Académique Documents

Professionnel Documents

Culture Documents

Powders

Transféré par

Iswahyuni Ekawati0 évaluation0% ont trouvé ce document utile (0 vote)

14 vues2 pagesvdfgf

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentvdfgf

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

14 vues2 pagesPowders

Transféré par

Iswahyuni Ekawativdfgf

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Powders

There is no official pharmaceutical definition for the term powder. In general,

however, a powder may be described as the fine particles which result from the

comminution of any dry substance. Comminution is a broadly used term referring to

many types of processes such as triturating, levigating, grinding, and pulverizing.

Finely devided powders may also be prepared by carefully controlled chemical and

physical reactions such as precipitation and crystal growth, followed by appropriate

treatment and drying of the finely devided particles. See comminution, page 30.

Powders consist of particles ranging from about 10,000 micrometers

(1micrometer=0,001mm)- 0,1. The most useful range for pharmaceutical powders

as dosage forms is in the paracolloidal and colloidal region (10-0,1). Despite the fact

that powdered dosage form have a continuous history of use since antiquity, the

lack of any restrictive definition reflects the art of their formulation rather than the

science of powder technology. The fineness of particles, in pharmaceutical

terminology, is defined by the USP in descriptive terms: very coarse, coarsem

moderately, fine, and very fine. Such designations generally correspond to groups of

standard mesh sieves which are identified by sieve numbers.

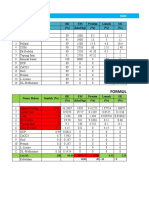

The nominal dimensions and descriptive terminology of powdered chemicals of

various degrees of fineness are given in Table 1. Since the classification scheme

refers to the number of wire strands in its constructionm it should be noted that

sieves with the higher sieve numbers retain finer particles that those with the lower

numbers.

The psysicochemical properties of powder are largely a fuction of the size and

surface area of the particles. Fine particles approaching the colloidal range diffuse in

a manner similar to a gas. The rate of settling of very small particles (up to 200

mesh) depends on the viscosity of the fluid suspension medium. Larger size

particles settle at a rate which depends primarily on the difference between the

density of the particle and that of the dispersion medium (Stokes low). High

concentrations of particles or aggregates of large particles do not follow Stokes low,

however, and is such cases the settling characteristics are related to the type of

aggregate which the particles form, structure density of the aggregates, and

particle geometry. Dosage forms consisting of powdered materials, either in the dry

or suspended state, reflect the characteristics which result form the surface

interactions of the particles. Particle size and surface activity influence such

physical characteristics as ease of mixing, dispersibility, and pharmaceutical

elegance. Attempts to deal with particle size diameters as a function of surface/ unit

volume have provided important information concerning adsorption, dissolution,

and particle- particle interaction. These same physicochemical parameters may

profoundly influence such important biopharmaceutic characteristics as degree of

solubility, bioavailability, pharmacological onset, and duration of drug action.

Knowledge of interfacial conditions and aggregation phenomena in dry powders

represent significant considerations for the pharmacist. As with other dosage forms,

powders are subject to the general processes of aggregation. Most aggregations in

powders result directly form the interaction of adsorbed films such as water or

gases present on the particulate surface. The absence of such surface impurities

generally reduces the tendency for the particles to aggregate under the normal

gravitational conditions and similarly increases the rate of solution in most solvents.

Although the absolute solubility in any solvent remains relatively unaffected by

traces of adsorbed impurities in surface films, the dissolution rate may be markedly

altered. Crystals of boric acid were formerly recommended for the

Vous aimerez peut-être aussi

- BVCCDVBGFNGFNGFHGGH HFGC: (School) (Course Title)Document2 pagesBVCCDVBGFNGFNGFHGGH HFGC: (School) (Course Title)Iswahyuni EkawatiPas encore d'évaluation

- (Company Name) - (Company Address)Document2 pages(Company Name) - (Company Address)Iswahyuni EkawatiPas encore d'évaluation

- Webster's Dictionary of English Usage PDFDocument994 pagesWebster's Dictionary of English Usage PDFAdam Frick98% (44)

- BVCCDVBGFNGFNGFHGGH HFGC: (School) (Course Title)Document2 pagesBVCCDVBGFNGFNGFHGGH HFGC: (School) (Course Title)Iswahyuni EkawatiPas encore d'évaluation

- EKA Document TitleDocument2 pagesEKA Document TitleIswahyuni EkawatiPas encore d'évaluation

- Title With Picture Layout: SubtitleDocument12 pagesTitle With Picture Layout: SubtitleIswahyuni EkawatiPas encore d'évaluation

- Title With Picture Layout: SubtitleDocument12 pagesTitle With Picture Layout: SubtitleIswahyuni EkawatiPas encore d'évaluation

- BVCCDFGC: (School) (Course Title)Document2 pagesBVCCDFGC: (School) (Course Title)Iswahyuni EkawatiPas encore d'évaluation

- Title With Picture Layout: SubtitleDocument12 pagesTitle With Picture Layout: SubtitleIswahyuni EkawatiPas encore d'évaluation

- (Company Name) (Company Address)Document2 pages(Company Name) (Company Address)Iswahyuni EkawatiPas encore d'évaluation

- Title With Picture Layout: SubtitleDocument12 pagesTitle With Picture Layout: SubtitleIswahyuni EkawatiPas encore d'évaluation

- Eka: An engaging abstractDocument2 pagesEka: An engaging abstractIswahyuni EkawatiPas encore d'évaluation

- Document SubtitleDocument2 pagesDocument SubtitleIswahyuni EkawatiPas encore d'évaluation

- GDocument2 pagesGIswahyuni EkawatiPas encore d'évaluation

- Document TitleDocument2 pagesDocument TitleIswahyuni EkawatiPas encore d'évaluation

- Document TitleDocument2 pagesDocument TitleIswahyuni EkawatiPas encore d'évaluation

- Kayu ManisDocument5 pagesKayu ManisDenmaskoko HeruPas encore d'évaluation

- (Company Name) (Company Address)Document2 pages(Company Name) (Company Address)Iswahyuni EkawatiPas encore d'évaluation

- PEX 09 02 Alida Torgersen 2ADocument4 pagesPEX 09 02 Alida Torgersen 2AIswahyuni EkawatiPas encore d'évaluation

- Prakt 1Document1 pagePrakt 1Iswahyuni EkawatiPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Bonding & Properties WorksheetDocument4 pagesBonding & Properties WorksheetCraig KingPas encore d'évaluation

- KANDUNGAN ZAT MAKANAN BAHAN PAKAN UNGGASDocument5 pagesKANDUNGAN ZAT MAKANAN BAHAN PAKAN UNGGASIrma Rahayu NingrumPas encore d'évaluation

- Metal SizesDocument2 pagesMetal Sizesjohnphilip1Pas encore d'évaluation

- Setavin Rco Asugal RSL!Document2 pagesSetavin Rco Asugal RSL!aniakonik0% (1)

- Register of Pesticides March 26 2020 Active IngredientDocument26 pagesRegister of Pesticides March 26 2020 Active Ingredient20 Võ Xuân KỳPas encore d'évaluation

- Presentation On White RustDocument12 pagesPresentation On White RustapparaomsPas encore d'évaluation

- Chem 229 Problem Set 6Document2 pagesChem 229 Problem Set 6Su KelesogluPas encore d'évaluation

- 1.molecules of Life PDFDocument47 pages1.molecules of Life PDFaeylynnPas encore d'évaluation

- Belzona 1321 (Ceramic S-Metal) : Key BenefitsDocument22 pagesBelzona 1321 (Ceramic S-Metal) : Key BenefitsIrvansyah RazadinPas encore d'évaluation

- Sliding TB 105mmDocument42 pagesSliding TB 105mmSaud AffanPas encore d'évaluation

- Shell Gadus S2 High Speed Coupling Grease Technical Data SheetDocument3 pagesShell Gadus S2 High Speed Coupling Grease Technical Data Sheetjuan felipe diazgranados santosPas encore d'évaluation

- Paraffins-101: Shekhar Khandekar Global Flow Assurance ManagerDocument55 pagesParaffins-101: Shekhar Khandekar Global Flow Assurance ManagerSamuel OnyewuenyiPas encore d'évaluation

- ASSAB Tool Steel Performance Comparison ChartDocument1 pageASSAB Tool Steel Performance Comparison ChartNugroho Faris Sudrajat100% (2)

- Grade 12 Chem Final ExamDocument3 pagesGrade 12 Chem Final Examabdimoh7522Pas encore d'évaluation

- Belt Conveyor Design - Apex FennerDocument94 pagesBelt Conveyor Design - Apex Fennerdhangka100% (12)

- Jurnal Etanol EngDocument5 pagesJurnal Etanol EnghukamaPas encore d'évaluation

- ks3 Acids and Alkalis Whats Your Idea PowerpointDocument11 pagesks3 Acids and Alkalis Whats Your Idea PowerpointManha abdellahPas encore d'évaluation

- KromatografiDocument51 pagesKromatografiNadia Ulfa BurhanuddinPas encore d'évaluation

- Chem 31 PROCEDURES (Practicals)Document9 pagesChem 31 PROCEDURES (Practicals)FMDCPas encore d'évaluation

- Mould MaterialsDocument22 pagesMould MaterialsArun PrasadPas encore d'évaluation

- Crude Oil Analysis ResultsDocument18 pagesCrude Oil Analysis Resultslutfi awnPas encore d'évaluation

- 6 MorDocument55 pages6 MorMadeline Delmo ArroyoPas encore d'évaluation

- Operating Instructions and Maintain EdiDocument119 pagesOperating Instructions and Maintain EdiPhạm Quang HuyPas encore d'évaluation

- Textiles Presentation (Final) - April 2017Document37 pagesTextiles Presentation (Final) - April 2017Natalia RodriguezPas encore d'évaluation

- Betadex Sulfobutyl Ether Sodium DetailsDocument11 pagesBetadex Sulfobutyl Ether Sodium DetailsLeidy GonzalezPas encore d'évaluation

- Analisis Del Carbono Organico TotalDocument6 pagesAnalisis Del Carbono Organico TotalCarlos Alberto Ormeño OrtizPas encore d'évaluation

- Youngs Modulus For Different MaterialsDocument3 pagesYoungs Modulus For Different Materialschaitanya kulkarniPas encore d'évaluation

- AGR524 4 HerbicideDocument34 pagesAGR524 4 HerbicideWalter DanaPas encore d'évaluation

- Qualitative Tests For ProteinsDocument8 pagesQualitative Tests For ProteinsFaye Cortez100% (1)

- WCH01 01 Que 20161013Document24 pagesWCH01 01 Que 20161013lolomg900% (1)