sontti, Arnab AttaDocument17 pagesChemical Engineering Journal: Somasekhara Goud Sontti, Arnab AttaSomaSekhar GoudPas encore d'évaluation

- Who Invented The TransformerDocument4 pagesWho Invented The TransformerJulioPas encore d'évaluation

- Format Failure Substation EqDocument2 pagesFormat Failure Substation EqTechnical SupplierPas encore d'évaluation

- Gerak Rotasi Terhadap Sumbu TetapDocument60 pagesGerak Rotasi Terhadap Sumbu TetapNikenPas encore d'évaluation

- Elex DC Cir 2Document2 pagesElex DC Cir 2Jaiko BendoPas encore d'évaluation

- Simulation of Push-Pull Inverter For Photovoltaic Applications Via MultisimDocument5 pagesSimulation of Push-Pull Inverter For Photovoltaic Applications Via MultisimaaronPas encore d'évaluation

- Exercise-1: Ans.: 5 MW, 360 MWH, 500 Mwh/DayDocument2 pagesExercise-1: Ans.: 5 MW, 360 MWH, 500 Mwh/DayAbreu Miguel Liliano LilianoPas encore d'évaluation

- Irfr 3607 PBFDocument10 pagesIrfr 3607 PBFOscar FernandezPas encore d'évaluation

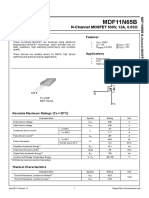

- MDF11N65BDocument6 pagesMDF11N65BElec FoPas encore d'évaluation

- Equilibrium of Bodies in Liquids Density and Relative DensityDocument16 pagesEquilibrium of Bodies in Liquids Density and Relative DensityAdegoke TofunmiPas encore d'évaluation

- Science8 Q3 Week2Document21 pagesScience8 Q3 Week2Kathrina De SenaPas encore d'évaluation

- Inbound 7181713037772966188Document15 pagesInbound 7181713037772966188keepersilent2Pas encore d'évaluation

- SoundDocument45 pagesSoundAli AbdallahPas encore d'évaluation

- KAUSHAL-Online Internship Cum Training Module A Unique Initiative by BHELDocument2 pagesKAUSHAL-Online Internship Cum Training Module A Unique Initiative by BHELUmar TechPas encore d'évaluation

- Gas Law Packet AnswersDocument6 pagesGas Law Packet Answersjerm655Pas encore d'évaluation