Académique Documents

Professionnel Documents

Culture Documents

Computer-Aided Hazard Identification: Paul Chung Department of Computer Science

Transféré par

JAGATHEESAN P0 évaluation0% ont trouvé ce document utile (0 vote)

18 vues12 pagesTitre original

34PC.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

18 vues12 pagesComputer-Aided Hazard Identification: Paul Chung Department of Computer Science

Transféré par

JAGATHEESAN PDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 12

Computer-aided Hazard

Identification

Paul Chung (p.w.h.chung@lboro.ac.uk)

Department of Computer Science

HAZOP Studies

n an established and widely used

technique in the process industry for

hazard identification

n time consuming, labour intensive

process

n tedious

n expensive

Computer-aided HAZOP

n different levels of support

n electronic report form

n electronic data

n automated hazard identification

n continuous operation

n batch operation

Automated Hazard

Identification

n continuous operation

n from basic research to commercial product -

HAZID

n basic technology

n signed directed graph representation

n fault propagation

n go through a list of deviations systematically and

identify the faults that cause the deviations and

the consequences that result from the faults and

deviations

HAZID Overview

n Features

n automated extraction of plant design from

a CAD system, e.g. Intergraph SmartPlant

P&ID and Smart Sketch

n convenient forms for adding any missing

process specific information

n tick boxes for selecting analysis options

n deviations, e.g. more flow, less flow, etc.

n items

HAZID Overview

n Features

n different output formats

n XML web page

n Excel spreadsheet

n query facility for viewing analysis results

n e.g. viewing faults and consequences relating to a

particular plant item

n e.g. viewing the propagation path between a particular

fault and consequence

n compare facility for viewing the difference

between two HAZID runs

n useful for after making a change to the design

HAZID Demo

HAZID Demo

Automated Hazard

Identification

n batch operation

n early research prototype (CHECKOP)

n basic technology

n action representation

n state-based simulation

n go through a set of operation instructions

systematically and identify potential ambiguities,

operating problems and hazards

n applying guidewords such as before, after, no

action, etc

CHECKOP Demonstration

([kettle] move-under [kitchen-tap]) ([tea-bag-tin] move-to [cup])

([kettle] open-lid ) ([tea-bag-tin] open-lid)

([kitchen-tap] turn-on ) ([tea-bag] move-into [cup])

([kettle] fill-from [kitchen-tap] ([kettle] move-to [cup])

with water until volume 50 %) ([cup] fill-from [kettle] with water until

([kitchen-tap] turn-off ) volume 80 %)

([kettle] close-lid) ([cup] react-content until elapsed-time 5

([kettle] move-to [kettle-base]) seconds)

([kettle-base] plug-to [power- ([milk-bottle] move-to [cup])

socket]) ([milk-bottle] open-lid)

([power-socket] switch-on) ([cup] fill-from [milk-bottle] with milk abs

([kettle] switch-on) amount 10 ml)

([kettle] heat-content until temp ([bottle] close-lid)

100 C) ([spoon] stir-content of [cup] until elapsed-

([kettle] switch-off) time 3 seconds)

([power-socket] switch-off)

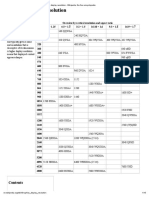

Batch HAZOP

Guideword Deviation Cause Consequence

No Action

Early Action

Early Termination

Late Action

Late Termination

Conclusions

n automated hazard identification

n continuous operation

n commercial tool that can reduce the time of

HAZOP

n batch operation

n promising area of research and development

for identifying problems associated with human

errors and operating procedures

Vous aimerez peut-être aussi

- Artificial Intelligence and Knowledge Processing: Methods and ApplicationsD'EverandArtificial Intelligence and Knowledge Processing: Methods and ApplicationsPas encore d'évaluation

- HALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionD'EverandHALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionPas encore d'évaluation

- Computer-Aided Hazard Identification: Paul Chung (P.w.h.chung@lboro - Ac.uk) Department of Computer ScienceDocument38 pagesComputer-Aided Hazard Identification: Paul Chung (P.w.h.chung@lboro - Ac.uk) Department of Computer Scienceamit64007Pas encore d'évaluation

- 6 Sigma GlossaryDocument104 pages6 Sigma GlossaryCSederPas encore d'évaluation

- Hazop Hazard & Operability StudiesDocument19 pagesHazop Hazard & Operability StudiesSayak BosePas encore d'évaluation

- Phase Technology PPA-70Xi Pour Point AnalyzerDocument27 pagesPhase Technology PPA-70Xi Pour Point AnalyzerasfsdfPas encore d'évaluation

- Fmea Process TemplateDocument20 pagesFmea Process TemplateLazarasBenny IsprithiyonePas encore d'évaluation

- 7 QC ToolsDocument44 pages7 QC ToolsNEHAPas encore d'évaluation

- Design Project 5Document3 pagesDesign Project 5pelayo240Pas encore d'évaluation

- Hazard and Operability Studies (HAZOP)Document28 pagesHazard and Operability Studies (HAZOP)anpuselvi125100% (1)

- Hazop Hazard & Operability StudiesDocument19 pagesHazop Hazard & Operability StudiesAppajiPas encore d'évaluation

- Testlink Installation GuideDocument11 pagesTestlink Installation GuideDwayneBravoPas encore d'évaluation

- Old Problem Solving ToolsDocument43 pagesOld Problem Solving ToolsVishakha VarshneyPas encore d'évaluation

- Kaizen TemplatesDocument14 pagesKaizen Templatesjfelix_aranaPas encore d'évaluation

- HAZOPDocument47 pagesHAZOPMiftakhul Nurdianto100% (4)

- Chapter 2 - SPCDocument75 pagesChapter 2 - SPCtebelayhabitamu12Pas encore d'évaluation

- Chapter2 DJF51082Document32 pagesChapter2 DJF51082Fiq IFTPas encore d'évaluation

- Https Tutorials Iq Harvard Edu R Rstatistics Rstatistics HTMLDocument25 pagesHttps Tutorials Iq Harvard Edu R Rstatistics Rstatistics HTMLcsscsPas encore d'évaluation

- Work Shop (23 HLM)Document23 pagesWork Shop (23 HLM)ferdhian RahmansyahPas encore d'évaluation

- Aspen Plus - Module IDocument193 pagesAspen Plus - Module IHafeez Ahmad50% (2)

- Quality Control Tools 7Document30 pagesQuality Control Tools 7indria purwantiningrum0% (1)

- Statistical Process ControlDocument47 pagesStatistical Process ControlAdrian Copa100% (1)

- ToolDocument50 pagesToolhedisomanPas encore d'évaluation

- Coagulometer Coatron A4Document6 pagesCoagulometer Coatron A4Devy Arianti100% (1)

- UC2013 Umetrics PetterMoree ApplicationsOfMultivariateDataAnalysisDocument31 pagesUC2013 Umetrics PetterMoree ApplicationsOfMultivariateDataAnalysisBlank BacktobasicPas encore d'évaluation

- Hazard and Operability StudyDocument21 pagesHazard and Operability StudyBubblePas encore d'évaluation

- A Scheme of High-Dimensional Key-Variable Search Algorithms For Yield ImprovementDocument8 pagesA Scheme of High-Dimensional Key-Variable Search Algorithms For Yield Improvement吳 澍 WU SU F74056297Pas encore d'évaluation

- Hazard and Operability Study (Hazop)Document22 pagesHazard and Operability Study (Hazop)Aun AbbasPas encore d'évaluation

- 7 QC ToolsDocument29 pages7 QC Toolsdspquality2023Pas encore d'évaluation

- Soft Sensing of Product Quality in The DebutanizerDocument8 pagesSoft Sensing of Product Quality in The DebutanizerMarcelo Feliciano FilhoPas encore d'évaluation

- Sciencedirect: Predictive Model To Evaluation Quality of The Manufacturing Process Using Matlab Tools Stella HrehovaDocument6 pagesSciencedirect: Predictive Model To Evaluation Quality of The Manufacturing Process Using Matlab Tools Stella HrehovaJunn Ree MontillaPas encore d'évaluation

- Statistical Process ControlDocument10 pagesStatistical Process ControlsushmaxPas encore d'évaluation

- 5-S and Value Stream Mapping: Douglas M. Stewart, Ph.D. Anderson Schools of Management University of New MexicoDocument28 pages5-S and Value Stream Mapping: Douglas M. Stewart, Ph.D. Anderson Schools of Management University of New MexiconabilPas encore d'évaluation

- A Study of Q Chart For Short Run PDFDocument37 pagesA Study of Q Chart For Short Run PDFEd100% (1)

- ISPE - Aseptic Filling Line - NJChapterPaulMelamudPresDocument13 pagesISPE - Aseptic Filling Line - NJChapterPaulMelamudPrespakdekroPas encore d'évaluation

- 7qc Tools ExplanationDocument64 pages7qc Tools ExplanationRajPas encore d'évaluation

- Chapter 6 - Hazard AnalysisDocument74 pagesChapter 6 - Hazard AnalysisHafiidz MalekPas encore d'évaluation

- 1.7 Basic Terminology and FiguresDocument7 pages1.7 Basic Terminology and Figuresanjo0225Pas encore d'évaluation

- Automating HPLC and GC-Method - ValidationDocument6 pagesAutomating HPLC and GC-Method - ValidationqncargbPas encore d'évaluation

- DMAIC Tool SummaryDocument1 pageDMAIC Tool SummaryGautam GoyalPas encore d'évaluation

- Processes and Technology: Operations Management - 6 EditionDocument46 pagesProcesses and Technology: Operations Management - 6 EditionSiddharth Narayanan ChidambareswaranPas encore d'évaluation

- Romanach PresentationDocument37 pagesRomanach PresentationAlejandro Romero ValenciaPas encore d'évaluation

- 7QC ToolsDocument48 pages7QC ToolsSudhagarPas encore d'évaluation

- V&V V&V V&V V&V: Requirements Engineering VV RequirementsDocument107 pagesV&V V&V V&V V&V: Requirements Engineering VV RequirementshadjPas encore d'évaluation

- 2 - Basic SPC MethodsDocument100 pages2 - Basic SPC MethodsWilliam BautistaPas encore d'évaluation

- Unit 5: Total Quality Management: Tools and TechniquesDocument71 pagesUnit 5: Total Quality Management: Tools and TechniquesdeepthikuppuswamyPas encore d'évaluation

- 7 Quality Control ToolsDocument25 pages7 Quality Control ToolsMohd FaizalPas encore d'évaluation

- Problem Solving Tools: Training Module OnDocument46 pagesProblem Solving Tools: Training Module OnThulasi RamPas encore d'évaluation

- 01 Fundamental PrinciplesDocument39 pages01 Fundamental PrinciplesJuliano SordanPas encore d'évaluation

- Phase Technology 70xi Pour Point AnalyzerDocument27 pagesPhase Technology 70xi Pour Point AnalyzerBash MatPas encore d'évaluation

- Introduction To Super Pro DesignerDocument8 pagesIntroduction To Super Pro Designerfelipekoblev100% (3)

- 7 QC ToolsDocument21 pages7 QC Toolsrakeshkumar20Pas encore d'évaluation

- Six Sigma Training PostersDocument32 pagesSix Sigma Training PostersDenise CheungPas encore d'évaluation

- HAZOPSDocument21 pagesHAZOPSMalak HindiPas encore d'évaluation

- Experience .: SummaryDocument6 pagesExperience .: SummaryMounith29Pas encore d'évaluation

- Problem Solving ToolsDocument38 pagesProblem Solving ToolsA C.GPas encore d'évaluation

- Knowledge Material For PGP 2020-22 Batch: Part 3/3Document12 pagesKnowledge Material For PGP 2020-22 Batch: Part 3/3Rohit ChourasiaPas encore d'évaluation

- Quality Tools4Document35 pagesQuality Tools4Aeron Paul AntonioPas encore d'évaluation

- Problem Solving Tools Pareto AnalysisDocument24 pagesProblem Solving Tools Pareto Analysissangameshwar.kadole1273Pas encore d'évaluation

- HazopDocument6 pagesHazopArman SikirmanPas encore d'évaluation

- Resume EeeeDocument4 pagesResume EeeeWhilmark Tican MucaPas encore d'évaluation

- Power Network Telecommunication: Powerlink - Technical DataDocument10 pagesPower Network Telecommunication: Powerlink - Technical Datawas00266Pas encore d'évaluation

- Dry DockingDocument27 pagesDry DockingRoshan D'silva100% (1)

- KSLCDocument52 pagesKSLCzacklawsPas encore d'évaluation

- ProductBrochure A35F A40F en 30A1006561Document24 pagesProductBrochure A35F A40F en 30A1006561Ji UvexPas encore d'évaluation

- Ice Rink: Name OriginsDocument6 pagesIce Rink: Name Originsmichol2014Pas encore d'évaluation

- Unit Ii Construction Practice - 10Document94 pagesUnit Ii Construction Practice - 10Arun KumarPas encore d'évaluation

- Average - Aptitude MCQ Questions and Solutions Wit - 1597107113795Document6 pagesAverage - Aptitude MCQ Questions and Solutions Wit - 1597107113795Manish ChavannavarPas encore d'évaluation

- Myanmar Power SystemDocument4 pagesMyanmar Power Systemkayden.keitonPas encore d'évaluation

- Mix Design PosterDocument1 pageMix Design PosterAbhilash KumarPas encore d'évaluation

- Human Resources Assistant Resume, HR, Example, Sample, Employment, Work Duties, Cover LetterDocument3 pagesHuman Resources Assistant Resume, HR, Example, Sample, Employment, Work Duties, Cover LetterDavid SabaflyPas encore d'évaluation

- 2018 Academic Sector Annual Report PDFDocument213 pages2018 Academic Sector Annual Report PDFEsperanza ReyesPas encore d'évaluation

- 5 CombiflameDocument8 pages5 CombiflamenitantharaniPas encore d'évaluation

- TCE BE EEE RulesandRegulationsDocument509 pagesTCE BE EEE RulesandRegulationsApliePas encore d'évaluation

- Service Pack 2Document149 pagesService Pack 2billwong169Pas encore d'évaluation

- Cidtt The GuideDocument268 pagesCidtt The GuideAbdul Shameem100% (1)

- David Beard Composer CV ShortDocument2 pagesDavid Beard Composer CV ShortEhsan KarimyPas encore d'évaluation

- Graphics Display Resolution - Wikipedia, The Free EncyclopediaDocument15 pagesGraphics Display Resolution - Wikipedia, The Free EncyclopediaKarun KumarPas encore d'évaluation

- Operator'S Manual: E-Series Ultraviolet Hand LampsDocument9 pagesOperator'S Manual: E-Series Ultraviolet Hand LampsGuiss LemaPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarPas encore d'évaluation

- 2016 HSC Engineering StudiesDocument40 pages2016 HSC Engineering StudiesR MathewPas encore d'évaluation

- Last - kmsg-2016-11-17 10 29 34Document588 pagesLast - kmsg-2016-11-17 10 29 34Anonymous HpW3UcqPas encore d'évaluation

- Mathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringDocument40 pagesMathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringVishal ShasiPas encore d'évaluation

- Database Upgrade 10g To 11gDocument28 pagesDatabase Upgrade 10g To 11gSubhasis1928Pas encore d'évaluation

- DELTA - IA-HMI - Danfoss VLT 2800 - FC Protocol - CM - EN - 20111122Document4 pagesDELTA - IA-HMI - Danfoss VLT 2800 - FC Protocol - CM - EN - 20111122Ronnie Ayala SandovalPas encore d'évaluation

- Chapter 7 Series Parallel CircuitsDocument70 pagesChapter 7 Series Parallel CircuitsAbdullrahman Al-ShammaaPas encore d'évaluation

- Micronta 12VDC Power Adapter 273-1653A InstructionsDocument2 pagesMicronta 12VDC Power Adapter 273-1653A Instructions240GL guyPas encore d'évaluation

- Advanced English Communication Skills LaDocument5 pagesAdvanced English Communication Skills LaMadjid MouffokiPas encore d'évaluation

- MultiplexersDocument23 pagesMultiplexersAsim WarisPas encore d'évaluation

- Scooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityDocument8 pagesScooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityAnonymous Mdw6y7Q1Pas encore d'évaluation