Académique Documents

Professionnel Documents

Culture Documents

07087-00000-MC03 General Specification For Piping Material Rev.0C PDF

Transféré par

tien0 évaluation0% ont trouvé ce document utile (0 vote)

20 vues9 pagesTitre original

07087-00000-MC03 General Specification for Piping material Rev.0C.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

20 vues9 pages07087-00000-MC03 General Specification For Piping Material Rev.0C PDF

Transféré par

tienDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 9

PMB

PETROVIETNAM-CPMB

CAMAU VIETNAM

WUHUAN

ENGINEERING

CA MAU FERTILIZER PLANT

Basic Design

}07087-00000-MCo3

CO.,LTD

tof 9 |Rev.0BC |rr-0¢

General Specification for Piping Materials

f SZ.

08 | Qn Tewe, | la” | adie |-Fe yp Wh b00F-08-0

0A

Rev. Description By ‘Check

Apprd Date & &

PETROVIETNAM-CPMB

CAMAU VIETNAM

ENGINEERING

WUHUAN ‘CA MAU FERTILIZER PLANT

Basic Design

07087—00000—Mc03

GENERAL

R MATERIAL

B INSPECTIONS AND TESTS

CO.,LTD —_| General Specification for piping materials

CONTENTS

# ‘THE DESCRIPTION OF PIPING CLASSIFICATION

2of9 | Rev.0€

PETROVIETNAM-CPMB

CAMAU VIETNAM

Basic Design

07087—00000—Mco3

WUHUAN CA MAU FERTILIZER PLANT

ENGINEERING

CO.,LTD General Specification for piping materials | 3 of 9 Rev. Oy

GENERAL

1.1 Intent

This engineering specification contains specific requirements for the selection of piping

materials to be used in CA MAU FERTILIZER Plant designed by Wuhuan Engineers Co.

Ltd.

1.2, Scope

This specification shall be applied to piping materials indicated on P&ID flow diagrams and

utility flow diagrams.

The specification of piping systems provided by manufacture should be approved by WEC.

This specification shall not be applied to special piping companion such as strainers, etc.

This specification are given minimum requirements for piping material and should be sent

to conduct vendors,

1.3 Unit

Unless otherwise specified, SI system and Celsius system shail be applied as the

measurement system for the drawings and documents to be submitted; however nominal

pipe size in inches and nominal diameter of piping components shall be in mm.

1.4 Codes and standards

Design, fabrication, testing and inspection of piping materials shall be accomplished in

accordance with the applicable Codes and Standards in the latest edition as follows:

ASME(The American Society of Mechanical Engineers)

‘ASME II: Material specification.

ASME V Non-Destructive Examination

ASME B16.3 Malleable Iron threads fittings

ASMEB1.20.1 Pipe Threads, General Purpose

ASME B1.1 Unified Inch Screw Threads (UN and UNR Tread Form)

ASME B18.31 Metric continuous and double-end stub

ASME B18.2.1/818.2.2: Square and hexagon bolts and nuts

ASME B16.1 Cast Iron pipe flange and Flanged fittings

ASME B16.5 Pipe Flanges and Flanged Fittings

PETROVIETNAM-CPMB

CA MAU VIETNAM

Lcbetbeeae CA MAU FERTILIZER PLANT

Basic Design

07087—00000—NC03

ENGINEERING

CO.,LTD

General Specification for piping materials

ASME B16.9 Factory-Made Wrought Steel Butt welding Fittings

ASMEB16.10 Face-to-Face and End-to-End Dimensions of Valves.

ASME B16.11 Forged Fittings, Socket-Welding and Threaded

Rev. O8,

ASME B16.20 Metallic Gaskets for Pipe Flanges: Ring-Joint, Spiral-Wound &Jacketed

ASME B16.21 Non-metallic Flat Gaskets for Pipe Flanges

ASME B16.34 Valves-Flanged, Threaded, and Welding End

ASMEB36.10M Welded and Seamless Wrought Steel Pipe

ASMEB36.19M Stainless Stee! Pipe

ASME B16.47 Large Diameter steel Flanges

ASME B16.48 Steel Line Blanks

ASME B31.1 Power Piping

ASME B31.3 Process Piping

API (American Petroleum Institute)

API 594 Wafer-type Check Valves

API 598 Valve Inspection and Test

API 599 Metal Plug Valves-Flanged Threaded and Welding Ends

API 600 Stee! Gate Valves, Flanged or Butt-Welding Ends

API 602 Compact Steel Gate Valves

API 607 Fire Test for Soft-Seated Quarter-Turn Valves,

API 609 Wafer-type Butterfly Valves

API6A Specification for threads in valve fittings and flanges

API 590 Stee! Line Blanks

API 6D: Specification for pipe line valves

API 603 Corrosion resistant valve

API 608 Metal ball valves- flanged, threaded and welding end

API RP 945 Avoiding Environmental Cracking in Amine Units

MSS (Manufacturers Standardization Society)

MSS SP-25 Standard Marking System for Valve ,Fittings Flanges and Unions

MSS SP-44 Steel Pipe Line Flanges

MSS SP-83 Carbon Steel Pipe Unions, Socket-Welding and Threaded

MSS SP-95 Nipples and Bull Plugs

MSS SP-97 integrally Reinforced Forged Branch Outlet fittings Socket welding Threaded

and Buttwelding Ends

MSS SP 72 Ball Valves

MSS SP 81 stainless steel bonnetless, flanged, knife gate valve

MSS SP 88 diaphragm type valves

Design specification

General specification for manual valves (07087-000000-MC14 Rev.0B).

PETROVIETNAM-CPMB

CAMAU VIETNAM

Basic Design

WUHUAN CA MAU FERTILIZER PLANT

ENGINEERING

Co.,LTD General Specification for piping materials | 5 of 9 Rev. Of

07087—00000—co3.

‘Specification for Painting (07087-000000-MC08 Rev.0C).

Austenitic Stainless steel for urea plant High pressure section (SPC.CR.UR.510 Rev.03).

‘Standard for piping of High pressure urea section (STD-TB-UPU-5002 Rev.02).

Index of piping material classification (07087-00000-MC10)

Piping material classification (07087-00000-MC11)

Piping Walll thickness table (07087-00000-MC12)

Piping Branch connection table (07087-00000-MC13)

Others

BS 1868 Forged Check Valves

BS 1873 Forged Globe Valves

BS EN ISO 17292 (been replaced for BS5351): Ball Valves

BS5352 Cast Check Valves

NACE RP0472-2000, Methods and Controls to Prevent In-Service Environmental Cracking

of carbon Steel Weldments in Corrosive Petroleum Refining Environments

MATERIAL

24 General

Material for individual piping components shall normally conform to ASME, ASTM, API, MSS|

BS or manufacturer's standard,

All piping materials shall be used only within the temperature and pressure range speoified

by piping class.

PWHT shall be provided in MDEA services for 82° C or higher operating temperature as per

API 945.

All piping material shall be heat treated in accordance with the applicable standard

requirements or specification in the engineering design,

Piping materials shall be stress relieved in accordance with ASME B31.3Furthermore, when

PWHT is required in each specification of the document, PIPING MATERIAL CLASSIFI-

-CATION.

Meanwhile, piping material for caustic, acid service fluids shall be stress relieved, All welds

in carbon steel piping shall, as a precautionary measure, be post weld heat treated, in order

to reduce susceptibility to Stress Corrosion Cracking. Further guidance is given in NACE

RPO4T2.

Copper and copper alloys are not allowed in the Plant.

BAL

PETROVIETNAM-CPMB

CA MAU VIETNAM

WUHUAN CA MAU FERTILIZER PLANT

07087—00000—MCO3

General Specification for piping materials

Co.,LTD

2.2 Pipe

Pipe size 1 14°, 2%", 3%", 5" shall not be used, unless particular case to match equipment

connection. Piping line connections to equipment with such connection sizes shall be made

with suitable adapter fitings.

In case of welded pipe, Wall thickness calculation shall be included considering of weld joint

efficiency factor.

Pipe dimensions shall be in accordance with B36.10M for carbon steel and with 836.19M for

stainless steel pipe, unless otherwise specified.

‘Wall thickness shail be calculated in accordance with ASME B31.3. Wall thickness has been

based on the minimum wall thickness required for the design pressure-temperature

conditions, with corrosion allowance and mechanical allowance.

The minimum thickness for DN40 and under shall be as follows:

Carbon steel! SCH 80

Austenitic stainless steel SCH 408

‘The corrosion allowance shall be determined by the intend service of the piping. In this,

specification the corro:

n allowance is specified as follows.

Carbon steel 1.6mm / 3.2mm

Austenitic stainless steel 0.0mm

23 Fitting

‘Wall thickness of butt -welding type fittings shall be equal or greater than the nominal wall

thickness of connected pipe. Where the wall thickness of the butt-weld fitting is greater than

the wall thickness of the pipe a taper bore of 1:5 shall be applied to the fiting,

For Hydrogen service: Screwed connections are not to be used,

Minimum size of small connections on process lines to be 1" for strength,

End preparation of butt-welding fittings shall be in accordance with ASME B16.25,

Long radius elbows shall be used. Short radius elbows may be used only where space limits

the use of long radius elbows.

Branch connections for individual piping classes shall be made in accordance with branch

table of individual piping class.

‘Stub end shall be in accordance with ASME 816.9 (Short pattern length) as specified in each

PETROVIETNAM-CPMB

oe CA MAU VIETNAM

= WUHUAN

ws ENGINEERING

Basic Design

CA MAU FERTILIZER PLANT

07087—00000—Mco3,

CO.,LTD —_| General Specification for piping materials | 7 of 9 | Rev. 0

PIPING MATERIALS CLASSIFICATION.

24 Flange

Standards:

ASME B16.5 Steel Pipe Flanges and Flanged Fittings

(Class 150- 1500: NPS 24 and under)

(Class 2500: NPS 12 and under)

ASME B16.47 8

(Class 150-900: NPS 26 to NPS 60)

ASME B16.1

(Cast Iron class 25, 125, 250 & 800)

Bore of SW and WN flange shall be matched for pipe SCH.

In Stainless Steel class (class150) use Welding Neck flanges only when Lap-Joint

plus Stub end is not suitable ( i.e. to connect the Water Butterily Valves ).

25 Valve

Refer to General specification for manual valves ~ Doc. No. 07087-000000-MC14 Rev.0B.

2.6 Gasket

Dimensions shall be as follows:

Gaskets in the piping classes should be in accordance with ASME B16.20& ASME B16.21.

(1) Spiral wound gasket ASME B16.20

(2) Ring joint gasket and grooves ASME B16.20

(3) Non-metallic gasket ASME B16.21

(4) Special gaskets Manufacture’s Standard

Non metalic flat gasket minimum thickness is 2 mm.

2.7 Bolts and Nuts

‘Stud bolt shall be threaded in their total length.

Dimensions and tolerances of thread shall be in accordance with ASME B18.2.1& ASME

B18.2.2,

2.8 Threads

Threads for pipes, flanges and fittings shall be as specified in ASME B1.20.1 Pipe Threads

(NPT).

‘be

PETROVIETNAM-CPMB

CAMAU VIETNAM

CPMB.

Basic Design

WUHUAN CA MAU FERTILIZER PLANT ee

ENGINEERING -

CO.,LTD —_| General Specification for piping materials| 8 of 9 | Rev. 0

Teflon seal tape should be used for threaded joint connections for which fluid temperature

doesn't exceed 150 degree Celsius.

B INSPECTION AND TESTS

Inspection and tests of individual piping components shall be accomplished in accordance with

ASTM, API, and other relevant standard. Additive requirements on inspection and tests shall be

described in procurement document.

THE DESCRIPTION OF PIPING CLASSIFICATION

‘The piping classification shall be detailed in project specification document MC10, Index of Piping

Material Classification.

Attachment

Abbreviations used inthis specification are defined in the following table.

ABBREVIATION ______ DESCRIPTION

BE Bevelled End

ew Butt Weld

cA Corrosion Allowance (in mm)

cs Carbon Steel

DES. Designation

ERW Electric Resistance Weld

EFW Electric Fusion Weld.

FF Full Face (Flat, Face)

FLG Flange

GALV Galvanized

He Brinell Hardness

ID&0D Inside Diameter & Outside Diameter

IR&OR Inside Ring& Outside Ring 4 t

LuFT Lift Type

u Lapped (Loose) Joint p

PETROVIETNAM-CPMB.

= ‘CAMAU VIETNAM

PMB

= WUHUAN CA MAU FERTILIZER PLANT

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Interplus - 880 DatasheetDocument4 pagesInterplus - 880 DatasheettienPas encore d'évaluation

- Iso 4624 PDFDocument15 pagesIso 4624 PDFRajan Steeve50% (2)

- Vpci - 386 Acrylic Primer/Topcoat: FeaturesDocument2 pagesVpci - 386 Acrylic Primer/Topcoat: FeaturesDenish Tiko AkbarPas encore d'évaluation

- Corrofill E DatasheetDocument2 pagesCorrofill E DatasheettienPas encore d'évaluation

- Iso 4624 PDFDocument15 pagesIso 4624 PDFRajan Steeve50% (2)

- 5 92 AB Plasmet EP1 August 18Document2 pages5 92 AB Plasmet EP1 August 18tienPas encore d'évaluation

- Protective DURAPLATE 301L/K coating provides long-term corrosion protectionDocument4 pagesProtective DURAPLATE 301L/K coating provides long-term corrosion protectiontienPas encore d'évaluation

- Pull Off Adhesion Testing of CoatingsDocument12 pagesPull Off Adhesion Testing of CoatingsDANIEL MOYYA100% (2)

- SW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFDocument2 pagesSW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFtienPas encore d'évaluation

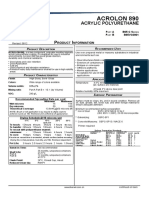

- 1A-Acrolon 890Document2 pages1A-Acrolon 890Stuart PhamPas encore d'évaluation

- Corrofill VE DatasheetDocument2 pagesCorrofill VE DatasheettienPas encore d'évaluation

- Corrofill EP DatasheetDocument2 pagesCorrofill EP DatasheettienPas encore d'évaluation

- Tank Linings 04 2013 - tcm157 1585Document7 pagesTank Linings 04 2013 - tcm157 1585anon_68738065100% (1)

- Pure Epoxies Vs Epoxy Mastics For Maintenance PDFDocument4 pagesPure Epoxies Vs Epoxy Mastics For Maintenance PDF003086100% (1)

- BS 7773-1995-Prepare Surface PDFDocument38 pagesBS 7773-1995-Prepare Surface PDFtienPas encore d'évaluation

- I-10 SURFACE PREPARATION Ferrous Metal v4 PDFDocument7 pagesI-10 SURFACE PREPARATION Ferrous Metal v4 PDFtienPas encore d'évaluation

- BS 4485-4-1996 PDFDocument34 pagesBS 4485-4-1996 PDFtienPas encore d'évaluation

- Sis 05 5900Document11 pagesSis 05 5900Taha Zia50% (2)

- 1490-Cleaning of Steel and Removal of SaltsDocument8 pages1490-Cleaning of Steel and Removal of SaltsjasminneePas encore d'évaluation

- Surface Preparation: Ponderosa Protective CoatingsDocument17 pagesSurface Preparation: Ponderosa Protective CoatingstienPas encore d'évaluation

- Properties of Thermal Sprayed Coatings For Internal Pipe PDFDocument116 pagesProperties of Thermal Sprayed Coatings For Internal Pipe PDFtien100% (1)

- Thermal Sprayed Aluminium For Subsea Heat Exchanger PDFDocument210 pagesThermal Sprayed Aluminium For Subsea Heat Exchanger PDFtienPas encore d'évaluation

- 07087-GS-MC02 Pipe Support Standard-SignatureDocument189 pages07087-GS-MC02 Pipe Support Standard-SignaturetienPas encore d'évaluation

- Properties of Thermal Sprayed Coatings For Internal Pipe PDFDocument116 pagesProperties of Thermal Sprayed Coatings For Internal Pipe PDFtien100% (1)

- Thermal Sprayed Aluminium For Subsea Heat Exchanger PDFDocument210 pagesThermal Sprayed Aluminium For Subsea Heat Exchanger PDFtienPas encore d'évaluation

- Materials Selection For Refineries and Associated FacilitiesDocument164 pagesMaterials Selection For Refineries and Associated Facilitiesqaisarabbas9002100% (20)

- CorrosionProtection Thermal Spray AluminumDocument10 pagesCorrosionProtection Thermal Spray AluminumtienPas encore d'évaluation

- 07087-GS-MC02 Standard For Piping Support Rev.2B (A4) PDFDocument189 pages07087-GS-MC02 Standard For Piping Support Rev.2B (A4) PDFtienPas encore d'évaluation

- 07087-GS-MC02 Standard For Piping Support Rev.2B (A4) PDFDocument189 pages07087-GS-MC02 Standard For Piping Support Rev.2B (A4) PDFtienPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)