Académique Documents

Professionnel Documents

Culture Documents

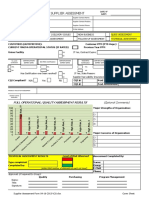

Preparation Method of Monthly QA/QC Report: Cover Page

Transféré par

CheeragTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Preparation Method of Monthly QA/QC Report: Cover Page

Transféré par

CheeragDroits d'auteur :

Formats disponibles

Preparation Method of Monthly QA/QC Report

Language : Korean and/or English words are available

Cover Page

Input name of business unit & project name

Input name of project QA/QC Manager and prepared date

01. Project Information

Input project summary in accordance with subject of format

Construction progress should be inputted in the QA/QC report every month

Quality key issues of this month : In put quality key issues for this month in terms of quality

Quality key issues of next month : In put quality key issues for next month in terms of quality

02. Site Overview

Attach the photo of site condition with explanation in every month

03. Project Organization

Input name and e-mail address of manager level personnel in Samsung C&T organization

Input name and e-mail address of manager & engineer level personnel in Client organization

Update project organization data in every month if some personnel will be changed

04. Quality Plan & Procedures

Input procedures project quality related

Initial data inputted should not be deleted and maintained every month on the report including updated data

Major revised reason should be recorded

05. Communication

Input QA/QC meeting performed under the superintendence of QA/QC manager with client

Input meeting subject QA/QC Manager participated with client

06. Nonconformity Control

Input nonconforming details and disposition

Type of Cause ( Multiple selections are available)

Man Material Machine Method Management

Inadequate Defective Incorrect No/poor Lack of input by

Capability raw material selection procedures management

Lack of knowledge Wrong material Poor maintenance Non compliance to Lack of

specified procedures communication

Lack of skill Lack of raw Defective Poor Inadequate

material equipment communication planning

Lack of motivation

Definitions

- Repair : Action on a nonconforming product to make it acceptable for the intended use

- Rework : Action on nonconforming product to make it conform to the requirements

- Re-grade : Alteration of the grade of a nonconforming product in order to make it conform to requirements

differing from the initial ones

- Scrap : Action on a nonconforming product to preclude its originally intended use

- Concession : Action on a nonconforming product to preclude its originally intended use

07. Internal & External Audit

Input actual audit date performed

08. Audit Finding Report

Input audit findings briefly

Input corrective action briefly

Input approved date about corrective action by HQ Q-HSE Div.

Submit clients audit report including corrective action by attachment in the monthly QA/QC report)

09. Quality Personnel (Korean & Local Staff)

Input part time or permanent by Yes or No

Input appointed date and dismissal date of quality manager

10. Quality Training and Awareness

Input training title and actual date

11. Control of Monitoring & Measuring Equipment

Input calibration status including subcontractors devices

12. KPI (Quality Objective & Target) Control

Input KPI, period, achievement level of project site

13. Customer Inspection

Input clients inspection status including quantity of application, accept and reject

14. Testing Status

Input routine inspection items through whole project period

(It is related to Civil & Building business unit)

15. Special Process Qualification Control

Input special process controlled of each business division

Input qualification date, dismissal date, Total average RT reject ratio, reject ratio per each month.

Reject ratio should be applied to RT joints (RT means, Radiographic Testing)

16. Quality Award

Input quality award status about who contributed to the quality objectives or quality level improvement at the

site

17. Quality Incident Record

Input quality incident and/or quality issues that are externally

18. Preventive Action

Quality concerns of next month : Input potential quality risk of next month major construction activities

Preventive action plan : Input preventive action plan due to potential quality risk

19. Management Review

Input management review actual date and attach an evidence data

It should be performed two times per year

20. Supporting Document List

List up attached documents in the monthly QA/QC report

Vous aimerez peut-être aussi

- Exam Cram Essentials Last-Minute Guide to Ace the PMP Exam: First EditionD'EverandExam Cram Essentials Last-Minute Guide to Ace the PMP Exam: First EditionPas encore d'évaluation

- Total Quality Management and Just-In-Time Production SystemDocument30 pagesTotal Quality Management and Just-In-Time Production SystemJannibee EstreraPas encore d'évaluation

- QA/QC Engineer Roles, Responsibilities & Project InspectionDocument4 pagesQA/QC Engineer Roles, Responsibilities & Project InspectionEmilJaredVirayPabustanPas encore d'évaluation

- Quality Manager Job DescriptionDocument2 pagesQuality Manager Job DescriptionAbdullah AnsariPas encore d'évaluation

- Quality Assurance Plan - ManoranjanDocument28 pagesQuality Assurance Plan - ManoranjanSourav MajiPas encore d'évaluation

- Senior Engineer Quality-RameshDocument4 pagesSenior Engineer Quality-RameshRamesh kumarPas encore d'évaluation

- CQM ProcessDocument6 pagesCQM ProcessXDXDXDPas encore d'évaluation

- QualityDocument16 pagesQualityBanner BrucePas encore d'évaluation

- Supplier Assessment: Cover PageDocument29 pagesSupplier Assessment: Cover PageMohammad Abbas NaqviPas encore d'évaluation

- Sundar GDocument2 pagesSundar GRazvan GheorghiesPas encore d'évaluation

- New QA DB and Kpi 22Document6 pagesNew QA DB and Kpi 22Senthilmani MuthuswamyPas encore d'évaluation

- NCP-27 Construction Quality ManagementDocument64 pagesNCP-27 Construction Quality ManagementArvind KumarPas encore d'évaluation

- QA Manager YogeshDocument4 pagesQA Manager YogeshParag WadekarPas encore d'évaluation

- Quality Manager & Production Manager CompetencyDocument6 pagesQuality Manager & Production Manager CompetencyManoj MehraPas encore d'évaluation

- lesson 2 Total quality managementDocument4 pageslesson 2 Total quality managementsatriajea.faustino.ePas encore d'évaluation

- Resume - Aditya WDocument3 pagesResume - Aditya WadityaPas encore d'évaluation

- Work Inspection ProcedureDocument5 pagesWork Inspection ProcedureRavi ValiyaPas encore d'évaluation

- May 28 20 QA QCDocument172 pagesMay 28 20 QA QCChristine PaulinePas encore d'évaluation

- Supplier Assessment Audit ReportDocument16 pagesSupplier Assessment Audit ReportKovacs AndreeaPas encore d'évaluation

- QMS Audit Check SheetDocument7 pagesQMS Audit Check Sheetaboo2uPas encore d'évaluation

- CONTRACTORS PROJECT QUALITY PLAN Rev01 - 1659063575Document69 pagesCONTRACTORS PROJECT QUALITY PLAN Rev01 - 1659063575Sofie CatahanPas encore d'évaluation

- Job Description - Senior QAQC CoordinatorDocument3 pagesJob Description - Senior QAQC CoordinatorJennifer French0% (1)

- Job Description - QAQC CoordinatorDocument3 pagesJob Description - QAQC CoordinatorJennifer FrenchPas encore d'évaluation

- Ravi Halleppanavar ResumeDocument5 pagesRavi Halleppanavar ResumeMNR SolutionsPas encore d'évaluation

- QMS Audit Check SheetDocument7 pagesQMS Audit Check Sheetaboo2uPas encore d'évaluation

- Application of C & Q Baseline Guide To Streamlining PerformanceDocument21 pagesApplication of C & Q Baseline Guide To Streamlining PerformancebaluchakpPas encore d'évaluation

- ASD CV Jan 21Document4 pagesASD CV Jan 21Anil DesalePas encore d'évaluation

- QA Lectute OM New BatchDocument73 pagesQA Lectute OM New BatchvenkateshPas encore d'évaluation

- QA vs. QCDocument9 pagesQA vs. QCTuan AnhPas encore d'évaluation

- InspectorDocument3 pagesInspectorTAMRAIZPas encore d'évaluation

- Activity Exemplar - Project Closeout ReportDocument3 pagesActivity Exemplar - Project Closeout ReportJordan K Wells100% (2)

- Understanding, Evaluating, Defining, and Managing Expectations Are Essential To SatisfyingDocument12 pagesUnderstanding, Evaluating, Defining, and Managing Expectations Are Essential To SatisfyingKubiriba Shaddie AllanPas encore d'évaluation

- Kra 12-13Document9 pagesKra 12-13Saran KumarPas encore d'évaluation

- Procurement QC SupervisorDocument2 pagesProcurement QC SupervisorAbdul Maroof100% (1)

- 08 Project Quality ManagementDocument18 pages08 Project Quality ManagementChris GonzalesPas encore d'évaluation

- Quality ControlDocument30 pagesQuality ControlMohammedPas encore d'évaluation

- Quality ControlDocument30 pagesQuality ControlkhanPas encore d'évaluation

- Introduction of Project Quality Management: in Oil and Gas IndustryDocument20 pagesIntroduction of Project Quality Management: in Oil and Gas IndustrySufira WahyuniPas encore d'évaluation

- Reviewing PQP Guide To InspectorsDocument21 pagesReviewing PQP Guide To InspectorsMohamed S. ElrapatPas encore d'évaluation

- Roles of QA QC ManagerDocument3 pagesRoles of QA QC ManagerAbdullah AnsariPas encore d'évaluation

- Improving Service Quality and ProductivityDocument23 pagesImproving Service Quality and ProductivityUtsav MahendraPas encore d'évaluation

- Inputs Tools and Technique OutputsDocument2 pagesInputs Tools and Technique OutputsBus Fare CollectionPas encore d'évaluation

- QAQCDocument56 pagesQAQCRavindra Babu Sivapu100% (1)

- QA Roles & ResponsibleDocument5 pagesQA Roles & ResponsibleMohd Ezan MohammadiahPas encore d'évaluation

- CEB ResearchDocument2 pagesCEB ResearchSaira Arish BukhariPas encore d'évaluation

- Quality ControlDocument37 pagesQuality ControlMark Anthony Limbo67% (3)

- NPI - Project Quality PlanDocument2 pagesNPI - Project Quality PlanVirginia GrandoPas encore d'évaluation

- SGI-R.08.17 Rev 0 - Quality Plan DBNRDocument26 pagesSGI-R.08.17 Rev 0 - Quality Plan DBNRLUISPas encore d'évaluation

- Job DescriptionDocument3 pagesJob Descriptionairsys7projecPas encore d'évaluation

- Yash Resume 2 2Document2 pagesYash Resume 2 2BaljeetPas encore d'évaluation

- Quality Monthly Report - NOV 2015Document15 pagesQuality Monthly Report - NOV 2015KumaravelPas encore d'évaluation

- ChryslerDocument117 pagesChryslerdokser29100% (1)

- QC Manager Roles ResponsibilitiesDocument4 pagesQC Manager Roles ResponsibilitiesEngr Primus ChinonyePas encore d'évaluation

- CC-1 Assessment Tool TemplateDocument6 pagesCC-1 Assessment Tool TemplateJayrod MoralesPas encore d'évaluation

- Job Description of Based On Designation QA/QCDocument16 pagesJob Description of Based On Designation QA/QCrickyPas encore d'évaluation

- Pmi-Acp Exam Prep Study Guide: Extra Preparation for Pmi-Acp Certification ExaminationD'EverandPmi-Acp Exam Prep Study Guide: Extra Preparation for Pmi-Acp Certification ExaminationPas encore d'évaluation

- ISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012D'EverandISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012Pas encore d'évaluation

- Xylem Water Solutions Pvt. Ltd. Customer Inspection Checklist for Sundilla Project KLIS Stage 3 Nose ConesDocument1 pageXylem Water Solutions Pvt. Ltd. Customer Inspection Checklist for Sundilla Project KLIS Stage 3 Nose ConesCheeragPas encore d'évaluation

- Inspection Checklist for Suction Bell CastingsDocument8 pagesInspection Checklist for Suction Bell CastingsCheeragPas encore d'évaluation

- YzcvfDocument2 pagesYzcvfCheeragPas encore d'évaluation

- What Is Air ConditioningDocument16 pagesWhat Is Air ConditioningCheeragPas encore d'évaluation

- Full Time MBA BrochureDocument25 pagesFull Time MBA BrochureCheeragPas encore d'évaluation

- SLMDocument1 pageSLMCheeragPas encore d'évaluation

- Form 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Document4 pagesForm 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961CheeragPas encore d'évaluation

- Staff Selection Commission: Registration Part Apply PartDocument1 pageStaff Selection Commission: Registration Part Apply PartCheeragPas encore d'évaluation

- Refrigeration and Air ConditioningDocument21 pagesRefrigeration and Air ConditioningShiva Kumar H MPas encore d'évaluation

- Steel Innovations Pvt. LTDDocument1 pageSteel Innovations Pvt. LTDCheeragPas encore d'évaluation

- Full Time MBA BrochureDocument25 pagesFull Time MBA BrochureCheeragPas encore d'évaluation

- ConceptofTunnelVentilationSystem RevADocument16 pagesConceptofTunnelVentilationSystem RevACheeragPas encore d'évaluation

- Metro Card Movement Details: S.No. Date From To 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19Document4 pagesMetro Card Movement Details: S.No. Date From To 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19CheeragPas encore d'évaluation

- DPRDocument5 pagesDPRCheeragPas encore d'évaluation

- Quality Management System, Quality Inspection & Execution Key Performance IndicatorsDocument2 pagesQuality Management System, Quality Inspection & Execution Key Performance IndicatorsCheeragPas encore d'évaluation

- SuviDocument14 pagesSuviCheeragPas encore d'évaluation

- IpiDocument2 pagesIpiCheeragPas encore d'évaluation

- NCR Bar ChartDocument1 pageNCR Bar ChartCheeragPas encore d'évaluation

- Project: DMRC Phase-Iii, Ce10 & 11 Lot-1: QA/QC Critical Observation Report For SLMDocument2 pagesProject: DMRC Phase-Iii, Ce10 & 11 Lot-1: QA/QC Critical Observation Report For SLMCheeragPas encore d'évaluation

- QA/QC report for DMRC CE10 & 11 Lot-1 projectDocument2 pagesQA/QC report for DMRC CE10 & 11 Lot-1 projectCheeragPas encore d'évaluation

- Jama Masjid Mode TablesDocument3 pagesJama Masjid Mode TablesCheeragPas encore d'évaluation

- June 2017 QA/QC Monthly ReportDocument3 pagesJune 2017 QA/QC Monthly ReportCheeragPas encore d'évaluation

- NewDocument15 pagesNewCheeragPas encore d'évaluation

- QA/QC Monthly Report of June 2017Document3 pagesQA/QC Monthly Report of June 2017CheeragPas encore d'évaluation

- Lal Quila Mode TablesDocument3 pagesLal Quila Mode TablesCheeragPas encore d'évaluation

- Internal Audit Report: IQA NO: 001 Date Jan.10th 2015 ISO 9001:2008 Clause Ref. Target DateDocument6 pagesInternal Audit Report: IQA NO: 001 Date Jan.10th 2015 ISO 9001:2008 Clause Ref. Target DateCheeragPas encore d'évaluation

- KG Mode Table Document for DMRCDocument3 pagesKG Mode Table Document for DMRCCheeragPas encore d'évaluation

- ListDocument6 pagesListCheeragPas encore d'évaluation

- IqspDocument1 pageIqspCheeragPas encore d'évaluation

- English Class Language DevicesDocument56 pagesEnglish Class Language DevicesKAREN GREGANDAPas encore d'évaluation

- Learn Six Sigma Process and Methodology BasicsDocument4 pagesLearn Six Sigma Process and Methodology BasicsGeorge MarkasPas encore d'évaluation

- What Is Architecture?Document17 pagesWhat Is Architecture?Asad Zafar HaiderPas encore d'évaluation

- Solar PV Array Modelling PDFDocument13 pagesSolar PV Array Modelling PDFsunilkumarece100% (1)

- Ice Cream: Uses and Method of ManufactureDocument6 pagesIce Cream: Uses and Method of ManufactureMari LizPas encore d'évaluation

- How To Prepare Squash Specimen Samples For Microscopic ObservationDocument3 pagesHow To Prepare Squash Specimen Samples For Microscopic ObservationSAMMYPas encore d'évaluation

- Elliptic Curve Cryptography and ApplicationsDocument9 pagesElliptic Curve Cryptography and ApplicationssiddthesquidPas encore d'évaluation

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- EdiTasc EDocument89 pagesEdiTasc EOglasnik MostarPas encore d'évaluation

- Fluorescent sensors for detection of heavy metalsDocument36 pagesFluorescent sensors for detection of heavy metalskawtherahmedPas encore d'évaluation

- SYS600 - Visual SCIL Application DesignDocument144 pagesSYS600 - Visual SCIL Application DesignDang JinlongPas encore d'évaluation

- 2016 John Timm Final Narrative WeeblyDocument8 pages2016 John Timm Final Narrative Weeblyapi-312582463Pas encore d'évaluation

- PSPO I Question AnswerDocument11 pagesPSPO I Question AnswerAurélie ROUEPas encore d'évaluation

- Paaralan Tungo Sa Magandang Kinabukasan" The Campaign Kicked Off in All The PublicDocument7 pagesPaaralan Tungo Sa Magandang Kinabukasan" The Campaign Kicked Off in All The PublicJOHN FRANCIS OCTAVIANOPas encore d'évaluation

- Garden Silk Mills Ltd.Document115 pagesGarden Silk Mills Ltd.jkpatel221Pas encore d'évaluation

- Liberal Theory: Key Aspects of Idealism in International RelationsDocument11 pagesLiberal Theory: Key Aspects of Idealism in International RelationsArpit JainPas encore d'évaluation

- Rolfsen Knot Table Guide Crossings 1-10Document4 pagesRolfsen Knot Table Guide Crossings 1-10Pangloss LeibnizPas encore d'évaluation

- Writing and Presenting A Project Proposal To AcademicsDocument87 pagesWriting and Presenting A Project Proposal To AcademicsAllyPas encore d'évaluation

- Applying Ocs Patches: Type Area Topic AuthorDocument16 pagesApplying Ocs Patches: Type Area Topic AuthorPILLINAGARAJUPas encore d'évaluation

- SMK ST GabrielDocument39 pagesSMK ST Gabrielzanariah1911Pas encore d'évaluation

- Google Fusion Tables: A Case StudyDocument4 pagesGoogle Fusion Tables: A Case StudySeanPas encore d'évaluation

- ECE 340 Lecture 26 Avalanche Zener BreakdownDocument20 pagesECE 340 Lecture 26 Avalanche Zener BreakdownDao ZhangPas encore d'évaluation

- Agricultural Typology Concept and MethodDocument13 pagesAgricultural Typology Concept and MethodAre GalvánPas encore d'évaluation

- Chapter 2: Science, Technology, and Society in Human Condition Lesson 1: Human FlourishingDocument5 pagesChapter 2: Science, Technology, and Society in Human Condition Lesson 1: Human FlourishingJcPas encore d'évaluation

- Laser Plasma Accelerators PDFDocument12 pagesLaser Plasma Accelerators PDFAjit UpadhyayPas encore d'évaluation

- Tamil Literary Garden 2010 Lifetime Achievement Award CeremonyDocument20 pagesTamil Literary Garden 2010 Lifetime Achievement Award CeremonyAnthony VimalPas encore d'évaluation

- Mri 7 TeslaDocument12 pagesMri 7 TeslaJEAN FELLIPE BARROSPas encore d'évaluation

- Tabelas Normativas DinDocument2 pagesTabelas Normativas DinDeimos PhobosPas encore d'évaluation

- Roland Barthes and Struggle With AngelDocument8 pagesRoland Barthes and Struggle With AngelAbdullah Bektas0% (1)

- حقيبة تعليمية لمادة التحليلات الهندسية والعدديةDocument28 pagesحقيبة تعليمية لمادة التحليلات الهندسية والعدديةAnjam RasulPas encore d'évaluation