Académique Documents

Professionnel Documents

Culture Documents

Operation V N P T I 77

Transféré par

Dhiraj SatyamTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Operation V N P T I 77

Transféré par

Dhiraj SatyamDroits d'auteur :

Formats disponibles

v) Reduce the load on generator and mainain

steam parameters.

vi) If 3 mills at less than 50% feeder speed or 2

mills are left in service, cut in oil gun

adjacent to working mills.

vii) Check furnace draft, air flow and drum level

are normal.

viii) Check flame is table and scanners sense

"Flame on".

ix) Check that associated elevation fuel

air damper close and windbox

pressufe is maintained 70 mm WC.

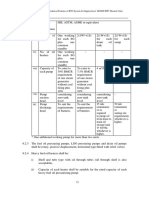

2.11.8 One Mill Trips

Mill discharge valves are closed i) Check the running mills share the load if

and/or thermal load control of mills are on auto.

Loss of elevation D.C. supply ii) Reduce the generator load if pressure starts

for more than 2 sees, and/or dropping.

Support ignition energy is removed iii) Start reserve mill and take load.

with 3 minutes of feeder starting,

and/or

Motor protection operates and /or iv) Check furnace draft is maintained normal

One P.A. Fan trips (mill in v) Check the correct air flow is maintained.

excess of 3 will trip starting

from bottom). vi) Check that drum level is maintain

normal.

vii) Check that tripped mill is isolated (hot air

gate closed, cold air damper minimum open,

feeder tripped).

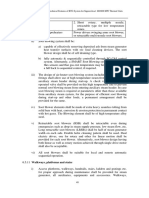

2.11.9.Coal Hangup in Mill

Choking of coal at inlet to mill.

High moisture in coal and /or i) Check feeder trip on "No coal flow & low

current" protection.

Too much fines in coal with moisture, ii) Check mill outlet temperature is less than

and/or 85C.

73

Vous aimerez peut-être aussi

- Super Critical Power - Part91Document1 pageSuper Critical Power - Part91Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part88Document1 pageSuper Critical Power - Part88Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part92Document1 pageSuper Critical Power - Part92Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part85Document1 pageSuper Critical Power - Part85Dhiraj SatyamPas encore d'évaluation

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part80Document1 pageSuper Critical Power - Part80Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part83Document1 pageSuper Critical Power - Part83Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part76Document1 pageSuper Critical Power - Part76Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part77Document1 pageSuper Critical Power - Part77Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part86Document1 pageSuper Critical Power - Part86Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part62Document1 pageSuper Critical Power - Part62Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part41Document1 pageSuper Critical Power - Part41Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part56Document1 pageSuper Critical Power - Part56Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part60Document1 pageSuper Critical Power - Part60Dhiraj SatyamPas encore d'évaluation

- Suitable For Remote Manual OperationDocument1 pageSuitable For Remote Manual OperationDhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part59Document1 pageSuper Critical Power - Part59Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part57Document1 pageSuper Critical Power - Part57Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part48Document1 pageSuper Critical Power - Part48Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part47Document1 pageSuper Critical Power - Part47Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part46Document1 pageSuper Critical Power - Part46Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part42Document1 pageSuper Critical Power - Part42Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part34Document1 pageSuper Critical Power - Part34Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part40Document1 pageSuper Critical Power - Part40Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part37Document1 pageSuper Critical Power - Part37Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part38Document1 pageSuper Critical Power - Part38Dhiraj SatyamPas encore d'évaluation

- Super Critical Power - Part35Document1 pageSuper Critical Power - Part35Dhiraj SatyamPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and CountriesDocument13 pagesThe Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and Countriesluisbmwm6Pas encore d'évaluation

- Apm p5 Course NotesDocument267 pagesApm p5 Course NotesMusumbulwe Sue MambwePas encore d'évaluation

- Javascript Applications Nodejs React MongodbDocument452 pagesJavascript Applications Nodejs React MongodbFrancisco Miguel Estrada PastorPas encore d'évaluation

- Maths PDFDocument3 pagesMaths PDFChristina HemsworthPas encore d'évaluation

- 4109 CPC For ExamDocument380 pages4109 CPC For ExamMMM-2012Pas encore d'évaluation

- Daraman vs. DENRDocument2 pagesDaraman vs. DENRJeng GacalPas encore d'évaluation

- TSR KuDocument16 pagesTSR KuAngsaPas encore d'évaluation

- What Is Retrofit in Solution Manager 7.2Document17 pagesWhat Is Retrofit in Solution Manager 7.2PILLINAGARAJUPas encore d'évaluation

- 450i User ManualDocument54 pages450i User ManualThượng Lê Văn0% (2)

- Tanzania Finance Act 2008Document25 pagesTanzania Finance Act 2008Andrey PavlovskiyPas encore d'évaluation

- An RambTel Monopole Presentation 280111Document29 pagesAn RambTel Monopole Presentation 280111Timmy SurarsoPas encore d'évaluation

- Appendix - 5 (Under The Bye-Law No. 19 (B) )Document3 pagesAppendix - 5 (Under The Bye-Law No. 19 (B) )jytj1Pas encore d'évaluation

- TAS5431-Q1EVM User's GuideDocument23 pagesTAS5431-Q1EVM User's GuideAlissonPas encore d'évaluation

- Electricity 10thDocument45 pagesElectricity 10thSuryank sharmaPas encore d'évaluation

- Unit 2Document97 pagesUnit 2MOHAN RuttalaPas encore d'évaluation

- Ytrig Tuchchh TVDocument10 pagesYtrig Tuchchh TVYogesh ChhaprooPas encore d'évaluation

- HandloomDocument4 pagesHandloomRahulPas encore d'évaluation

- Feasibility Study of Diethyl Sulfate ProductionDocument3 pagesFeasibility Study of Diethyl Sulfate ProductionIntratec SolutionsPas encore d'évaluation

- Amerisolar AS 7M144 HC Module Specification - CompressedDocument2 pagesAmerisolar AS 7M144 HC Module Specification - CompressedMarcus AlbaniPas encore d'évaluation

- Phase 1: API Lifecycle (2 Days)Document3 pagesPhase 1: API Lifecycle (2 Days)DevendraPas encore d'évaluation

- Group 1 Disaster Management Notes by D. Malleswari ReddyDocument49 pagesGroup 1 Disaster Management Notes by D. Malleswari Reddyraghu ramPas encore d'évaluation

- Shubham Tonk - ResumeDocument2 pagesShubham Tonk - ResumerajivPas encore d'évaluation

- Vinera Ewc1201Document16 pagesVinera Ewc1201josue1965Pas encore d'évaluation

- Functions of Commercial Banks: Primary and Secondary FunctionsDocument3 pagesFunctions of Commercial Banks: Primary and Secondary FunctionsPavan Kumar SuralaPas encore d'évaluation

- Interoperability Standards For Voip Atm Components: Volume 4: RecordingDocument75 pagesInteroperability Standards For Voip Atm Components: Volume 4: RecordingjuananpspPas encore d'évaluation

- Google App EngineDocument5 pagesGoogle App EngineDinesh MudirajPas encore d'évaluation

- JAZEL Resume-2-1-2-1-3-1Document2 pagesJAZEL Resume-2-1-2-1-3-1GirlieJoyGayoPas encore d'évaluation

- Sterling B2B Integrator - Installing and Uninstalling Standards - V5.2Document20 pagesSterling B2B Integrator - Installing and Uninstalling Standards - V5.2Willy GaoPas encore d'évaluation

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 pagesPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiPas encore d'évaluation

- General Field Definitions PlusDocument9 pagesGeneral Field Definitions PlusOscar Alberto ZambranoPas encore d'évaluation