Académique Documents

Professionnel Documents

Culture Documents

Astm e 1390

Transféré par

MohamedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Astm e 1390

Transféré par

MohamedDroits d'auteur :

Formats disponibles

Designation: E 1390 90 (Reapproved 2000) An American National Standard

Standard Guide for

Illuminators Used for Viewing Industrial Radiographs1

This standard is issued under the fixed designation E 1390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope size of the screen shall allow the user to view the radiograph

1.1 This guide provides the recommended minimum re- without excessive glare. If the illuminator is to be used for

quirements for illuminators used for viewing industrial film viewing radiographs of various sizes, masks of various sizes

radiographs using transmitted light. and configurations, for example, circular or rectangular, shall

1.2 The illuminator has to ensure the same safety for be provided. Alternately, an adjustable aperture may be used.

personnel, or users of any electric apparatus, as specified by 6. Illumination Requirements3

electrical standards applicable in the country in which the

illuminator is used. 6.1 Luminance:

6.1.1 The luminance (or brightness) of the transmitted light

2. Referenced Documents through the radiograph shall not be less than 30 cd/m2 for film

2.1 ASTM Standards: densities equal or less than 2.5, and 10 cd/m2 for film densities

E 1316 Terminology for Nondestructive Examinations2 greater than 2.5.

NOTE 1Where possible, approximately 100 cd/m2 or higher lumi-

3. Terminology nance should be used.

3.1 DefinitionsFor definitions of terms used in this guide, 6.1.2 To achieve the maximum luminance value, that is, 10

see Terminology E 1316. cd/m2, given in 6.1.1, the illuminator brightness shall be at

4. Significance and Use least 105 cd/m2. This should be determined with a suitably

calibrated photometer or telephotometer placed at the center of

4.1 The function of the illuminator is to provide sufficient the viewing surface. Follow manufacturers instructions in

illumination and viewing capabilities to visually review indus- using the photometer.

trial film radiographs by light transmitted through them for the 6.1.3 When servicing is required, it shall usually be suffi-

purpose of identification and interpretation of the images. cient to follow manufacturers recommendations in, for ex-

4.2 This guide is to be used primarily for the manufacturer ample, replacing a bulb.

of illuminators and is not intended to be applicable to the users 6.2 Spectral Characteristics of Illuminator Light Source

of illuminators. Requirements, if imposed on users, should be The color of the light used to illuminate the radiograph is

--`-`-`,,`,,`,`,,`---

established by contractual agreement. normally white. However, in the case of colored film bases,

5. Design Characteristics light with adapted colors may be used if they have been

recommended by the film manufacturers.

5.1 GeneralThe illuminator shall consist of a housing

6.3 Diffusion of LightIf the illuminator has a diffusing

with one or more of the sides containing a viewing screen

screen, the light shall be sufficiently divergent so that both eyes

illuminated from the inside of the housing. The viewing screen

of the observer receive rays from all parts of the screen. The

may also be the diffusing screen. There shall be thermal

divergence factor shall exceed 0.7 (see 9.1.1).

protection to prevent overheating, and subsequent damage to

6.4 Uniformity of IlluminationThe screen shall be uni-

the radiographs placed on the viewing screen. The housing or

formly illuminated, the uniformity factor g being higher than

system may or may not require ventilation. A rheostat or

0.5 (see 9.1.2).

suitable electrical circuit shall be provided to vary the light

intensity. 7. Anti-Glare Protection

5.2 Viewing ScreenThe viewing screen shall be easy to 7.1 The illuminator shall be fitted with an anti-glare switch

clean and made of material which is resistant to scratches. The or device that minimizes the probability of the operator being

subjected to excessive glare when the radiograph is removed.

1

This guide is under the jurisdiction of ASTM Committee E-7 on Nondestructive This switch or device may be manual or automatic.

Testing and is the direct responsibility of Subcommittee E07.01on Radiology (X and

Gamma) Method.

3

Current edition approved Oct. 26, 1990. Published December 1990. Luminance requirements are intended to be satisfied by the illuminator

2

Annual Book of ASTM Standards, Vol 03.03. manufacturer.

Copyright ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

1

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

E 1390

8. Heating Protection

8.1 Appropriate precautions shall be taken to ensure that the

temperature of the housing does not exceed 60C (140F) at

the usual contact surface after one hour of operation at a 50 %

duty cycle.

8.2 A radiograph having a density of 2.0 when placed on the

illuminator viewing surface shall not warp or curl after 1 min

of continuous viewing time and 1 h of operation of the

illuminator at 50 % of duty cycle.

9. Photometric Measurements of Illuminator4

9.1 Photometric measurements of the illuminator shall be

carried out in a darkened room. The photometer should be used

in the middle part of its measuring scale. The illuminator shall

not allow any direct light to escape when the viewing screen is

completely masked.

9.1.1 Divergence and Dispersion of Light (of Diffuser)

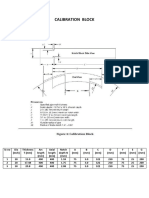

The brightness shall be measured on a semi-circle, the center of FIG. 1 Measurement Angles of Diversion and Dispersion of Light

which is center of the screen. The diameter of the circle is

approximately the same as the maximum dimension of the and Lmin. The uniformity factor g shall be calculated according

screen (the diagonal). The radius of this semi-circle should be to the equation:

at least 25 cm (10 in.). The brightness is measured with the aid Lmin

g 5L

--`-`-`,,`,,`,`,,`---

of an appropriate illumination photometer whose sensitive max

surface is tangent to the curve of the circle (see Fig. 1). These These measurements and calculations for g shall be made at

measurements shall be made at angles of 5 (L5), 20 (L20), and three brightness levels (low, medium, high).

45 ( L45) relative to the normal (L 0) to the diffusing screen.

The divergence factor shall be calculated according to the 10. Identification Marking

following equation: 10.1 The following information shall be permanently af-

L 45 1 L20 fixed to the illuminator by the manufacturer:

Divergence Factor 5 2 L5 10.1.1 Nominal operating voltage or permissible voltage

These measurements and calculations shall be made in both range,

planes formed by the two diagonals and the corresponding 10.1.2 Nominal line frequency or permissible frequency

semi-circle. For illuminators with variable intensity capability, range,

they shall be made at three brightness levels (low, medium, 10.1.3 Whether direct, or alternating current, or both, may

high) along the diagonals of the rectangular screen or along be used,

two diameters at 90 angles to each other for a circular screen. 10.1.4 Nominal power consumption, and

9.1.2 Uniformity of Illumination on ScreenIf the screen is 10.1.5 Maximum brightness in cd/m2.

rectangular or circular, it shall be divided into squares measur- 11. Operating Instructions

ing approximately 5.0 cm (2 in.) on a side. The brightness of 11.1 Operating instructions shall be provided with each

each square shall be measured separately. In both cases, the illuminator, and include the following, as a minimum:

network of the squares shall be arranged so that the middle 11.1.1 The operation of the illuminator,

square is centered in the middle of the screen. The average of 11.1.2 Instructions for mounting and replacement of lamps

the four highest and the average of the four lowest readings and screens,

shall be determined. These averages will be designated Lmax 11.1.3 Care and maintenance procedures, and

11.1.4 Safety precautions.

4

12. Keywords

Photometric measurements are intended to be satisfied by the illuminator

manufacturer. 12.1 illumination; illuminator; radiographs; viewing

Copyright ASTM International

2

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

E 1390

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

--`-`-`,,`,,`,`,,`---

Copyright ASTM International

3

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

Vous aimerez peut-être aussi

- ASTM A435 A435M-17 Standard Specification For Straight-Beam Ultrasonic Examination of Steel Plates PDFDocument3 pagesASTM A435 A435M-17 Standard Specification For Straight-Beam Ultrasonic Examination of Steel Plates PDFEdwinMauricioMacabeoPas encore d'évaluation

- Aws d1.1 Ut Inspection ProcedureDocument17 pagesAws d1.1 Ut Inspection ProcedureMohanadPas encore d'évaluation

- Level 2 Ques (1) RTDocument34 pagesLevel 2 Ques (1) RTVishal Sharma100% (1)

- ASME SECTION V, Article 8 Mandatory Appendices PDFDocument24 pagesASME SECTION V, Article 8 Mandatory Appendices PDFguaropelaoPas encore d'évaluation

- Acceptable Criteria API RP 2X Level C Acceptable Criteria API RP 2X Level CDocument1 pageAcceptable Criteria API RP 2X Level C Acceptable Criteria API RP 2X Level CRamakrishnan AmbiSubbiah100% (5)

- Astm e 1158Document5 pagesAstm e 1158KEN KPas encore d'évaluation

- RT Technique Sheet + Report Rev 4Document2 pagesRT Technique Sheet + Report Rev 4g_sancheti100% (3)

- Asme Section II A Sa-435 Sa-435mDocument4 pagesAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xPas encore d'évaluation

- Calibration Block As Per API 1104Document2 pagesCalibration Block As Per API 1104Chandrashekhar Thiramdasu100% (1)

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pages7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Astm E2033Document10 pagesAstm E2033Jorge SuarezPas encore d'évaluation

- Fifth Assignment IprDocument1 pageFifth Assignment IprAnjum phdPas encore d'évaluation

- Bell KJ Thesis 2 PDFDocument84 pagesBell KJ Thesis 2 PDFlifeinhimPas encore d'évaluation

- Astm 608 PDFDocument6 pagesAstm 608 PDFIslam FawzyPas encore d'évaluation

- Business Model Canvas WorkshopDocument82 pagesBusiness Model Canvas WorkshopAlex Cowan98% (94)

- Schau BergerDocument20 pagesSchau Bergerdakkid100% (4)

- NalliDocument23 pagesNalliMohamme IrfanPas encore d'évaluation

- API 1104 - UT Acceptance StandardsDocument5 pagesAPI 1104 - UT Acceptance StandardsABDIELPas encore d'évaluation

- Astm E1065 E1065m 20Document10 pagesAstm E1065 E1065m 20Mohamed AboelkhierPas encore d'évaluation

- Figure T-434.2.1 Nonpiping Calibration BlocksDocument1 pageFigure T-434.2.1 Nonpiping Calibration BlocksChandrashekhar ThiramdasuPas encore d'évaluation

- Iso 5580-1985 Illuminators RT PDFDocument9 pagesIso 5580-1985 Illuminators RT PDFMario Gaytan100% (1)

- Dac & DGSDocument14 pagesDac & DGSAhmad Daniel100% (1)

- Radiographic Testing (RT) Level - 2 Specific Exam-2Document7 pagesRadiographic Testing (RT) Level - 2 Specific Exam-2Mohammed Aljawhar100% (1)

- DS 324 ManualDocument44 pagesDS 324 ManualAshish Srivastava100% (1)

- IQIDocument9 pagesIQIalouisPas encore d'évaluation

- 25 MM Nozzle Paut Scan PlanDocument4 pages25 MM Nozzle Paut Scan PlanRupam BaruahPas encore d'évaluation

- Astm-E-2373e2373m-14 TofdDocument13 pagesAstm-E-2373e2373m-14 TofdmajidPas encore d'évaluation

- En 462-1Document12 pagesEn 462-1fredkruger2012100% (1)

- Radiographic Inspection Report SheetDocument1 pageRadiographic Inspection Report SheetMike BoyesPas encore d'évaluation

- The AnswerDocument24 pagesThe AnswerrezokaPas encore d'évaluation

- Iqi'sDocument6 pagesIqi's24inspector100% (1)

- NDT Procedure BS EN 10160:1999 (Full Version Available From N-D-T.com)Document6 pagesNDT Procedure BS EN 10160:1999 (Full Version Available From N-D-T.com)Mark BrailsfordPas encore d'évaluation

- Level Ii QuestionsDocument19 pagesLevel Ii QuestionsAmit Sindhya0% (1)

- RT Interpretation DefectsDocument12 pagesRT Interpretation Defectsbenergy84Pas encore d'évaluation

- Ut PDFDocument88 pagesUt PDFphillipskincaidPas encore d'évaluation

- SNIS UT 578 - Steel PlatesDocument14 pagesSNIS UT 578 - Steel PlatesShailesh DeshmukhPas encore d'évaluation

- API 1104 Defects Acceptance Criteria FinalDocument9 pagesAPI 1104 Defects Acceptance Criteria Finalazizieh5701Pas encore d'évaluation

- National Step Tablet Vs Step Wedge Comparision FilmDocument4 pagesNational Step Tablet Vs Step Wedge Comparision FilmManivannanMudhaliarPas encore d'évaluation

- RT Formulas For CalculationsDocument4 pagesRT Formulas For CalculationsdanemsalPas encore d'évaluation

- Saferad ProcedureDocument19 pagesSaferad ProcedureExsan OthmanPas encore d'évaluation

- Api RP 2x-Acceptance CriteriaDocument6 pagesApi RP 2x-Acceptance CriteriaAllwynPas encore d'évaluation

- MT Work InstructionDocument3 pagesMT Work Instructionpandab bkPas encore d'évaluation

- Astm E1165Document7 pagesAstm E1165Sai FujiwaraPas encore d'évaluation

- Angle DACDocument1 pageAngle DACJeevanandam ShanmugasundaramPas encore d'évaluation

- DIN en 462-1 Image Quality of Radiographs (Wire Type)Document10 pagesDIN en 462-1 Image Quality of Radiographs (Wire Type)QA QC100% (2)

- UT ProcedureDocument6 pagesUT ProcedureMurali YPas encore d'évaluation

- Positive Material Identification ProcedureDocument6 pagesPositive Material Identification Procedureomar100% (1)

- Ut Procedure Selon AsmeDocument9 pagesUt Procedure Selon AsmeMajdi JerbiPas encore d'évaluation

- High Temperature Ultrasonic ScanningDocument7 pagesHigh Temperature Ultrasonic ScanningscribdmustaphaPas encore d'évaluation

- Beamtool Scan Plan Inspection Layout: 25Mm 200Mm 100Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/ΜsDocument3 pagesBeamtool Scan Plan Inspection Layout: 25Mm 200Mm 100Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/Μsநந்த குமார் சம்பத் நாகராஜன்Pas encore d'évaluation

- Catalogo General Sonatest PDFDocument105 pagesCatalogo General Sonatest PDFjimmy david espinoza mejiaPas encore d'évaluation

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTPas encore d'évaluation

- Radiography Testing Level I and II PDFDocument87 pagesRadiography Testing Level I and II PDFIdeal NaradmuniPas encore d'évaluation

- 2011 PipeWizard Training Part 01Document62 pages2011 PipeWizard Training Part 01rajeev jegadeesan100% (1)

- RI CW 3Document6 pagesRI CW 3Saut Maruli Tua Samosir100% (2)

- Se 747Document16 pagesSe 747Roohian Ali100% (1)

- Section II A SA-435 - SA-435MDocument3 pagesSection II A SA-435 - SA-435MSocrates MoralesPas encore d'évaluation

- Aws d1.1 RT Inspection ProcedureDocument14 pagesAws d1.1 RT Inspection ProcedureMohanadPas encore d'évaluation

- RT Level IIDocument17 pagesRT Level IIHussain AL-AqilPas encore d'évaluation

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantPas encore d'évaluation

- Aws d1.1 Tubular Vs Non TubularDocument1 pageAws d1.1 Tubular Vs Non TubularrendraPas encore d'évaluation

- Eddy Current Array TutorialDocument13 pagesEddy Current Array TutorialsameerPas encore d'évaluation

- Vacuum Box Test PDFDocument3 pagesVacuum Box Test PDFWilson RodriguezPas encore d'évaluation

- E1390-12 Especificación Estándar para Iluminadores Utilizados para Ver Radiografías Industriales1Document3 pagesE1390-12 Especificación Estándar para Iluminadores Utilizados para Ver Radiografías Industriales1fredy lopezPas encore d'évaluation

- E1390-12 Standard Specification For Illuminators Used For Viewing Industrial RadiographsDocument3 pagesE1390-12 Standard Specification For Illuminators Used For Viewing Industrial RadiographsMuhammed Abo-FandoodPas encore d'évaluation

- Preparing An Optical Microscope For Dimensional MeasurementsDocument6 pagesPreparing An Optical Microscope For Dimensional Measurementsmohamed senoussiPas encore d'évaluation

- Pig Cups IPP1 98Document1 pagePig Cups IPP1 98MohamedPas encore d'évaluation

- LG2 Gauge Pig IPP8 00Document1 pageLG2 Gauge Pig IPP8 00MohamedPas encore d'évaluation

- Inpipe Products: Foam Pig Specification TableDocument1 pageInpipe Products: Foam Pig Specification TableMohamedPas encore d'évaluation

- Hi Seal BI DI IPP27 99Document1 pageHi Seal BI DI IPP27 99MohamedPas encore d'évaluation

- Slurry Blasting Standards PDFDocument14 pagesSlurry Blasting Standards PDFMohamedPas encore d'évaluation

- A231A231Document4 pagesA231A231MohamedPas encore d'évaluation

- Fracture AssesmentDocument30 pagesFracture AssesmentMohamedPas encore d'évaluation

- GlassRock Wire Mesh BlanketsDocument2 pagesGlassRock Wire Mesh BlanketsMohamedPas encore d'évaluation

- Asnt CatalogDocument51 pagesAsnt CatalogMohamed100% (1)

- Music Sheet The Farmer in The DellDocument2 pagesMusic Sheet The Farmer in The DellKaew SiritarnPas encore d'évaluation

- Overture Services, Inc. v. Google Inc. - Document No. 81Document2 pagesOverture Services, Inc. v. Google Inc. - Document No. 81Justia.comPas encore d'évaluation

- CHAPTER VII - Limitations To The CopyrightDocument28 pagesCHAPTER VII - Limitations To The CopyrightvidiyaPas encore d'évaluation

- Dspic 30Document248 pagesDspic 30ariel_cacciaPas encore d'évaluation

- Flashes by Tim O'Rourke (Excerpt)Document12 pagesFlashes by Tim O'Rourke (Excerpt)I Read YAPas encore d'évaluation

- Intermediate Accounting I IntangiblesDocument7 pagesIntermediate Accounting I IntangiblesGiny BenavidezPas encore d'évaluation

- True Patent Value 知識點整理 - PDF PDFDocument1 pageTrue Patent Value 知識點整理 - PDF PDFLog LouPas encore d'évaluation

- As 7630 (2017) - Railway Infrastructure - Track ClassificationDocument6 pagesAs 7630 (2017) - Railway Infrastructure - Track ClassificationbriankimbjPas encore d'évaluation

- Intellectual Property LawsDocument66 pagesIntellectual Property LawsMohammed RaeesPas encore d'évaluation

- Neverland Patent & Brand Mark Owner Sakhi (Rachel)Document28 pagesNeverland Patent & Brand Mark Owner Sakhi (Rachel)neverlandengineerPas encore d'évaluation

- Collapsing Life EventsDocument12 pagesCollapsing Life EventsallextrastodoPas encore d'évaluation

- D81250GC20 Ag PDFDocument310 pagesD81250GC20 Ag PDFIrina OanăPas encore d'évaluation

- Fan Drive - Remove and InstallDocument3 pagesFan Drive - Remove and InstallMbahdiro KolenxPas encore d'évaluation

- Eaton Fuller 15webDocument4 pagesEaton Fuller 15webmancorabechPas encore d'évaluation

- Pronouns Practise WorksheetDocument2 pagesPronouns Practise WorksheetadiPas encore d'évaluation

- Society For Pure English, Tract 01 (1919) by Society For Pure EnglishDocument18 pagesSociety For Pure English, Tract 01 (1919) by Society For Pure EnglishGutenberg.orgPas encore d'évaluation

- Full Download Business Analysis and Valuation Asia Pacific 2nd Edition Palepu Solutions ManualDocument22 pagesFull Download Business Analysis and Valuation Asia Pacific 2nd Edition Palepu Solutions Manualbaydayenory6100% (38)

- Legal Aspects OF SportDocument10 pagesLegal Aspects OF Sportgreer goodwindPas encore d'évaluation

- The Old Toy Room E BookDocument18 pagesThe Old Toy Room E Bookxbx8s9bqg9Pas encore d'évaluation

- DP 2 2 Practice PDFDocument3 pagesDP 2 2 Practice PDFIrfan J SaputraPas encore d'évaluation

- Dwnload Full Organizational Behavior 4th Edition Hitt Solutions Manual PDFDocument35 pagesDwnload Full Organizational Behavior 4th Edition Hitt Solutions Manual PDFtaint.cockleq6t154100% (8)

- James Paul KennyDocument2 pagesJames Paul Kennyapi-229593028Pas encore d'évaluation

- All Might Jump Rope Workout Routine PDFDocument4 pagesAll Might Jump Rope Workout Routine PDFAria YamasakiPas encore d'évaluation

- 1995 Schoemaker ScenarioPlanning ToolforStrategicThinking SloanManagementReviewDocument17 pages1995 Schoemaker ScenarioPlanning ToolforStrategicThinking SloanManagementReviewimmaculate79Pas encore d'évaluation