Académique Documents

Professionnel Documents

Culture Documents

A High Precision Constant Current Source Applied in LED Driver

Transféré par

carolain_msTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A High Precision Constant Current Source Applied in LED Driver

Transféré par

carolain_msDroits d'auteur :

Formats disponibles

A high precision constant current source applied

in LED driver

Hongtao Mu, Li Geng*, Jun Liu

Department of Microelectronics

Xian Jiaotong University

Xian, China

gengli@mail.xjtu.edu.cn

AbstractLED is generally driven by constant current because by adjusting the gate voltage of the power MOSFETs by a

the color and brightness of LED are directly related to their negative feedback control. Compared with the switch-mode

forward current. The current accuracy is a very important index regulator, the linear regulator is more accurate and stable, but

for a high performance LED driver. In this paper, a constant less efficient [3]. In this paper, a new linear regulated constant

current source applied in LED driver is proposed to improve the current source is designed to improve the current accuracy.

accuracy of the LED current. The constant current source

1.0

consists of a reference current generator, a current mirror and a

current regulator. An accurate current mirror with high

impedance is utilized which eliminates the channel length 0.8

modulation effect of the MOSFETs. A new current regulator in

which MOSFET operates in linear region instead of saturation

region is proposed to improve the current accuracy and the 0.6

ILED (A)

drivers efficiency. The proposed circuit is based on chartered

0.35m 3.3/5V process and has been simulated by Cadence

0.4

spectre. The output current is 150mA. Simulation results show

that current accuracy of +/-0.5% for a wide output voltage range

from 0.35V to 13V is obtained. 0.2

Keywords-LED driver; constant current source; current regulator.

0.0

0 1 2 3 4 5 6

I. INTRODUCTION VF (V)

In recent years, light emitting diode (LED) is gradually Figure 1. Voltage-current characteristic of LED

applied to replace the traditional lighting like cold cathode

fluorescent lamp (CCFL) due to their advantages such as high Fig.2 shows the basic block diagram of the LED driver

luminous efficiency, super longevity, safety for environment using constant current source. The constant current source

and wide color gamut [1]. They have been used to broad supplies constant current for each LED string without being

applications like general illumination, portable lighting, affected by the variation of LEDs forward voltage and other

backlighting and automotive lighting. variation such as temperature and power supply.

From the voltage-current characteristic of LED as shown in

Fig.1, we can see that a little variation of voltage across the

LED can cause large current change when LED is fully

conducted. Since the color and brightness of LED are directly

related to their forward current, in order to avoid color shift

and maintain constant brightness, LED should be driven with

constant current.

In general, there are two approaches to maintain a constant

current in a LED string. The first is the switch-mode constant

current source. It adopts peak current control (PCC) or

hysteretic current control (HCC) to regulate the current [2].

Because it works in the switch state, the efficiency is high.

However, its problems are big ripple current, strong radiation Figure 2. Block diagram of the LED driver

interference and low accuracy. The second approach is the

linear regulated constant current source. It regulates the current

978-1-4244-6554-5/11/$26.00 2011 IEEE

The constant current source consists of a reference current II. PROPOSED CONSTANT CURRENT SOURCE

generator, a current mirror and a current regulator, as shown in Fig.6 shows the topology of the proposed constant current

Fig.3. source. A reference current IREF is generated by the reference

current generator and multiplied by ratio M through the current

mirror. The current regulator multiplies MIREF with a ratio of N

to the output and maintains the output current IOUT constant.

Figure.3 Block diagram of the constant current source

As mentioned in [4], traditional current mirror encounters

poor current precision due to channel length modulation effect.

In [5], the current mirror shown in Fig.4 employs an

operational amplifier and a PMOSFET to eliminate channel

length modulation effect. However, the output impedance is

Figure 6. Proposed constant current source

not high enough which makes the current accuracy worse

when the voltage across resistor R changes.

A. High Precision Current Mirror

A high precision current mirror [7] is utilized, as shown in

Fig.7. The current mirror not only has highly accurate current

ratio but also keeps immune to the output voltage variation due

to its high output impedance.

Figure 4. Structure of current mirror in [5]

In [6], two current regulators are discussed, as shown in

Fig.5. The output current is Vref/Rsense for current regulator

in Fig.5 (a). Parasitic resistance of the chip ground will affect

the current accuracy. In Fig.5 (b), a traditional current mirror

replaces the sensing resistor. The output current is decided by

the width ratio of M3 to M2. However, the current accuracy is

influenced by the mismatch between M2 and M3.

Additionally, the efficiency of current regulator is not high, Figure 7. High precision current mirror

because M2 and M3 work in saturation region which results in

larger voltage drop.

MP1, MP3 and MP4 are used as a two-stage cascade

current mirror. MP2, MP5, MP6, MN1 and MN2 are used to

clamp the drain voltages of MP1 and MP3 to be the same level

which eliminates channel length modulation effect. Three

negative feedback gain stages MP7, MP8 and MP9 can

significantly increase the output impedance.

B. Proposed Current Regulator

The proposed current regulator is shown in Fig.8. M2 and

M3 are forced to operate in the linear region by connecting the

gates of them to supply voltage VDD, which has two

(a) (b)

advantages.

Figure 5. Two kinds of current regulators in [6]

III. SIMULATION RESULTS

Fig.9 shows the simulation result of the relationship

between output current IOUT and output voltage VOUT of the

constant current source. The output current is 150mA. The

current maintains highly constant in a wide output voltage

range. It obtains +/-0.5% current accuracy for a VOUT variation

from 0.35V to 13V. The proposed constant current source can

supply constant current for each LED string precisely without

being affected by the variation of LEDs forward voltage.

0.16

0.15

0.14

Figure 8. Proposed current regulator 0.13

0.12

0.11

Firstly, it improves the efficiency of the constant current 0.10

source. Operating in linear region, M2 and M3 can also 0.09

IOUT (A)

perform as a current mirror. The MOSFETs operating in linear 0.08

0.07

region can be regarded as a resistor, which can be expressed as:

0.06

0.05

2

R= (1) 0.04

COX (W / L) [ 2(VGS VTH ) VDS ] 0.03

0.02

If the drain-source voltage VDS and the threshold voltage 0.01

VTH of M2 and M3 are the same, the current ratio is 0.00

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VOUT (V)

I M 3 RM 2 (W / L) M 3

= = (2) Figure 9. The relationship between output current and output voltage of

I M 2 RM 3 (W / L) M 2 proposed constant current source

According to (1), the turn-on resistors of M2 and M3 can

Fig.10 shows the relationship between output current IOUT

be reduced by enlarging the channel width of MOSFETs,

and the supply voltage VDD applied on the constant current

which reduces the voltage across M3. Hence, the efficiency of

source. The current source obtains the current accuracy of

current source can be improved. It also alleviates the threshold

0.3% when the supply voltage has a +/-10% variation.

voltage and W/L mismatch of M2 and M3 [8].

0.1505

Secondly, it improves the current accuracy. When a

MOSFET operates in linear region, the current ID is

0.1504

1

I D = COX [ 2(VGS VTH ) VDS ]VDS (3)

2 0.1503

IOUT(A)

Variations of the W/L and the VTH due to process may

result in current inaccuracy. Assuming that the variations of 0.1502

W/L and VTH are (W/L), VTH, the current variation can be

calculated as

0.1501

I I

I = (W / L) + (VGS VTH )

(W / L) (VGS VTH ) 0.1500

4.4 4.5 4.6 4.7 4.8 4.9 5.0 5.1 5.2 5.3 5.4 5.5 5.6

1 W

COX [ 2(VGS VTH ) VDS ]VDS COX VDS VTH (4)

VDD (V)

= Figure 10. The relationship between output current and supply voltage

2 L

So the current accuracy of the MOSFET is

Fig.11 shows the relationship between output current IOUT

I (W / L) 2VTH and the temperature. The output current has a high accuracy of

+ (5) 0.1% when the temperature changes from -50C to 100C.

I W /L 2(VGS VTH ) VDS

In application, we want to regulate the brightness of LED

Because the gate of M2 and M3 are both connected to as we need as well as to save the power. The brightness of

supply voltage, the influence on current precision by the LED can be adjusted according to the duty cycle of PWM

variation of VTH is greatly reduced. As a result, the current control signal. This can be achieved by PWM dimming

accuracy is enhanced.

strategy in which the LED is on or off, controlled by the PWM IV. CONCLUSION

signal.

Fig.12 shows the waves of output current (above) and A constant current source for LED with high current

PWM control signal (below) in dimming mode. When Vpwm is accuracy is presented. By utilizing the high precision current

high, the output current Iout is 150mA; when Vpwm is low, Iout is mirror, the channel length modulation effect is eliminated.

zero. The designed current source operates well when it is in Furthermore, the current accuracy and efficiency of the

the dimming mode. current driver are improved by the proposed current regulator.

0.15016 Current accuracy of +/-0.5% for a wide output voltage range

from 0.35V to 13V is obtained. The output current can also

0.15015 maintain constant for +/-10% variation of power supply and a

wide temperature change from -50C to 100C. It has the

0.15014

good features of high accuracy, low power dissipation and

good robustness to the operation condition. In addition, the

IOUT (A)

0.15013

output current can also be highly accurate in dimming mode

0.15012 when LED is on.

0.15011

0.15010 REFERENCES

[1]. Yuequan Hu, Jovanovic and M. Milan, A Novel LED Driver with

0.15009 Adaptive Drive Voltage, Applied Power Electronics Conference and

-60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 Exposition (APEC), p.565-571, 2008.

o

temperature ( C) [2]. In-Hwan Oh, An Analysis of Current Accuracies in Peak and

Figure 11. The relationship between output current and temperature Hysteretic Current Controlled Power LED Drivers, Twenty-Third

Annual IEEE, Applied Power Electronics Conference and Exposition

(APEC), p.572-577, 2008.

[3]. Feng Tian, Xiang Wu, Jingao Liu, Research and Realization of

Innovative LED Illumination System for DLP Projector International

Conference on Audio, Language and Image Processing (ICALIP),

p.194-199, 2008.

[4]. Tse-Ju Liao and Chern-Lin Chen, Robust LED Backlight Driver with

Low Output Voltage Drop and High Output Current Accuracy,

International Conference on Software Engineering and Technology

(ICSET), p.63-66, 2008

[5]. Chun-Yu Hsieh, Young-Sheng Wei, Ke-Horng Chen and Tseng-Chun

(a) Lin, Efficient LED driver with an adaptive reference tracking

technique, 16th IEEE International Conference on Electronics,

Circuits, and Systems (ICECS), p.291-294, 2009.

[6]. Chi-Hao Wu and Chern-Lin Chen, High-Efficiency Current-Regulated

Charge Pump for a White LED Driver, Express Briefs, IEEE

Transactions on Circuits and Systems II, vol.56, no.10, p.763-767, Oct.

2009.

[7]. Kuo-Hsing Cheng, Chi-Che Chen and Chun-Fu Chung, Accurate

Current Mirror with High Output Impedance, 8th IEEE International

Conference on Electronics, Circuits and Systems (ICECS), p.565-568,

2001.

(b)

[8]. Lakshmikumar, K.R., Hadaway, R.A., Copeland and M.A.,

Characterization and modeling of mismatch in MOS transistors for

Figure 12. The output current of current source in the dimming mode. (a) precision analog design, IEEE J. Solid-State Circuits, vol.21, no.6,

Output current; (b) PWM signal. fPWM=100kHz and the duty of dimming p.1057-1066, Dec. 1986.

Ddimming=50%

Vous aimerez peut-être aussi

- Cat 15Document2 pagesCat 15Gustavo Vargas0% (1)

- Illumination: "The Established Leader Ee Review"Document6 pagesIllumination: "The Established Leader Ee Review"IVex Brykz Jay Ro60% (5)

- Light Combat AircraftDocument5 pagesLight Combat AircraftUtsav NiroulaPas encore d'évaluation

- Injection Moulding - Quality Molded PartsDocument28 pagesInjection Moulding - Quality Molded PartsQuản Lê Đình100% (3)

- Pragmatic Electrical Engineering: FundamentalsDocument201 pagesPragmatic Electrical Engineering: FundamentalsaminmominPas encore d'évaluation

- Indonesia's First Maritime Service Solution Provider: Company ProfileDocument10 pagesIndonesia's First Maritime Service Solution Provider: Company Profilemuh_akbar2451Pas encore d'évaluation

- PI Sheet ConfigDocument18 pagesPI Sheet ConfigKaushik BosePas encore d'évaluation

- Switch v7LAB StudentDocument206 pagesSwitch v7LAB Studentkcf4scribdPas encore d'évaluation

- Design of A Low-Dropout Linear RegulatorDocument4 pagesDesign of A Low-Dropout Linear RegulatorParindraPas encore d'évaluation

- ISCAS07 YangDocument4 pagesISCAS07 YangBarani TPas encore d'évaluation

- Design and Analysis of Negative Output LuoDocument6 pagesDesign and Analysis of Negative Output LuoYaredPas encore d'évaluation

- Isscc 2019 / Session 18 / Analog Techniques / 18.7: 18.7 A 0.7V, 2.35% 3 σ-Accuracy Bandgap Reference in 12nm CmosDocument3 pagesIsscc 2019 / Session 18 / Analog Techniques / 18.7: 18.7 A 0.7V, 2.35% 3 σ-Accuracy Bandgap Reference in 12nm CmosLuis CasmaPas encore d'évaluation

- Design, Modelling and Implementation of Interleaved Boost DC-DC ConverterDocument13 pagesDesign, Modelling and Implementation of Interleaved Boost DC-DC ConverterInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Shyam Course ProjectDocument6 pagesShyam Course ProjectBhukya Reethvik RathodPas encore d'évaluation

- Non-Isolated High Gain DC-DC Converter For PV Applications With Closed Loop ControlDocument6 pagesNon-Isolated High Gain DC-DC Converter For PV Applications With Closed Loop Controlbhawna guptaPas encore d'évaluation

- Transformer Based Resonant DC Inverter For Brushless DC Motor Drive SystemDocument7 pagesTransformer Based Resonant DC Inverter For Brushless DC Motor Drive SystemStudents Xerox ChidambaramPas encore d'évaluation

- Buck RegulatorDocument6 pagesBuck RegulatorBhukya Reethvik RathodPas encore d'évaluation

- Uc Power Control PDFDocument6 pagesUc Power Control PDFjokerPas encore d'évaluation

- Voltage Sag Mitigation Using Dynamic Voltage Restorer SystemDocument5 pagesVoltage Sag Mitigation Using Dynamic Voltage Restorer SystemAnonymous xaeuoo4Pas encore d'évaluation

- A Novel Four-Level Voltage Source Inverter-Influence of Switching Strategies On The Distribution of Power LossesDocument11 pagesA Novel Four-Level Voltage Source Inverter-Influence of Switching Strategies On The Distribution of Power LossesKanomba JavaPas encore d'évaluation

- Ijsrp p3178 PDFDocument11 pagesIjsrp p3178 PDFJeannot MpianaPas encore d'évaluation

- Single Phase AC To AC Conversion Without Frequency RestrictionsDocument4 pagesSingle Phase AC To AC Conversion Without Frequency RestrictionsTaniyaPas encore d'évaluation

- Voltage Dip's Mitigation During PV-Grid-Connection Using STATCOMDocument7 pagesVoltage Dip's Mitigation During PV-Grid-Connection Using STATCOMMohammedSaeedPas encore d'évaluation

- 5 Level InverterDocument6 pages5 Level InverterRameshRtsPas encore d'évaluation

- Badin 2011Document9 pagesBadin 2011gerson gomesPas encore d'évaluation

- InvertersDocument8 pagesInvertersJeffrey A PobladorPas encore d'évaluation

- High-Performance CMOS Current Mirrors: Application To Linear Voltage-to-Current Converter Used For Two-Stage Operational AmplifierDocument6 pagesHigh-Performance CMOS Current Mirrors: Application To Linear Voltage-to-Current Converter Used For Two-Stage Operational AmplifierShaheer DurraniPas encore d'évaluation

- Analysis of Cmos Dynamic Comparators For Low Power and High Speed AdcsDocument7 pagesAnalysis of Cmos Dynamic Comparators For Low Power and High Speed AdcsNoReply ProgramPas encore d'évaluation

- Simulation and Prototype Implementation of Phase Shift Full Bridge DC DC ConverterDocument4 pagesSimulation and Prototype Implementation of Phase Shift Full Bridge DC DC ConverterjimmyPas encore d'évaluation

- E3sconf Posei2021 02021Document4 pagesE3sconf Posei2021 02021WilliamPas encore d'évaluation

- A Brief Review On Multilevel Inverter Topologies: Amol K. Koshti M. N.RaoDocument7 pagesA Brief Review On Multilevel Inverter Topologies: Amol K. Koshti M. N.RaoDr-Ismayil CPas encore d'évaluation

- AC To AC Voltage Controller Using PWM Technique Without DC LinkDocument4 pagesAC To AC Voltage Controller Using PWM Technique Without DC LinkANKIT PRAJAPATIPas encore d'évaluation

- Steady-State Analysis of An Interleaved Boost Converter With Coupled InductorsDocument9 pagesSteady-State Analysis of An Interleaved Boost Converter With Coupled InductorsNanda AzizahPas encore d'évaluation

- QRS DDTDocument35 pagesQRS DDTgoshfukdPas encore d'évaluation

- A Voltage-Mode PWM Buck Regulator With End-Point PredictionDocument5 pagesA Voltage-Mode PWM Buck Regulator With End-Point PredictionWen DwenPas encore d'évaluation

- Comparative Study of MLI and Dual Inverter Using Space Vector Modulation TechniquesDocument8 pagesComparative Study of MLI and Dual Inverter Using Space Vector Modulation Techniquesshiva256Pas encore d'évaluation

- Progress in Electromagnetics Research C, Vol. 13, 1-18, 2010Document18 pagesProgress in Electromagnetics Research C, Vol. 13, 1-18, 2010anis_ba011Pas encore d'évaluation

- Chapt02 FCDocument38 pagesChapt02 FCjoel marshallPas encore d'évaluation

- Design and Simulation of Interleaved SEPIC Converter For Photo Voltaic ApplicationsDocument5 pagesDesign and Simulation of Interleaved SEPIC Converter For Photo Voltaic Applicationsardi taher1991Pas encore d'évaluation

- A Buck-Boost Common-Mode Transformerless Inverter For Photovoltaic ApplicationsDocument5 pagesA Buck-Boost Common-Mode Transformerless Inverter For Photovoltaic ApplicationsIndra PratamaPas encore d'évaluation

- Ijser: Simulation of Active Front End Converter Based VFD For Induction MotorsDocument6 pagesIjser: Simulation of Active Front End Converter Based VFD For Induction Motorsabdallah hosinPas encore d'évaluation

- 4 Current Mirrors 2022Document55 pages4 Current Mirrors 2022Waleed RazzaqPas encore d'évaluation

- Design and Verification of A High Performance LEDDocument8 pagesDesign and Verification of A High Performance LEDsandeep bagulPas encore d'évaluation

- Analysis of Total Harmonic DistortionDocument5 pagesAnalysis of Total Harmonic DistortionME SOUNDPas encore d'évaluation

- A Low-Cost Solar Micro-Inverter With Soft-SwitchingDocument6 pagesA Low-Cost Solar Micro-Inverter With Soft-Switchingmohamed parvezPas encore d'évaluation

- PV FED Interleaved Boost Converter For BLDC MotorDocument8 pagesPV FED Interleaved Boost Converter For BLDC MotorIJRASETPublicationsPas encore d'évaluation

- Steady-State Analysis of An Interleaved Boost Converter With Coupled InductorsDocument9 pagesSteady-State Analysis of An Interleaved Boost Converter With Coupled InductorsSasanga HewagamaPas encore d'évaluation

- Performance of Difference PFC Converter For Improved Converter Efficiency: A ReviewDocument6 pagesPerformance of Difference PFC Converter For Improved Converter Efficiency: A ReviewJohn PetersPas encore d'évaluation

- Three Phase Induction Motor Using Single PhaseDocument8 pagesThree Phase Induction Motor Using Single PhasehezugPas encore d'évaluation

- Paper 2002Document12 pagesPaper 2002Miguel VenzPas encore d'évaluation

- Design and Performance Evaluation of 2kva Microcontroller - Based StabilizerDocument14 pagesDesign and Performance Evaluation of 2kva Microcontroller - Based StabilizerGAPOSA ElectricalPas encore d'évaluation

- Power Quality Pblms Created by Drives and PQ Impact On DrivesDocument5 pagesPower Quality Pblms Created by Drives and PQ Impact On DrivesGagan GillPas encore d'évaluation

- Wave Shaping of Current Using PWM Rectifiers: Mahasweta Bhattacharya, Ashish SrivastavaDocument5 pagesWave Shaping of Current Using PWM Rectifiers: Mahasweta Bhattacharya, Ashish SrivastavaerpublicationPas encore d'évaluation

- A Comparative Study of Various Multi-Level Inverter Based On Multi-CellDocument4 pagesA Comparative Study of Various Multi-Level Inverter Based On Multi-CellTarak BenslimanePas encore d'évaluation

- Feed Forward Controller For Compensation of DC-Link Capacitor Unbalance Voltages and Ripple Reduction Based BLDCM Drive SystemDocument6 pagesFeed Forward Controller For Compensation of DC-Link Capacitor Unbalance Voltages and Ripple Reduction Based BLDCM Drive SystemSiddharth Jayashekar KPas encore d'évaluation

- High-Efficient Multilevel Half-Bridge ConverterDocument9 pagesHigh-Efficient Multilevel Half-Bridge Converter'Mantas PuhtėjavasPas encore d'évaluation

- Tutorial2 QDocument5 pagesTutorial2 QKiet Kuat KongPas encore d'évaluation

- Novel Asymmetrical Multilevel Inverter Topology With Reduced Number of Switches For Photovoltaic ApplicationsDocument6 pagesNovel Asymmetrical Multilevel Inverter Topology With Reduced Number of Switches For Photovoltaic ApplicationsKRISHNA PRASADPas encore d'évaluation

- Efficient Amplitude Modulator and Ripple Canceller For Visible Light CommunicationDocument6 pagesEfficient Amplitude Modulator and Ripple Canceller For Visible Light CommunicationXicong LiPas encore d'évaluation

- Analysis and Characterization of Various Current Mirror Topologies in 90 NM TechnologyDocument6 pagesAnalysis and Characterization of Various Current Mirror Topologies in 90 NM TechnologyGurinder Pal SinghPas encore d'évaluation

- Sabata Et Al Switching AmpDocument7 pagesSabata Et Al Switching AmpWill ForfangPas encore d'évaluation

- REEEFFFSESDocument6 pagesREEEFFFSESezradural99Pas encore d'évaluation

- Design and Simulation of Single Phase Z-Source Buck Boost Matrix ConverterDocument7 pagesDesign and Simulation of Single Phase Z-Source Buck Boost Matrix Convertervinay kumarPas encore d'évaluation

- 고전압비와 낮은 전압 스트레스를 가진 단일 스위치와 전압 체배 회로를 이용한 새로운 비절연형 DC-DC 컨버터Document5 pages고전압비와 낮은 전압 스트레스를 가진 단일 스위치와 전압 체배 회로를 이용한 새로운 비절연형 DC-DC 컨버터Armandinho CaveroPas encore d'évaluation

- Transformer Less Voltage Quadrupler Based DC-DC Converter With Coupled Inductor and PI Filter For Increased Voltage Gain and EfficiencyDocument8 pagesTransformer Less Voltage Quadrupler Based DC-DC Converter With Coupled Inductor and PI Filter For Increased Voltage Gain and EfficiencywelsyaPas encore d'évaluation

- How To Use MySQL With ErlangDocument2 pagesHow To Use MySQL With ErlangarthurbulivaPas encore d'évaluation

- Government College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusDocument111 pagesGovernment College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusSalma Mehajabeen ShajahanPas encore d'évaluation

- TGS8100 Product InfomationDocument10 pagesTGS8100 Product Infomationbemxgm-1Pas encore d'évaluation

- SWIMS Directory of LibrariesDocument17 pagesSWIMS Directory of LibrariessudakshinaroyPas encore d'évaluation

- WEdu Abroad - Study Abroad E-GuidebookDocument111 pagesWEdu Abroad - Study Abroad E-GuidebookRithyKhouyPas encore d'évaluation

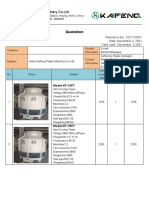

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyPas encore d'évaluation

- Drive List BoxDocument3 pagesDrive List BoxLuis Carlos VillegasPas encore d'évaluation

- ABB Ability Safety Plus For Hoists BrochureDocument12 pagesABB Ability Safety Plus For Hoists BrochureCarlos Bruno MatosPas encore d'évaluation

- Vogt Valves: Catalog & Application ManualDocument161 pagesVogt Valves: Catalog & Application ManualAngelique DeanPas encore d'évaluation

- BC Ii 800Document38 pagesBC Ii 800Pop Ciprian100% (2)

- Aes MatlabDocument32 pagesAes MatlabbalajithrillerPas encore d'évaluation

- PC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensDocument2 pagesPC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensSarah JenkinsPas encore d'évaluation

- IsCAN Labview DeveloperDocument30 pagesIsCAN Labview Developerafsala1982Pas encore d'évaluation

- Final Project Miguel Santana GallegoDocument44 pagesFinal Project Miguel Santana GallegoDaniel PereiraPas encore d'évaluation

- Emmeskay MIL-SIL TutorialDocument52 pagesEmmeskay MIL-SIL TutorialNeacsu EugenPas encore d'évaluation

- Admit Card: Examination Centre: Centre CodeDocument1 pageAdmit Card: Examination Centre: Centre CodekrishnaPas encore d'évaluation

- Blue Solar Charge Controller MPPT: NOT AcceptedDocument12 pagesBlue Solar Charge Controller MPPT: NOT Accepted1382acePas encore d'évaluation

- Shear Stress Though Tapered Pipe Thread - Eng-TipsDocument4 pagesShear Stress Though Tapered Pipe Thread - Eng-TipsrodrigoperezsimonePas encore d'évaluation

- NB! This Price List Applies To Service Agreements, That Are Concluded With Nordea Bank AB Latvia BranchDocument34 pagesNB! This Price List Applies To Service Agreements, That Are Concluded With Nordea Bank AB Latvia Branchwaraxe23Pas encore d'évaluation

- Workstation-Sub Micro Space PlanDocument21 pagesWorkstation-Sub Micro Space Planarnella_hPas encore d'évaluation

- Waste Management in Selected Hotels in GoaDocument11 pagesWaste Management in Selected Hotels in GoaSyna SoaresPas encore d'évaluation

- Wire CodeDocument7 pagesWire CodeAryans Kumar0% (1)