Académique Documents

Professionnel Documents

Culture Documents

SAMPLE ISO Course Syllabus NEW

Transféré par

khansCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SAMPLE ISO Course Syllabus NEW

Transféré par

khansDroits d'auteur :

Formats disponibles

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

SYLLABUS (COURSE SPECIFICATION)

INSTITUTION

Yanbu Industrial College DEPARTMENT

Mechanical Engineering Technology

A. Course Identification and General Information

Course Title

MATERIALS TECHNOLOGY

Course Code

Credit hours

3

Program(s) in which the course is offered

Associate Degree of Science in Mechanical Maintenance Technology

Associate Degree of Science in Manufacturing Technology

Choose a program...

Choose a program...

Faculty members responsible for the course

Name

Role

Engr.Haqqani Arshad

Course Coordinator

Dr.Saji Varghese

Program Coordinator

Subject Matter Expert

Head of Department

Level at which this course is offered

Associate

Vocational

Certificate

Bachelor

Professional

Masters

Special Program

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 1 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

Year at which this course is offered

Foundation Year

Second Year

Third Year

Fourth Year

Fifth Year

Pre-requisites for this course (if any)

CHEM 101

Co-requisites for this course (if any)

CHEM 101

Location (if not on main campus)

Main Campus

Course Description

This course introduces the principles of manufacture of ferrous and non-ferrous metals and their alloys,

thermal insulating, and corrosive resisting materials. The course covers the basics of physical

metallurgy, powder metallurgy, shaping, forming, casting, plastic molding, heat treatment processes

and joining techniques of industrial materials. Laboratory applications focus on physical microstructure

examination of engineering materials. The student receives appropriate practical experience in carrying

out heat treatments and the study of their effects on the material, microstructures and mechanical

properties.

B. Course Objectives and Learning Outcomes

Courses Contribution to Program and College/Institute Goals

The contribution of the course is analytical looked into by mapping course learning outcomes (CLOs) with course

objectives. The course objectives are consistent with programs, and college goals to prepare its graduates for a profession

ready employment.

Mapping Matrix (Curriculum Matrix)

Mapping of course learning outcomes (CLOs) to Program(s) goals

Mapping of CLOs

ABET/ETAC Student Outcomes / Program Specific Criterions

to College goals

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 2 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

(Program Criterion)Engineering Knowledge Competency

Professional And Ethical Responsibility (i)

Management Skills (Program Criterion)

Impact Of Engineering Solution (j)

Program Specific Practical Skills

Engineering Fundamentals (b)

Program Specific Knowledge

Self Directed Learning (h)

Communication Skills (g)

Experimental Skills (c)

Engineering Tools (a)

Designing Skills (d)

Analytical Skills (f)

Accountability (k)

Teamwork (e)

CLO 1.01

(Enter 5-8 maximum) Course Learning Outcomes (CLOs)

CLO 1.02

CLO 2.01

CLO 2.02

CLO 3.01

CLO 3.02

CLO 4.01

CLO 4.02

CLO 5.01

CLO 5.02

CLO 6.01

CLO 6.02

Course Objectives

Upon successful completion of this course, the students will be able to:

Identify different engineering materials.

Describe the micro structure of metallic materials and bondings.

State the various process of heat treatment carried out on a plain carbon steel.

Explain briefly the most common manufacturing processes.

Describe the different joining processes.

Make appropriate selection for both materials and manufacturing processes for specific application.

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 3 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

Intended Learning Outcomes in the Domains of Learning

Knowledgeand Understanding

Course Learning Outcomes Teaching Strategies and Activities Assessment Methods

1. 02 Describe

The different mechanical properties.

The micro structure of metallic Active Learning

Collaborative/Cooperati Four quizzes, four

materials and bondings. assignments, one midterm

The critical conditions for hardening, ve Learning examination and one Final

case hardening & alloying hardening. Technology Tools examination.

The different forming & shaping

processes

The different joining processes

1. 03 List Active Learning Four quizzes, four

Collaborative/Cooperative assignments, one midterm

the different types of iron and steel and examination and one Final

their production Learning

examination.

the elements of the process of sand casting Discussion Strategies

.

the different groups of welding

1. 04 Identify

Active Learning

the different heat treatment Collaborative/Cooperative Four quizzes, four

processes assignments, one midterm

the various manufacturing processes Learning examination and one Final

Critical Thinking examination.

different engineering materials

.

Technology Tools

for various manufacturing

processes

1. 05 Recognize

the effect of carbon content on steel & Active Learning

Collaborative/Cooperative Four quizzes, four

mechanical properties. assignments, one midterm

the difference between soldering & Learning examination and one Final

brazing Critical Thinking examination.

The difference between cold working & Discussion Strategies .

hot working process Technology Tools

1. 06 Define Active Learning

Four quizzes, four

different manufacturing processes for Collaborative/Cooperative

assignments, one midterm

specific applications Learning examination and one Final

examination.

Critical Thinking

Cognitive Skills

Course Learning Outcomes Teaching Strategies and Activities Assessment Methods

2.02 Rate Four quizzes, four

different engineering materials to their Active Learning assignments, one

mechanical properties. midterm

Collaborative/Cooperati

examination and

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 4 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

ve Learning

Critical Thinking one Final

Discussion Strategies examination.

Technology Tools

.

2.03 Analyze

Active Learning

the different heat treatment methods for Collaborative/Cooperati

steel Four quizzes, four

the micro structure of metallic materials ve Learning assignments, one

Critical Thinking midterm examination

Discussion Strategies and one Final

Technology Tools examination

2.04 Evaluate Active Learning

Collaborative/Cooperati

the different types of iron and steel Four quizzes, four

and their properties. ve Learning

assignments, one

Critical Thinking

midterm examination

Discussion Strategies

and one Final

Technology Tools examination

2.05 Contrast

Active Learning

the different joining

Collaborative/Cooperati Four quizzes, four

processes.

assignments, one

the various manufacturing ve Learning

midterm examination

processes Critical Thinking

and one Final

Discussion Strategies

examination

Technology Tools

2.06 Explain Active Learning

Collaborative/Cooperati Four quizzes, four

And select different engineering assignments, one

materials for various ve Learning

midterm examination

manufacturing processes Critical Thinking

and one Final

Discussion Strategies

examination

Interpersonal Skills and Responsibility

Course Learning Outcomes Teaching Strategies and Activities Assessment Methods

3.02 Present

Individual assignment

Leadership skills and be a responsible Teamwork assessment done

and homework through peer input in group

member of the team in the mini Team work and group

projects.

project. projects to promote Assessment of group

interpersonal skills assignment by including

including leadership

individual contribution.

qualities and team

player.

3.03 Demonstrate Individual assignment Teamwork assessment done

and homework through peer input in group

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 5 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

Team work and group

The capacity for self-directed projects to promote

learning such as being able to interpersonal skills

including leadership projects.

conduct independent internet

qualities and team Assessment of group

usage and library research. player. assignment by including

individual contribution

Communication, Information Technology and Numerical Skills

Course Learning Outcomes Teaching Strategies and Activities Assessment Methods

4.02 Demonstrate Assignments and

Effectively in written and oral form in reports to be written in 5% credit is

the preparation of the projects and in proper English and

provided to

the presentations. good writing style

oral

should be followed.

presentations.

4.03 Assess

IT for presentations and Assignments and

designs reports to be written in 5% credit is

proper English and provided to

good writing style oral

should be followed. presentations.

4.04 Assess Assignments and 5% credit is

Browse the internet, for solutions to reports to be written in provided to

the assignments and gain knowledge proper English and oral

in the latest researches done on good writing style presentations.

certain topics should be followed.

Psychomotor Skills (if applicable)

Course Learning Outcomes Teaching Strategies and Activities Assessment Methods

5.02 Show

Active Learning

And identify the different Collaborative/Cooperati

engineering materials

ve Learning one midterm

Critical Thinking laboratory

Discussion Strategies examination and

Technology Tools one Final lab

Projects and examination.

presentations

Problem solving

5.03 Perform Active Learning one midterm

Collaborative/Cooperati laboratory

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 6 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

Perform tension test for ve Learning

different engineering materials Critical Thinking

Perform hardness test for Discussion Strategies

metallic materials Technology Tools

examination

Projects and

and one Final

presentations lab

Problem solving examination

5.04 Operate Active Learning

Collaborative/Cooperati

The % of carbon for plain carbon

steels ve Learning

Critical Thinking

Discussion Strategies one midterm

Technology Tools laboratory

Projects and examination

and one Final

presentations lab

Problem solving examination

5.05 Perform Active Learning

Collaborative/Cooperati

Perform various heat treatments for

steels. ve Learning

Critical Thinking one midterm

Discussion Strategies laboratory

Technology Tools examination

Projects and and one Final

presentations lab

Problem solving examination

5.06 Show

Active Learning

Collaborative/Cooperati

And evaluate the mechanical properties

ve Learning

of heat treated specimens.

Critical Thinking one midterm

Discussion Strategies laboratory

Technology Tools examination

Projects and and one Final

presentations lab

Problem solving examination

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 7 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

C. Course Components

Total Contact Hours and Credit Hoursper Semester

Lecture Laboratory Tutorial Practical Other Total

Contact Hours 2 3 0

Credit Hours

Forms and Schedule of Assessment Tasks During the Semester

Form of assessment Proportion of final

Assessment task Week due assessment

Summative Formative

3

Assignments

Assignments 6 5%

Assignments 10

Assignments 13

Quizzes 4

Quizzes 7

Quizzes 11 10%

Quizzes 14

Midterm lab Exam 7

Midterm theory Exam 8

Mini projects & laboratory assesment 13

Final lab Exam 15

Final Examination 16

Student Support

)Availability of teaching staff for individual student consultations and academic advice per week)

Teachers are available for consultation (outside class hours) for 10 hours a week, approximately 2 hours per

day.

Provide special attention and support to weak students as per the MET department policies and guidelines.

Additional problems and solutions are uploaded in the e-learning for practice.

Small discussion groups are formed to support and reinforce the course learning outcomes.

Topics to be Covered

List of topics Weeks Contact

Hours

Introduction to Materials Technology: History of materials 1 2

Classification of Engineering Materials, structure of materials, bonding in materials 2 2

Mechanical Properties of Materials: Hardness, Fatigue, strength 3 2

Iron & Steel: Smelting, Steel making, Composition of steel. 4 2

Alloy Steels: Constructional Steels, Tool & Die Steels, Stainless Steel, Principal effects of 5 2

alloying elements

Cast Iron: Composition of cast irons, influence of cooling rate. 6 2

The Crystal Structure of Metals: Lattice structure, solidification 7 2

Alloys: Eutectics, Solid solutions, crystalline & polycrystalline arrangement. 8 2

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 8 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

Equilibrium Diagrams: Obtaining equilibrium diagrams, types of equilibrium diagrams. 9 2

Mechanical Deformation of Metals: Slip, Annealing, Hot & Cold working processes 10 2

The Heat Treatment of Plain Carbon Steels: Principles of Hardening, Hardening process, 11 2

tempering process, Hardenability, Heat treatment furnaces.

The Mechanical Shaping of Metals: shaping processes, powder metallurgy 12 2

Casting Processes: Ingot casting, sand casting, die casting centrifugal casting, choice of 13 2

casting processes.

Methods of Joining Materials: Adhesives, soldering & Brazing, welding. 14 2

Review 15 2

Laboratory Outline (if applicable)

Laboratory exercises Weeks Contact

Hours

Introduction 1 3

Visit toYIC mechanical stores 2 3

Physical Examination of industrial materials 3 3

Tensile tests of industrial materials 4 3

Hardness Testing 5 3

Microscopic examination of metallic materials 6 3

Mechanical evaluation of carbon content of plain carbon steels 7 3

Annealing process 8 3

Hardening process 9 3

Tempering process 10 3

Mechanical properties of heat treated specimens 11 3

Mechanical properties of heat treated specimens 12 3

Microscopic examination of heat treated specimens 13 3

Revision 14 3

Final Lab Exam 15 3

D. Teaching and Learning Resources and Facilities

Required Textbook(s)

Title and ISBN Author(s) Publication year Edition Publisher

Materials for Engineers & Raymond A. Higgins 2010 5th Edition Newness Press

Technicians

Essential References/RecommendedBooks

Title and ISBN Author(s) Publication year Edition Publisher

Materials of Science and 1999. John Wiley & Sons,

Engineering, William Callister 4th edition Inc

Materials for Engineering Raymond A. Higgins 1987 5th Edition Edward Arnold

Technicians Publishing

Required Software/Computer-BasedPrograms/Laboratory Equipment

Name Version (if any) Model/Year Company Other

Accommodation and Facilities

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 9 of 10

R O YAL C O M M I S S I O N C O LLE G E S AN D I N S TIT UTE S AT YAN B U

Other Resources

E. Course Evaluation and Improvement Processes

Confidential standard student survey (done by Quality Assurance Accreditation Committee

-QAAC, YIC)

Focus group discussion with small groups of students to get the feedback.

Peer observations and assistance, independent assessment of standards achieved by

students, independent advice on assignment tasks.

Improved use of IT support & services like Moodle and smart board.

Cross checking of examination papers or assignment tasks.

Improvements done based on the outcomes passing ratio (OPR) results.

Submitting the Course Assessment and Evaluation Report (CAIR)

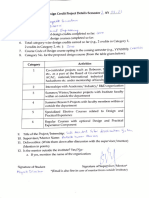

Curriculum

Head of Head - Curriculum

Developer Development Unit

Department(s) Development Dept.

Head(s)

Name Engr.Haqqani Arshad Dr.Fahad Alhujaili Dr.Liaqat Hayat

Signature

Completion

Date

Received Date

Approved Date

Y09-06-02-09/01 Issue no: 02 Friday, 26 May 2017 Page 10 of 10

Vous aimerez peut-être aussi

- Encouraging ShopliftingDocument21 pagesEncouraging ShopliftingDadi Bangun WismantoroPas encore d'évaluation

- Vibration Analysis Manual Rev0Document143 pagesVibration Analysis Manual Rev0iradanke100% (5)

- Diploma in Mechanical Engineering Program StructureDocument168 pagesDiploma in Mechanical Engineering Program Structureyamuna APas encore d'évaluation

- Advanced Vibration AnalysisDocument24 pagesAdvanced Vibration AnalysisM Hamza NadeemPas encore d'évaluation

- Hand BookDocument114 pagesHand BookPhani TejaPas encore d'évaluation

- Technological University's Mechanical Engineering Program OutcomesDocument5 pagesTechnological University's Mechanical Engineering Program OutcomesMarvin Sarmiento TalimonganPas encore d'évaluation

- Sample Action Research Proposal - DepEd Camsur FormatDocument7 pagesSample Action Research Proposal - DepEd Camsur FormatJenny Rose Figura Feolino100% (7)

- Research ProposalDocument33 pagesResearch ProposalTIZITAW MASRESHA100% (4)

- EViews 7 Users Guide IDocument686 pagesEViews 7 Users Guide Iitaliano5100% (3)

- University of Science and Technology of Southern PhilippinesDocument12 pagesUniversity of Science and Technology of Southern PhilippinesJohn Edenson Velono100% (1)

- Syllabus m24-1 Ee, Ece. CpeDocument8 pagesSyllabus m24-1 Ee, Ece. Cpegaryart111Pas encore d'évaluation

- Innovation Best Practices 3mDocument4 pagesInnovation Best Practices 3mDarleen Joy UdtujanPas encore d'évaluation

- CET-305 Course SpecificationDocument15 pagesCET-305 Course SpecificationAlia ShabbirPas encore d'évaluation

- 2WEEK 2 - Program StudyDocument33 pages2WEEK 2 - Program Study87vr772j64Pas encore d'évaluation

- SSOM BBA Scheme and SyllabusDocument78 pagesSSOM BBA Scheme and SyllabusHippie TribePas encore d'évaluation

- University of Baguio's Vision, Mission and ObjectivesDocument7 pagesUniversity of Baguio's Vision, Mission and ObjectivesKathie LawrencePas encore d'évaluation

- Technological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToDocument4 pagesTechnological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToMarvin Sarmiento TalimonganPas encore d'évaluation

- CT043-3-1-IN Introduction To Networking (VD1) 20 September 2019Document2 pagesCT043-3-1-IN Introduction To Networking (VD1) 20 September 2019Jang Hang ChooPas encore d'évaluation

- KIET Group Internship Report on Industry ProjectDocument4 pagesKIET Group Internship Report on Industry ProjectShivam YadavPas encore d'évaluation

- CT050-3-2 Web Applications (VD1) 6 January 2020Document2 pagesCT050-3-2 Web Applications (VD1) 6 January 2020makkarjsPas encore d'évaluation

- EMGT101-1 - Syllabus Eng'g ManagementDocument7 pagesEMGT101-1 - Syllabus Eng'g ManagementChe PetarealPas encore d'évaluation

- Asia Pacific University course explores systems developmentDocument3 pagesAsia Pacific University course explores systems developmentKrishna TodiPas encore d'évaluation

- EMGT103 - Industrial Organization and ManagementDocument7 pagesEMGT103 - Industrial Organization and ManagementMayden PabalanPas encore d'évaluation

- Mechanics Od Deformable BodiesDocument6 pagesMechanics Od Deformable BodiesCarlito PantalunanPas encore d'évaluation

- OBE3 - TrimesterDocument177 pagesOBE3 - Trimesterrhsajib94Pas encore d'évaluation

- MCET102 Lab ManualDocument88 pagesMCET102 Lab ManualBasem AaPas encore d'évaluation

- VSU College of Engineering course syllabusDocument10 pagesVSU College of Engineering course syllabusCabagnot Piolo JuliusPas encore d'évaluation

- General Chemistry Obe SyllabusDocument10 pagesGeneral Chemistry Obe SyllabusDe MiPas encore d'évaluation

- Bachelor of Science in Architecture - Faculty of Built Environment and SurveyingDocument2 pagesBachelor of Science in Architecture - Faculty of Built Environment and SurveyingApi MashPas encore d'évaluation

- 1.syllabus Mathematics For Engineers GE ELEC24Document8 pages1.syllabus Mathematics For Engineers GE ELEC24Ralph AdduPas encore d'évaluation

- University of Petroleum & Energy Studies School of Business DehradunDocument8 pagesUniversity of Petroleum & Energy Studies School of Business DehradunHarshil JainPas encore d'évaluation

- CareerCompass EngineeringTechDocument1 pageCareerCompass EngineeringTechINES CONCEPCION SANCHEZ RodriguezPas encore d'évaluation

- DBMS Course FileDocument193 pagesDBMS Course Fileabdul rehmanPas encore d'évaluation

- Physical Chemistry For Engineers 2: Page 1 of 7 2018Document7 pagesPhysical Chemistry For Engineers 2: Page 1 of 7 2018Astra BeckettPas encore d'évaluation

- 1. Elements of Aeronautical EngineeringDocument6 pages1. Elements of Aeronautical Engineeringyexov33854Pas encore d'évaluation

- Adobe Scan Jan 23, 2023Document1 pageAdobe Scan Jan 23, 2023msknowsevtPas encore d'évaluation

- EcschDocument9 pagesEcschDaisyQueenPas encore d'évaluation

- Strategic Management Lesson Plan MARA UniversityDocument10 pagesStrategic Management Lesson Plan MARA UniversityLyana InaniPas encore d'évaluation

- CH128P Syllabus-E01Document8 pagesCH128P Syllabus-E01Christian LeePas encore d'évaluation

- SRM Institute of Science & Technology - Academic Curricula (2018 Regulations) - ControlDocument4 pagesSRM Institute of Science & Technology - Academic Curricula (2018 Regulations) - Controlsateesh shivharePas encore d'évaluation

- CM011L-Syllabus-MBDJ 1st Q 2019-20 FridayDocument10 pagesCM011L-Syllabus-MBDJ 1st Q 2019-20 FridayJarell De JuanPas encore d'évaluation

- Visvesvaraya Technological University BelagaviDocument9 pagesVisvesvaraya Technological University BelagaviZeeshan DuddiandaPas encore d'évaluation

- C 20 Polymer Technology 1 2 SemDocument157 pagesC 20 Polymer Technology 1 2 SemGirishPas encore d'évaluation

- Davao Del Sur State College Institute of Computing, Engineering and Technology Information Technology DepartmentDocument8 pagesDavao Del Sur State College Institute of Computing, Engineering and Technology Information Technology DepartmentRegor LongPas encore d'évaluation

- MSR PPT Format - 2022Document10 pagesMSR PPT Format - 2022Hima N TalatiPas encore d'évaluation

- SyllabusDocument2 pagesSyllabusDiksha NasaPas encore d'évaluation

- AMJ30804 UniMAP Teaching Plan Template Latest V2Document10 pagesAMJ30804 UniMAP Teaching Plan Template Latest V2kheng weiPas encore d'évaluation

- Annual Gender and Development (Gad) Plan and Budget: Aurora Pioneers Memorial CollegeDocument2 pagesAnnual Gender and Development (Gad) Plan and Budget: Aurora Pioneers Memorial CollegeEvaPas encore d'évaluation

- 2022年学院各专业人才培养计划Document67 pages2022年学院各专业人才培养计划梁轩Pas encore d'évaluation

- PPC Geethanjali Course FileDocument308 pagesPPC Geethanjali Course FilesurykPas encore d'évaluation

- Nil Nil Faculty of ManagementDocument19 pagesNil Nil Faculty of ManagementDiksha NasaPas encore d'évaluation

- Dayananda Sagar College Engineering induction program detailsDocument37 pagesDayananda Sagar College Engineering induction program detailskalaPas encore d'évaluation

- 1 Thermal-EngineeringDocument100 pages1 Thermal-Engineeringmantusahu472Pas encore d'évaluation

- Framework Curriculum ReviewDocument23 pagesFramework Curriculum Reviewa_magomnang100% (1)

- Complete Material of PPC v1 - 2Document308 pagesComplete Material of PPC v1 - 2Prashanth GanjiPas encore d'évaluation

- IXP4888 - FordegreeDocument2 pagesIXP4888 - FordegreevinothPas encore d'évaluation

- 5652 BEng Hons Mechanical Engineering FT 20203010Document36 pages5652 BEng Hons Mechanical Engineering FT 20203010Simohamed ZganiPas encore d'évaluation

- EMSMS4A - Solid Mechanics and Stress Analysis 4 2022Document24 pagesEMSMS4A - Solid Mechanics and Stress Analysis 4 2022Dieter BothaPas encore d'évaluation

- Curriculum 224202444152Document40 pagesCurriculum 224202444152Om ShindePas encore d'évaluation

- Table of SpecificationDocument4 pagesTable of SpecificationfrancessichPas encore d'évaluation

- Title of The Field Work ReportDocument3 pagesTitle of The Field Work Reportzindafive1Pas encore d'évaluation

- MmdsschsyllDocument50 pagesMmdsschsyllRidhwanPas encore d'évaluation

- Syllabus M24-1 CEDocument8 pagesSyllabus M24-1 CEDanPas encore d'évaluation

- Correlation282019-202029V3 0Document22 pagesCorrelation282019-202029V3 0Dem DemPas encore d'évaluation

- 5 SedDocument1 page5 SedkhansPas encore d'évaluation

- Basic Measurement: ObjectiveDocument2 pagesBasic Measurement: ObjectivekhansPas encore d'évaluation

- Scanned With CamscannerDocument1 pageScanned With CamscannerkhansPas encore d'évaluation

- Esdd 34Document1 pageEsdd 34khansPas encore d'évaluation

- Assignment - 04Document2 pagesAssignment - 04khansPas encore d'évaluation

- Quiz1 SEC1Document1 pageQuiz1 SEC1khansPas encore d'évaluation

- Hasan Samkari 3713126Document1 pageHasan Samkari 3713126khansPas encore d'évaluation

- Assignment (2) 213Document3 pagesAssignment (2) 213khansPas encore d'évaluation

- Energies 15 05088 v2Document18 pagesEnergies 15 05088 v2khansPas encore d'évaluation

- SCHEDULEDocument1 pageSCHEDULEkhansPas encore d'évaluation

- Teaching Interest Form For 212 - 1Document1 pageTeaching Interest Form For 212 - 1khansPas encore d'évaluation

- Polar 01Document1 pagePolar 01khansPas encore d'évaluation

- SDP IdeasDocument1 pageSDP IdeaskhansPas encore d'évaluation

- SCHEDULEDocument1 pageSCHEDULEkhansPas encore d'évaluation

- Assess S8Document1 pageAssess S8khansPas encore d'évaluation

- SCHEDULE1Document2 pagesSCHEDULE1khansPas encore d'évaluation

- Assess S1Document1 pageAssess S1khansPas encore d'évaluation

- Lab04 ProjectsDocument1 pageLab04 ProjectskhansPas encore d'évaluation

- MET213 01 TheoryDocument1 pageMET213 01 TheorykhansPas encore d'évaluation

- TeamsDocument1 pageTeamskhansPas encore d'évaluation

- MarksDocument1 pageMarkskhansPas encore d'évaluation

- Quiz 3 BalancingDocument1 pageQuiz 3 BalancingkhansPas encore d'évaluation

- Yanbu Industrial College Mechanical Engineering Grade Report 2014-15Document1 pageYanbu Industrial College Mechanical Engineering Grade Report 2014-15khansPas encore d'évaluation

- Yanbu Industrial College Mechanical Engineering Grade Report 2014-15Document1 pageYanbu Industrial College Mechanical Engineering Grade Report 2014-15khansPas encore d'évaluation

- Assess S1Document1 pageAssess S1khansPas encore d'évaluation

- Project Evaluation1Document1 pageProject Evaluation1khansPas encore d'évaluation

- All LogoDocument1 pageAll LogokhansPas encore d'évaluation

- IntroductionDocument6 pagesIntroductionkhansPas encore d'évaluation

- Automated ParkingDocument10 pagesAutomated ParkinglovePas encore d'évaluation

- Guidelines For Dissolution of Novel Dosage FormDocument8 pagesGuidelines For Dissolution of Novel Dosage FormvivekPas encore d'évaluation

- Full Doc PDFDocument452 pagesFull Doc PDFRosita Bacon SuenoPas encore d'évaluation

- REPORT Types of Reports and Proposal StructureDocument4 pagesREPORT Types of Reports and Proposal StructureAlexandru RaduPas encore d'évaluation

- An Estimation of Technical Efficiency of Garlic Production in Khyber Pakhtunkhwa PakistanDocument10 pagesAn Estimation of Technical Efficiency of Garlic Production in Khyber Pakhtunkhwa Pakistanazni herasaPas encore d'évaluation

- NUS Business SchoolDocument9 pagesNUS Business Schoolajay16071988Pas encore d'évaluation

- Data Analytic ReportDocument16 pagesData Analytic ReportVIDHI MODIPas encore d'évaluation

- Impact of Daily Learning Activities in Learning English Among Grade 10 Students of Cainta Catholic College A.Y. 2020-2021Document86 pagesImpact of Daily Learning Activities in Learning English Among Grade 10 Students of Cainta Catholic College A.Y. 2020-2021ramon picayoPas encore d'évaluation

- Top Down and Bottom Down - PsicolinguisticaDocument2 pagesTop Down and Bottom Down - PsicolinguisticaSamara MorganPas encore d'évaluation

- Articles About EducationDocument6 pagesArticles About EducationLIPSONPas encore d'évaluation

- Ibrahim 2013Document10 pagesIbrahim 2013Cristina Saldias PorrasPas encore d'évaluation

- More PMP AgileDocument7 pagesMore PMP Agilerashdan rosmanPas encore d'évaluation

- Itl 608 SignatureassignmentDocument8 pagesItl 608 Signatureassignmentapi-415022394Pas encore d'évaluation

- 6 Psychology Studies With Marketing Implications PDFDocument10 pages6 Psychology Studies With Marketing Implications PDFJenny GonzalezPas encore d'évaluation

- Evaluation of Doctor's Perception About The Role of The Pharmacy in Pharmaceutical Services in Tengku Rafi'an Siak Hospital and Dr. Rasidin Padang HospitalDocument6 pagesEvaluation of Doctor's Perception About The Role of The Pharmacy in Pharmaceutical Services in Tengku Rafi'an Siak Hospital and Dr. Rasidin Padang HospitalInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- SHS - English For Acad Module 1Document8 pagesSHS - English For Acad Module 1vBloody BunnyPas encore d'évaluation

- Ok - Helen Sebastian Final2Document72 pagesOk - Helen Sebastian Final2Lhen Gui Sebastian100% (1)

- NColge - 1372 - Industrial and Organisational PsychologyDocument242 pagesNColge - 1372 - Industrial and Organisational PsychologyPrince SinghPas encore d'évaluation

- TML IML DefinitionDocument2 pagesTML IML DefinitionFicticious UserPas encore d'évaluation

- Good Manufacturing PracticesDocument12 pagesGood Manufacturing PracticesRambabu komati - QA100% (4)

- Purpose of CalibrationDocument2 pagesPurpose of Calibrationsakata_abera4Pas encore d'évaluation

- Gender Race and Class in Media A Critical Reader 5th Edition Dines Test BankDocument8 pagesGender Race and Class in Media A Critical Reader 5th Edition Dines Test Bankkathleenbaileytcgsrikobx100% (24)

- Poster SwissmedicDocument1 pagePoster SwissmedicDavid Maycotte-CervantesPas encore d'évaluation

- RelationalismeDocument24 pagesRelationalismeSyafrie MuhammadPas encore d'évaluation