Académique Documents

Professionnel Documents

Culture Documents

Siemens Injector Test Data New6 PDF

Transféré par

Jose HasinTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Siemens Injector Test Data New6 PDF

Transféré par

Jose HasinDroits d'auteur :

Formats disponibles

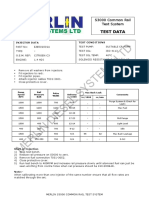

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: BK2Q-9K546-AG TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: FORD TEST OIL TEMP: 40C

ENGINE: TRANSIT 2.2/2.4 TDCI CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 92-98 <60.0 <90.0 Max Fuel

1500 1200 1200 62-68 High Mid Range

1500 800 600 32-39 Mid Range

1500 400 600 17-23 Light Load

400 250 700 11-15 Idle

400 150-250 700 N/A S.O.I

400 800 100 0.5-4.0 Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40000Z TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: PSA 9636680280 1980.F0 TEST OIL TEMP: 40C

ENGINE: DW10 BTED 2.0HDi 64kW CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 77-82 <60.0 <90.0 Max Fuel

1500 1200 1200 60-63 High Mid Range

1500 800 600 25-30 Mid Range

1500 400 600 18-22 Light Load

400 250 700 13-15 Idle

400 150-250 700 N/A S.O.I

400 800 80 1.0-3.0 Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40057 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511315 TEST OIL: ISO 4113

O.E.M. REF: FORD 4S7Q 9K546 AF TEST OIL TEMP: 40C

ENGINE: JAGUAR 2.7V6 CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 85-88 <60.0 <90.0 Max Fuel

1500 1200 1200 58-61 High Mid Range

1500 800 600 27-30 Mid Range

1500 400 600 18-20 Light Load

400 250 700 10-12 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40086 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511610 TEST OIL: ISO 4113

O.E.M. REF: FORD TEST OIL TEMP: 40C

CAPACITANCE: 3.0-4.5 Uf @ 20C

ENGINE: -

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail Max Back Leak

Pulse Delivery

Speed Pressure Comments

Width cc/1000 cc/1000 cc/min

RPM BAR

Purge System & Check for

1000 1500 1000 - - -

Leaks

1000 1500 800 42-48 <60 <60.0 Max Power

1000 1150 1200 57-63 - - Max Torque

1000 1000 700 30-36 - - Emissions

1000 850 120 0.5-2.5 - - Pre-Injection

400 250 500 4-8 - - Idle

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero. Set to 100RPM and 700 pulse width.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40087 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511606 TEST OIL: ISO 4113

O.E.M. REF: REN K9KIAM VERS TEST OIL TEMP: 40C

ENGINE: K9K CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 55-60 <60.0 <90.0 Max Fuel

1500 1200 1200 N/A High Mid Range

1500 800 600 N/A Mid Range

1500 400 600 N/A Light Load

400 250 700 6-8 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40103 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511316 TEST OIL: ISO 4113

O.E.M. REF: FORD 5U3Q 9K546 AA TEST OIL TEMP: 40C

ENGINE: LION V6 EURO 4 JAGUAR & PSA CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 85-88 <60.0 <90.0 Max Fuel

1500 1200 1200 58-62 High Mid Range

1500 800 600 27-30 Mid Range

1500 400 600 16-18 Light Load

400 250 700 11-12 Idle

400 150-250 700 N/A S.O.I

400 800 100 -- Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40148Z (5WS-40007) TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: FORD 2S6Q9F593AB TEST OIL TEMP: 40C

PSA 1980.E7 CAPACITANCE: 3.0-4.5 Uf @ 20C

ENGINE: DV41.4HDi 50Kw EURO 3

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail Max Back Leak

Pulse Delivery

Speed Pressure Comments

Width cc/1000 cc/1000 cc/min

RPM BAR

Purge System & Check for

1000 1500 1000 - - -

Leaks

1000 1500 800 30-36 <60 <60.0 Max Power

1000 1150 1200 44-50 - - Max Torque

1000 1000 700 23-29 - - Emissions

1000 850 120 0.5-2.5 - - Pre-Injection

400 250 500 3-7 - - Idle

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero. Set to 100RPM and 700 pulse width.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40149-Z TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511612 TEST OIL: ISO 4113

O.E.M. REF: FORD, PSA EURO 4 TEST OIL TEMP: 40C

ENGINE: 1.4 L CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail Max Back Leak

Pulse Delivery

Speed Pressure Comments

Width cc/1000 cc/1000 cc/min

RPM BAR

Purge System & Check for

1000 1500 1000 33-39 - -

Leaks

1000 1500 800 29-34 <60 <60.0 Max Power

1000 1150 1200 36-41 - - Max Torque

1000 1000 700 24-29 - - Emissions

1000 850 100 0.5-2.0 - - Pre-Injection

400 250 600 5-8 - - Idle

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero. Set to 100RPM and 700 pulse width.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40156-4Z TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: FORD FOCUS 1.8 EURO 4 TEST OIL TEMP: 40C

ENGINE: - CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 82-86 <60.0 <90.0 Max Fuel

1500 1200 1200 57-63 High Mid Range

1500 800 600 26-30 Mid Range

1500 400 600 15-20 Light Load

400 250 700 10-12 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40156Z TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF:FORD 1373550 TEST OIL TEMP: 40C

PSA 9659244280

CAPACITANCE: 3.0-4.5 Uf @ 20C

VOLVO 8603564

ENGINE: DW10 2.0HDI 100KW (CLASS 5)

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail Max Back Leak

Pulse Delivery

Speed Pressure Comments

Width cc/1000 cc/1000 cc/min

RPM BAR

Purge System & Check for

1000 1500 1000 - - -

Leaks

1000 1500 800 43-49 <60 <60.0 Max Power

1000 1150 1200 55-61 - - Max Torque

1000 1000 700 33-39 - - Emissions

1000 850 120 0.5-2.5 - - Pre-Injection

400 250 500 5-8 - - Idle

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero. Set to 100RPM and 700 pulse width.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40200 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511602 TEST OIL: ISO 4113

O.E.M. REF: PSA 1980K5 TEST OIL TEMP: 40C

ENGINE: PSA DW10 2.0 HDi 100KW CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 88-92 <60.0 <90.0 Max Fuel

1500 1200 1200 60-63 High Mid Range

1500 800 600 30-34 Mid Range

1500 400 600 12-14 Light Load

400 250 700 8-9.5 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40249 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511364 TEST OIL: ISO 4113

O.E.M. REF: LAND ROVER LR006495 TEST OIL TEMP: 40C

ENGINE: DT17 2.7 V6 CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 76-81 <60.0 <90.0 Max Fuel

1500 1200 1200 52-57 High Mid Range

1500 800 600 27-30 Mid Range

1500 400 600 15-17 Light Load

400 250 700 8-10 Idle

400 150-250 700 N/A S.O.I

400 800 100 0.5-2.0 Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40250 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511611 TEST OIL: ISO 4113

O.E.M. REF: FORD 1432322 TEST OIL TEMP: 40C

ENGINE: LYNX 1.8 TDCI 85-92KW CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail Max Back Leak

Pulse Delivery

Speed Pressure Comments

Width cc/1000 cc/1000 cc/min

RPM BAR

Purge System & Check for

1000 1500 1000 - - -

Leaks

1000 1500 800 33-39 <60 <60.0 Max Power

1000 1150 1200 37-43 - - Max Torque

1000 1000 700 22-28 - - Emissions

1000 850 120 0.5-2.5 - - Pre-Injection

400 250 500 3-7 - - Idle

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero. Set to 100RPM and 700 pulse width.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40252 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59513553 TEST OIL: ISO 4113

O.E.M. REF: LANDROVER TEST OIL TEMP: 40C

ENGINE: LION V6 UG CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 75-80 <60.0 <90.0 Max Fuel

1500 1200 1200 N/A High Mid Range

1500 800 600 N/A Mid Range

1500 400 600 N/A Light Load

400 250 700 10-12 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40253 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: 6H4Q-9K-546CB TEST OIL TEMP: 40C

ENGINE: FORD/ PSA LION V6 CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1200 65-70 <60.0 <90.0 Max Fuel

1500 1200 900 45-50 High Mid Range

1500 800 600 29-31 Mid Range

1500 400 400 8-9 Light Load

400 250 700 10-11 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40387 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59513597 TEST OIL: ISO 4113

O.E.M. REF: 6H4Q-9K-546CB TEST OIL TEMP: 40C

ENGINE: FORD/ PSA LION V6 CAPACITANCE: 3.0-4.5 Uf @ 20C

R/ROVER SPORT 3.6L V8

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1200 65-70 <60.0 <90.0 Max Fuel

1500 1200 900 45-50 High Mid Range

1500 800 600 29-31 Mid Range

1500 400 400 8-9 Light Load

400 250 700 10-11 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40441 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511603 TEST OIL: ISO 4113

O.E.M. REF: PSA 1980K8 TEST OIL TEMP: 40C

ENGINE: PSA DW10 2.0 HDi 100KW CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 77-80 <60.0 <90.0 Max Fuel

1500 1200 1200 55-58 High Mid Range

1500 800 600 27-30 Mid Range

1500 400 600 12-14 Light Load

400 250 700 7.5-9 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40516 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59511612 TEST OIL: ISO 4113

O.E.M. REF: PSA 9663429280 TEST OIL TEMP: 40C

ENGINE: DV4 TD CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 87-93 <60.0 <90.0 Max Fuel

1500 1200 1200 57-63 High Mid Range

1500 800 600 27-32 Mid Range

1500 400 600 14-18 Light Load

400 250 700 8-12 Idle

400 150-250 700 N/A S.O.I

400 800 100 0.5-4 Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40539 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59513554 TEST OIL: ISO 4113

O.E.M. REF: VW/AUDI/SKODA TEST OIL TEMP: 40C

ENGINE: 1.6L CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1200 62-68 <60.0 <90.0 Max Fuel

1500 1200 900 47-53 High Mid Range

1500 800 600 27-33 Mid Range

1500 400 440 10-14 Light Load

400 250 700 10-14 Idle

400 150-250 700 N/A S.O.I

400 800 100 - Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 5WS-40677 TEST PUMP: SUITABLE CR PUMP

TYPE: A2C59513556 TEST OIL: ISO 4113

O.E.M. REF: PSA/ FORD/MAZDA/VOLVO TEST OIL TEMP: 40C

ENGINE: 1.5L (82kW) CAPACITANCE: 3.0-4.5 Uf @ 20C

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3201R.

Close protective cover.

Switch S3000 to Piezo.

IMPORTANT:-

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

Pump Rail

Pulse Delivery Max Back Leak

Speed Pressure Comments

Width cc/1000

RPM BAR

cc/1000 cc/min

Purge System & Check

1000 1000 700 N/A

- - for Leaks

1500 1600 1600 77-82 <60.0 <90.0 Max Fuel

1500 1200 1200 60-63 High Mid Range

1500 800 600 32-36 Mid Range

1500 400 600 22-24 Light Load

400 250 700 14-18 Idle

400 150-250 700 N/A S.O.I

Pre Injection

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection. Close Protective cover. Run Test Bench to 400RPM. Increase Rail

pressure slowly until atomised fuel can just be seen emitting from nozzle holes. Rail pressure

should be 150-200BAR.

Dry Seat Test

Select pump only on S3000. Remove nozzle sleeve and adaptor cable from injector.

Running at 100RPM, 1000BAR and zero pulse width visually check nozzle tip for leaks

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

Vous aimerez peut-être aussi

- Inyectores Delphi Tabla ValoresDocument30 pagesInyectores Delphi Tabla Valoresbruttus139Pas encore d'évaluation

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJuan David Cepeda GonzalesPas encore d'évaluation

- S3000 Common Rail Test System DataDocument28 pagesS3000 Common Rail Test System DataFernando SanchezPas encore d'évaluation

- Boschinjectortestplans 29 WEBDocument156 pagesBoschinjectortestplans 29 WEBedward06Pas encore d'évaluation

- Bosch CR Pumps Test Data PDFDocument146 pagesBosch CR Pumps Test Data PDFInyectronix Vyh100% (2)

- Siemens Pump Test Plans 4Document10 pagesSiemens Pump Test Plans 4DJAMel LPas encore d'évaluation

- Delphiinjectortestplans 12WEBDocument30 pagesDelphiinjectortestplans 12WEBkampee100% (1)

- Delphi Injector Test Plans 9 WebDocument26 pagesDelphi Injector Test Plans 9 WebAdrian MacayaPas encore d'évaluation

- S3000 Common Rail Test DataDocument20 pagesS3000 Common Rail Test Dataaddelyn_robescu8794100% (7)

- Merlin Diesel Systems Ltd injector calibration and testing documentationDocument126 pagesMerlin Diesel Systems Ltd injector calibration and testing documentationLucas Man100% (2)

- Denso-Injector PDFDocument20 pagesDenso-Injector PDFZauron Kent TouchitPas encore d'évaluation

- Delphi Injector Test PlansDocument21 pagesDelphi Injector Test PlansZauron Kent Touchit67% (6)

- S3000 Common Rail Test System DataDocument28 pagesS3000 Common Rail Test System DataInkanata Sac94% (16)

- Denso Control Valve & Rod 2016Document4 pagesDenso Control Valve & Rod 2016Екатерина КалашниковаPas encore d'évaluation

- VDO Diesel IAM Roadmap Q3 2018 ENDocument13 pagesVDO Diesel IAM Roadmap Q3 2018 ENLuis Miranda100% (2)

- 2017 Common Rail Parts Catalog-ERIKC DieselDocument60 pages2017 Common Rail Parts Catalog-ERIKC DieselЕкатерина КалашниковаPas encore d'évaluation

- Bk2q-9k546-Ag 20190701 112041 PDFDocument2 pagesBk2q-9k546-Ag 20190701 112041 PDFคุณชายธวัชชัย เจริญสุขPas encore d'évaluation

- Ricambi DensoDocument10 pagesRicambi DensoSprinter Transit Van100% (1)

- Fit For The Future:: Everything For Diesel ServiceDocument68 pagesFit For The Future:: Everything For Diesel Servicemihai37100% (2)

- DENSO Rastavljanje DizneDocument22 pagesDENSO Rastavljanje Diznegalaxy63Pas encore d'évaluation

- CRI Injector Shim RefDocument5 pagesCRI Injector Shim RefGuler Rahim100% (3)

- Modifikacii HP 3Document5 pagesModifikacii HP 3pankituna5487Pas encore d'évaluation

- Common Rail Spare Parts ListDocument57 pagesCommon Rail Spare Parts Listbuztedcgycom67% (3)

- Denso FIRAD Catalogue PDFDocument20 pagesDenso FIRAD Catalogue PDFdchosgo2639Pas encore d'évaluation

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDocument63 pagesERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаPas encore d'évaluation

- Quick Test and Injector Clamping SystemDocument2 pagesQuick Test and Injector Clamping SystemAsif ShahPas encore d'évaluation

- Injection P Ump Test Specifications 196000-327#Document4 pagesInjection P Ump Test Specifications 196000-327#Manuel João JoãoPas encore d'évaluation

- Denso Type CR Injector ShimsDocument11 pagesDenso Type CR Injector ShimsCostinDodenech100% (2)

- Manual NCT-3000 (En) PDFDocument15 pagesManual NCT-3000 (En) PDFvintiloiusPas encore d'évaluation

- A5 Common RailDocument24 pagesA5 Common RailanshelPas encore d'évaluation

- Measure Piezo Injector CurrentDocument6 pagesMeasure Piezo Injector CurrentSutikno100% (1)

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocument32 pagesEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- 1458718041Document24 pages1458718041Jose Camacho HernandezPas encore d'évaluation

- Illidio SerraDocument24 pagesIllidio SerraVictor GarciaPas encore d'évaluation

- Taian Xingzhou Experimental Equipment Co rod and injector partsDocument1 pageTaian Xingzhou Experimental Equipment Co rod and injector partsHenry BlancoPas encore d'évaluation

- Common Railmod3Document261 pagesCommon Railmod3Edinson Ariel Chavarro Quintero100% (1)

- 3042f843 Plano de TesteDocument1 page3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- Injector Numbers and Spec-1Document1 pageInjector Numbers and Spec-1Michael RauschPas encore d'évaluation

- Valve For Bosch Piezoelectric InjectorsDocument4 pagesValve For Bosch Piezoelectric InjectorsKammoePas encore d'évaluation

- Common Rail Injector Repair Tool Sets Instruction ManualDocument17 pagesCommon Rail Injector Repair Tool Sets Instruction ManualAnonymous 5tkF5bFwO100% (1)

- Cod InjectorDocument1 pageCod InjectorLupuAna100% (2)

- CRT075-EN BOSCH Third Measuring Tool 9pcs KitDocument8 pagesCRT075-EN BOSCH Third Measuring Tool 9pcs KitLuc Mutombo MukuluPas encore d'évaluation

- 1 - Catalog 2019 PDFDocument33 pages1 - Catalog 2019 PDFAndres VargasPas encore d'évaluation

- StanadyneDocument4 pagesStanadynemurillo_rodriguez8382Pas encore d'évaluation

- Common Rail Injector Test PointsDocument5 pagesCommon Rail Injector Test Pointsreza jangiPas encore d'évaluation

- vp44 Pump Detail Schematic PDF FreeDocument7 pagesvp44 Pump Detail Schematic PDF Freepablo pérezPas encore d'évaluation

- Denso Cri Repair Guide v4Document22 pagesDenso Cri Repair Guide v4Oscar Delgado100% (4)

- 00000774Document18 pages00000774roberto lopezPas encore d'évaluation

- DATODocument1 pageDATOMiguel RojasPas encore d'évaluation

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- Piezo ElectricmeteringDocument7 pagesPiezo Electricmeteringeko sulistyo utomo100% (1)

- 8 Operation Instruction: 8.1. Before StartDocument10 pages8 Operation Instruction: 8.1. Before StartJRC DIESELPas encore d'évaluation

- Dpico: Inj. Pump Calibration DataDocument6 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniPas encore d'évaluation

- Bosch Inline Piezo Injector Delivery PlanDocument9 pagesBosch Inline Piezo Injector Delivery PlandieseldvPas encore d'évaluation

- Siemens Injector Test Data New6Document20 pagesSiemens Injector Test Data New6cartronix2010100% (2)

- S3000 Common Rail Test System DataDocument28 pagesS3000 Common Rail Test System Dataصلاح طه السيد0% (1)

- AP Cutsheet VV WEB V200-ProlificDocument4 pagesAP Cutsheet VV WEB V200-ProlificRJ GevenPas encore d'évaluation

- S5000-1-Test-Data Ui Up Bosch, DelphiDocument29 pagesS5000-1-Test-Data Ui Up Bosch, DelphiEdinson Ariel Chavarro Quintero100% (1)

- Delphi Pump Test Plans 4 WebDocument54 pagesDelphi Pump Test Plans 4 WebAspro Brazil Se Iglesias100% (4)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaD'EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaPas encore d'évaluation

- C15 Engine Connecting Rod SpecsDocument2 pagesC15 Engine Connecting Rod SpecsYubiangel Celeste Perugini Parababith100% (1)

- 09 Tightening Torques of Bolts & NutsDocument3 pages09 Tightening Torques of Bolts & NutstruryPas encore d'évaluation

- Pontiac V8 EngineDocument19 pagesPontiac V8 Engineroberto100% (1)

- Yamaha F130aet - 2016 - Parts CatalogueDocument74 pagesYamaha F130aet - 2016 - Parts Catalogueanon_674708607100% (1)

- M1200 PinoutDocument2 pagesM1200 PinoutRaviVelugulaPas encore d'évaluation

- 2.0l Duratec EngineDocument577 pages2.0l Duratec EngineBrian DirouPas encore d'évaluation

- Waukesha F18GL-GLD - S-7775-45Document10 pagesWaukesha F18GL-GLD - S-7775-45kman548Pas encore d'évaluation

- Homologation Form Number 5714 Group 1Document28 pagesHomologation Form Number 5714 Group 1ImadPas encore d'évaluation

- 7146-7 - Super NWD 5200 TK7146-7Document235 pages7146-7 - Super NWD 5200 TK7146-7Victor LepizPas encore d'évaluation

- Sceintific Review of HHO KitDocument3 pagesSceintific Review of HHO KitAsim RiazPas encore d'évaluation

- 11obdg01 Hybrid DiagnosticsDocument1 087 pages11obdg01 Hybrid DiagnosticsZARQA BMW100% (1)

- n60 Ent m37 Ds ExtendedDocument9 pagesn60 Ent m37 Ds ExtendedAlexandros KontosPas encore d'évaluation

- Suzu Elf 4hk1 4jj1 EngineDocument23 pagesSuzu Elf 4hk1 4jj1 EnginefalahPas encore d'évaluation

- 2013 GM Performance Parts CatalogDocument388 pages2013 GM Performance Parts CatalogruglyotPas encore d'évaluation

- TD301 Petrol Engine Datasheet 0417 PDFDocument3 pagesTD301 Petrol Engine Datasheet 0417 PDFAman BARIHAPas encore d'évaluation

- Cat 320 D PDFDocument5 pagesCat 320 D PDFAditya Ramadhanch Aj100% (1)

- Parts Manual Backhoe Loader 416 eDocument669 pagesParts Manual Backhoe Loader 416 eManuel Andres Manrique Lopez85% (20)

- Foreword: Bajaj Auto Limited International Marketing DepartmentDocument43 pagesForeword: Bajaj Auto Limited International Marketing DepartmentDinesh sirviPas encore d'évaluation

- Motor Ka24de PDFDocument86 pagesMotor Ka24de PDFpedro melendezPas encore d'évaluation

- 3512 Marine Engine Governor Operation and ComponentsDocument6 pages3512 Marine Engine Governor Operation and ComponentsChung ChungPas encore d'évaluation

- Oil specifications are changing: Comma explains the new ACEA standardsDocument8 pagesOil specifications are changing: Comma explains the new ACEA standardsdin_thorpe3248Pas encore d'évaluation

- Shop Manual: D51EX D51PXDocument36 pagesShop Manual: D51EX D51PXSuharto ZuhriPas encore d'évaluation

- Halderman AutoTec ch29Document37 pagesHalderman AutoTec ch29PardeepPas encore d'évaluation

- Diesel Combustion AnalysisDocument46 pagesDiesel Combustion AnalysisTed Diehl100% (2)

- VARIABLE LOADS AND POWER PLANT CAPACITY FACTORSDocument41 pagesVARIABLE LOADS AND POWER PLANT CAPACITY FACTORSlawliet lawfordPas encore d'évaluation

- Tad 1232 GeDocument2 pagesTad 1232 GeRômulo MatildesPas encore d'évaluation

- Ficha Tecnica Motor DP6H-UFAA88Document9 pagesFicha Tecnica Motor DP6H-UFAA88SYA33% (3)

- Belarus English 90-92Document222 pagesBelarus English 90-92njudit850% (2)

- 2uz HistoryDocument130 pages2uz HistoryTaimoor Ahmed100% (2)

- Toyota Obd1 Old1Document3 pagesToyota Obd1 Old1tomasykPas encore d'évaluation