Académique Documents

Professionnel Documents

Culture Documents

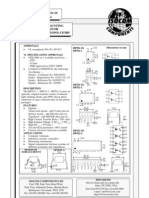

CRCW

Transféré par

Indah Cempluk ApriyantiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CRCW

Transféré par

Indah Cempluk ApriyantiDroits d'auteur :

Formats disponibles

D/CRCW e3

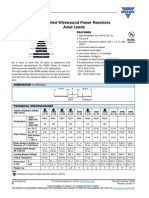

Vishay

Standard Thick Film Chip Resistors

FEATURES

Stability R/R = 1 % for 1000 h at 70 C

2 mm pitch packaging option for 0603 size

Pure tin solder contacts on Ni barrier layer

provides compatibility with lead (Pb)-free and lead

containing soldering processes

Metal glaze on high quality ceramic

AEC-Q200 qualified

Material categorization: For definitions of compliance

please see www.vishay.com/doc?99912

STANDARD ELECTRICAL SPECIFICATIONS

SIZE RATED LIMITING

DISSIPATION ELEMENT TEMPERATURE TOLERANCE RESISTANCE

MODEL COEFFICIENT RANGE SERIES

INCH METRIC P70 C VOLTAGE ppm/K %

W Umax. AC/DC

100 1 E24; E96

0.063 50 1R0 to 10M

D10/CRCW0402 0402 RR 1005M 200 5 E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 C = 1.5 A

100 1 E24; E96

0.10 75 1R0 to 10M

D11/CRCW0603 0603 RR 1608M 200 5 E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 C = 2.0 A

100 1 E24; E96

0.125 150 1R0 to 10M

D12/CRCW0805 0805 RR 2012M 200 5 E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 C = 2.5 A

0.25 200 100 1 1R0 to 10M E24; E96

D25/CRCW1206 1206 RR 3216M 200 5 E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 C = 3.5 A

0.5 200 100 1 1R0 to 10M E24; E96

CRCW1210 1210 RR 3225M 200 5 E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 C = 5.0 A

1.0 200 100 1 1R0 to 2M2 E24; E96

CRCW1218 1218 RR 3246M 200 5 E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 C = 7.0 A

0.75 400 100 1 1R0 to 10M E24; E96

CRCW2010 2010 RR 5025M 200 5 E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 C = 6.0 A

1.0 500 100 1 1R0 to 10M E24; E96

CRCW2512 2512 RR 6332M 200 5 E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 C = 7.0 A

Notes

These resistors do not feature a limited lifetime when operated within the permissible limits. However, resistance value drift increasing over

operating time may result in exceeding a limit acceptable to the specific application, thereby establishing a functional lifetime.

Marking: See data sheet Surface Mount Resistor Marking (document number 20020).

Power rating depends on the max. temperature at the solder point, the component placement density and the substrate material.

Document Number: 20035 For technical questions, contact: thickfilmchip@vishay.com www.vishay.com

Revision: 04-Jun-12 125

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

Vishay Standard Thick Film Chip Resistors

TECHNICAL SPECIFICATIONS

D10/ D11/ D12/ D25/

PARAMETER UNIT CRCW0402 CRCW0603 CRCW0805 CRCW1206 CRCW1210 CRCW1218 CRCW2010 CRCW2512

Rated dissipation P70 (1) W 0.063 0.1 0.125 0.25 0.5 1.0 0.75 1.0

Limiting element voltage

V 50 75 150 200 200 200 400 500

Umax. AC/DC

Insulation voltage V > 75 > 100 > 200 > 300 > 300 > 300 > 300 > 300

Uins (1 min)

Insulation resistance > 109

Category temperature

C - 55 to + 155

range

Failure rate h-1 < 0.1 x 10- 9

Weight mg 0.65 2 5.5 10 16 29.5 25.5 40.5

Note

(1) The power dissipation on the resistor generates a temperature rise against the local ambient, depending on the heat flow support of the

printed-circuit board (thermal resistance). The rated dissipation applies only if the permitted film temperature of 155 C is not exceeded.

PART NUMBER AND PRODUCT DESCRIPTION

Part Number: CRCW0603562RFKEC

C R C W 0 6 0 3 5 6 2 R F K E C

MODEL VALUE TOLERANCE TCR PACKAGING SPECIAL

CRCW0402 R = Decimal F = 1.0 % K = 100 ppm/K EA, EB, Up to 2 digits

CRCW0603 K = Thousand J = 5.0 % N = 200 ppm/K EC, ED,

CRCW0805 M = Million Z = Jumper 0 = Jumper EE, EF,

CRCW1206 0000 = Jumper EG, EH,

CRCW1210

EI, EL,

CRCW1218

CRCW2010 EK

CRCW2512

Product Description: D11/CRCW0603 100 562R 1 % ET6 e3

D11/CRCW0603 100 562R 1% ET6 e3

MODEL TCR RESISTANCE VALUE TOLERANCE PACKAGING LEAD (Pb)-FREE

D10/CRCW0402 200 ppm/K 10R = 10 5% ET1, ET2, e3 = Pure tin

D11/CRCW0603 100 ppm/K 562R = 562 1% ET3, ET4, termination finish

D12/CRCW0805 10K = 10 k ET5, ET6,

D25/CRCW1206 1M0 = 1 M ET7, ET8,

CRCW1210

0R0 = Jumper ET9, EF4,

CRCW1218

CRCW2010 E02, E67,

CRCW2512 E82

www.vishay.com For technical questions, contact: thickfilmchip@vishay.com Document Number: 20035

126 Revision: 04-Jun-12

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

Standard Thick Film Chip Resistors Vishay

PACKAGING

MODEL CODE QUANTITY CARRIER TAPE WIDTH PITCH REEL DIAMETER

ED = ET7 10 000 180 mm/7"

CRCW0402 8 mm 2 mm

EE = EF4 50 000 330 mm/13"

EI = ET2 5000 180 mm/7"

ED = ET3 10 000 180 mm/7"

8 mm 2 mm

EL = ET4 20 000 285 mm/11.25"

CRCW0603 EE = ET8 50 000 330 mm/13"

EA = ET1 5000 180 mm/7"

EB = ET5 10 000 8 mm 4 mm 285 mm/11.25"

EC = ET6 20 000 Paper tape acc. 330 mm/13"

to IEC 60068-3

EA = ET1 5000 Type I 180 mm/7"

CRCW0805 EB = ET5 10 000 8 mm 4 mm 285 mm/11.25"

EC = ET6 20 000 330 mm/13"

EA = ET1 5000 180 mm/7"

CRCW1206 EB = ET5 10 000 8 mm 4 mm 285 mm/11.25"

EC = ET6 20 000 330 mm/13"

EA = ET1 5000 180 mm/7"

CRCW1210 EB = ET5 10 000 8 mm 4 mm 285 mm/11.25"

EC = ET6 20 000 330 mm/13"

CRCW1218 EK = ET9 4000 12 mm 4 mm 180 mm/7"

CRCW2010 EF = E02 4000 Blister tape acc. 12 mm 4 mm 180 mm/7"

to IEC 60068-3

EG = E67 2000 Type II 8 mm

CRCW2512 12 mm 180 mm/7"

EH = E82 4000 4 mm

DIMENSIONS

SOLDER PAD DIMENSIONS in millimeters

SIZE DIMENSIONS in millimeters

REFLOW SOLDERING WAVE SOLDERING

INCH METRIC L W H T1 T2 a b l a b l

0402 1005 1.0 0.05 0.5 0.05 0.35 0.05 0.25 0.05 0.2 0.1 0.4 0.6 0.5

+ 0.10

0603 1608 1.55 - 0.05 0.85 0.1 0.45 0.05 0.3 0.2 0.3 0.2 0.5 0.9 1.0 0.9 0.9 1.0

+ 0.20 + 0.20

0805 2012 2.0 - 0.10 1.25 0.15 0.45 0.05 0.3 - 0.10 0.3 0.2 0.7 1.3 1.2 0.9 1.3 1.3

+ 0.10

1206 3216 3.2 - 0.20 1.6 0.15 0.55 0.05 0.45 0.2 0.4 0.2 0.9 1.7 2.0 1.1 1.7 2.3

1210 3225 3.2 0.2 2.5 0.2 0.55 0.05 0.45 0.2 0.4 0.2 0.9 2.5 2.0 1.1 2.5 2.2

+ 0.10

1218 3246 3.2 - 0.20 4.6 0.15 0.55 0.05 0.45 0.2 0.4 0.2 1.05 4.9 1.9 1.25 4.8 1.9

2010 5025 5.0 0.15 2.5 0.15 0.6 0.1 0.6 0.2 0.6 0.2 1.0 2.5 3.9 1.2 2.5 3.9

2512 6332 6.3 0.2 3.15 0.15 0.6 0.1 0.6 0.2 0.6 0.2 1.0 3.2 5.2 1.2 3.2 5.2

Document Number: 20035 For technical questions, contact: thickfilmchip@vishay.com www.vishay.com

Revision: 04-Jun-12 127

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

Vishay Standard Thick Film Chip Resistors

FUNCTIONAL PERFORMANCE

Single Pulse

1000

Pulse Load Pmax. (W)

2512

1218

2010

100 1210

1206

0805

0603

10 0402

0.1

0.01

10-6 10-5 10-4 10-3 10-2 10-1 1 10 100

Pulse Duration t i (s)

Maximum pulse load, single pulse; applicable if P 0 and n < 1000 and max.;

for permissible resistance change equivalent to 8000 h operation

Continuous Pulse

1000

Continuous Pulse Load Pmax. (W)

2512

1218

2010

100 1210

1206

0805

0603

10 0402

0.1

0.01

10-6 10-5 10-4 10-3 10-2 10-1 1 10 100

Pulse Duration t i (s)

Maximum pulse load, continuous pulses; applicable if P P (amb) and max.;

for permissible resistance change equivalent to 8000 h operation

(V)

2000

max.

1800 2512

Pulse Voltage

1600

2010

1400

1200

1000

800 1206/1210/1218

600

400 0805

0603

200

0402

0 -6

10 10- 5 10- 4 10- 3 10- 2 10- 1 1 10

Pulse Duration t i (s)

Maximum pulse voltage, single and continuous pulses; applicable if

P Pmax.; for permissible resistance change equivalent to 8000 h operation

www.vishay.com For technical questions, contact: thickfilmchip@vishay.com Document Number: 20035

128 Revision: 04-Jun-12

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

Standard Thick Film Chip Resistors Vishay

Derating

Fraction of Rated Dissipation P70

100

50

0

- 50 0 50 70 100 C 150

Ambient Temperature amb

120

Attenuation of 3rd Harmonic A3 in dB

100

80

1206, 2010

0805

60

40 0603

0402

20

0

10 100 1K 10K 100K 1M 10M

Resistance Value R in

Current Noise A1 in V/V

100

2

040

6 0 3

10 0

5

080 6

120 0

201

1

0.1

0.01

100 1K 10K 100K 1M 10M

Resistance Value R in

Document Number: 20035 For technical questions, contact: thickfilmchip@vishay.com www.vishay.com

Revision: 04-Jun-12 129

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

Vishay Standard Thick Film Chip Resistors

TEST PROCEDURES AND REQUIREMENTS

REQUIREMENTS

PERMISSIBLE CHANGE (R)

IEC

EN

60068-2 SIZE 0402 to 2512

60115-1 TEST PROCEDURE

TEST

CLAUSE STABILITY STABILITY

METHOD

CLASS 1 CLASS 2

OR BETTER OR BETTER

Stability for product types:

D/CRCW e3 1 to 10 M

4.5 - Resistance - 1% 5%

4.7 - Voltage proof U = 1.4 x Uins; 60 s No flashover or breakdown

U = 2.5 x P 70 x R

4.13 - Short time overload 2 x Umax.; 0.25 % R + 0.05) 0.5 % R + 0.05)

duration: Acc. to style

Solder bath method;

Sn60Pb40

Good tinning ( 95 % covered)

non activated flux;

no visible damage

(235 5) C

(2 0.2) s

4.17.2 58 (Td) Solderability

Solder bath method;

Sn96.5Ag3Cu0.5

Good tinning ( 95 % covered)

non-activated flux;

no visible damage

(245 5) C

(3 0.3) s

Temperature (20/- 55/20) C and

4.8.4.2 - 100 ppm/K 200 ppm/K

coefficient (20/125/20) C

Shear RR 1608 and smaller: 9 N

4.32 21 (Uu3) No visible damage

(adhesion) RR 2012 and larger: 45 N

Depth 2 mm; No visible damage, no open circuit in bent position

4.33 21 (Uu1) Substrate bending

3 times (0.25 % R + 0.05 )

30 min. at - 55 C;

30 min. at 125 C

Rapid change of

4.19 14 (Na)

temperature 5 cycles (0.25 % R + 0.05 ) (0.5 % R + 0.05 )

1000 cycles (1 % R + 0.05 ) (1 % R + 0.05 )

4.23 - Climatic sequence: -

4.23.2 2 (Ba) Dry heat 125 C; 16 h

55 C; 90 % RH;

4.23.3 30 (Db) Damp heat, cyclic

24 h; 1 cycle

4.23.4 1 (Aa) Cold - 55 C; 2 h (1 % R + 0.05 ) (2 % R + 0.1 )

4.23.5 13 (M) Low air pressure 1 kPa; (25 10) C; 1 h

55 C; 90 % RH;

4.23.6 30 (Db) Damp heat, cyclic

24 h; 5 cycles

4.23.7 - DC load U = P 70 x R

U = P 70 x R Umax.;

1.5 h on; 0.5 h off;

Endurance

4.25.1 -

at 70 C 70 C; 1000 h (1 % R + 0.05 ) (2 % R + 0.1 )

70 C; 8000 h (2 % R + 0.1 ) (4 % R + 0.1 )

www.vishay.com For technical questions, contact: thickfilmchip@vishay.com Document Number: 20035

130 Revision: 04-Jun-12

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

Standard Thick Film Chip Resistors Vishay

TEST PROCEDURES AND REQUIREMENTS

REQUIREMENTS

PERMISSIBLE CHANGE (R)

IEC

EN

60068-2 SIZE 0402 to 2512

60115-1 TEST PROCEDURE

TEST

CLAUSE STABILITY STABILITY

METHOD CLASS 1 CLASS 2

OR BETTER OR BETTER

Stability for product types:

D/CRCW e3 1 to 10 M

Solder bath method

Resistance to

4.18.2 58 (Td) (260 5) C; (0.25 % R + 0.05 ) (0.5 % R + 0.05 )

soldering heat

(10 1) s

Flamability, IEC 60695-11-5;

4.35 - No burning after 30 s

needle flame test 10 s

(40 2) C;

Damp heat,

4.24 78 (Cab) (93 3) % RH; (1 % R + 0.05 )

steady state

56 days

Endurance at

4.25.3 - upper category 155 C, 1000 h (1 % R + 0.05 ) (2 % R + 0.1 )

temperature

IEC 61340-3-1;

Electrostatic

3 pos. + 3 neg.

4.40 - discharge (1 % R + 0.05 )

discharges;

(human body model)

ESD voltage acc. to size

Component solvent Isopropyl alcohol;

4.29 45 (XA) No visible damage

resistance 50 C; method 2

Isopropyl alcohol;

Solvent resistance Marking legible,

4.30 45 (XA) 50 C; method 1,

of marking no visible damage

toothbrush

f = 10 Hz to 2000 Hz;

Vibration, endurance x, y, z 1.5 mm;

4.22 6 (Fc) (0.25 % R + 0.05 ) (0.5 % R + 0.05 )

by sweeping A 200 m/s2;

10 sweeps per axis

U= 15 x P 70 x R

Periodic electric 2 x Umax.;

4.37 - (1 % R + 0.05 )

overload 0.1 s on; 2.5 s off;

1000 cycles

Single pulse high = 10 x P 70 x R

4.27 - voltage overload, 2 x Umax.; (1 % R + 0.05 )

10 s/700 s 10 pulses

All tests are carried out in accordance with the following specifications:

EN 60115-1, generic specification

EN 140400, sectional specification

EN 140401-802, detail specification

IEC 60068-2-x, environmental test procedures

Packaging of components is done in paper or blister tapes according to IEC 60286-3.

Document Number: 20035 For technical questions, contact: thickfilmchip@vishay.com www.vishay.com

Revision: 04-Jun-12 131

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

Vishay), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishays knowledge of

typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding

statements about the suitability of products for a particular application. It is the customers responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular application.

Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over

time. All operating parameters, including typical parameters, must be validated for each customer application by the customers

technical experts. Product specifications do not expand or otherwise modify Vishays terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk.

Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for

such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document

or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

2017 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 08-Feb-17 1 Document Number: 91000

Vous aimerez peut-être aussi

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerPas encore d'évaluation

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayelecompinnPas encore d'évaluation

- Resistor 10r0Document8 pagesResistor 10r0ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣPas encore d'évaluation

- Vishay Bccomponents: FeaturesDocument16 pagesVishay Bccomponents: FeaturesPetrutStefanVartolomeiPas encore d'évaluation

- Type RN73 Series: Key FeaturesDocument5 pagesType RN73 Series: Key FeaturesdannnirPas encore d'évaluation

- DSFDocument3 pagesDSFJose Maria SantosPas encore d'évaluation

- An Overview of Military Film Surface-Mount ResistorsDocument6 pagesAn Overview of Military Film Surface-Mount ResistorsazhagaanPas encore d'évaluation

- X7R Tip & RingDocument16 pagesX7R Tip & Ringdovesnest_inPas encore d'évaluation

- NHG A: Aluminum Electrolytic Capacitors/ NHG Radial Lead TypeDocument5 pagesNHG A: Aluminum Electrolytic Capacitors/ NHG Radial Lead TypeChaitanya VaidyaPas encore d'évaluation

- Surface Mount Multilayer Ceramic Chip Capacitors: Automotive GradeDocument17 pagesSurface Mount Multilayer Ceramic Chip Capacitors: Automotive Gradedovesnest_inPas encore d'évaluation

- 22 Ohm ResistorDocument11 pages22 Ohm ResistorDwp BhaskaranPas encore d'évaluation

- Datasheet PDFDocument5 pagesDatasheet PDFgbaetaPas encore d'évaluation

- Data Sheet: General Purpose Chip ResistorsDocument9 pagesData Sheet: General Purpose Chip ResistorsJamesSmith2014Pas encore d'évaluation

- Siwo-Kul CablesDocument10 pagesSiwo-Kul CablesKiliardt ScmidtPas encore d'évaluation

- 5×20 MM Time-Lag 218 SeriesDocument4 pages5×20 MM Time-Lag 218 SeriesarunkollamPas encore d'évaluation

- Surface Mount Multilayer Ceramic Chip Capacitors: Commerical GradeDocument19 pagesSurface Mount Multilayer Ceramic Chip Capacitors: Commerical Gradedovesnest_inPas encore d'évaluation

- HTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HCV With Bracket (English)Document3 pagesHTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HCV With Bracket (English)crplzPas encore d'évaluation

- C0G Dielectric, 10Vdc-200Vdc (Automotive Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Document18 pagesC0G Dielectric, 10Vdc-200Vdc (Automotive Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)dovesnest_inPas encore d'évaluation

- 1717949Document2 pages1717949vikas_ojha54706Pas encore d'évaluation

- Codificare Rezistente SMD 60A Are 412 Ohmi CF TabelDocument6 pagesCodificare Rezistente SMD 60A Are 412 Ohmi CF Tabelromeo1966Pas encore d'évaluation

- Id Almiec CPH Tech eDocument60 pagesId Almiec CPH Tech ealltheloveintheworldPas encore d'évaluation

- Vs-30Bq100Pbf: Vishay High Power ProductsDocument7 pagesVs-30Bq100Pbf: Vishay High Power ProductspatopickPas encore d'évaluation

- Chip Resistors - CR, LCR and ULCR: FeaturesDocument6 pagesChip Resistors - CR, LCR and ULCR: FeaturesmanivelcPas encore d'évaluation

- WW25W, WW20W, WW10W, WW12W, WW08W, WW06W 1%, 5%Document8 pagesWW25W, WW20W, WW10W, WW12W, WW08W, WW06W 1%, 5%Fazli WadoodPas encore d'évaluation

- P521Document3 pagesP521ge_bdPas encore d'évaluation

- Surface Mount Ceramic Surface Mount Multi - Layer DS: Outline DrawingDocument6 pagesSurface Mount Ceramic Surface Mount Multi - Layer DS: Outline DrawingTim SmithPas encore d'évaluation

- Aluminium CappacitorDocument5 pagesAluminium CappacitorHieuhl LePas encore d'évaluation

- Schrack PE014024 DatasheetDocument3 pagesSchrack PE014024 DatasheetViorelPas encore d'évaluation

- SMD FusesDocument5 pagesSMD FusesatentinPas encore d'évaluation

- RH, NH: Vishay DaleDocument5 pagesRH, NH: Vishay DaleAndrea CallegaroPas encore d'évaluation

- TVRDocument27 pagesTVRmarcoskakoPas encore d'évaluation

- 24V - D3427 and 5V D3423Document14 pages24V - D3427 and 5V D3423Pradeeban NPas encore d'évaluation

- HF43F DatasheetDocument3 pagesHF43F Datasheetdff1967dffPas encore d'évaluation

- 1N4148WS (SMD) PDFDocument5 pages1N4148WS (SMD) PDFRobmixPas encore d'évaluation

- Loc 110Document6 pagesLoc 110Freezer Aurelio Pinto ParedesPas encore d'évaluation

- Vishay Sfernice: FeaturesDocument4 pagesVishay Sfernice: FeaturesAnonymous onIfGeuU0Pas encore d'évaluation

- Data Sheet Res PDFDocument5 pagesData Sheet Res PDFToufani Rizal AlfarisiPas encore d'évaluation

- Kem A4003 ExvDocument16 pagesKem A4003 ExvAndrzej GomulaPas encore d'évaluation

- Nichicon CS Pencil CapacitorsDocument2 pagesNichicon CS Pencil CapacitorsVaslejeanPas encore d'évaluation

- High Power Resistors: Type Bds 100 SeriesDocument2 pagesHigh Power Resistors: Type Bds 100 Seriesmanjubd1Pas encore d'évaluation

- D/CRCW E3: VishayDocument10 pagesD/CRCW E3: VishayBenyamin Farzaneh AghajariePas encore d'évaluation

- 1N5221B To 1N5267B: Vishay SemiconductorsDocument6 pages1N5221B To 1N5267B: Vishay SemiconductorsMircea PanzariuPas encore d'évaluation

- BYG21K-M3/HM3, BYG21M-M3/HM3: Vishay General SemiconductorDocument4 pagesBYG21K-M3/HM3, BYG21M-M3/HM3: Vishay General SemiconductorbehzadPas encore d'évaluation

- Capacitor Tantalio SMT 1206KEM T2005 T491Document24 pagesCapacitor Tantalio SMT 1206KEM T2005 T491Jeziel Vazquez NavaPas encore d'évaluation

- IRFPG50Document9 pagesIRFPG50tarpinoPas encore d'évaluation

- Antamount: Vishay SpragueDocument22 pagesAntamount: Vishay SpraguemohamedPas encore d'évaluation

- CuAg0,1P PDFDocument8 pagesCuAg0,1P PDFirajfarji2481Pas encore d'évaluation

- SDM40E20L /S /C /A: Dual Surface Mount Schottky Barrier DiodeDocument3 pagesSDM40E20L /S /C /A: Dual Surface Mount Schottky Barrier DiodeIng Jose David Bolaños de GarciaPas encore d'évaluation

- Aluminum Electrolytic Capacitors: SpecificationsDocument1 pageAluminum Electrolytic Capacitors: SpecificationsbehzadPas encore d'évaluation

- Tyco PCB RelaysDocument6 pagesTyco PCB RelaysgfiarePas encore d'évaluation

- MMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagDocument13 pagesMMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagJan KowalskiPas encore d'évaluation

- 2n7002k DiodesDocument7 pages2n7002k DiodesRofo2015Pas encore d'évaluation

- Varistor 222k.6kvDocument5 pagesVaristor 222k.6kvJess AJPas encore d'évaluation

- Anchor Audio Liberty MPB-4500 SchematicDocument3 pagesAnchor Audio Liberty MPB-4500 SchematicIgnacio Barriga Núñez0% (1)

- HFD2Document4 pagesHFD2Miguel PerniaPas encore d'évaluation

- Modern Glass CharacterizationD'EverandModern Glass CharacterizationMario AffatigatoPas encore d'évaluation

- Marine Electrical Practice: Marine Engineering SeriesD'EverandMarine Electrical Practice: Marine Engineering SeriesÉvaluation : 4 sur 5 étoiles4/5 (8)

- 4 Watt Led Driver CircuitDocument17 pages4 Watt Led Driver CircuitNomade VoyageurPas encore d'évaluation

- Asm30 Link Util 51317eDocument280 pagesAsm30 Link Util 51317eСтоян БанчевPas encore d'évaluation

- Arduino KNX 6Document14 pagesArduino KNX 6alko123Pas encore d'évaluation

- Radio Paging - Remote Control System: Designed by Autotech R&D 2004Document18 pagesRadio Paging - Remote Control System: Designed by Autotech R&D 2004alko123Pas encore d'évaluation

- Qfn36 FootprintDocument2 pagesQfn36 Footprintalko123100% (1)

- IPE UserGuideDocument42 pagesIPE UserGuideJohnny QuestPas encore d'évaluation

- Output Module: Current VersionDocument2 pagesOutput Module: Current Versionalko123Pas encore d'évaluation

- 16ch SchematicDocument1 page16ch Schematicalko123Pas encore d'évaluation

- Atex GuidelinesDocument76 pagesAtex GuidelinesAN.ADAMMSPas encore d'évaluation

- 1 EN ACT Part1 v8Document144 pages1 EN ACT Part1 v8ana silvaPas encore d'évaluation

- 20151014-161344 - Q& A On The Transposition of LVD 2014 35 EuDocument19 pages20151014-161344 - Q& A On The Transposition of LVD 2014 35 Eualko123Pas encore d'évaluation

- C02e AshxDocument186 pagesC02e AshxRanaJafaryPas encore d'évaluation

- 16 RelayDocument1 page16 Relayalko123Pas encore d'évaluation

- Output Module: Current VersionDocument2 pagesOutput Module: Current Versionalko123Pas encore d'évaluation

- Yageo 1nF X7R 0805Document17 pagesYageo 1nF X7R 0805alko123Pas encore d'évaluation

- EMC Filter Design With RB Common Mode ChokesDocument22 pagesEMC Filter Design With RB Common Mode Chokeskaem1189Pas encore d'évaluation

- BomDocument4 pagesBomalko123Pas encore d'évaluation

- NG CD 55a1111 A1-668341Document2 pagesNG CD 55a1111 A1-668341kpPas encore d'évaluation

- Header 6pin Right AngleDocument7 pagesHeader 6pin Right Anglealko123Pas encore d'évaluation

- Header 6pin StraightDocument7 pagesHeader 6pin Straightalko123Pas encore d'évaluation

- Panasonic - Aluminium Electrolytic Capacitors - SMDDocument6 pagesPanasonic - Aluminium Electrolytic Capacitors - SMDalko123Pas encore d'évaluation

- C02e AshxDocument186 pagesC02e AshxRanaJafaryPas encore d'évaluation

- C02e AshxDocument186 pagesC02e AshxRanaJafaryPas encore d'évaluation

- Headers & Wire Housings WR-PHD 2.54mm 2pin THT HeaderDocument4 pagesHeaders & Wire Housings WR-PHD 2.54mm 2pin THT Headeralko123Pas encore d'évaluation

- NG CD 55a1111 A1-668341Document2 pagesNG CD 55a1111 A1-668341kpPas encore d'évaluation

- Kermet 22pF NP0 0402Document21 pagesKermet 22pF NP0 0402alko123Pas encore d'évaluation

- Kermet 100nF X7R 0402Document25 pagesKermet 100nF X7R 0402alko123Pas encore d'évaluation

- Precision Thick Film Chip Resistors Erj XG, 1G ERJ 1R, 2R, 3R, 6R ERJ 3E, 6E, 8E, 14, 12, 1TDocument4 pagesPrecision Thick Film Chip Resistors Erj XG, 1G ERJ 1R, 2R, 3R, 6R ERJ 3E, 6E, 8E, 14, 12, 1Talko123Pas encore d'évaluation

- Irm 05 Spec MeanwellDocument3 pagesIrm 05 Spec Meanwellalko123Pas encore d'évaluation

- Vishay Dale 33ohm ResistorsDocument11 pagesVishay Dale 33ohm Resistorsalko123Pas encore d'évaluation

- Periodic Table of Elements - With Added InfoDocument1 pagePeriodic Table of Elements - With Added InfoEdgar Clyde LopezPas encore d'évaluation

- Applied Physics - M. ArumugamDocument71 pagesApplied Physics - M. ArumugamAditi NarendranPas encore d'évaluation

- Optical Computer: A Seminar OnDocument19 pagesOptical Computer: A Seminar Onchikulenka50% (2)

- 4 Bit Shift RegisterDocument6 pages4 Bit Shift Registerpenchal_chinniPas encore d'évaluation

- Stamford DM110 Voltage RegulatorDocument71 pagesStamford DM110 Voltage RegulatorThomas Pendergrass100% (2)

- d30n03 MosfetDocument5 pagesd30n03 MosfetDomingo GomezPas encore d'évaluation

- PhysicsDocument18 pagesPhysicsHimanshu DidwaniaPas encore d'évaluation

- SumitomoDocument8 pagesSumitomoedgar100% (1)

- Panasonic Sa Pt560eDocument159 pagesPanasonic Sa Pt560esaul64Pas encore d'évaluation

- Astec NTS 353Document2 pagesAstec NTS 353VovkaPas encore d'évaluation

- Reference Manual: Date: 10/17/08Document31 pagesReference Manual: Date: 10/17/08Abhishek RanjanPas encore d'évaluation

- Analysis and Design of High Step-Up DC-DC Converter With Coupled-Inductor TechniqueDocument6 pagesAnalysis and Design of High Step-Up DC-DC Converter With Coupled-Inductor Techniqueharis shehzadPas encore d'évaluation

- Akira CT 14cps5cpt Ete 2Document44 pagesAkira CT 14cps5cpt Ete 2michael603100% (1)

- Noise Margin Criteria For Digital Logic Circuits: Ieee Transactions On Education, Vol. 30, No. 4, Novemlitlt Ly3Document6 pagesNoise Margin Criteria For Digital Logic Circuits: Ieee Transactions On Education, Vol. 30, No. 4, Novemlitlt Ly3Khadir AhmedPas encore d'évaluation

- Kirchof LawsDocument33 pagesKirchof LawsZain SaleemPas encore d'évaluation

- TL494-D PWM Duty Cycle GenerationDocument14 pagesTL494-D PWM Duty Cycle GenerationMashood NasirPas encore d'évaluation

- NPN Epitaxial Silicon Transistor: High Voltage General Purpose ApplicationsDocument4 pagesNPN Epitaxial Silicon Transistor: High Voltage General Purpose ApplicationsNam TàoPas encore d'évaluation

- Ram Rom MemoryDocument8 pagesRam Rom MemorySohit ThapaPas encore d'évaluation

- Irda-Welder User Manual T-870aDocument15 pagesIrda-Welder User Manual T-870aRogertagalliuPas encore d'évaluation

- Introduction To EXAFS Experiments and TheoryDocument35 pagesIntroduction To EXAFS Experiments and TheoryandyblablaPas encore d'évaluation

- 50 TOP TRANSISTORS Questions and Answers PDFDocument8 pages50 TOP TRANSISTORS Questions and Answers PDFamadullah janPas encore d'évaluation

- Static Var CompensatorDocument6 pagesStatic Var Compensatoralexandre_foxtrotPas encore d'évaluation

- J309 10 N Channel FETDocument6 pagesJ309 10 N Channel FETwhynot05Pas encore d'évaluation

- Optimal Design of A Thermoelectric Cooling - Heating System For Car PDFDocument118 pagesOptimal Design of A Thermoelectric Cooling - Heating System For Car PDFYuva RajPas encore d'évaluation

- NanotechnologyDocument55 pagesNanotechnologySachin BajpaiPas encore d'évaluation

- BUK213Document16 pagesBUK213Nemesys TOFPas encore d'évaluation

- 0740 800 172 GBDocument106 pages0740 800 172 GBGustavo LeaoPas encore d'évaluation

- Microelectronic PillsDocument33 pagesMicroelectronic PillsAnu MavelyPas encore d'évaluation

- MOSFET SelectorDocument75 pagesMOSFET SelectorLefter TironPas encore d'évaluation