Académique Documents

Professionnel Documents

Culture Documents

DIN en ISO 14175-2008-06 - Welding Consumables, Gases and Gas Mixtures For Fusion Welding and Allied Processes

Transféré par

Eduardo Javier Granados SanchezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DIN en ISO 14175-2008-06 - Welding Consumables, Gases and Gas Mixtures For Fusion Welding and Allied Processes

Transféré par

Eduardo Javier Granados SanchezDroits d'auteur :

Formats disponibles

DEUTSCHE NORM June 2008

DIN EN ISO 14175

D

ICS 25.160.20; 71.100.20 Supersedes

DIN EN 439:1995-05

Welding consumables

Gases and gas mixtures for fusion welding and allied processes

(ISO 14175:2008)

English version of DIN EN ISO 14175:2008-06

Schweizustze

Gase und Mischgase fr das Lichtbogenschweien und verwandte Prozesse

(ISO 14175:2008)

Englische Fassung DIN EN ISO 14175:2008-06

Document comprises 13 pages

No part of this standard may be reproduced without prior permission of

DIN Deutsches Institut fr Normung e. V., Berlin. Beuth Verlag GmbH, 10772 Berlin, Germany,

has with

Provided by IHS under license the DIN

exclusive right of sale for German Standards (DIN-Normen). License provided by I.H.S. Germany

English price group 9

www.din.de !$Nr"

For Internal Use Only www.beuth.de 1439379

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

National foreword

This standard has been published in accordance with a decision taken by Technical Committee CEN/TC 121

Welding (Secretariat: DIN, Germany) to adopt, without alteration, International Standard ISO 14175 as a

European Standard. ISO 14175:2008 was prepared by Technical Committee ISO/TC 44/SC 3 Welding

consumables (Secretariat: ANSI, USA).

The responsible German body involved in its preparation was the Normenausschuss Schweitechnik

(Welding Standards Committee), Technical Committee NA 092-00-03 AA Schweizustze (DVS AG W 5).

The DIN Standards corresponding to the International Standards referred to in the EN are as follows:

ISO 4063 DIN EN ISO 4063

Amendments

This standard differs from DIN EN 439:1995-05 as follows:

a) The content of International Standard ISO 14175:2008 has been adopted in full.

b) The scope has been extended to include, among others, laser welding, laser cutting and arc braze

welding.

c) Clause 3 Terms and definitions has been included.

d) Standard designations have been modified (ISO standard designations).

Previous editions

DIN 8559: 1964-08

DIN 32526: 1978-08

DIN EN 439: 1994-10, 1995-05

National Annex NA

(informative)

Bibliography

DIN EN ISO 4063, Welding and allied processes Nomenclature of processes and reference numbers

2

Provided by IHS under license with DIN License provided by I.H.S. Germany

For Internal Use Only

Uncontrolled copy when printed

EUROPEAN STANDARD EN ISO 14175

NORME EUROPENNE

EUROPISCHE NORM March 2008

ICS 25.160.20; 71.100.20 Supersedes EN 439:1994

English Version

Welding consumables - Gases and gas mixtures for fusion

welding and allied processes (ISO 14175:2008)

Produits consommables pour le soudage - Gaz et Schweizustze - Gase und Mischgase fr das

mlanges gazeux pour le soudage par fusion et les Lichtbogenschweien und verwandte Prozesse

techniques connexes (ISO 14175:2008) (ISO 14175:2008)

This European Standard was approved by CEN on 7 February 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the

official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMIT EUROPEN DE NORMALISATION

EUROPISCHES KOMITEE FR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

2008 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN ISO 14175:2008: E

worldwide for CEN national Members.

Provided by IHS under license with DIN License provided by I.H.S. Germany

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

: -

EN ISO 14175:2008

: (E)

Foreword

This document (EN ISO 14175:2008) has been prepared by Technical Committee ISO/TC 44 "Welding and

allied processes" in collaboration with Technical Committee CEN/TC 121 Welding the secretariat of which is

held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by September 2008, and conflicting national standards shall be

withdrawn at the latest by September 2008.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 439:1994.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain,

Sweden, Switzerland and the United Kingdom.

Endorsement notice

The text of ISO 14175:2008 has been approved by CEN as a EN ISO 14175:2008 without any modification.

2

Provided by IHS under license with DIN License provided by I.H.S. Germany

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

1 Scope

This International Standard specifies requirements for the classification of gases and gas mixtures used in

fusion welding and allied processes including, but not limited to:

tungsten arc welding (Process 141);

gas-shielded metal arc welding (Process 13);

plasma arc welding (Process 15);

plasma arc cutting (Process 83);

laser welding (Process 52);

laser cutting (Process 84);

arc braze welding (Process 972).

NOTE Process numbers are in accordance with ISO 4063.

The purpose of this International Standard is to classify and designate shielding, backing, process and assist

gases in accordance with their chemical properties and metallurgical behaviour as the basis for correct

selection by the user and to simplify the possible qualification procedures.

Gas purities and mixing tolerances are specified as delivered by the supplier (manufacturer) and not at the

point of use.

Gases or gas mixtures may be supplied in either liquid or gaseous form, but when used for welding and allied

processes, the gases are always used in the gaseous form.

Fuel gases, such as acetylene, natural gas, propane, etc., and resonator gases, as used in gas lasers, are not

covered by this International Standard.

Transportation and handling of gases and containers shall be in accordance with local, national and regional

standards and regulations as required.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 31-0:1992, Quantities and units Part 0: General principles

Provided by IHS under license with DIN License provided by I.H.S. Germany 3

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

base gas

major or only component of a pure or mixed gas

3.2

classification

number of this International Standard, followed by the symbol for the gas or gas mixture (main group and sub-

group)

3.3

component

gaseous substance that is essential to the performance of the gas mixture

EXAMPLE In a mixture containing 11 % of CO2 in argon, CO2 is considered a component while argon is the base

gas.

3.4

container

vessel used for the shipment and/or storage of pure or mixed gases in a gaseous or liquid state

3.5

designation

classification plus the symbols for all chemical components plus the nominal composition in volume percent

NOTE Symbols for chemical components are given in 5.2.

EXAMPLE A mixture of argon containing 11 % CO2 is designated as ISO 14175-M20-ArC-11.

3.6

impurity

gaseous substance with chemical composition different from the base gas, component or gas mixture

3.7

mixture

gas consisting of two or more components

3.8

nominal value

percentage value of a component, quoted by the manufacturer or supplier, which corresponds to the general

composition given by the designation

3.9

symbol

main-group and sub-group of a gas mixture

NOTE Symbols are given in Table 2 (see also 5.1).

EXAMPLE The symbol for a mixture of argon containing 11 % CO2 is M20.

4

Provided by IHS under license with DIN License provided by I.H.S. Germany

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

4 Properties of gases

4.1 General

Relevant physical and chemical properties of the gases considered in this International Standard are given in

Table 1.

Table 1 Properties of gas components

Relative Boiling point

Density a Reactivity

Chemical density a at 0,101 MPa

Type of gas (air = 1,293) during

symbol to air

welding

kg/m3 C

Argon Ar 1,784 1,380 185,9 Inert

Helium He 0,178 0,138 268,9 Inert

Carbon dioxide CO2 1,977 1,529 78,5 b Oxidizing

Oxygen O2 1,429 1,105 183,0 Oxidizing

Nitrogen N2 1,251 0,968 195,8 Low reactive c

Hydrogen H2 0,090 0,070 252,8 Reducing

a Specified at 0 C and 0,101 MPa (1,013 bar).

b Sublimation temperature (solid to gas transition temperature).

c The behaviour of nitrogen varies with different materials and applications. Possible influences must be

considered by the user.

4.2 Rounding-off procedure

For purposes of determining compliance with the requirements of this International Standard, the actual test

values obtained shall be subjected to the rounding-off rules of ISO 31-0:1992, Annex B, Rule A. If the

measured values are obtained by equipment calibrated in units other than those of this International Standard,

the measured values shall be converted to the units of this International Standard before rounding off. If an

average value is to be compared to the requirements of this International Standard, rounding off shall be done

only after calculating the average. In the case where the testing standard cited in the normative references of

this International Standard contains instructions for rounding off that conflict with the instructions of this

International Standard, the rounding-off requirements of the testing standard shall apply. The rounded-off

results shall fulfill the requirements of the appropriate table for the classification under test.

5 Classification and designation

5.1 Classification

5.1.1 General

Gases and gas mixtures shall be classified by the number of this International Standard, followed by the

symbol for the gas in accordance with Table 2.

NOTE The classification is based on the reactivity of the gas or gas mixture.

Provided by IHS under license with DIN License provided by I.H.S. Germany 5

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

5.1.2 Main group

The letter codes and numbers used for the main groups are:

I: inert gases and inert gas mixtures;

M1, M2 and M3: oxidising mixtures containing oxygen and/or carbon dioxide;

C: highly oxidising gas and highly oxidising mixtures;

R: reducing gas mixtures;

N: low reactive gas or reducing gas mixtures, containing nitrogen;

O: oxygen;

Z: gas mixtures containing components not listed or mixtures outside the composition ranges listed in

Table 2.

5.1.3 Sub-group

The main groups, except Z, are divided into sub-groups based on the presence and level of different

components having an influence on the reactivity (see Table 2). The values indicated in Table 2 are nominal

values.

5.1.4 Classification examples

EXAMPLE 1 For a gas mixture containing 6 % carbon dioxide, 4 % oxygen in argon:

Classification: ISO 14175 M25

EXAMPLE 2 For a gas mixture containing 30 % helium in argon:

Classification: ISO 14175 I3

EXAMPLE 3 For a gas mixture containing 5 % hydrogen in argon:

Classification: ISO 14175 R1

EXAMPLE 4 For a gas mixture containing 0,05 % of oxygen in argon:

Classification: ISO 14175 Z

5.2 Designation

5.2.1 General

Gases and gas mixtures are designated by the classification (see 5.1) and the symbols of their chemical

components as below, followed by the corresponding nominal composition in volume percent:

Ar: argon

C: carbon dioxide

H: hydrogen

N: nitrogen

6

Provided by IHS under license with DIN License provided by I.H.S. Germany

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

O: oxygen

He: helium

The base gas symbol shall be followed by the symbols for the other components in decreasing order of

percent, followed by the nominal composition values, in volume percent, which are separated by a dash.

5.2.2 Designation examples

EXAMPLE 1 For a gas mixture containing 6 % carbon dioxide, 4 % oxygen in argon:

Classification: ISO 14175 M25

Designation: ISO 14175 M25 ArCO 6/4

EXAMPLE 2 For a gas mixture containing 30 % helium in argon:

Classification: ISO 14175 I3

Designation: ISO 14175 I3 ArHe 30

EXAMPLE 3 For a gas mixture containing 5 % hydrogen in argon:

Classification: ISO 14175 R1

Designation: ISO 14175 R1 ArH 5

EXAMPLE 4 For a gas mixture containing 7,5 % argon, 2,5 % carbon dioxide in helium:

Classification: ISO 14175 M12

Designation: ISO 14175 M12 HeArC 7,5/2,5

For gas mixtures containing components listed, but outside the ranges in Table 2, the letter Z prefixes the

symbol for the base gas and symbols for components as above, followed by the nominal composition values,

in volume percent, which are separated by a dash.

EXAMPLE 5 For a gas mixture containing 0,05 % of oxygen in argon:

Classification: ISO 14175 Z

Designation: ISO 14175 Z ArO 0,05

For gas mixtures containing components not listed in Table 2, the letter Z prefixes the symbol for the base gas

and symbols for components as above, but with a plus sign preceding the unlisted component, followed by the

nominal composition values, in volume percent, which are separated by a dash.

EXAMPLE 6 For a gas mixture containing 0,05 % of xenon, chemical symbol Xe, in argon:

Classification: ISO 14175 Z

Designation: ISO 14175 Z Ar+Xe 0,05

Provided by IHS under license with DIN License provided by I.H.S. Germany 7

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

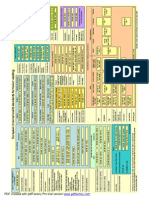

Table 2 Classification of process gases for fusion welding and allied processes

Symbol Components in nominal percentage of volume

Main Sub- Oxidizing Inert Reducing Low reactivity

group group CO2 O2 Ar He H2 N2

I 1 100

2 100

3 balance 0,5 u He u 95

M1 1 0,5 u CO2 u 5 balance a 0,5 u H2 u 5

2 0,5 u CO2 u 5 balance a

3 0,5 u O2 u 3 balance a

4 0,5 u CO2 u 5 0,5 u O2 u 3 balance a

M2 0 5 < CO2 u 15 balance a

1 15 < CO2 u 25 balance a

2 3 < O2 u 10 balance a

3 0,5 u CO2 u 5 3 < O2 u 10 balance a

4 5 < CO2 u 15 0,5 u O2 u 3 balance a

5 5 < CO2 u 15 3 < O2 u 10 balance a

6 15 < CO2 u 25 0,5 u O2 u 3 balance a

7 15 < CO2 u 25 3 < O2 u 10 balance a

M3 1 25 < CO2 u 50 balance a

2 10 < O2 u 15 balance a

3 25 < CO2 u 50 2 < O2 u 10 balance a

4 5 < CO2 u 25 10 < O2 u 15 balance a

5 25 < CO2 u 50 10 < O2 u 15 balance a

C 1 100

2 balance 0,5 u O2 u 30

R 1 balance a 0,5 u H2 u 15

2 balance a 15 < H2 u 50

N 1 100

2 balance a 0,5 u N2 u 5

3 balance a 5 < N2 u 50

4 balance a 0,5 u H2 u 10 0,5 u N2 u 5

5 0,5 u H2 u 50 balance

O 1 100

Z Gas mixtures containing components not listed, or mixtures outside the composition ranges listed.b

a For the purpose of this classification, argon may be substituted partially or completely by helium.

b Two gas mixtures with the same Z-classification may not be interchangeable.

8

Provided by IHS under license with DIN License provided by I.H.S. Germany

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

6 Tolerances of mixtures

Mixture tolerances apply to the volumetric percentage of the components in accordance with Table 3.

Table 3 Mixture tolerances

Component gas nominal concentration

Allowable tolerance

%

>5 10 % of the nominal

1 to 5 0,5 % absolute

<1 Not specified in this International Standard

EXAMPLE 1 An addition of 25 % carbon dioxide nominal value shall not vary by more than 2,5 % (from 22,5 % to

27,5 %).

EXAMPLE 2 An addition of 2,5 % oxygen shall not vary by more than 0,5 % (from 2,0 % to 3,0 %).

7 Purities and dew point

The purity and dew point of gas components and gas mixtures shall meet the requirements of Table 4.

Moisture can be expressed as concentration in ppm (parts per million) or as dew points at 0,101 MPa in C.

Purities and moisture contents for special gas mixtures are not specified in this International Standard.

8 Testing

Testing of gases and gas mixtures for composition and impurity may be carried out by the manufacturer or

supplier using established standards for testing and control (see also Bibliography). The results of the testing

shall fulfil the requirements given in Tables 2 and 3.

Any special or additional testing requirements should be agreed between the purchaser and the manufacturer

or supplier.

Table 4 Minimum requirements on purities and moisture contents of gases and gas mixtures

Purity Dew point at Moisture

Main groups/gas % by volume 0,101 MPa ppm max.

minimum C volume

I inert 99,99 50 40

M1 a gas mix 99,9 50 40

M2 a gas mix 99,9 44 80

M3 a gas mix 99,9 40 120

Ca carbon dioxide 99,8 40 120

R reducing 99,95 50 40

N nitrogen 99,9 50 40

O oxygen 99,5 50 40

NOTE For certain applications a higher purity and/or lower dew point may be

recommended to avoid possible oxidation and contamination

a Nitrogen: 1 000 ppm maximum.

Provided by IHS under license with DIN License provided by I.H.S. Germany 9

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

9 Retesting

If any test fails to meet the requirement, that test shall be repeated twice. The results of both retests shall

meet the requirement. Samples for the retest may be taken from the original container or from a new

container. Retests need only be for those specific elements that failed to meet their test requirement. If the

results of one or both retests fail to meet the requirement, the gas under test shall be considered as not

meeting the requirements of this specification for that classification and designation.

In the event that, during preparation or after completion of any test, it is clearly determined that prescribed or

proper procedures were not followed in preparing the sample(s) or in conducting the tests, the test shall be

considered invalid, without regard to whether the test was actually completed, or whether the test results met,

or failed to meet, the requirement. That test shall be repeated following proper prescribed procedures. In this

case, the requirement for doubling the number of test samples does not apply.

10 Marking

The outside of each container (see 3.4) shall be clearly marked with at least the following information:

a) name of manufacturer or supplier;

b) trade name;

c) designation in accordance with this International Standard (see 5.2);

d) health and safety warnings in accordance with local, national and regional standards and regulations as

required.

10

Provided by IHS under license with DIN License provided by I.H.S. Germany

For Internal Use Only

Uncontrolled copy when printed

DIN EN ISO 14175:2008-06

EN ISO 14175:2008 (E)

Bibliography

[1] ASTM E260, Standard Practice for Packed Column Gas Chromatography

[2] JIS Z 3253, Shielding gases for arc welding and plasma arc cutting

[3] ISO 4063, Welding and allied processes Nomenclature of processes and reference numbers

Provided by IHS under license with DIN License provided by I.H.S. Germany 11

For Internal Use Only

Uncontrolled copy when printed

Vous aimerez peut-être aussi

- En Iso 15609-1-2004Document10 pagesEn Iso 15609-1-2004Marija IvanovskaPas encore d'évaluation

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- Aws B2.5 - B2.5M-2021Document34 pagesAws B2.5 - B2.5M-2021Noe NuñezPas encore d'évaluation

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielPas encore d'évaluation

- Filler Metal Selection ChartDocument1 pageFiller Metal Selection ChartMuhammed NoorulPas encore d'évaluation

- Astm B 148 2009Document5 pagesAstm B 148 2009WillianPas encore d'évaluation

- Tacom Weld Code SteelDocument165 pagesTacom Weld Code SteelAles Kubat0% (1)

- Iso 15614-3 2008 PDFDocument24 pagesIso 15614-3 2008 PDFmomoPas encore d'évaluation

- Iso 3834 2 2005 en PDFDocument6 pagesIso 3834 2 2005 en PDFRamamoorthy SundarPas encore d'évaluation

- Arc Basics - FA 2009 ISO 14175 Revised StandardDocument10 pagesArc Basics - FA 2009 ISO 14175 Revised StandardCatalinPas encore d'évaluation

- ISO 1579-1 (Part Only)Document5 pagesISO 1579-1 (Part Only)sn200709100% (1)

- PED 2014-68-EU Guidelines EN PDFDocument218 pagesPED 2014-68-EU Guidelines EN PDFMali MedoPas encore d'évaluation

- PED 2014-68-EU Guidelines en v3Document233 pagesPED 2014-68-EU Guidelines en v3GentelmanOnlyPas encore d'évaluation

- prEN 14700-FD-2013-11-Consumiveis para Revestimentos DurosDocument15 pagesprEN 14700-FD-2013-11-Consumiveis para Revestimentos DurosRicardo FernandesPas encore d'évaluation

- Iso 14344 2010Document9 pagesIso 14344 2010MOHAMEDPas encore d'évaluation

- BS 1140 PDFDocument23 pagesBS 1140 PDFjensdcvPas encore d'évaluation

- Din en Iso 3834 5Document17 pagesDin en Iso 3834 5Eduardo Elí Garcia Jimenez100% (2)

- BS en 10027-2Document16 pagesBS en 10027-2Adrian VintilaPas encore d'évaluation

- ISO 9692 3 2002 Joint PreparationDocument16 pagesISO 9692 3 2002 Joint PreparationLHYT NTUAPas encore d'évaluation

- 4 Gerry McCarthy PDFDocument42 pages4 Gerry McCarthy PDFbharani dharanPas encore d'évaluation

- CEN ISO TR 14745 (2015) (E) CodifiedDocument4 pagesCEN ISO TR 14745 (2015) (E) CodifiedacampanellajoaquimamPas encore d'évaluation

- BS en Iso 9013 - 2003Document4 pagesBS en Iso 9013 - 2003OteloElMoroPas encore d'évaluation

- Iso 17639 2022Document10 pagesIso 17639 2022Marcus Gimenes0% (1)

- Guide Fusion Welding Standards Per enDocument2 pagesGuide Fusion Welding Standards Per enMakhfud EdyPas encore d'évaluation

- Din en 15085 2Document24 pagesDin en 15085 2David Hoffman100% (1)

- Welding Metallurgy and Weldability of Stainless SteelsDocument6 pagesWelding Metallurgy and Weldability of Stainless SteelsoifhiudsnfPas encore d'évaluation

- Din en Iso 14341Document15 pagesDin en Iso 14341Rahul AherPas encore d'évaluation

- Iso 23277-2006 PDFDocument8 pagesIso 23277-2006 PDFAtim SahidPas encore d'évaluation

- ISO 3821-2008 Mangueiras de Borracha para Soldadura, Corte e AfinsDocument22 pagesISO 3821-2008 Mangueiras de Borracha para Soldadura, Corte e AfinsvictorPas encore d'évaluation

- Asme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023Document42 pagesAsme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023mmendozagPas encore d'évaluation

- en 10052 PDFDocument29 pagesen 10052 PDFmojgfdPas encore d'évaluation

- Guide To ISO14731Document8 pagesGuide To ISO14731scandalthegoodPas encore d'évaluation

- En 1090 Workshop 14 June 2019 FinalDocument2 pagesEn 1090 Workshop 14 June 2019 FinalHanuman RaaoPas encore d'évaluation

- ISO 9692-3-2002 Joint PreparationDocument16 pagesISO 9692-3-2002 Joint PreparationtndeshmukhPas encore d'évaluation

- B16.44 2012Document24 pagesB16.44 2012Edwin MariacaPas encore d'évaluation

- DRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Document18 pagesDRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Osu AmpawanonPas encore d'évaluation

- CEN ISO TR 20174 EN Grouping System-Japan PDFDocument29 pagesCEN ISO TR 20174 EN Grouping System-Japan PDFumur kaçamaklıPas encore d'évaluation

- BS en 439 94 PDFDocument12 pagesBS en 439 94 PDFDario RamljakPas encore d'évaluation

- EN ISO 9606-1 (2017) (E) CodifiedDocument8 pagesEN ISO 9606-1 (2017) (E) Codifiedsviluppi____0% (1)

- 9 ISO 15608 Grouping of MaterialsDocument14 pages9 ISO 15608 Grouping of MaterialsTuTuy An100% (1)

- Iso 3834-5 2005Document14 pagesIso 3834-5 2005HARISH KUMAR B MEKINSPas encore d'évaluation

- BS EN ISO 15607-2003 金属材料焊接程序规范和合格鉴定.总则 PDFDocument22 pagesBS EN ISO 15607-2003 金属材料焊接程序规范和合格鉴定.总则 PDFunknown1711100% (1)

- ISO 3834 - in GLDocument88 pagesISO 3834 - in GLDesmond ChinPas encore d'évaluation

- EN ISO 15792-1 (2008) A1 (2011) (E) CodifiedDocument3 pagesEN ISO 15792-1 (2008) A1 (2011) (E) CodifiedQuality Team50% (2)

- CH4 1 Welding Joint SymbolsDocument32 pagesCH4 1 Welding Joint SymbolsGuillermo MartínezPas encore d'évaluation

- Info 15614 - 2017Document34 pagesInfo 15614 - 2017uğur özdemirPas encore d'évaluation

- Survey Welding-Standards 03-11-2011Document0 pageSurvey Welding-Standards 03-11-2011Florin SoicuPas encore d'évaluation

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEPas encore d'évaluation

- SC Qual 145r4-10 Combined Document Finnish Proposal and Checklist DVS-Zert Germany ISO 3834 PDFDocument53 pagesSC Qual 145r4-10 Combined Document Finnish Proposal and Checklist DVS-Zert Germany ISO 3834 PDFAlienshowPas encore d'évaluation

- BS en Iso 9606-4 - 1999Document26 pagesBS en Iso 9606-4 - 1999jesonelitePas encore d'évaluation

- CEN ISO TR 20173 - en Grouping Syst - American MaterialDocument61 pagesCEN ISO TR 20173 - en Grouping Syst - American Materialumur kaçamaklı100% (2)

- En 10225Document1 pageEn 10225cornelrusuPas encore d'évaluation

- EN ISO 14175 EnglishDocument15 pagesEN ISO 14175 EnglishbarbierPas encore d'évaluation

- ISO 13920 - Tolerâncias para Juntas SoldadasDocument7 pagesISO 13920 - Tolerâncias para Juntas SoldadasRicardo RicardoPas encore d'évaluation

- DIN EN 14700: Welding Consumables For Hard-FacingDocument14 pagesDIN EN 14700: Welding Consumables For Hard-FacingHany Elsayed100% (1)

- Din en Iso 7089Document3 pagesDin en Iso 7089Ravindra ErabattiPas encore d'évaluation

- Din en Iso 11463Document17 pagesDin en Iso 11463Antonio MakkarovPas encore d'évaluation

- Din en Iso 15614-3 - 2008-06Document23 pagesDin en Iso 15614-3 - 2008-06Alfalloy Testing and Inspection Services Pvt. Ltd.Pas encore d'évaluation

- Iso 7380Document8 pagesIso 7380pradelles100% (1)

- Cae PDFDocument1 146 pagesCae PDFerzengenhariaPas encore d'évaluation

- Chapter 1 MindmapDocument1 pageChapter 1 MindmapEduardo Javier Granados SanchezPas encore d'évaluation

- Altair Compose 2019 DatasheetDocument2 pagesAltair Compose 2019 DatasheetEduardo Javier Granados SanchezPas encore d'évaluation

- Grade Levels and Structure of The Educational System of MexicoDocument1 pageGrade Levels and Structure of The Educational System of MexicoEduardo Javier Granados SanchezPas encore d'évaluation

- Chords Music Blanc II PDFDocument1 pageChords Music Blanc II PDFEduardo Javier Granados SanchezPas encore d'évaluation

- Chapter 2 MindmapDocument1 pageChapter 2 MindmapEduardo Javier Granados SanchezPas encore d'évaluation

- Neuber Plasticity CorrectionDocument1 pageNeuber Plasticity CorrectionEduardo Javier Granados SanchezPas encore d'évaluation

- 1DMeshing PDFDocument58 pages1DMeshing PDFEduardo Javier Granados SanchezPas encore d'évaluation

- NCode Premium Materials DatabaseDocument13 pagesNCode Premium Materials DatabaseEduardo Javier Granados SanchezPas encore d'évaluation

- Recent Advances in Adhesive Science and Technology - Wojciech Gutowski PDFDocument382 pagesRecent Advances in Adhesive Science and Technology - Wojciech Gutowski PDFEduardo Javier Granados Sanchez100% (1)

- Bonding Alternatives For Structural Requirements.Document6 pagesBonding Alternatives For Structural Requirements.Eduardo Javier Granados SanchezPas encore d'évaluation

- Bangkok Railway LineDocument2 pagesBangkok Railway LineEduardo Javier Granados SanchezPas encore d'évaluation

- Ejercicios Solidworks PDFDocument50 pagesEjercicios Solidworks PDFRic Frs80% (5)

- Neuber Plasticity Correction R&O Material CurveUR2202Document1 pageNeuber Plasticity Correction R&O Material CurveUR2202Eduardo Javier Granados SanchezPas encore d'évaluation

- Neuber Plasticity CorrectionDocument1 pageNeuber Plasticity CorrectionEduardo Javier Granados SanchezPas encore d'évaluation

- Hyperworks 14.0 Release Notes PDFDocument350 pagesHyperworks 14.0 Release Notes PDFEduardo Javier Granados SanchezPas encore d'évaluation

- Arc Welding ParametersDocument7 pagesArc Welding ParametersEduardo Javier Granados SanchezPas encore d'évaluation

- Advanced High - Strength Steel Repairability Phase 1 Final ReportDocument22 pagesAdvanced High - Strength Steel Repairability Phase 1 Final ReportEduardo Javier Granados SanchezPas encore d'évaluation

- Lean Six Sigma and Statistical Tools For Engineers and Engineering ManagersDocument273 pagesLean Six Sigma and Statistical Tools For Engineers and Engineering ManagersBogdan CorneaPas encore d'évaluation

- Neuber Plasticity Correction R&O Material CurveUR2202Document1 pageNeuber Plasticity Correction R&O Material CurveUR2202Eduardo Javier Granados SanchezPas encore d'évaluation

- 091Document1 page091Eduardo Javier Granados SanchezPas encore d'évaluation

- NJTCDocument1 pageNJTCEduardo Javier Granados SanchezPas encore d'évaluation

- 1 Crash Book For StudentDocument294 pages1 Crash Book For StudentheinsteinzPas encore d'évaluation

- Cold Rolled Steel Sheet-JFE PDFDocument32 pagesCold Rolled Steel Sheet-JFE PDFEduardo Javier Granados SanchezPas encore d'évaluation

- Alex Mercado PhrasesDocument4 pagesAlex Mercado PhrasesEduardo Javier Granados SanchezPas encore d'évaluation

- 01 RPBW Whitney Museum of American Art FullDocument1 page01 RPBW Whitney Museum of American Art FullEduardo Javier Granados SanchezPas encore d'évaluation

- Arch DesignDocument2 pagesArch DesignEduardo Javier Granados SanchezPas encore d'évaluation

- Global 7000Document5 pagesGlobal 7000Eduardo Javier Granados SanchezPas encore d'évaluation

- Architecture & DesignDocument5 pagesArchitecture & DesignEduardo Javier Granados SanchezPas encore d'évaluation

- Practice Test 4 CHM 112Document16 pagesPractice Test 4 CHM 112Froileth PulidoPas encore d'évaluation

- Portable Laser Spectrometer: Carbon Analysis Directly in Air, No Argon Gas RequiredDocument4 pagesPortable Laser Spectrometer: Carbon Analysis Directly in Air, No Argon Gas RequiredNivedita SahooPas encore d'évaluation

- Redox ReactionsDocument21 pagesRedox Reactionssudeepjoseph0% (2)

- Hydrofluoric Alkylation:: Corrosion and PreventionDocument26 pagesHydrofluoric Alkylation:: Corrosion and PreventionJarukit Jr JunjiewchaiPas encore d'évaluation

- Nomenclature: Review ProblemsDocument1 pageNomenclature: Review ProblemsJohn Yoro ParlindunganPas encore d'évaluation

- Hall Heroult Process and Hooper ProcessDocument9 pagesHall Heroult Process and Hooper ProcesssaadPas encore d'évaluation

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 pagesWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200kashyap_structuralPas encore d'évaluation

- Palmer's Brewing Water Adjustment App Version 1.5 (US Units)Document1 pagePalmer's Brewing Water Adjustment App Version 1.5 (US Units)Andres Felipe Castellanos PulidoPas encore d'évaluation

- Stoichiometry Practice Test: 4 Al + 3 O 2 Al ODocument5 pagesStoichiometry Practice Test: 4 Al + 3 O 2 Al OJamiu Yusuf AsukuPas encore d'évaluation

- EP Bearing & Chassis GreaseDocument2 pagesEP Bearing & Chassis Greasechem KhanPas encore d'évaluation

- Uppc Upcat Tutorials Science SubsetDocument36 pagesUppc Upcat Tutorials Science SubsetGandaPas encore d'évaluation

- BraceletsDocument48 pagesBraceletsmohammad nadherPas encore d'évaluation

- Solvay ProcessDocument20 pagesSolvay ProcessSon TranPas encore d'évaluation

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraPas encore d'évaluation

- Buyer'S Guide: K-Tig Vs K-PawDocument4 pagesBuyer'S Guide: K-Tig Vs K-PawBrad PortelliPas encore d'évaluation

- Binary CompoundsDocument5 pagesBinary CompoundsLiza RPas encore d'évaluation

- F5 Science Chapter 2Document17 pagesF5 Science Chapter 2Syafiq SyazPas encore d'évaluation

- 11th Chemistry Book Back Questions New BookDocument38 pages11th Chemistry Book Back Questions New BookNaveen KumarPas encore d'évaluation

- Tuesday 11 June 2019: ChemistryDocument28 pagesTuesday 11 June 2019: ChemistryThunn NayChi LinPas encore d'évaluation

- Oxidative Treatment of Bromide Containing Waters Formation of Bromine and Its Reactios With Inorganic and Organic PDFDocument28 pagesOxidative Treatment of Bromide Containing Waters Formation of Bromine and Its Reactios With Inorganic and Organic PDFGiuliaPas encore d'évaluation

- Böhler Folder Strip Cladding EN WEB PDFDocument0 pageBöhler Folder Strip Cladding EN WEB PDFCarlos Bermejo AlvarezPas encore d'évaluation

- 8.1 Types of Chemical Reactions QP - Gcse Ocr Chemistry Gateway ScienceDocument17 pages8.1 Types of Chemical Reactions QP - Gcse Ocr Chemistry Gateway SciencenuPas encore d'évaluation

- Physical and Chemical Changes NotesDocument2 pagesPhysical and Chemical Changes NotesMidhun Bhuvanesh.B 7APas encore d'évaluation

- Pitting Corrosion: MechanismDocument4 pagesPitting Corrosion: MechanismCarlos BustamantePas encore d'évaluation

- 7 Coordination CompoundsDocument17 pages7 Coordination CompoundsAishwarya Chauhan100% (1)

- Daftar Bahan Berbahaya Dan BeracunDocument8 pagesDaftar Bahan Berbahaya Dan BeracunSylvia Yemita100% (1)

- New Test Apparatus DesignDocument10 pagesNew Test Apparatus Designzafarchem_iqbalPas encore d'évaluation

- Ncert Solutions Class 10 Science Chapter 1 Chemical Reactions and EquationDocument5 pagesNcert Solutions Class 10 Science Chapter 1 Chemical Reactions and EquationJeel AgrawalPas encore d'évaluation

- Chemistry P2 11 MS - Docx 0Document5 pagesChemistry P2 11 MS - Docx 0rayanahmedmaillPas encore d'évaluation

- AQA C2 Revision BookletDocument25 pagesAQA C2 Revision BookletNicole Lee0% (1)