Académique Documents

Professionnel Documents

Culture Documents

08 - Section-3 Three Phase Separation

Transféré par

Oladayo SiyanbolaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

08 - Section-3 Three Phase Separation

Transféré par

Oladayo SiyanbolaDroits d'auteur :

Formats disponibles

Flowlines and Manifolds Petrofac

SECTION 3

THREE-PHASE SEPARATION

1 Introduction

1.1 Separator Types

2 Flow Patterns

3 Separator Internals

4 Principles of Separation

5 The Separation Process

5.1 Inlet Separation

6 Separation Systems

6.1 Production Separators

7 Separator Instrumentation

8 Separator Control

8.1 Pressure Control

8.2 Level Control

9 Process Shutdowns

9.1 Planned Shutdown

9.2 Startup Procedure

9.3 Startup After Emergency or Short-term Shutdown

10 High Pressure Relief Valves

Figures

3.1 Three-phase Horizontal Separator

3.2 Vertical Separator Internals

3.3 Three-phase Separator Internals

3.4 The Separation System

3.5 Production Train Separator and Instrumentation

3.6 Separator Pressure Control

Training Services Page 1 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

1 INTRODUCTION

A separator is a vessel in which a mixture of fluids, that are not soluble in

each other, can be segregated.

On offshore installations, separators are used to segregate gas from liquid,

or one liquid from another such as water from oil.

1.1 Separator Types

Separators are classified in two ways:

By the position or shape of the vessel

By the number of fluids to be segregated

The following two vessel shapes are commonly used:

Horizontal - as shown in Figure 3.1

Vertical as shown in Figure 3.2

The number of phases refer to the number of streams that leave the vessel,

not the number of phases that are in the inlet stream.

For separation of gas and liquid, the separator is referred to as a two-phase

type.

For separation of gas, oil and water, the separator is referred to as a three-

phase type.

Some wellstreams contain sand or other solid particles which are also

removed in a separator. To achieve this, special internal devices are

provided in order to collect and dispose of these solid materials such as

sand, hence the term sandwashing of the separators.

Training Services Page 2 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

2 FLOW PATTERNS

The flow in both horizontal and vertical separators is similar for two-phase

separators whereby the mixture enters at the side or end of the vessel, the

lighter fluid (usually gas) passes out at the top, and the heavier fluid is

withdrawn at the bottom.

Flow in a three-phase separator is shown in Figure 3.1; the fluid entering at

one end of the vessel and the liquids being allowed to settle out at the left-

hand side of the vessel.

The oil layer floats on top of the water layer and spills over the weir into

the oil chamber, where it is withdrawn under level control.

The water layer remains on the left-hand side of the weir and is withdrawn

under separate level control.

Problems can, and do, arise with the interface level control between the oil

and water layers usually due to an emulsion of oil and water at the

interface. This type of problem can normally be overcome by using

demulsifying agents, chemicals that break down emulsions, in order to give

cleaner separation of the fluids.

Training Services Page 3 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

3 SEPARATOR INTERNALS

A wide variety of mechanical devices are used inside separators in order to

improve their efficiency and operation (refer to Figure 3.3). Those most

commonly used are as follows:

(1) Deflector Plates or Diverters

A deflector plate is used in gas-liquid separators and placed in front of

the inlet nozzle of the vessel.

The plate can be flat or dished, and as the inlet stream strikes it, the

liquid falls to the bottom and the gas flows around the plate.

In a vertical type vessel, the deflector may divert the stream around

the walls of the vessel in order to create a centrifugal action.

(2) Mist Pads

Mist pads are most frequently used within gas-liquid separators to

remove the vapour mist from the gas.

The pad is made of closely woven wire mesh and is typically 4 to 8in

thick. It is held in place by a sturdy grid frame which prevents it from

being swept out or torn by a sudden surge of gas flow.

(3) Coalescing Plates

There are several configurations of coalescing plates and they are

available from different vendors.

They are used in gas-liquid vessels to remove liquid from the gas by

causing small droplets to combine into larger drops which will

separate more readily.

(4) Straightening Vanes

Typical of those used on Shell installations is the Schoepentoeterl

type. These allow the use of smaller vessels, which are just as

efficient as the larger vessels with longer residence times.

Straightening vanes are installed to reduce turbulence.

They are also used in gas-liquid separation vessels and installed when

hydrate formation or paraffins would prevent the use of mist pads due

to blocking etc.

(5) Filter Elements

Filters are used to remove mist from the gas in oil-water vessels. The

separator usually contains an access hatch in order to allow

replacement of the elements.

(6) Centrifugal Devices

These are used in gas-liquid separators. They impart a swirling action

to the inlet stream that concentrates the flow of the liquid phase onto

the wall of the device.

Training Services Page 4 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

(7) Horizontal Baffles

These are used in gas-liquid separators in order to prevent waves

forming within the liquid phase. They are normally located near to the

liquid level in the vessel.

(8) Vortex Breakers

It is normally a good idea to include a simple vortex breaker or liquid

draw-off nozzles in order to prevent a vortex from forming, which

could result in some gas being drawn out through the liquid line.

(9) Water Jets

Water jets are sometimes referred to as sand jets. Their purpose is to

spray the sides and bottom of the vessel with a high pressure stream

of water in order to remove sand and other solid particles from the

walls and base of the vessel.

4 PRINCIPLES OF SEPARATION

Two factors are necessary for separators to function properly:

(1) The fluids that are to be separated must be insoluble with each other ie

they will not dissolve with each other.

(2) The fluids must not be of the same mass, ie they must be different

in density.

Separators depend upon the effect of gravity to segregate the fluids, if the

fluids are soluble in each other, no separation is possible by gravity alone.

For example, a mixture of distillate and crude oil will not separate in a

vessel because they will dissolve together. They must therefore be

segregated in a distillation process.

Since a separator depends upon gravity to separate the fluids, the ease with

which two fluids can be segregated depends upon the difference in the

density or weight per unit volume of the fluids.

Gas weighs far less than oil for the same volume, and will therefore

separate within a matter of seconds.

However, although oil is lighter than water, there is not such a marked

difference in weight and separation of oil and water can take several

minutes. (A typical specific gravity for oil is 0.84, which means that a given

volume of oil would weigh 84% as much as the same as water.)

Therefore the primary factor that affects separation of fluids is that of the

difference between their densities.

Training Services Page 5 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

5 THE SEPARATION PROCESS

The separation of oil, gas and water from each other is largely achieved by

one or both of the following:

Physical separation

Flash separation

Physical separation of liquids, solids and gases can be achieved naturally in

a number of ways including:

Settling of solids and layering of liquids through differences in densities

Coalescence

Filtration

Velocity changes

Centrifugal forces

Impingement

Flash separation of gas and water vapour from the liquid phase is achieved

when the well fluids mixture is discharged into a vessel at:

A reduced pressure

A higher temperature

With an enlarged volume

The effect of all of these processes can be optimised by ensuring that:

The equipment design incorporates features to make use of as many as

possible of the above separation processes

The separation equipment has been sized to accommodate the peak

anticipated flowrates

Sufficient time is allowed for the separation process to take place

efficiently

A three-phase separator is illustrated in Figure 3.3. The upper section of the

vessel is designed to separate gas from the liquid, while the lower section is

designed to collect and degas the oil, and to separate oil and water by

gravity separation, so that the three phases can be discharged from the

vessel separately, each in a relatively clean state; it should be appreciated

however that a three-phase separator will seldom produce water-clean oil

and oil-free water.

Normally efficient separation of the oil, gas and water is achieved in a

series of stages:

Training Services Page 6 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

5.1 Inlet Separation

The bulk of the liquid-gas separation takes place in this section.

The well fluid entering the vessel is subjected to a rapid and sudden change

of direction and velocity, when it strikes an inlet momentum breaker or

diverter plate.

This redirects the mixture back against the dished end of the vessel which

helps to minimise splatter and prevent the production of a mist of small

particles. With the reduced operating pressure and enlarged space

available, this results in the liberation of flash gas and an oil mist which

rise, while the heavier slugs and large droplets of liquid fall to the bottom

of the tank.

6 SEPARATION SYSTEMS

Separators are located downstream of the wellhead xmas tree, choke and

production/test manifolds and provide the following functions:

Clean-up/test separation

Test separation

Production separation (bulk)

Clean-up/test separators are used in the initial stages of well production

when the flow of oil is likely to be contaminated with mud and sand. Test

separators are used to test the flow of individual wells and are

instrumented to measure flow of oil, water and gas. Production separators

form an integral part of the production train.

As the capacity of a separator is limited, it may be necessary to have a

number of separators to handle the well fluid flow. Also it will be seen that

the most effective form of separation may be in stages so there could be

two, three or even four separators in series; each of these groups of

separators is known as a train.

6.1 Production Separators

Most platforms in the North Sea produce water in varying quantities which

are expressed as a percentage of the liquid to storage. This water

percentage is called the water cut and if a platform is producing oil into

storage with a water cut of 13% then there is 87% oil going into storage.

On gravity platforms, that is, platforms with subsea storage facilities, the

water flows through the train into the storage cells where the water settles

out leaving dry oil to be exported. Provided the separators are not

overloaded and the design throughput of the process train can be

maintained, this is the better mode of operation. However, circumstances

can dictate that three-phase separation is required.

Training Services Page 7 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

Figure 3.1 shows a simplified sketch of a typical three-phase separator. The

difference between two and three-phase separators is that on the three-

phase separator:

A weir is fitted

An additional level indicating controller (LIC) and level control valve

(LCV) are fitted

The weir forms a dam which creates a section where the water can separate

out of the oil. The water falls to the bottom of the separator with the drier

oil on top which flows over the top of the weir into the oil section. In this

example the oil level is controlled by the LIC-2 and its associated LCV.

On the upstream side of the weir LIC-1 and its LCV are controlling the level

of the water. The controller is often at the interface level where the oil and

water meet. The interface is not a clear division of oil and water but an

emulsion of the two. Emulsion is one of the main problem areas of three-

phase control in that it makes interface level control difficult.

Two sightglasses are fitted to a three-phase separator; one to show the

interface level and the other the oil level. An example of an oil level gauge

or sightglass is shown in Figure 3.3.

7 SEPARATOR INSTRUMENTATION

Within the limits of design and construction all separators have the same

basic instruments and controls as follows:

(1) Pressure Indicator (PI)

Monitors the pressure in the separator with readout both locally and

remotely, the remote readout being transmitted to a central location

such as the Central control room (CCR) or local equipment room

(LER).

(2) Temperature Indicator (TI)

Monitors the separator temperature, again indicated both locally and

remotely.

(3) Pressure Safety Valve (PSV)

Relief valves are installed on each separator, one in service and the

other isolated. The relieving pressure is set, tested and certified at

an authorised centre. No alteration to this setting is allowed after

the relief valve has been certified.

(4) Manual Blowdown Line

This gives the facility to manually depressurise the separator, the gas

being routed to the flare system.

Training Services Page 8 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

(5) Gas Outlet Line

This is split into two streams - the gas to the recompression and

treating section and the gas to flare.

(6) Pressure Indicating Controller (PIC) and PCV

These two instruments control the separator pressure. The PIC

monitors and modulates the PCV as required.

(7) Gas Off-take Flowmeter

This measures the volume of gas flowing from the separator in both

flare or recompression mode. Generally this flow is a remote readout

in the control room on both indicator and recorder.

(8) Level Indicating Controller and Level Control Valve

The LIC monitors the level and modulates the LCV to control the

level at the setpoint. This is another instrument which gives local

and remote readout in the control room.

(9) Oil Outlet Line

This line, which has the LCV in it, leads the oil to the next link in the

process train which could be a lower stage of separation, storage or

transfer pumps.

(10) Drains

This gives the facility to manually drain down the separator through

the closed drain system.

A typical production two-phase crude oil separator is shown in Figure 3.5.

Training Services Page 9 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

8 SEPARATOR CONTROL

All separators are fitted with the following protection facilities:

Low level alarm

Low level shutdown

High level alarm

High level shutdown

High pressure alarm

High pressure shutdown

High pressure relief valves

In order to give added safety by preventing gas blowby between

separators, a shut off valve is fitted to the pipework connecting the

vessels. This valve is designed to close on a Low Low level being

detected in the upstream vessel, or a high pressure being detected

in the downstream vessel.

Should either/both of these conditions be detected, then excessive pressure

from an upstream vessel will not be communicated to a lower pressure

rated vessel.

Where crude cooling is installed prior to the final-stage separator this can

be fitted with:

High temperature alarm

High temperature shutdown

High integrity protection system (HIPS) - this provides an alternative

(electronic) means of shutdown as a backup to the high level

shutdown systems on the separators

Regardless of what function is being monitored the sequence for alarm and

shutdown is the same. The first notice is the alarm allowing the operator to

take corrective action.

If no corrective action is taken or the action is ineffective further

deterioration occurs and a shutdown results. All level, pressure or

temperature shutdowns normally result in the closure of all of the producing

wells' upper master gate (surface safety valves) and flow wing valves.

Training Services Page 10 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

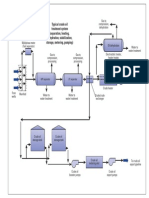

8.1 Pressure Control

When the gas recompression and treating facilities are operating, the gas

from the separators flows directly to them; separator pressure being

controlled by the backpressure in the downstream gas plant. Figure 3.6 is a

diagram of a four-stage separation system and shows typical operating

pressures at each stage.

Separator pressure control varies depending on the operating mode but the

first-stage separator will always be gas stream flow pressure. Pressure in

the other separators is designed for stable operation of the gas compressors

which compress gas from the second, third and fourth-stage separators.

The PICs on each separator will be set slightly above the pressure the gas

plant is holding on them. If the gas plant fails to take all of the gas from one

or more of the separators, the pressure in those vessels will start to rise. As

soon as it reaches the pressure setpoint the controller opens the PCV to

route the excess gas to the flare.

8.2 Level Control

The control of the oil level in the separator is the same regardless of

whether gas is being recompressed or flared. Each separator has a level

control system which regulates the position of a control valve in the oil

outlet line. If the level rises, the controller opens the control valve;

conversely, the valve closes when the level falls.

9 PROCESS SHUTDOWNS

During startup and shutdown, equipment and pipework are subject to

additional stresses and strains from expansion and contraction. Where

possible, action to prevent an emergency shutdown, for example, cutting

back production to avoid high level trip, is good operating practice. A

shutdown may still be required to cure the fault but it can be planned, as

can the remedial action, so minimising the shutdown time.

9.1 Planned Shutdown

Where a shutdown is planned it should be carried out in a manner which

creates the least disturbance and shocks to the process and also to the

reservoir. Wells should be closed in slowly using the chokes prior to closing

their surface safety valve (SSV).

The reason for shutting down will determine whether the train can be left

pressurised and undrained or if maintenance is to be done. In this case, the

separator train must be depressurised, drained and isolated.

All isolations must be logged to ensure the train is correctly deisolated prior

to startup.

Training Services Page 11 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

Prior to restart after an emergency shutdown, not only must the cause of

the shutdown be cured but also the fault which created the cause. For

example, a high pressure trip would require that the high pressure be bled

off and the fault which caused the high pressure cured before restarting.

9.2 Startup Procedure

Before any startup, pre-start checklists will be used by operations to ensure

that all systems are in a state of readiness.

These checklists will include the following:

All utilities, including hydrate inhibitor, chemical injection, flare

systems (HP and LP), closed drains and produced water, are to be

available at the battery limits

Pressure purging with nitrogen up to a pressure of 2 barg at the initial

startup or following maintenance work where the system is air filled

until an oxygen content of 3% is achieved

Locked and interlocked valves are in their normal operating position

Spectacle blinds and spades are in their normal startup position

In line block valves are in the correct position as per the valve position

schedule in the operating manual

All instrumentation is fully commissioned, checked and ready for

service

ESD systems are to be at process level startup status

Power generation and distribution are to be at normal status, with

switchgear racked-in and deisolated

Safety detection and protection systems are to be at normal status

Control valve handwheels are disengaged

At least one main oil line booster pump and one main oil line are

ready for startup

A series of operational checklists for verification of pre-startup

requirements will be available for each system and subsystem

The importance of good communications between all involved sections

must be of the highest quality at all times, particularly at this startup

NB stage.

Commence wellhead fluid flow into the first stage of separation from

the wellheads and manifold section

Training Services Page 12 of 13 Petrofac 2010

Flowlines and Manifolds Petrofac

Continuous visual checks for leaks are obviously most important at this

critical stage as pressure and temperatures increase to their normal

operating conditions

Separator off-gas will be flared initially. Flares should have been

nitrogen purged and pilots commissioned prior to initial flaring

Gas compression feed valve remains shut until the HP gas system is

brought into operation

When the interface level exceeds the low trip setting, reset the

shutdown valve to commence water treatment by routing produced

water to the water treatment facilities

When the oil level exceeds the low trip setting reset the shutdown

valve thus allowing oil to flow to the next stage of separation

As levels are established throughout the separation train the export

pumping facilities are brought on line and oil flow through the plant

stabilised

As soon as conditions are stable, chemical injections such as scale

inhibitor, corrosion inhibitor, demulsifier etc are commissioned

9.3 Startup After Emergency or Short-term Shutdown

Startup after emergency or short-term shutdown follows the same

procedure as startup after a prolonged shutdown, except for those items

not applicable. For example, after an emergency shutdown all manual block

valves will still be open. The fault which caused the shutdown must be

rectified prior to opening up the well SSV.

Training Services Page 13 of 13 Petrofac 2010

Petrofac

Training Services Petrofac 2010

Figure 3.1

Figure 3.2

Petrofac Training Services / June 2010

Figure 3.3

1) Inlet Divertor

2) Vapour Mist Pad

3) Coalescing Plates

4) Straitening Vanes

5) Weir Plate

6) Gas Outlet

7) Vertical

8) Vortex Breaker

9) Sand Jetting Facility

Petrofac Training Services / June 2010

Figure 3.4

Petrofac Training Services / June 2010

Figure 3.5

Petrofac Training Services / June 2010

Figure 3.6

Petrofac Training Services / June 2010

Vous aimerez peut-être aussi

- Separator & Production FacilitiesDocument11 pagesSeparator & Production FacilitiestumiPas encore d'évaluation

- Chap3 - Seperators and Seperation TechniquesDocument37 pagesChap3 - Seperators and Seperation Techniquesghgh140Pas encore d'évaluation

- 3 Phase Separators ( Separators') - Ascom SeparationDocument5 pages3 Phase Separators ( Separators') - Ascom Separationnaveenbaskaran1989Pas encore d'évaluation

- Oil/Water Separators: T P: O WDocument4 pagesOil/Water Separators: T P: O Wvgogulakrishnan100% (1)

- There Phase Oil Water Gas SeparatorsDocument6 pagesThere Phase Oil Water Gas SeparatorsHAMZA GUERFI100% (1)

- Horizontal Three Phase SeparatorDocument1 pageHorizontal Three Phase SeparatorsandeepPas encore d'évaluation

- K.O DrumDocument7 pagesK.O DrumsaririskihasibuanPas encore d'évaluation

- Bucket and Weir Type SeparatorDocument3 pagesBucket and Weir Type SeparatorAdewunmi OlufemiPas encore d'évaluation

- of 3-Phase-Separator PDFDocument25 pagesof 3-Phase-Separator PDFD K SPas encore d'évaluation

- Three Phase Separator DesignDocument5 pagesThree Phase Separator DesignAymen KhlifiPas encore d'évaluation

- Three Phase Separators - Times DefinitionDocument5 pagesThree Phase Separators - Times DefinitionPragathees Waran100% (1)

- Saeid Three Phase Separator and API 521 Flare KOD DesignDocument16 pagesSaeid Three Phase Separator and API 521 Flare KOD DesignNila Gama100% (1)

- Glycol Dehydration Instrumentation and ControlsDocument3 pagesGlycol Dehydration Instrumentation and ControlsdndudcPas encore d'évaluation

- User's GuideDocument30 pagesUser's GuideAnonymous Wd2KONPas encore d'évaluation

- Finger Type Slug CatcherDocument41 pagesFinger Type Slug CatcherIrfaan Taufiiqul Rayadi100% (1)

- Sample Problem StatementDocument2 pagesSample Problem Statementsunildubey02Pas encore d'évaluation

- Design of 3 Phase Production SeparatorDocument8 pagesDesign of 3 Phase Production Separatormyself_riteshPas encore d'évaluation

- Produced Water Treatment Lecture NotesDocument34 pagesProduced Water Treatment Lecture Notesganesh100% (2)

- 11-4080 HYSYS Relief Valve Sizing Demo Guide FinalDocument18 pages11-4080 HYSYS Relief Valve Sizing Demo Guide FinalNoman Abu-FarhaPas encore d'évaluation

- Relief and Blowdown System FlaringDocument5 pagesRelief and Blowdown System FlaringRicardo NapitupuluPas encore d'évaluation

- High Fidelity Dynamic Simulation of Compressor SystemsDocument9 pagesHigh Fidelity Dynamic Simulation of Compressor SystemsTrần Quang ThắngPas encore d'évaluation

- APEX Deoiler HydrocycloneDocument9 pagesAPEX Deoiler HydrocycloneChem.EnggPas encore d'évaluation

- Flow StationDocument28 pagesFlow StationqualityPas encore d'évaluation

- Three Phase Separator - Liquid InternalsDocument7 pagesThree Phase Separator - Liquid Internalsmehul10941Pas encore d'évaluation

- SeparatersDocument23 pagesSeparatersArdin BarzanPas encore d'évaluation

- HTP - PRC.PRG.10010-Process Plant Steady State Simulation-Iulie 2009 PDFDocument11 pagesHTP - PRC.PRG.10010-Process Plant Steady State Simulation-Iulie 2009 PDFFlorin Daniel Anghel100% (1)

- Part 2 - Single Phase FlowDocument34 pagesPart 2 - Single Phase FlowAbd Rashid Abd AzizPas encore d'évaluation

- Quantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantDocument12 pagesQuantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantmofiyinfoluPas encore d'évaluation

- PDOC 3phase Separator Operation ManualDocument20 pagesPDOC 3phase Separator Operation Manualduazo2009Pas encore d'évaluation

- Three Phase SeparatorsDocument44 pagesThree Phase SeparatorsAtif100% (2)

- Three Phase SeparatorsDocument6 pagesThree Phase SeparatorsJatin RamboPas encore d'évaluation

- Separador BifásicoDocument42 pagesSeparador BifásicoAldoDeLaCerda100% (1)

- 2nd Stage Separator: For Production Conditions / The Process Can Be AchievedDocument5 pages2nd Stage Separator: For Production Conditions / The Process Can Be AchievedihsansepalmaPas encore d'évaluation

- Open Drain Separator SizingDocument23 pagesOpen Drain Separator SizingSuchart TarasapPas encore d'évaluation

- Hysys CompressDocument4 pagesHysys CompressVidyasenPas encore d'évaluation

- Three Phase Separator Sizing - No InternalDocument2 pagesThree Phase Separator Sizing - No InternalSaeid Rahimi MofradPas encore d'évaluation

- DP Level Measurement BasicsDocument2 pagesDP Level Measurement Basicsjsrplc7952Pas encore d'évaluation

- Separator GeneralDocument12 pagesSeparator GeneralMeshariAlEnezi100% (1)

- Flow AssuranceDocument47 pagesFlow Assuranceabhi1648665100% (1)

- Flow Assurance IntroductionDocument71 pagesFlow Assurance IntroductionClement ChimaPas encore d'évaluation

- FLARENETDocument19 pagesFLARENETrohmanPas encore d'évaluation

- 2005 Crude Oil Emulsions - A State-Of-The-Art ReviewDocument9 pages2005 Crude Oil Emulsions - A State-Of-The-Art ReviewOscar RoaPas encore d'évaluation

- ABC Guide To Gas Hydrates Awareness: Revision: 1.0 Oct 2002Document32 pagesABC Guide To Gas Hydrates Awareness: Revision: 1.0 Oct 2002Amir Abaza100% (1)

- Process Engineer - Blowdown Valve (BDV) To Flare SystemDocument2 pagesProcess Engineer - Blowdown Valve (BDV) To Flare Systemkenoly123Pas encore d'évaluation

- 11-3842 PSV Jump StartDocument20 pages11-3842 PSV Jump StartchikukotwalPas encore d'évaluation

- Flow Assurance Presentation - Rune Time 3Document27 pagesFlow Assurance Presentation - Rune Time 3Adeel Jamil100% (1)

- Slug Catcher-Finger Type DesignDocument5 pagesSlug Catcher-Finger Type Designdndudc86% (7)

- MysepDocument16 pagesMysepsterlingPas encore d'évaluation

- KO DrumDocument3 pagesKO DrumArynda Dimas SadewoPas encore d'évaluation

- Real Separator GuideDocument23 pagesReal Separator GuideMuhammad Athar100% (6)

- Natural Gas Quality Enhancement: Training Report ONDocument20 pagesNatural Gas Quality Enhancement: Training Report ONRajkishan GuptaPas encore d'évaluation

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979D'EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonPas encore d'évaluation

- Vessel Internal &functionDocument31 pagesVessel Internal &functionnawarsPas encore d'évaluation

- 10 Separation Systems 2007 Petroleum Production EngineeringDocument16 pages10 Separation Systems 2007 Petroleum Production EngineeringHaziq YussofPas encore d'évaluation

- Separator Vessel: Ms. Shreya SahajpalDocument6 pagesSeparator Vessel: Ms. Shreya SahajpalShreya Sahajpal KaushalPas encore d'évaluation

- Lec 2 (Refinery)Document18 pagesLec 2 (Refinery)Alan Mob4Pas encore d'évaluation

- Separator VesselDocument15 pagesSeparator VesselShaho Abdulqader Mohamedali67% (3)

- Three-Phase Separator .: University of KerbalaDocument11 pagesThree-Phase Separator .: University of Kerbalamuhiemin MazinPas encore d'évaluation

- Introduction To Production SeparatorsDocument37 pagesIntroduction To Production Separatorsjps21Pas encore d'évaluation

- Piping & Instrumentation DiagramDocument20 pagesPiping & Instrumentation DiagramOladayo Siyanbola100% (2)

- WellheadsDocument138 pagesWellheadsOladayo SiyanbolaPas encore d'évaluation

- Oil & Gas FundamentalsDocument40 pagesOil & Gas FundamentalsOladayo Siyanbola100% (1)

- Introduction To Well Integrity - 04 December 2012Document154 pagesIntroduction To Well Integrity - 04 December 2012n73686861Pas encore d'évaluation

- Well Test Design and Well Test Design and Analysis - WTA Analysis - WTADocument3 pagesWell Test Design and Well Test Design and Analysis - WTA Analysis - WTAOladayo SiyanbolaPas encore d'évaluation

- Nodalanalysis Introductiontoinflowandoutflowperformance Next 161121154412Document58 pagesNodalanalysis Introductiontoinflowandoutflowperformance Next 161121154412Jaimin PrajapatiPas encore d'évaluation

- Introduction To Reservoir EngineeringDocument82 pagesIntroduction To Reservoir Engineeringweldsv50% (2)

- Surface Safety ValvesDocument12 pagesSurface Safety ValvesOladayo SiyanbolaPas encore d'évaluation

- Coiled TubingDocument32 pagesCoiled TubingGeetha Bakki100% (2)

- Complete Thesis - (07.04.2018)Document341 pagesComplete Thesis - (07.04.2018)Oladayo SiyanbolaPas encore d'évaluation

- Surface BOP Stack Operations API - Vertical Well Kill SheetDocument0 pageSurface BOP Stack Operations API - Vertical Well Kill Sheetjosesito_amoroso20050% (1)

- Density of Oil Water MixtureDocument2 pagesDensity of Oil Water MixtureOladayo SiyanbolaPas encore d'évaluation

- SM10-Declaration of ISM Company (I.1-R.1)Document1 pageSM10-Declaration of ISM Company (I.1-R.1)Oladayo SiyanbolaPas encore d'évaluation

- QA-RD7AE-V8 English API Formula SheetDocument4 pagesQA-RD7AE-V8 English API Formula SheetYogesh GavaliPas encore d'évaluation

- Distance Learning Drilling Calculations Part 1Document211 pagesDistance Learning Drilling Calculations Part 1Eddy Rochmadi100% (2)

- Reservoir Performance AnalysisDocument30 pagesReservoir Performance AnalysisOladayo Siyanbola100% (1)

- DC Part 1 AnswersDocument32 pagesDC Part 1 AnswersRaJaPas encore d'évaluation

- Standard P I Club - A Master S Guide To Enclosed Space EntryDocument60 pagesStandard P I Club - A Master S Guide To Enclosed Space EntryRihardsPas encore d'évaluation

- Epf Crude Oil TreatmentDocument1 pageEpf Crude Oil Treatmentafroznishat100% (2)

- 3rd Semester Visitation RoasterDocument14 pages3rd Semester Visitation RoasterOladayo SiyanbolaPas encore d'évaluation

- Well LoggingDocument3 pagesWell LoggingOladayo SiyanbolaPas encore d'évaluation

- Evaluating Uncertainty in The VolumesDocument6 pagesEvaluating Uncertainty in The VolumesOladayo SiyanbolaPas encore d'évaluation

- IntroductionDocument13 pagesIntroductionOladayo SiyanbolaPas encore d'évaluation

- History of FeminismDocument2 pagesHistory of FeminismOladayo SiyanbolaPas encore d'évaluation

- The Petroleum Industry BillDocument4 pagesThe Petroleum Industry BillOladayo SiyanbolaPas encore d'évaluation

- Well Loggin1Document3 pagesWell Loggin1Oladayo SiyanbolaPas encore d'évaluation

- Macroscopic Displacement of Fluids in A ReservoirDocument11 pagesMacroscopic Displacement of Fluids in A ReservoirOladayo SiyanbolaPas encore d'évaluation

- Database Management Systems: Lecture - 5Document37 pagesDatabase Management Systems: Lecture - 5harisPas encore d'évaluation

- Bsi 2 A. 175, Alumminium Aloy Bolts Nov 1962 PDFDocument15 pagesBsi 2 A. 175, Alumminium Aloy Bolts Nov 1962 PDFengr_usman04Pas encore d'évaluation

- Electricity: ElectromagnetsDocument17 pagesElectricity: ElectromagnetsAyushJaiswalPas encore d'évaluation

- AlternatorDocument14 pagesAlternatorTaraknath MukherjeePas encore d'évaluation

- Abb Sas GeneralDocument43 pagesAbb Sas Generalsabill arasyidPas encore d'évaluation

- Class 10 CatalogueDocument5 pagesClass 10 CatalogueharishchandraPas encore d'évaluation

- Computer MCQ Test For Nts 4,5,6Document1 pageComputer MCQ Test For Nts 4,5,6Mohsan NaqiPas encore d'évaluation

- Chapter 1 AssignmentDocument4 pagesChapter 1 Assignmenthamster808100% (3)

- DRK109A&B Touch-Screen Bursting Strength TesterDocument2 pagesDRK109A&B Touch-Screen Bursting Strength Testermohamadreza1368Pas encore d'évaluation

- Electricity Markets PDFDocument2 pagesElectricity Markets PDFAhmed KhairiPas encore d'évaluation

- Essilor MR - Blue - 20-1Document132 pagesEssilor MR - Blue - 20-1Primoz DolinsekPas encore d'évaluation

- 20-F201007-SC-010 R0 - Design Calculation of Foam Tank and Fire Pump ShedDocument187 pages20-F201007-SC-010 R0 - Design Calculation of Foam Tank and Fire Pump ShedSaravan KumarPas encore d'évaluation

- Bafbana Module 5Document12 pagesBafbana Module 5VILLANUEVA, RAQUEL NONAPas encore d'évaluation

- MODULE About Derivatives (Basic Calculus)Document10 pagesMODULE About Derivatives (Basic Calculus)Emely Rose Prieto TallonPas encore d'évaluation

- From Navier Stokes To Black Scholes - Numerical Methods in Computational FinanceDocument13 pagesFrom Navier Stokes To Black Scholes - Numerical Methods in Computational FinanceTrader CatPas encore d'évaluation

- Bedia CLS 40 45 GBDocument36 pagesBedia CLS 40 45 GBkadir kayaPas encore d'évaluation

- Confidence IntervalDocument22 pagesConfidence Intervallloyd balinsuaPas encore d'évaluation

- Remote Sensing of Environment: SciencedirectDocument28 pagesRemote Sensing of Environment: SciencedirectAmmara HabibPas encore d'évaluation

- Question Bank - PolyDocument16 pagesQuestion Bank - Polyمحمود صابرPas encore d'évaluation

- Class 10 - Maths - Arithmetic ProgressionsDocument51 pagesClass 10 - Maths - Arithmetic ProgressionsgajulasureshPas encore d'évaluation

- Maths4u SylDocument87 pagesMaths4u SylDJPas encore d'évaluation

- ASME Boiler Feed WaterDocument30 pagesASME Boiler Feed WaterHendri KurniawanPas encore d'évaluation

- Product Perspective: XP Button, LV Button and VK FrameDocument54 pagesProduct Perspective: XP Button, LV Button and VK FrameGokul krishnanPas encore d'évaluation

- Smith Meter Microloadnet Operator Reference Manual-A Voir PDFDocument96 pagesSmith Meter Microloadnet Operator Reference Manual-A Voir PDFmehrezPas encore d'évaluation

- BioFluid Mechanics 1Document29 pagesBioFluid Mechanics 1roxannedemaeyerPas encore d'évaluation

- JAGUAR E-TYPE: Assembly Instructions 1: View of The Engine View of The CockpitDocument17 pagesJAGUAR E-TYPE: Assembly Instructions 1: View of The Engine View of The Cockpitfranciss87Pas encore d'évaluation

- A Quick Tutorial On RSLogix Emulator 5000Document9 pagesA Quick Tutorial On RSLogix Emulator 5000slavezerorjPas encore d'évaluation

- Paracetamol Overdose: BW 40 KG Without Fluid RestrictionDocument2 pagesParacetamol Overdose: BW 40 KG Without Fluid RestrictionAndy TanPas encore d'évaluation

- Anomaly Detection Principles and Algorithms: Mehrotra, K.G., Mohan, C.K., Huang, HDocument1 pageAnomaly Detection Principles and Algorithms: Mehrotra, K.G., Mohan, C.K., Huang, HIndi Wei-Huan HuPas encore d'évaluation