Académique Documents

Professionnel Documents

Culture Documents

TR PM Check List

Transféré par

Muhammad Akif Naeem0 évaluation0% ont trouvé ce document utile (0 vote)

1K vues5 pagestransformer PM checklist

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documenttransformer PM checklist

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

1K vues5 pagesTR PM Check List

Transféré par

Muhammad Akif Naeemtransformer PM checklist

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

JUBAIL UNITED PETROCHEMICAL COMPANY Garin

‘Checkiit Title Checklist No!

Check list to do Maintenance of 34.5 KV / MET-CHL-EE-00066-05

4.16KV &

34.5KV / 13.8KV Transformers

Function Department | Rev. No:

Technical Engineering Support 03

Department (Electrical) ERE

‘approved By ef Date Approved Page No:O4 of O5

ESD Sr. _— | 02/12/2014

Manager/ =

GM Maintenance

TAG NO. TAG DESCRIPTION | Job Executed Date =

DISTRIBUTION

FREQUENCY: TRANSFORMER

sY

Dominant Failure Mode :- Electrical Insulat ‘SAP Notification / Order No.

Failure

1.0 MAINTENANCE CHECKS

= Follow work instruction number: MET-WIN-EE-00068-05.

Carry out following checks (CHKS)/ Cleaning (CLN) and Repair (REP) as

required complete activities should be marked by "Y" for YES and "N" for NO.

- Put N/A whichever item is not applicable while doing maintenance

Note:-

Fill up checklist for yearly inspection of transformer (MET-CHL-EE-00120-

06) before working on this chec!

ee eee

Check equipment

is isolated and

SWP is received.

2. _ | Clean Transformer

from dust/dirt by

hand held air

blower, dry cotton

cloth.

3, _ | Check there is no

oll leakage from

HV bushing

Prepared by; Sadanandan Sudheer

Staff Electrical Engineer ESD __-

Reviewed by ; Majdi Al Faraj

Pecliod Sener, a

Date : 02/12/2014 |

Date : 02/12/2014 |

Date: 02/12/2014

Page No: 02 of 05 |

4. | Check for

cleanliness of HV

Bushings and clean

them if required

5, | Check for loose |

connections at HV

bushing terminal

Check there is no oll

leakage from LV

bushing

Check for

cleanliness of LV

Bushings and clean

them if required.

Check for loose

connections at LV

bushing terminal

Do visual inspection

of core ground

bushing and test

core ground

insulation

To test core

ground megger,

disconnect

ground

connection from

tapping point

Do not

disconnect

from ground

bushing.

10.

Check Neutral

bushing connection

for loose and clean

the insulator.

id

Record maximum

temperature

reached in oll

temperature

indicator and reset

the maximum value

indication pointer.

12.

Record maximum

temperature

reached in winding

temperature

indicator and reset

the maximum value

indication pointer

wherever applicable.

13,

Visually inspect

relief vent device for

any abnormalities

and rusting,

DOC No.

MET-CHL-€E-00066-05

Date: 02/12/2014 Rev. No: 03

| age No: 03 of 05

DESCRIPTION

14,

Inspect flag position

on sudden pressure

rise relay.

REPAIR

Sa

15

Check the tightness

of all power and

control cables.

16.

Check continuity of

earthing for tank,

control cabinet and

air terminal chamber

17.

‘Operate OFF load

tap changer to

check its smooth

operation. After

checking, put it back

on original tap

position.

18.

19.

Visually inspect

control wiring

integrity for any

damage in

insulation,

Check IP Integrity of

the control cabinet

and air terminal

chamber

20.

‘Check Space heater

connections for

tightness

21.

Check space heater

thermostat setting

between 70° F to

80° F and record.

22.

Do insulation

resistance check of

HV , LV Windings

along with cable and

NGR disconnected.

23

‘Measurement of,

resistance and

inductance of

transformer winding

24.

‘Clean NGR from

dust/dirt by hand

held air blower, dry

cotton cloth,

25.

‘Check tightness of

terminals on NGR

26.

Measure the

resistance of NGR (6

'Q for 4.16 KV and

19,922 for 13.8 KV

XFR)

2.1 Maximum Temperature indicator readings

(Sr. | Parameter Maximum value reached

Noricis| iia OP tal ei

1 Oil temperature Indicator

2 Winding Temperature Indicator

2.2 Space Heater Thermostat Setting

Expected value ‘Actual Value Remark

Between 70° F to 80° F

2.3 Insulation resistance measurement (Checklist point 22)

Short all LV terminals of

transformer and connect to

ground during meggering..

Short all HV terminals of

transformer and connect to

ground during meggering..

HY Side To Ground

Using 5KV Megger

LV Side To Ground

Using 500 V Megger

2.4 Measurement of transformer resistance and inductance

Sr. No Winding Resistance Inductance

1 Meter details

2 HV Side | Between Hi and H2

Between H2 and H3

Between H3 and Hi

3 LV Side | Between X1 and x2

Between X2 and X3

| Between X3 and X1

2.5 Measurement of NGR resistance:

Meter used Expected value Measured value

‘DOE No. Peta “sears

_MET-CHL-EE-00066-05 | 729° No: 05 of 05

Date: 02/12/2014 | Rev. No: 03

3.0 General Remarks

‘Any general observation made while performing maintenance should be noted down

below,

Performed by Reviewed by

Name(s): Name:

Signature: Signature:

Date: Date:

Y’ Put tick mark in the status column after completion of SAP | bate:

related _ Notification /Order is closed technically asl

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Switchboards InspectionDocument72 pagesSwitchboards InspectionMuhammad Akif NaeemPas encore d'évaluation

- QC INSPECTOR ElectricalDocument3 pagesQC INSPECTOR ElectricalMuhammad Akif Naeem100% (2)

- Sss Module: Transformer Tapping OptionsDocument2 pagesSss Module: Transformer Tapping OptionsMuhammad Akif NaeemPas encore d'évaluation

- LED Bulb Quotation-A Model and T ModelDocument2 pagesLED Bulb Quotation-A Model and T ModelMuhammad Akif NaeemPas encore d'évaluation

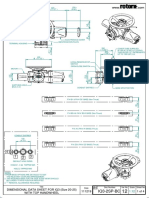

- IQ3-2SP-BC: A4 1 of 4 Dimensional Data Sheet For Iq3 (Size 20-25) With Top Handwheel 111219Document4 pagesIQ3-2SP-BC: A4 1 of 4 Dimensional Data Sheet For Iq3 (Size 20-25) With Top Handwheel 111219Muhammad Akif NaeemPas encore d'évaluation

- S 1481Document2 pagesS 1481Muhammad Akif NaeemPas encore d'évaluation

- BusDuct PM Check ListDocument3 pagesBusDuct PM Check ListMuhammad Akif NaeemPas encore d'évaluation

- Basic Terms To Get StartDocument3 pagesBasic Terms To Get StartMuhammad Akif NaeemPas encore d'évaluation

- Ampacities of Insulated Conductors (From NEC Table 310 16)Document2 pagesAmpacities of Insulated Conductors (From NEC Table 310 16)Muhammad Akif NaeemPas encore d'évaluation

- Optical Fiber TrainingDocument181 pagesOptical Fiber TrainingMuhammad HarisPas encore d'évaluation

- Nestle PakistanDocument1 pageNestle PakistanMuhammad Akif NaeemPas encore d'évaluation

- Assignment No.1 VLSM Addressing SchemeDocument1 pageAssignment No.1 VLSM Addressing SchemeMuhammad Akif Naeem100% (1)