Académique Documents

Professionnel Documents

Culture Documents

Pyro Valve

Transféré par

hkr0101Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pyro Valve

Transféré par

hkr0101Droits d'auteur :

Formats disponibles

LIQUID ROCKET COMPONENTS: PYROTECHNIC VALVES

By Tom Mueller

For an amateur rocketeer seeking to build a to fit in the 1.5 inch rocket diameter. In this

liquid rocket, one of the most difficult article I will describe the design of the

components to obtain or build are remotely valves that were used on these two

operated valves. A liquid rocket will require vehicles, and variations of them that have

at least one valve to start the flow of been used in other rocket applications.

propellants to the combustion chamber. In

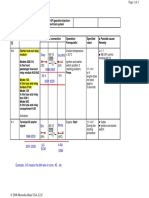

the two small liquid rockets I have flown in Figure 1 shows the fire valve I used in the

the last year or so, both used a pyrotechnic XLR-50 rocket. This valve supplied helium

fire valve located between the pressurant to the propellant tanks, with an initial helium

tank and the propellant tanks. The tank pressure of 800 psia. The design

propellants were held in the tanks by burst consists of an aluminum piston with three

disks (or equivalent) in the propellant run O-rings used to seal between ports. In the

lines. When the fire valve was actuated, pre-fire position, as shown in Figure 1a, two

the sudden pressure rise in the propellant of the O-rings seal the inlet , while both

tanks blew the burst disks, allowing tanks are vented to atmosphere. To actuate

propellant to flow to the injector. This the fire valve, a black powder charge is

method of controlling the flow to the rocket ignited by application of 12 volts to a thin

allows the use of only one valve, and nichrome wire in contact with the charge.

eliminates liquid valves. In the case of the The rapid expansion of the gases from the

first rocket, the XLR-50 which flew in charge push the piston over against a stop,

October 1993, elimination of the liquid valve as shown in Figure 1b. In this position, the

was important because the oxidizer was helium tank is now connected to both

liquid oxygen, and a small cryogenic propellant tanks, allowing them to quickly

compatible valve is very difficult to pressurize. The tank vents are closed, with

construct. For the second rocket, which the fuel tank vent now allowing the excess

flew in October 1994, the small size squib charge gases to vent.

prevented the use of liquid valves. In fact,

the single pryo valve I used was barely able

Figure 1 XLR-50 rocket helium fire valve

The valve shown in Figure 1 consisted of a was identical in operation to the XLR-50

stainless steel body with a 0.375 inch valve, with the major difference being its

diameter piston. The O-rings were viton integration into the vehicle body. The valve

and the squib charge was contained in a body was a 1.5 inch diameter aluminum

Delrin plastic cap. The Delrin was used to bulkhead that separated the nitrogen

prevent shorting of the nichrome wire, and pressurant tank and the oxidizer tank.

also to provide a frangible fuse in case the Because of the very small diameter of the

squib charge proved to be a little too rocket, the clearances between ports and O-

energetic. In practice I’ve never had the rings were minimized, just allowing the

Delrin cap fracture. The inlet and outlet valve to fit. The fuel outlet port was located

lines to the tanks were silver brazed to the at the vehicle center, providing pressure to

valve body. The valve was tested many the fuel tank by the central stand pipe that

times at inlet pressures of up to 1000 psi passed axially down the oxidizer tank. The

without any problems, other than the O- piston stop was a piece of heat treated alloy

rings would need replaced after several steel that was attached to the valve body by

firings due to minor nicks from the ports. To a screw. This stop was originally aluminum,

help alleviate this problem, the edges of the but was bent by the impact of the piston in

ports were rounded to help prevent the O- initial tests of the valve. The black powder

ring from getting pinched as the piston charge in the Delrin cap was reduced and

translates. This was accomplished using a the black powder was changed from FFFg to

small strip of emery cloth that was secured a courser FFg powder, but the problem

in a loop in one end of a short length of persisted. The stop was re-made from oil

0.020 stainless wire. The other end of the hardening steel and the problem was

wire was clamped in a pin vise which in turn solved. In this application, the port

was chucked in a hand drill. As the wire diameters were only 1/16 inch so only a

was rotated by the drill, the emery was small amount of rounding was required to

pulled snugly into the port, where it prevent the O-rings from getting pinched in

deformed into the shape of the inlet, and the ports. The valve operated with a

rounded the sharp

edge. I used WD-40

as a lubricant for this

operation, allowing

the emery to wear out

until it would finally

pull through the port. I

repeated this process

a few times for each

port until the piston

would slide through

the bore without the

O-rings snagging the

ports. Another

requirement is to

lubricate the O-rings

with a little Krytox

grease. This helps

the piston move freely

and greatly reduces

the problem of nicked

O-rings.

The pyro valve I used

in the 25 lbf thrust

micro rocket that was

launched in October

of 1994 is shown in Figure 2 Fire valve for Micro Rocket

Figure 2. This valve

In testing the valve with water at a

lock-up pressure of 800 psi, I was

pleased to find that even with the

large ports, O-ring pinching was not a

problem. One saving factor was that

the larger size of the ports made it

easier to round the entrances on the

bore side. The valve was tested with

water several times successfully

before giving it to Mark for the static

test of his hybrid.

The only problem that occurred during

the static test of hybrid rocket was

that the leads to the nichrome wire

kept shorting against the valve body,

Three attempts were made before the

squib was finally ignited and the

engine ran beautifully. I have since

been able to solve this problem by

soldering insulated 32 gauge copper

wire to the nichrome wire leads

inside the Delrin cap. In this way I

can provide long leads to the valve

with reliable ignition.

Figure 3 Fire valve for Mark Ventura's hydrogen

peroxide hybrid rocket My next liquid rocket is a 650 lbf

design that burns LOX and propane at

nitrogen lock-up pressure of 1000 psi. 500 psia. This engine uses a Condor

ablative chamber obtained from a surplus

A more challenging application of the same yard. For this reason I call it the Condor

basic valve design was used for the fire rocket. This rocket uses a scuba tank with

valve of Mark Ventura’s peroxide hybrid, as 3000 psi helium for the pressurant. I

shown in Figure 3. This was the first decided to build a high pressure version of

application of this valve where liquid was my valve as the helium isolation valve for

the fluid being controlled, rather than gas. this rocket. When firing this rocket, just

In this case the liquid was 85% hydrogen prior to the 10 second count, this valve will

peroxide. The second difficulty was the fact be fired, pressurizing the propellant tanks to

that the ports were required to be 0.20 inch 600 psi. I assumed going in to this design

in diameter in order to handle the required that the O-rings slipping past a port simply

flow rate. The valve was somewhat simpler wasn’t going to work at 3000 psi. At these

than the previous valves in that only a pressures, the O-ring would extrude into the

single inlet and outlet were required. The port. In order to get around this problem I

valve body was made from a piece of 1.5 came up with the design shown in Figure 4.

inch diameter 6061 aluminum, in which a For this valve, the O-ring groves were

1/2 inch piston bore was drilled. The piston moved from the piston to the cylinder bore

was also 6061 with viton O-rings, which are of the valve body, so the O-rings do not

peroxide compatible. The ports were 1/4 move relative to the ports. The piston is

inch pipe threads tapped into the aluminum made from stainless steel with a smooth

body. The excess material on the sides of surface finish and generous radii on all of

the valve was milled off, so that the valve the corners. The clearance between the

was only about 3/4 of an inch thick, and piston and the bore was kept very small to

weighed only 4 ounces. Even though the prevent extrusion of the O-rings. The valve

piston size was 1/2 inch, the same charge operation is similar to the one shown in

volume used in the 3/8 inch valves was Figure 3, and the valve body is made in the

sufficient to actuate the piston. same way except female AN ports were

When the propellant tanks are pressurized

by the helium pyro valve, the LOX tank

auto vent valve (shown in Figure 6) closes.

If the engine is not fired after a reasonable

amount of time, the LOX will warm up,

building pressure until something gives

(probably the LOX tank). The pyro valve

shown in Figure 5 is used as the

emergency tank vent if the engine cannot

be fired. The valve body is stainless steel

with a stainless tube stub welded on for

connection to the LOX tank. This valve

has been tested to 800 psi with helium and

works fine. In this case, some ‘nicking’ of

the O-rings can be tolerated because the

O-rings are not required to seal after the

valve is fired. The ports in the bore are still

rounded, however, to prevent the O-rings

from getting nicked or pinched during

assembly of the valve.

Even though it is not a pyro valve, I have

shown the LOX auto-vent valve in Figure 6

because this design has proven to be very

useful for venting cryogenic propellant

tanks without requiring a separately

actuated valve or control circuit. The

valve uses a Teflon slider that is kept in

the vent position as shown in Figure 6a.

Figure 4 High pressure helium fire valve for Condor This allows the tank to vent to the

liquid rocket atmosphere, keeping the propellant at its

normal boiling point. When the helium

used rather than NPT ports. When the system is activated, the pressurant pushes

valve is fired, the piston travels from the the slider closed against the vent port,

position shown in Figure 4a to that shown in sealing off the LOX tank, as shown in Figure

4b. During this travel, the inlet pressure on 6b. An O-ring is used around the slider to

the second O-ring will cause it to “blow out” give it a friction fit so the aspiration of the

as the piston major diameter translates LOX tank does not “suck” the slider to the

past the O-ring groove. The O-ring is

retained around the piston, causing no

obstruction or other problems. This valve

has been tested at 2400 psi inlet pressure

with helium and works fine. It will be tested

at 3000 psi prior to the first hot fire tests of

the condor rocket next spring.

As a side note, essentially an identical

valve design as the one used on the

Condor and Mark’s valve is shown in

NASA SP-8080, “Liquid Rocket Pressure

Regulators, Relief Valves, Check Valves,

Burst Disks and Explosive Valves”.

A second pyro valve is used on the condor

system as shown in Figure 5. This valve is

used to vent the LOX tank in the event of a Figure 5 LOX tank emergency vent for Condor

failure to open the fire valve to the engine. Rocket

Figure 3 Automatic LOX tank vent valve

closed position. This problem happened to pin that is removed by an explosive squib to

David Crisalli when he scaled this design up hold the valve in the closed position. When

for use on his 1000 lbf rocket system. I the squib is ignited, the pin is pulled by the

have used this design on the LOX tank of action of the charge on a piston, allowing

my XLR-50 rocket, which used a 1/4 inch the valves to be pulled to the open position

diameter slider, and on the condor LOX by a spring. This method may not be very

tank, which uses a 1/2 inch slider. In both elegant, but it is simple, light, and packages

cases the vent valve worked perfectly. well on the vehicle. David Crisalli has

successfully employed this technique on his

The main fire valve on the Condor rocket is large rocket.

a pair of ball valves that are chained

together to a single lever so that both the That covers the extent of the pyro valves I

fuel and oxidizer can be actuated have built or plan to build so far. In the next

simultaneously for smooth engine startup. newsletter I will present the design and flight

For static testing of the rocket I will use a of the small hypergolic propellant Rocket

double acting air cylinder to actuate the that used the valve shown in Figure 2.

valves. For flight, however, I plan to use a

Vous aimerez peut-être aussi

- Tube Plug Method PDFDocument63 pagesTube Plug Method PDFbarun1977Pas encore d'évaluation

- 02.understanding Process Equipment For Operators & Engineers-54Document5 pages02.understanding Process Equipment For Operators & Engineers-54Aatish ChandrawarPas encore d'évaluation

- CTI Feed WaterheaterDocument9 pagesCTI Feed WaterheaterИринаPas encore d'évaluation

- Troubleshooting Steam EjectorsDocument6 pagesTroubleshooting Steam EjectorsGabriel Eduardo Contreras PerozoPas encore d'évaluation

- Failure of Primary Waste Heat BoilerAiche-12-008Document5 pagesFailure of Primary Waste Heat BoilerAiche-12-008Hsein Wang100% (1)

- Modern Engineering For Design of Liquid (326-452)Document127 pagesModern Engineering For Design of Liquid (326-452)Misha's Kitchen And OtherPas encore d'évaluation

- A Practical Guide To Free Energy' Devices: A Suggested Electrolyzer DesignDocument0 pageA Practical Guide To Free Energy' Devices: A Suggested Electrolyzer Designsonja_ŽarićPas encore d'évaluation

- Design, Development and Experimentation of Aqua-Silencer For Four Stroke Petrol EngineDocument5 pagesDesign, Development and Experimentation of Aqua-Silencer For Four Stroke Petrol EngineBasavaraj S MPas encore d'évaluation

- Corrosion Mitigation: Within Dehydrating TanksDocument4 pagesCorrosion Mitigation: Within Dehydrating TanksJavier FernandoPas encore d'évaluation

- Advances in Delayed CokingDocument8 pagesAdvances in Delayed Cokingjojumathew100% (1)

- The Auxiliary Boiler Failures: Tom Herman, Mickey Roberson, Ron ParrDocument5 pagesThe Auxiliary Boiler Failures: Tom Herman, Mickey Roberson, Ron Parrvaratharajan g rPas encore d'évaluation

- P 1 HLF 03Document3 pagesP 1 HLF 03obaidullah.dsuPas encore d'évaluation

- SLMR 1913 03 30Document20 pagesSLMR 1913 03 30Russell HartillPas encore d'évaluation

- Vortex TrapDocument6 pagesVortex Trapsilvioap100% (1)

- Unique Online Leak Repair TechniquesDocument8 pagesUnique Online Leak Repair TechniquesMario Alfredo MunafóPas encore d'évaluation

- Laminations Led To IncidentDocument3 pagesLaminations Led To IncidentAhmad KadafiPas encore d'évaluation

- Replacement of A Secondary Reformer: Guy WillemsenDocument15 pagesReplacement of A Secondary Reformer: Guy Willemsenvaratharajan g rPas encore d'évaluation

- REEDS - BOILERS - PAGES 01 To 40Document40 pagesREEDS - BOILERS - PAGES 01 To 40Narendra niranjan MathiyarasuPas encore d'évaluation

- Spe 0501 0029 JPT PDFDocument2 pagesSpe 0501 0029 JPT PDFMicaela Flores LanzaPas encore d'évaluation

- Casing Drilling: An Emerging TechnologyDocument2 pagesCasing Drilling: An Emerging TechnologyMicaela Flores LanzaPas encore d'évaluation

- Engineers: Automobile Division Proceedings of The Institution of MechanicalDocument10 pagesEngineers: Automobile Division Proceedings of The Institution of Mechanicalacar1Pas encore d'évaluation

- Scientific American Supplement, No. 787, January 31, 1891D'EverandScientific American Supplement, No. 787, January 31, 1891Pas encore d'évaluation

- Emd Mi549Document7 pagesEmd Mi549DerekPas encore d'évaluation

- Emd-Mi549 RadiadoresDocument7 pagesEmd-Mi549 RadiadoresVictor Raul Tobosque MuñozPas encore d'évaluation

- How to Install Electric Bells, Annunciators, and AlarmsD'EverandHow to Install Electric Bells, Annunciators, and AlarmsPas encore d'évaluation

- 4.1 Piston AccumulatorsDocument18 pages4.1 Piston AccumulatorsDmitry DauhalPas encore d'évaluation

- DIY Particle AcceleratorDocument8 pagesDIY Particle AcceleratorGideon KandemiriPas encore d'évaluation

- Determination of HCV of Solid or Liquid Fuel Using Bomb CalorimeterDocument11 pagesDetermination of HCV of Solid or Liquid Fuel Using Bomb CalorimeterRavi PatilPas encore d'évaluation

- SGP Assignment Kaustubh Urade Types of Circuit Breakers 2017bel018Document7 pagesSGP Assignment Kaustubh Urade Types of Circuit Breakers 2017bel018Kaustubh UradePas encore d'évaluation

- Modular Condenser Replacement at Ano-1 Solves Operating Problems and Improves PerformanceDocument9 pagesModular Condenser Replacement at Ano-1 Solves Operating Problems and Improves Performancelifemillion2847Pas encore d'évaluation

- An Inexpensive Way To Do Flash Chromatography: BarryDocument1 pageAn Inexpensive Way To Do Flash Chromatography: BarryNgọcKhánhÔngPas encore d'évaluation

- Report by KKParthiban On Boiler Explosion of A Shell Type High PR BoilerDocument97 pagesReport by KKParthiban On Boiler Explosion of A Shell Type High PR Boilerparthi20065768100% (1)

- Tubing PatcDocument2 pagesTubing PatcAminollah PayvandPas encore d'évaluation

- 09 Oct 17 3317 16 Generator Field Windings Moisture EffectsDocument9 pages09 Oct 17 3317 16 Generator Field Windings Moisture EffectsAhemadPas encore d'évaluation

- LGP REPORT #3 - SimpasaDocument15 pagesLGP REPORT #3 - SimpasaBeckham ChailePas encore d'évaluation

- Spe PetrobrasDocument12 pagesSpe PetrobrasLawrence MbahPas encore d'évaluation

- Study Sheet EquipmentDocument3 pagesStudy Sheet EquipmentAna DraguPas encore d'évaluation

- Generator Bushing DesignsDocument10 pagesGenerator Bushing DesignsPradeep_VashistPas encore d'évaluation

- TAMT0101 TalkDocument29 pagesTAMT0101 TalkchipulinoPas encore d'évaluation

- NL Master Specification Guide For Public Funded Buildings: Re-Issued 2017/05/31Document5 pagesNL Master Specification Guide For Public Funded Buildings: Re-Issued 2017/05/31Shubham SharmaPas encore d'évaluation

- Fusible PlugsDocument27 pagesFusible PlugsadityaayyagariPas encore d'évaluation

- Fog PlantDocument6 pagesFog PlantAleks Prox100% (1)

- Trouble Shooting Vibration in A Pulverized Coal Fired BoilerDocument13 pagesTrouble Shooting Vibration in A Pulverized Coal Fired Boilerparthi20065768100% (1)

- 01 Cyclone Basics Problem SolvingDocument21 pages01 Cyclone Basics Problem SolvingdeepakattavarPas encore d'évaluation

- An Overview of UL Underground Storage Tank Standards: UL58, 1746 and 1316Document8 pagesAn Overview of UL Underground Storage Tank Standards: UL58, 1746 and 1316Felipe rPas encore d'évaluation

- Findings On Shut Down Inspection of An AFBC BoilerDocument30 pagesFindings On Shut Down Inspection of An AFBC Boilerparthi20065768Pas encore d'évaluation

- Weld DistortionDocument3 pagesWeld DistortiongovimanoPas encore d'évaluation

- All Metal PCP Field Trial Update: A. Damnjanovic, S. Jahn, G. Mitskopoulos, L. SeinceDocument7 pagesAll Metal PCP Field Trial Update: A. Damnjanovic, S. Jahn, G. Mitskopoulos, L. SeinceVenus DobosPas encore d'évaluation

- A Case Study On Hydrogen Damage in A CFBC BoilerDocument38 pagesA Case Study On Hydrogen Damage in A CFBC Boilerparthi20065768100% (1)

- Coiled Tubing Used As A Continuous-Sucker-Rod System in Slim HolesDocument2 pagesCoiled Tubing Used As A Continuous-Sucker-Rod System in Slim HolesMarilyn Garzón AguirrePas encore d'évaluation

- Fuel Handling SystemDocument4 pagesFuel Handling SystemRoel FranciscoPas encore d'évaluation

- M8WLKNK1Document4 pagesM8WLKNK1DavidArcherPas encore d'évaluation

- Magnetic ORMUS Vortex TrapDocument10 pagesMagnetic ORMUS Vortex TrapZach Royer100% (2)

- CondenserDocument33 pagesCondenserSatyam KumarPas encore d'évaluation

- Cracking of Alloy 800H Reformer RiserDocument14 pagesCracking of Alloy 800H Reformer RiserTiah Nam Kuan100% (1)

- Globe Valve Lab ReportDocument8 pagesGlobe Valve Lab ReportPeterJohn32Pas encore d'évaluation

- Splbe - Master Plumber 2015 15.: Page 1 of 7Document7 pagesSplbe - Master Plumber 2015 15.: Page 1 of 7gregPas encore d'évaluation

- Steam Engine Indicator Diagram: Effect of Piping ArrangementsDocument54 pagesSteam Engine Indicator Diagram: Effect of Piping ArrangementsGiovanni AndradePas encore d'évaluation

- SPE-184102-MS (2 Technology For Cementation)Document14 pagesSPE-184102-MS (2 Technology For Cementation)Randy SooknananPas encore d'évaluation

- Scientific American Supplement, No. 470, January 3, 1885D'EverandScientific American Supplement, No. 470, January 3, 1885Pas encore d'évaluation

- Z22Se: Camshaft and Balancer Shaft Chains: Tech NoteDocument8 pagesZ22Se: Camshaft and Balancer Shaft Chains: Tech NoteJou PowerPas encore d'évaluation

- Valves and Solenoid Valves Series NA: 3/2 - 5/2 - 5/3-Way CC CO CP With Holes Configured According NAMUR StandardsDocument6 pagesValves and Solenoid Valves Series NA: 3/2 - 5/2 - 5/3-Way CC CO CP With Holes Configured According NAMUR StandardsmohamedPas encore d'évaluation

- Atlas Copco CM760d Tier III Instruction ManualDocument454 pagesAtlas Copco CM760d Tier III Instruction ManualRobert Russell100% (4)

- Teco LVTEFCDocument40 pagesTeco LVTEFCJeremy MoorePas encore d'évaluation

- Motor SCH AJM ATJDocument11 pagesMotor SCH AJM ATJaritmeticsPas encore d'évaluation

- PompaDocument230 pagesPompaDodi SuhendraPas encore d'évaluation

- ATPL Nhom4 BDHKDocument114 pagesATPL Nhom4 BDHKVăn Thành NguyễnPas encore d'évaluation

- Preface: Manual For Operation & Maintenance of 200 Series Inline Engines With One-Piece Injection PumpDocument114 pagesPreface: Manual For Operation & Maintenance of 200 Series Inline Engines With One-Piece Injection PumpDevi Beni Tanaya100% (1)

- FILL RITE Fuel-Pump-ManualDocument16 pagesFILL RITE Fuel-Pump-ManualWUILLIANSPas encore d'évaluation

- Dynamic BalancingDocument9 pagesDynamic BalancingAbhiruchi PatilPas encore d'évaluation

- Eai-1kd EwdDocument1 pageEai-1kd Ewdcartronix2010Pas encore d'évaluation

- User GuideDocument46 pagesUser GuideMitko VirliosPas encore d'évaluation

- Alternator Slt18 MD: Three-Phase Brushless Synchronous Alternator With AVR - 4 PolesDocument7 pagesAlternator Slt18 MD: Three-Phase Brushless Synchronous Alternator With AVR - 4 PoleshirararaPas encore d'évaluation

- Fundamentals of Centrifugal PumpsDocument70 pagesFundamentals of Centrifugal PumpsFrancisco GarcíaPas encore d'évaluation

- 2ZZ Engine DevelopmentDocument9 pages2ZZ Engine Developmentdavid_garlock100% (1)

- 4706 - Pro48-705 Pinout For 2003-2006 Nissan 350Z/ Infiniti G35 VQ35DEDocument1 page4706 - Pro48-705 Pinout For 2003-2006 Nissan 350Z/ Infiniti G35 VQ35DEAdan Flores CorreaPas encore d'évaluation

- 3406 Testing & Adjusting ESS PDFDocument53 pages3406 Testing & Adjusting ESS PDFharikrishnanpd3327Pas encore d'évaluation

- Yamaha ReportDocument15 pagesYamaha ReportCheshta NavalPas encore d'évaluation

- KTM 450 EXC Electric ChecksDocument3 pagesKTM 450 EXC Electric Checksburgerbiter100% (1)

- Parts Catalog: 25, 30 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25, 30 HP (521cc) 2 Stroke ModelsRonei MartinsPas encore d'évaluation

- RTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWDocument1 pageRTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWMohamed MohamedPas encore d'évaluation

- Starter Lock-Out Relay TestDocument1 pageStarter Lock-Out Relay TestПеђа БекићPas encore d'évaluation

- CoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyDocument6 pagesCoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyShaip Sankar100% (1)

- 2009 Handok Hydraulic CatalogDocument10 pages2009 Handok Hydraulic CatalogMauricio Ariel H. OrellanaPas encore d'évaluation

- Service Note 179 Mitsui MAN B&WDocument6 pagesService Note 179 Mitsui MAN B&WИгорьPas encore d'évaluation

- Assy Conveyor 4 MTR (2 Unit) : Part Number Description Qty. Item NODocument11 pagesAssy Conveyor 4 MTR (2 Unit) : Part Number Description Qty. Item NOFaiz Qilafa ZimamPas encore d'évaluation

- KgdkydlhxlhditDocument223 pagesKgdkydlhxlhditjorge luis guevara martinezPas encore d'évaluation

- Accelerator Control System: SectionDocument2 pagesAccelerator Control System: SectionRichard Wilson Mera JaimePas encore d'évaluation

- Chapter 7 Induction Machines-EEE301Document96 pagesChapter 7 Induction Machines-EEE301DilekPas encore d'évaluation

- 1969 Ford Car Shop Manual Volume One ChassisDocument413 pages1969 Ford Car Shop Manual Volume One Chassisdavidpiston100% (6)