Académique Documents

Professionnel Documents

Culture Documents

B. Mix Design Manual

Transféré par

eddieCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

B. Mix Design Manual

Transféré par

eddieDroits d'auteur :

Formats disponibles

Since 1948

SLUMP TEST PROCEDURE

(FIELD TESTING)

1 To obtain a representative sample, take 2 Dampen inside of cone and place it on a 3 Fill cone 1/3 full by volume and

samples from two or more regular intervals smooth, moist, non-absorbent, level surface rod 25 times with 5/8-inch-di-

throughout the discharge of the mixer or large enough to accommodate both the ameter x 24-inch-long

truck. DO NOT take samples at the begin- slumped concrete and the slump cone. hemispherical tip steel

ning or the end of the discharge. Stand or, foot pieces throughout the test tamping rod. (This is a

procedure to hold the cone firmly in place. specification requirement

which will produce

non-standard results unless followed exact-

ly.) Distribute rodding evenly over the entire

cross section of the sample.

4 Fill cone 2/3 full by volume. Rod 5 Fill cone to overflowing. Rod this 6 Remove the excess con-

this layer 25 times with rod layer 25 times with rod pene- crete from the top of the

penetrating into, but not trating into but not through, cone, using tamping rod as

through first layer. Distribute second layer. Distribute a screed. Clean overflow

rodding evenly over the rodding evenly over the entire from base of cone.

entire cross section of the cross section of this layer.

layer.

7 Immediately lift 8 Lay a straight edge across the top of

cone vertically with the slump cone. Measure the amount

slow, even motion. Do of slump in inches

not jar the concrete or from the bottom of

tilt the cone during the straight edge to the

this process. Invert the top of the slumped

withdrawn cone, and concrete at a point

place next to, but not over the original

touching the slumped concrete. (Perform in center of the base. The slump operation shall

5-10 seconds with no lateral or torsional be completed in a maximum elapsed time of 2

motion.) 1/2 minutes. Discard concrete. DO NOT use in

any other tests.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Self-Coached Climber - The Guide To Movem - Dan M (1) HagueDocument376 pagesSelf-Coached Climber - The Guide To Movem - Dan M (1) HagueBill Frisch100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Social Media and Loneliness - Why An Instagram Picture May Be Worth More Than A Thousand Twitter WordsDocument13 pagesSocial Media and Loneliness - Why An Instagram Picture May Be Worth More Than A Thousand Twitter WordsCarlos Leite Filho100% (1)

- Analysis of Rack and Pinion Using AnsysDocument21 pagesAnalysis of Rack and Pinion Using AnsysTejas Prakash100% (1)

- GBE Version 3: API: New API SpecificationDocument44 pagesGBE Version 3: API: New API SpecificationAdi BauPas encore d'évaluation

- Shedule OF Doors & WindowsDocument1 pageShedule OF Doors & WindowseddiePas encore d'évaluation

- Ground Floor Plan (Redmarks)Document1 pageGround Floor Plan (Redmarks)eddiePas encore d'évaluation

- Batching Plant Layout 2Document1 pageBatching Plant Layout 2eddiePas encore d'évaluation

- Department of Public Works and Highways: Roads Management Cluster Ii (Multilateral) UpmoDocument24 pagesDepartment of Public Works and Highways: Roads Management Cluster Ii (Multilateral) UpmoeddiePas encore d'évaluation

- Department of Public Works and Highways: Misamis Occidental To Lanao Del NorteDocument2 pagesDepartment of Public Works and Highways: Misamis Occidental To Lanao Del NorteeddiePas encore d'évaluation

- Revised Mobilization of EquipmentDocument1 pageRevised Mobilization of EquipmenteddiePas encore d'évaluation

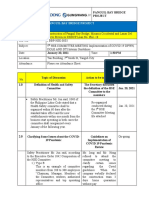

- Project:: Panguil Bay Bridge ProjectDocument4 pagesProject:: Panguil Bay Bridge ProjecteddiePas encore d'évaluation

- Take-Off Water DistributionDocument2 pagesTake-Off Water DistributioneddiePas encore d'évaluation

- PullBoxDocument1 pagePullBoxeddiePas encore d'évaluation

- April 22, 2021 Piling and Dreding ActivitiesDocument4 pagesApril 22, 2021 Piling and Dreding ActivitieseddiePas encore d'évaluation

- #2.response To Comments Sheet - Package2 Part1 Design Drawing (DH-PBBP-IDC-009) - 210225Document6 pages#2.response To Comments Sheet - Package2 Part1 Design Drawing (DH-PBBP-IDC-009) - 210225eddiePas encore d'évaluation

- Submission of Package 1 - Part 3 14 Abutment Piles and ILM Yard Piles - Rev.1Document3 pagesSubmission of Package 1 - Part 3 14 Abutment Piles and ILM Yard Piles - Rev.1eddiePas encore d'évaluation

- Package 2 Part 1 Design DrawingsDocument45 pagesPackage 2 Part 1 Design DrawingseddiePas encore d'évaluation

- Department of Public Works and Highways: Roads Management Cluster Ii (Multilateral) UpmoDocument24 pagesDepartment of Public Works and Highways: Roads Management Cluster Ii (Multilateral) UpmoeddiePas encore d'évaluation

- Package 2 Part 1 Design DrawingsDocument45 pagesPackage 2 Part 1 Design DrawingseddiePas encore d'évaluation

- Package 2 Part 1 Design DrawingsDocument45 pagesPackage 2 Part 1 Design DrawingseddiePas encore d'évaluation

- Project Two Storey Residence Subject Bil PDFDocument5 pagesProject Two Storey Residence Subject Bil PDFRonna MaePas encore d'évaluation

- Revised Mobilization of EquipmentDocument1 pageRevised Mobilization of EquipmenteddiePas encore d'évaluation

- Estimate S: I. EarthworksDocument58 pagesEstimate S: I. EarthworksRaul ArranguezPas encore d'évaluation

- Arma+ Shapes As of 13 May 2020Document7 pagesArma+ Shapes As of 13 May 2020eddiePas encore d'évaluation

- SDSDSDSDDocument36 pagesSDSDSDSDeddiePas encore d'évaluation

- Estimate S: I. EarthworksDocument58 pagesEstimate S: I. EarthworksRaul ArranguezPas encore d'évaluation

- Narrow House 4.2x14mDocument19 pagesNarrow House 4.2x14meddiePas encore d'évaluation

- Troxler StorageDocument3 pagesTroxler StorageeddiePas encore d'évaluation

- RectifyDocument3 pagesRectifyeddiePas encore d'évaluation

- A 2Document6 pagesA 2eddiePas encore d'évaluation

- FormDocument1 pageFormeddiePas encore d'évaluation

- Kitchen Basics: Planning and TrendsDocument58 pagesKitchen Basics: Planning and TrendseddiePas encore d'évaluation

- PCAB List of Licensed Contractors For CFY 2018-2019 As of 08 Oct 2018 - WebDocument754 pagesPCAB List of Licensed Contractors For CFY 2018-2019 As of 08 Oct 2018 - WebQueen SlayePas encore d'évaluation

- 6 Month Summer Training Project ReportDocument33 pages6 Month Summer Training Project ReportDevendra Potdar100% (6)

- Operation & Service Manual For Cable Tensiometer: SeriesDocument28 pagesOperation & Service Manual For Cable Tensiometer: SeriesJonatan BernalPas encore d'évaluation

- Guaranteed Restore Points Oracle 11g - Flash Back to SCN or RP (39Document2 pagesGuaranteed Restore Points Oracle 11g - Flash Back to SCN or RP (39PraveenPas encore d'évaluation

- TRL External CommunicationDocument3 pagesTRL External CommunicationAyushGargPas encore d'évaluation

- Physics Assignment 1Document4 pagesPhysics Assignment 1Trí Võ PhạmPas encore d'évaluation

- Impact of GIC On Power TransformersDocument141 pagesImpact of GIC On Power TransformersAkash Verma100% (1)

- TVL CSS11 Q4 M1Document12 pagesTVL CSS11 Q4 M1Richard SugboPas encore d'évaluation

- Dental Material Final ReportDocument7 pagesDental Material Final ReportAbdullah Muhammed khaleel HassanPas encore d'évaluation

- WCS1400 / WCS1400S: FeaturesDocument7 pagesWCS1400 / WCS1400S: FeaturesbahrowiadiPas encore d'évaluation

- Design of Three Span Steel Composite FlyoverDocument85 pagesDesign of Three Span Steel Composite FlyoverStructural SpreadsheetsPas encore d'évaluation

- Solidworks Flow SimulationDocument7 pagesSolidworks Flow SimulationpatrickNX94200% (1)

- An Intelligent Algorithm For The Protection of Smart Power SystemsDocument8 pagesAn Intelligent Algorithm For The Protection of Smart Power SystemsAhmed WestministerPas encore d'évaluation

- SQL SlidesDocument65 pagesSQL SlidescopsamostoPas encore d'évaluation

- Water Pinch PresentationDocument14 pagesWater Pinch PresentationDafiMaboPas encore d'évaluation

- Calentador Catalitico de TuberíasDocument2 pagesCalentador Catalitico de TuberíasDavid RomeroPas encore d'évaluation

- Report On The Quantitative Techniques in BusinessDocument10 pagesReport On The Quantitative Techniques in BusinessBaron FrancisPas encore d'évaluation

- A Prediction of Water Quality Analysis Using Machine LearningDocument6 pagesA Prediction of Water Quality Analysis Using Machine LearningmonacmicsiaPas encore d'évaluation

- Chapter 13: The Electronic Spectra of ComplexesDocument42 pagesChapter 13: The Electronic Spectra of ComplexesAmalia AnggreiniPas encore d'évaluation

- Live load and wind pressure on sloping roofsDocument11 pagesLive load and wind pressure on sloping roofsAbel BerhanemeskelPas encore d'évaluation

- Lesson 17: Lightning Accidents: Grade 9-Science-Sussex College - WennappuwaDocument5 pagesLesson 17: Lightning Accidents: Grade 9-Science-Sussex College - WennappuwaSwarnapaliliyanagePas encore d'évaluation

- Active Heating and CoolingDocument16 pagesActive Heating and Coolinga_j_sanyal2590% (1)

- TM View Software User - S ManualDocument190 pagesTM View Software User - S ManualLuis SánchezPas encore d'évaluation

- Ice o Matic - Cim0436faDocument2 pagesIce o Matic - Cim0436faJean RamosPas encore d'évaluation

- Speedrunfile 1Document26 pagesSpeedrunfile 1Adrian AquinoPas encore d'évaluation

- MC0081Document385 pagesMC0081Purushottam KumarPas encore d'évaluation

- Eng Grammar Book 8Document77 pagesEng Grammar Book 8ЖАНСАЯ Сейдахмет50% (2)

- Mediburn 30Document35 pagesMediburn 30Vsee EnkoPas encore d'évaluation