Académique Documents

Professionnel Documents

Culture Documents

Aisc Edition Member Dimensions and Properties Viewer

Transféré par

muh2006Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aisc Edition Member Dimensions and Properties Viewer

Transféré par

muh2006Droits d'auteur :

Formats disponibles

"AISC 14.1 Properties Viewer.

xls" Program

Version 1.0

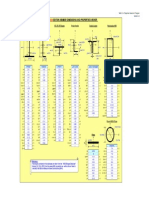

AISC 14th EDITION MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single Angles Double Angles Rectangular HSS

Y Y Y Y Y Y

k1=0.875

k tf=0.685 tf=0.273 b=6 t(des)=0.233

bf=5.75 t=0.375

y(bar)=1.07 x(bar)=1.44

x(bar)=0.443 tf=0.36 d=6 t=0.4375 X

d=21.1 T X d=3 X X d=6 h=5 X

d=5.09 X y(bar)=2.43

tw=0.43 tw=0.132 tw=0.24 b=8 y(bar)=1.62

(0, 3/8, or 3/4

bf=8.27 bf=1.37 gap) b=5

W21X68 C3X3.5 WT5X11 L8X6X7/16 2L6X6X3/8 HSS5X5X1/4

A= 20 in.^2 A= 1.09 in.^2 A= 3.24 in.^2 A= 5.99 in.^2 A= 8.76 in.^2 A= 4.3 in.^2

d= 21.1 in. d= 3 in. d= 5.09 in. d= 6 in. d= 6 in. h= 5 in.

tw = 0.43 in. tw = 0.132 in. tw = 0.24 in. b= 8 in. b= 6 in. b= 5 in.

bf = 8.27 in. bf = 1.37 in. bf = 5.75 in. t= 0.4375 in. t= 0.375 in. t(des) = 0.233 in.

tf = 0.685 in. tf = 0.273 in. tf = 0.36 in. k(des) = 0.938 in. wt./ft. = 29.8 plf. wt./ft. = 15.62 plf.

k(des) = 1.19 in. k(des) = 0.6875 in. k(des) = 0.66 in. k(det) = 0.9375 in. Ix = 30.8 in.^4 Ix = 16 in.^4

k(det) = 1.375 in. k(det) = 0.6875 in. k(det) = 0.9375 in. wt./ft. = 20.2 plf. Sx = 7.02 in.^3 Sx = 6.41 in.^3

k1 = 0.875 in. T= 1.625 in. gage = 2.75 in. Ix = 39.3 in.^4 rx = 1.87 in. rx = 1.93 in.

T= 18.375 in. gage = --- in. wt./ft. 11 plf. Sx = 7.06 in.^3 y(bar) = 1.62 in. Zx = 7.61 in.^3

gage = 5.5 in. rts = 0.456 in. bf/(2*tf) 7.99 rx = 2.56 in. Zx = 12.5 in.^3 Iy = 16 in.^4

wt./ft. = 68 plf. ho = 2.73 in. d/tw 21.2 y(bar) = 2.43 in. yp = 0.365 in. Sy = 6.41 in.^3

bf/(2*tf) 6.04 wt./ft. = 3.5 plf. Ix = 6.88 in.^4 Zx = 12.9 in.^3 Iy = 53.9 in. ry = 1.93 in.

h/tw = 43.6 eo = 0.493 in. Sx = 1.72 in.^3 yp = 1.15 in. Sy = 8.98 in. Zy = 7.61 in.^3

Ix = 1480 in.^4 Ix = 1.57 in.^4 rx = 1.46 in. Iy = 19.3 in.^4 ry = 2.48 in. h(flat) = 3.875 in.

Sx = 140 in.^3 Sx = 1.04 in.^3 y(bar) = 1.07 in. Sy = 4.23 in.^3 Zy = 14.2 b(flat) = 3.875 in.

rx = 8.6 in. rx = 1.2 in. Zx = 3.02 in.^3 ry = 1.8 in. ro(bar) = 3.42 J= 25.8 in.^4

Zx = 160 in.^3 Zx = 1.24 in.^3 yp = 0.282 in. x(bar) = 1.44 in. H= 0.824 C= 10.5 in.^3

Iy = 64.7 in.^4 Iy = 0.169 in.^4 Iy = 5.71 in.^4 Zy = 7.5 in.^3 Qs = 0.998 A(surf) = 1.6 ft^2/ft

Sy = 15.7 in.^3 Sy = 0.182 in.^3 Sy = 1.99 in.^3 xp = 0.374 in.

ry = 1.8 in. ry = 0.394 in. ry = 1.33 in. Iz = 10.2 in.^4 Round HSS & Pipes

Zy = 24.4 in.^3 x(bar) = 0.443 in. Zy = 3.05 in.^3 Sz = 3.51 in.^3 Y

rts = 2.17 in. Zy = 0.364 in.^3 Qs = 0.834 rz = 1.31 in. t(nom)=0.322

ho = 20.4 in. xp = 0.296 in. J= 0.119 in.^4 TAN() = 0.559

J= 2.45 in.^4 J= 0.0226 in.^4 Cw = 0.107 in.^6 Qs = 0.85

Cw = 6760 in.^6 Cw = 0.276 in.^6 a= 1.53 in. J= 0.396 in.^4 Plates O.D.=8.63 X

a= 84.52 in. a= 5.62 in. ro(bar) = 2.16 in. Cw = 1.55 in.^6 Y

W no = 42.2 in.^2 ro(bar) = 1.57 in. H= 0.83 a= 3.18 in. t=0.375 I.D.=7.98

Sw = 59.8 in.^4 H= 0.646 ro(bar) = 4.02 in. X

Qf = 27.4 in.^3 H= b=12 Pipe8STD

Qw = 78.7 in.^3 A= 7.85 in.^2

t= 0.375 in. O.D. = 8.63 in.

b= 12 in. I.D. = 7.98 in.

wt./ft. = 15.31 plf. t(nom) = 0.322 in.

A= 4.50 in.^2 t(des) = 0.3 in.

Reference: Ix = 0.053 in.^4 wt./ft. = 28.6 plf.

The shapes contained in this database are taken from the "AISC Shapes Database" Sx = 0.281 in.^3 Ix = Iy = 68.1 in.^4

Version 14.1 (Oct. 2013) from the www.AISC.org website as well as those listed in rx = 0.108 in. Sx = Sy = 15.8 in.^3

the AISC 14th Edition Manual of Steel Construction (2011).

Iy = 54.00 in.^4 rx = ry = 2.95 in.

Sy = 9.00 in.^3 Zx = Z y = 20.8 in.^3

ry = 3.46 in. J= 136 in.^4

J= 54.05 in.^4 C= --- in.^3

"AISC 14.1 Properties Viewer.xls" Program

Version 1.0

NOMENCLATURE FOR AISC VERSION 14.1 MEMBER PROPERTIES AND DIMENSIONS:

A= Cross-sectional area of member (in.^2)

d= Depth of member, parallel to Y-axis (in.)

h= Depth of member, parallel to Y-axis (in.)

tw = Thickness of web of member (in.)

bf = Width of flange of member, parallel to X-axis (in.)

b= Width of member, parallel to X-axis (in.)

tf = Thickness of flange of member (in.)

k= Distance from outer face of flange to web toe of fillet (in.)

k1 = Distance from web centerline to flange toe of fillet (in.)

T= Distance between fillets for wide-flange or channel shape = d(nom)-2*k(det) (in.)

gage = Standard gage (bolt spacing) for member (in.) (Note: gages for angles are available by viewing comment box at cell K18.)

Ix = Moment of inertia of member taken about X-axis (in.^4)

Sx = Elastic section modulus of member taken about X-axis (in.^3)

rx = Radius of gyration of member taken about X-axis (in.) = SQRT(I x/A)

Iy = Moment of inertia of member taken about Y-axis (in.^4)

Sy = Elastic section modulus of member taken about Y-axis (in.^3)

ry = Radius of gyration of member taken about Y-axis (in.) = SQRT(I y/A)

Zx = Plastic section modulus of member taken about X-axis (in.^3)

Zy = Plastic section modulus of member taken about Y-axis (in.^3)

rts = SQRT(SQRT(Iy*Cw)/Sx) (in.)

xp = horizontal distance from designated member edge to plastic neutral axis (in.)

yp = vertical distance from designated member edge to plastic neutral axis (in.)

ho = Distance between centroid of flanges, d-tf (in.)

J= Torsional moment of inertia of member (in.^4)

Cw = Warping constant (in.^6)

C= Torsional constant for HSS shapes (in.^3)

a= Torsional property, a = SQRT(E*Cw/G*J) (in.)

E= Modulus of elasticity of steel = 29,000 ksi

G= Shear modulus of elasticity of steel = 11,200 ksi

W no = Normalized warping function at a point at the flange edge (in.^2)

Sw = Warping statical moment at a point on the cross section (in.^4)

Qf = Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Qw = Statical moment at the mid-depth of the section (in.^3)

x(bar) = Distance from outside face of web of channel shape or outside face of angle leg to Y-axis (in.)

y(bar) = Distance from outside face of outside face of flange of WT or angle leg to Y-axis (in.)

eo = Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) t f*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

xo = x-coordinate of shear center with respect to the centroid of the section (in.)

yo = y-coordinate of shear center with respect to the centroid of the section (in.)

ro(bar) = Polar radius of gyration about the shear center = SQRT(xo^2+yo^2+(Ix+Iy)/A) (in.)

H= Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

LLBB = Long legs back-to-back for double angles

SLBB = Short legs back-to-back for double angles

h(flat) = The workable flat (straight) dimension along the height, h (in.)

b(flat) = The workable flat (straight) dimension along the width, b (in.)

A(surf) = The total surface area of a rectangular or square HSS section (ft.^2/ft.)

STD = Standard weight (Schedule 40) pipe section

XS = Extra strong (Schedule 80) pipe section

XXS = Double-extra strong pipe section

Vous aimerez peut-être aussi

- AISC Properties ViewerDocument4 pagesAISC Properties ViewerGANESHPas encore d'évaluation

- Programas-mas-base-de-Datos ColonosDocument135 pagesProgramas-mas-base-de-Datos ColonosJesus SolorzanoPas encore d'évaluation

- AISC Properties ViewerDocument3 pagesAISC Properties Viewerchriscivil12Pas encore d'évaluation

- Ixx Iyy CalcDocument13 pagesIxx Iyy CalcjurieskPas encore d'évaluation

- CalDocument43 pagesCalPrasaad SlvPas encore d'évaluation

- AISC 14.1 Properties ViewerDocument2 pagesAISC 14.1 Properties ViewerJay GalvanPas encore d'évaluation

- Design of Plate Elements - v1.7Document49 pagesDesign of Plate Elements - v1.7faridullah100% (1)

- Moment Distribution Method On Structural MemberDocument98 pagesMoment Distribution Method On Structural MemberPaul Henry Trono CunananPas encore d'évaluation

- Jindal SectionsDocument2 pagesJindal Sectionsanon_107812982Pas encore d'évaluation

- Column Effective LengthDocument1 pageColumn Effective LengthjanethPas encore d'évaluation

- MOMENT CONNECTION-AISC-extended-r5Document24 pagesMOMENT CONNECTION-AISC-extended-r5raghav abudhabi0% (1)

- Section Propeties To Staad Parametric FormationDocument160 pagesSection Propeties To Staad Parametric FormationVignesh VenkatasubramanianPas encore d'évaluation

- Steel Section Properties From ArcellorDocument69 pagesSteel Section Properties From Arcellorsymon ellimacPas encore d'évaluation

- Weld Group 01Document11 pagesWeld Group 01Sneyder NeyPas encore d'évaluation

- Xtra Strong (XS) Size Steel Pipe Weights TAble CalculatorDocument1 pageXtra Strong (XS) Size Steel Pipe Weights TAble CalculatorshownpuPas encore d'évaluation

- Haitham Al GabryDocument90 pagesHaitham Al GabryKhaledMostafaPas encore d'évaluation

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosPas encore d'évaluation

- Base Plate Very EccentricityDocument7 pagesBase Plate Very Eccentricityอัชวิน เจริญสินPas encore d'évaluation

- Ground Floor Columns at B1, B2 EtcDocument12 pagesGround Floor Columns at B1, B2 EtcRennie Dourado PlateroPas encore d'évaluation

- 00000-Metri-Imperial Unit ToolsDocument4 pages00000-Metri-Imperial Unit ToolsPop JiPas encore d'évaluation

- Sizing Steel Sections For BeamsDocument25 pagesSizing Steel Sections For BeamsAnonymous ujfx6mPas encore d'évaluation

- DesignDocument13 pagesDesignAnshulGuptaPas encore d'évaluation

- Steel ColumnsDocument40 pagesSteel Columnsagphyo770% (1)

- Lashing Lug Pedestal Anchor & Concrete DesignDocument23 pagesLashing Lug Pedestal Anchor & Concrete DesignMyunSu GooPas encore d'évaluation

- Indian Steel Weight Calculator FreeDocument1 pageIndian Steel Weight Calculator Freeparth shahPas encore d'évaluation

- Pipe Rack Foundation DesignDocument29 pagesPipe Rack Foundation DesignYatendra TyagiPas encore d'évaluation

- Seismic AnalysisDocument13 pagesSeismic AnalysisJea Manguing-YubalPas encore d'évaluation

- Crimp PLTDocument5 pagesCrimp PLTSai SushankPas encore d'évaluation

- AISC Properties ViewerDocument2 pagesAISC Properties ViewerNoeBongaPas encore d'évaluation

- AISC Properties DatabaseDocument7 pagesAISC Properties DatabaseShekh Muhsen Uddin AhmedPas encore d'évaluation

- SPACE GASS Revit Structure LinkDocument6 pagesSPACE GASS Revit Structure LinkozbuildPas encore d'évaluation

- Roger Caffin's Catenary Curve CalculatorDocument6 pagesRoger Caffin's Catenary Curve Calculatorviggen_one2002Pas encore d'évaluation

- INDIAN Steel TableDocument6 pagesINDIAN Steel TableKingshuk SarkarPas encore d'évaluation

- Bearing CheckDocument6 pagesBearing CheckdhanushkaPas encore d'évaluation

- PadeyeDocument14 pagesPadeyeMarshall Minggat AmpiPas encore d'évaluation

- Column DesignDocument4 pagesColumn DesignRafsanjani AbasPas encore d'évaluation

- Deck Girder - Top GirderDocument3 pagesDeck Girder - Top GirdervibishnanPas encore d'évaluation

- The Design Is Adequate.: A W B L T (Weight PDocument1 pageThe Design Is Adequate.: A W B L T (Weight PAhmed AjelPas encore d'évaluation

- Steel 2022 BeamDocument26 pagesSteel 2022 BeamRaven Von DizonPas encore d'évaluation

- Aisc - Chapter JDocument13 pagesAisc - Chapter JDinesh KumarPas encore d'évaluation

- Welding Capacity Analysis: Weld Is Adequate & Stress Ratio 0.86Document1 pageWelding Capacity Analysis: Weld Is Adequate & Stress Ratio 0.86Engr Benalito A Catap IIIPas encore d'évaluation

- Design Base Plate For I Beam - Bottom BracketDocument1 pageDesign Base Plate For I Beam - Bottom BracketCon CanPas encore d'évaluation

- 15 Ton Tank Concrete PlatformDocument1 page15 Ton Tank Concrete PlatformerickquintoPas encore d'évaluation

- Structural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchesDocument4 pagesStructural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchessitheeqPas encore d'évaluation

- Steel Beam Design As Per AISC ASDDocument3 pagesSteel Beam Design As Per AISC ASDmohsenPas encore d'évaluation

- AASHTO Simplified Shear CalcDocument9 pagesAASHTO Simplified Shear CalcSharyn PolleyPas encore d'évaluation

- Beam CalculationDocument49 pagesBeam CalculationRobin Charles SamuelPas encore d'évaluation

- Load Calculation: Self-Weight of Materials SL No Material Density (KN/M)Document6 pagesLoad Calculation: Self-Weight of Materials SL No Material Density (KN/M)ajith chandranPas encore d'évaluation

- Conexion 1Document262 pagesConexion 1luisfdogaviriaPas encore d'évaluation

- Support CalculationDocument16 pagesSupport Calculationhosny1987Pas encore d'évaluation

- Sfex Pad Eyes Calculations 35T - 32MMDocument1 pageSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaPas encore d'évaluation

- Saddle Angle - Formula K - 12.28.20Document2 pagesSaddle Angle - Formula K - 12.28.20Rey FiedacanPas encore d'évaluation

- Detail Dimensi Material GRPDocument5 pagesDetail Dimensi Material GRPdwi noviana nugrohoPas encore d'évaluation

- Design of Staircase - 10182021Document1 pageDesign of Staircase - 10182021Bry RamosPas encore d'évaluation

- 11 RECT TANK 4.0M X 3.0M X 3.3M H - Flocculator PDFDocument3 pages11 RECT TANK 4.0M X 3.0M X 3.3M H - Flocculator PDFaaditya chopadePas encore d'évaluation

- Tabla de PerfilesDocument3 pagesTabla de PerfilesYomara Vera GonzálezPas encore d'évaluation

- Aisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosDocument3 pagesAisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosJharri E HuertoPas encore d'évaluation

- Aisc Edition Member Dimensions and Properties ViewerDocument4 pagesAisc Edition Member Dimensions and Properties Viewerjuan carlos tinta mamaniPas encore d'évaluation

- Programas Mas Base de DatosDocument100 pagesProgramas Mas Base de DatosJesus SolorzanoPas encore d'évaluation

- Diseño de Elementos en Tracción - LRFDDocument263 pagesDiseño de Elementos en Tracción - LRFDAlejandro CardenasPas encore d'évaluation

- Architectural SymbolsDocument34 pagesArchitectural SymbolsNiallburke100% (4)

- TX DRILLED SHAFT FOUNDATION - s416Document6 pagesTX DRILLED SHAFT FOUNDATION - s416muh2006Pas encore d'évaluation

- Steel QuizDocument2 pagesSteel Quizmuh2006Pas encore d'évaluation

- Welding Drawings 1Document18 pagesWelding Drawings 1muh2006Pas encore d'évaluation

- Necchi 524Document55 pagesNecchi 524muh2006Pas encore d'évaluation

- Welding Drawings 2Document10 pagesWelding Drawings 2cfcshakerPas encore d'évaluation

- DWSSDocument5 pagesDWSSCarlos Valverde PortillaPas encore d'évaluation

- ShearReinfCalc01 09 07Document6 pagesShearReinfCalc01 09 07n5i4s3h2a1Pas encore d'évaluation

- Torsion Spring Instruction ManualDocument4 pagesTorsion Spring Instruction Manualmuh2006Pas encore d'évaluation

- Beam AshrafDocument2 pagesBeam Ashrafmuh2006Pas encore d'évaluation

- Lintel DesignDocument5 pagesLintel DesignZayyan Romjon100% (1)

- Fusion Iomemory Iodrive2Document24 pagesFusion Iomemory Iodrive2muh2006Pas encore d'évaluation

- Symmetric Profile MatrixDocument2 pagesSymmetric Profile Matrixmuh2006Pas encore d'évaluation

- Road EstimateDocument2 pagesRoad EstimateCarlos Valverde PortillaPas encore d'évaluation

- Tacoma: Customer Experience Center 1-800-331-4331Document22 pagesTacoma: Customer Experience Center 1-800-331-4331muh2006Pas encore d'évaluation

- Torsional Section Properties of Steel ShapesDocument19 pagesTorsional Section Properties of Steel Shapessm8575100% (9)

- CraneBeam v1 1Document39 pagesCraneBeam v1 1satya_jayantiPas encore d'évaluation

- Torsional Section Properties of Steel ShapesDocument19 pagesTorsional Section Properties of Steel Shapessm8575100% (9)

- Torsional Section Properties of Steel ShapesDocument19 pagesTorsional Section Properties of Steel Shapessm8575100% (9)

- Torsional Section Properties of Steel ShapesDocument19 pagesTorsional Section Properties of Steel Shapessm8575100% (9)

- W1 - EN - Anchor Selector Chart 2019 05 24Document1 pageW1 - EN - Anchor Selector Chart 2019 05 24garpheetPas encore d'évaluation

- Weld Group MethodDocument10 pagesWeld Group Methodmuh2006Pas encore d'évaluation

- أسئلة إمتحان بلدية الشارقة للمهندسينDocument11 pagesأسئلة إمتحان بلدية الشارقة للمهندسينossmaaPas encore d'évaluation

- Torsional Section Properties of Steel ShapesDocument19 pagesTorsional Section Properties of Steel Shapessm8575100% (9)

- Torsional Section Properties of Steel ShapesDocument19 pagesTorsional Section Properties of Steel Shapessm8575100% (9)

- Mooncalendar Worksheet-2021Document6 pagesMooncalendar Worksheet-2021muh2006100% (1)

- Lateral Force Resisting System: Shear Walls 1Document42 pagesLateral Force Resisting System: Shear Walls 1muh2006Pas encore d'évaluation

- FEMA P-2139-2 Wood 508Document366 pagesFEMA P-2139-2 Wood 508muh2006Pas encore d'évaluation

- FEMA P-2139-4 Steel 508Document208 pagesFEMA P-2139-4 Steel 508muh2006Pas encore d'évaluation

- FEMA P-2139-1 Commonalities 508Document154 pagesFEMA P-2139-1 Commonalities 508muh2006Pas encore d'évaluation

- 0901b8038042b661 PDFDocument8 pages0901b8038042b661 PDFWaqasAhmedPas encore d'évaluation

- I5386-Bulk SigmaDocument1 pageI5386-Bulk SigmaCleaver BrightPas encore d'évaluation

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDocument2 pagesHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaPas encore d'évaluation

- ProAim InstructionsDocument1 pageProAim Instructionsfeli24arias06Pas encore d'évaluation

- Qualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Document23 pagesQualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Saqlain Siddiquie100% (1)

- Learner Guide HDB Resale Procedure and Financial Plan - V2Document0 pageLearner Guide HDB Resale Procedure and Financial Plan - V2wangks1980Pas encore d'évaluation

- Options Trading For Beginners Aug15 v1Document187 pagesOptions Trading For Beginners Aug15 v1Glo BerriPas encore d'évaluation

- Catalog enDocument292 pagesCatalog enSella KumarPas encore d'évaluation

- Elb v2 ApiDocument180 pagesElb v2 ApikhalandharPas encore d'évaluation

- Land Use Paln in La Trinidad BenguetDocument19 pagesLand Use Paln in La Trinidad BenguetErin FontanillaPas encore d'évaluation

- Sem 4 - Minor 2Document6 pagesSem 4 - Minor 2Shashank Mani TripathiPas encore d'évaluation

- Troubleshooting For Rb750Glr4: Poe Does Not WorkDocument7 pagesTroubleshooting For Rb750Glr4: Poe Does Not Workjocimar1000Pas encore d'évaluation

- Pradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural CitizensDocument2 pagesPradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural Citizenssairam namakkalPas encore d'évaluation

- Spine Beam - SCHEME 4Document28 pagesSpine Beam - SCHEME 4Edi ObrayanPas encore d'évaluation

- ESK-Balcony Air-ADocument2 pagesESK-Balcony Air-AJUANKI PPas encore d'évaluation

- TNCT Q2 Module3cDocument15 pagesTNCT Q2 Module3cashurishuri411100% (1)

- Carry Trade Calculator 1.54Document3 pagesCarry Trade Calculator 1.54Gabriel RomanPas encore d'évaluation

- DevelopmentPermission Handbook T&CPDocument43 pagesDevelopmentPermission Handbook T&CPShanmukha KattaPas encore d'évaluation

- Mcqs in Wills and SuccessionDocument14 pagesMcqs in Wills and Successionjudy andrade100% (1)

- Characteristics of Planetary Candidates Observed by Kepler, IIDocument106 pagesCharacteristics of Planetary Candidates Observed by Kepler, IIRick FeedPas encore d'évaluation

- Electric Arc Furnace STEEL MAKINGDocument28 pagesElectric Arc Furnace STEEL MAKINGAMMASI A SHARAN100% (3)

- Dunham Bush Midwall Split R410a InverterDocument2 pagesDunham Bush Midwall Split R410a InverterAgnaldo Caetano100% (1)

- VB 850Document333 pagesVB 850Laura ValentinaPas encore d'évaluation

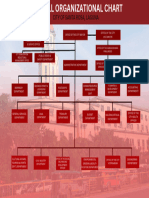

- Org ChartDocument1 pageOrg Chart2021-101781Pas encore d'évaluation

- EP2120 Internetworking/Internetteknik IK2218 Internets Protokoll Och Principer Homework Assignment 4Document5 pagesEP2120 Internetworking/Internetteknik IK2218 Internets Protokoll Och Principer Homework Assignment 4doyaPas encore d'évaluation

- Two 2 Page Quality ManualDocument2 pagesTwo 2 Page Quality Manualtony sPas encore d'évaluation

- Oops in PythonDocument64 pagesOops in PythonSyed SalmanPas encore d'évaluation

- Risk and Uncertainty in Estimating and TenderingDocument16 pagesRisk and Uncertainty in Estimating and TenderingHaneefa ChPas encore d'évaluation

- Fcode 54 en El SytucDocument2 pagesFcode 54 en El SytucAga MenonPas encore d'évaluation

- 11 TR DSU - CarrierDocument1 page11 TR DSU - Carriercalvin.bloodaxe4478100% (1)