Académique Documents

Professionnel Documents

Culture Documents

Wps Mma Pipe

Transféré par

Dimitris Nikou0 évaluation0% ont trouvé ce document utile (0 vote)

299 vues2 pagesThis welding procedure specification outlines the parameters for a multi-run fillet weld using the gas metal arc welding process with solid wire electrode. The weld will be deposited on 6mm thick steel in the flat position using 3.2mm diameter filler metal with a spray arc transfer and heat input of 0.9 kJ/cm. The filler metal is E 42 5 B 4 2 H5 and the shielding gas is a gas mixture flowed at a rate of 15-20 l/min.

Description originale:

Wps Mma Pipe

Copyright

© © All Rights Reserved

Formats disponibles

XLSX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis welding procedure specification outlines the parameters for a multi-run fillet weld using the gas metal arc welding process with solid wire electrode. The weld will be deposited on 6mm thick steel in the flat position using 3.2mm diameter filler metal with a spray arc transfer and heat input of 0.9 kJ/cm. The filler metal is E 42 5 B 4 2 H5 and the shielding gas is a gas mixture flowed at a rate of 15-20 l/min.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme XLSX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

299 vues2 pagesWps Mma Pipe

Transféré par

Dimitris NikouThis welding procedure specification outlines the parameters for a multi-run fillet weld using the gas metal arc welding process with solid wire electrode. The weld will be deposited on 6mm thick steel in the flat position using 3.2mm diameter filler metal with a spray arc transfer and heat input of 0.9 kJ/cm. The filler metal is E 42 5 B 4 2 H5 and the shielding gas is a gas mixture flowed at a rate of 15-20 l/min.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme XLSX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

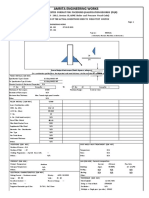

Welding Procedure Specification According to EN ISO 15609, 2004

Manufacturer TEI WM WPS No:003

PQR No:003

Method of preparation and cleaning: Grinding/Brusing

Test Pieces

No. Welding Process Thickness Welding position Joint type Parent metal (specification)

1 111 6(mm) PB Fillet P235GH

Weld Preparation Sketch

Joint Design Welding Sequence

Type of Wire feed

Filler metal current travel Heat input Metal

Run Process (mm) Current (A) Voltage (V) polarity (cm/min) (Kj/cm) transfer

1 111 3.2 100-140 25-30 Dc+ 18-23 0.9 Spray arc

2 111 3.2 100-140 25-30 Dc+ 18-23 0.9 Spray arc

Filler metal E 42 5 B 4 2 H5 Type, Designation, Trade name BOHLER FOX EV 50

300-350C @

Any special drying or baking 2h Shielding gas Gas flow rate (l/min)

Tungsteen electrode type N/A Deatails of back gouging/backing N/A

Preheat temperature (C) N/A

Interpass temperature (C) N/A Pulse welding details N/A

Other information

Torch angle 80

Waving/Oscilation Weaving

Post Weld Heat Treatment

Cooling rate

Method remarks Heating rate (C/h) Holding time (min) Hold temperature (C) (C/h)

The above test piece was welded in presence of

Tsiamis Ioannis

Location/ Date of welding Issued by

Kozani TEI WM

1/4/2017

Vous aimerez peut-être aussi

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamPas encore d'évaluation

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabPas encore d'évaluation

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 pagesTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavPas encore d'évaluation

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Pas encore d'évaluation

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyPas encore d'évaluation

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191Pas encore d'évaluation

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukalePas encore d'évaluation

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanPas encore d'évaluation

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Document1 913 pagesPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- Course Module 4Document6 pagesCourse Module 4Makise AghataPas encore d'évaluation

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielPas encore d'évaluation

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Alishar SP 2Document84 pagesAlishar SP 2Alam MD SazidPas encore d'évaluation

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidPas encore d'évaluation

- WPS ListDocument2 pagesWPS ListAdeel OmerPas encore d'évaluation

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONPas encore d'évaluation

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriPas encore d'évaluation

- Baking and Drying Temperature of ElectrodesDocument1 pageBaking and Drying Temperature of ElectrodesshisPas encore d'évaluation

- WPS RegisterDocument2 pagesWPS RegisterdaveswinburnePas encore d'évaluation

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταPas encore d'évaluation

- QC - Consumables Colour Coding and IdentificationDocument3 pagesQC - Consumables Colour Coding and IdentificationfizanlaminPas encore d'évaluation

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviPas encore d'évaluation

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoPas encore d'évaluation

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanPas encore d'évaluation

- CF8M VS CF8 Stainless Steel Casting - JC CastingDocument7 pagesCF8M VS CF8 Stainless Steel Casting - JC CastingSHivaprasad APITPas encore d'évaluation

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraPas encore d'évaluation

- 1036330-23-349 Al 464 HV Hùng Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pages1036330-23-349 Al 464 HV Hùng Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh BinhPas encore d'évaluation

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinPas encore d'évaluation

- WPSDocument6 pagesWPSYASH BARDHAN SinghPas encore d'évaluation

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS - 023Document10 pagesWPS - 023MAT-LION0% (1)

- 1662 15Document117 pages1662 15RajamanikkamPas encore d'évaluation

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoPas encore d'évaluation

- WPQR SBM 029Document3 pagesWPQR SBM 029HoJienHauPas encore d'évaluation

- En 15085-2020-What Has ChangedDocument2 pagesEn 15085-2020-What Has ChangedBoran YelkenciogluPas encore d'évaluation

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- VP16 PDFDocument13 pagesVP16 PDFKara WhitePas encore d'évaluation

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYPas encore d'évaluation

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangPas encore d'évaluation

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaPas encore d'évaluation

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaPas encore d'évaluation

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaPas encore d'évaluation

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouPas encore d'évaluation

- PWPS Fillet WeldDocument2 pagesPWPS Fillet WeldUgonnaPas encore d'évaluation

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document1 pageDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPPas encore d'évaluation

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriPas encore d'évaluation

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- P. WpsDocument14 pagesP. WpsIsmiArdyPas encore d'évaluation

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSPas encore d'évaluation

- Duties of The RWCDocument3 pagesDuties of The RWCbluegalago100% (1)

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidPas encore d'évaluation

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104Pas encore d'évaluation

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouPas encore d'évaluation

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouPas encore d'évaluation

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Document1 page(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- Form 5068A Crane Use Planning Process REV 2015Document4 pagesForm 5068A Crane Use Planning Process REV 2015Samuel LumbanrajaPas encore d'évaluation

- Navsea S9074-Aq-Gib-010-248Document137 pagesNavsea S9074-Aq-Gib-010-248Brenno Moura MouraPas encore d'évaluation

- PR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionDocument37 pagesPR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionDimitris NikouPas encore d'évaluation

- TR ISO 15608 Steel Grouping AvskriftDocument5 pagesTR ISO 15608 Steel Grouping AvskriftDimitris NikouPas encore d'évaluation

- N-100170-P-QH - IK13-00001 - 1 Lifting Devices Auxliary Boiler PlantDocument2 pagesN-100170-P-QH - IK13-00001 - 1 Lifting Devices Auxliary Boiler PlantDimitris NikouPas encore d'évaluation

- Sect 11a P Welding DocumDocument30 pagesSect 11a P Welding DocumDimitris NikouPas encore d'évaluation

- Application For Qualification Acc DIN18800-7 - Rev 2.3Document8 pagesApplication For Qualification Acc DIN18800-7 - Rev 2.3Dimitris NikouPas encore d'évaluation

- EN 1493-1998 Vehicle LiftsDocument27 pagesEN 1493-1998 Vehicle LiftsDimitris NikouPas encore d'évaluation

- JJ Sietas Workinstructions For OffshoreDocument12 pagesJJ Sietas Workinstructions For OffshoreDimitris NikouPas encore d'évaluation

- Application For Qualification Acc DIN18800-7 - Rev 2.3Document8 pagesApplication For Qualification Acc DIN18800-7 - Rev 2.3Dimitris NikouPas encore d'évaluation

- 1371-1 LPI For CastingsDocument26 pages1371-1 LPI For CastingsDimitris NikouPas encore d'évaluation

- EN 1493-1998 Vehicle LiftsDocument27 pagesEN 1493-1998 Vehicle LiftsDimitris NikouPas encore d'évaluation

- DNV AuditDocument2 pagesDNV AuditDimitris NikouPas encore d'évaluation

- Boss Type PinDocument1 pageBoss Type PinDimitris NikouPas encore d'évaluation

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouPas encore d'évaluation

- Welding Procedure Specification: (Ref. Specification: en Iso 15609 2004)Document49 pagesWelding Procedure Specification: (Ref. Specification: en Iso 15609 2004)Dimitris Nikou100% (1)

- WQTC1Document2 pagesWQTC1Dimitris NikouPas encore d'évaluation

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouPas encore d'évaluation

- WPQRDocument3 pagesWPQRDimitris NikouPas encore d'évaluation

- Boss Type PinDocument1 pageBoss Type PinDimitris NikouPas encore d'évaluation

- Pin CoverDocument1 pagePin CoverDimitris NikouPas encore d'évaluation

- 1435 RT Welding InspectionDocument39 pages1435 RT Welding InspectionDimitris NikouPas encore d'évaluation

- WPQR3Document3 pagesWPQR3Dimitris NikouPas encore d'évaluation

- Tank Check List - Standard APIAS1940Document17 pagesTank Check List - Standard APIAS1940Dimitris NikouPas encore d'évaluation

- VGB-S-013!00!2014-12-En - Construction and Installation Supervision in The Manufacture and Assembly of Water-Tube Boilers and Associated Systems in TheDocument156 pagesVGB-S-013!00!2014-12-En - Construction and Installation Supervision in The Manufacture and Assembly of Water-Tube Boilers and Associated Systems in TheDimitris Nikou0% (1)

- Astm A578 - 07 PDFDocument5 pagesAstm A578 - 07 PDFMuhammad Maulana100% (1)

- Boss Type PinDocument1 pageBoss Type PinDimitris NikouPas encore d'évaluation

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Document1 pageL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouPas encore d'évaluation

- Hoshin Kanri SampleDocument8 pagesHoshin Kanri SampleDimitris NikouPas encore d'évaluation

- Twi Hardness TestingDocument8 pagesTwi Hardness TestingchungndtPas encore d'évaluation

- The References Are Taken From Nidi (Nickel Development Institute) Twi (The Welding Institute) Lincoln Electric International Molybdenum AssociationDocument21 pagesThe References Are Taken From Nidi (Nickel Development Institute) Twi (The Welding Institute) Lincoln Electric International Molybdenum Associationarif maulanafPas encore d'évaluation

- Compressor BearingsDocument55 pagesCompressor BearingsAnonymous OFP2ygPId100% (1)

- Stoody 104TJ SAW005Document1 pageStoody 104TJ SAW005Juaros LeonPas encore d'évaluation

- TMT RebarsDocument15 pagesTMT RebarsMohan Dakshina0% (1)

- 1 WPS 132Document2 pages1 WPS 132VishnuGK100% (1)

- A1031A1031M-12 Standard Specification For Steel, Sheet and Strip, Heavy-Thickness Coils, Alloy, Drawing Steel and Structural Steel, Hot-RolledDocument5 pagesA1031A1031M-12 Standard Specification For Steel, Sheet and Strip, Heavy-Thickness Coils, Alloy, Drawing Steel and Structural Steel, Hot-Rolledtjt4779Pas encore d'évaluation

- Bending Catalogo QR ENG LRDocument5 pagesBending Catalogo QR ENG LRLeandro MolaresPas encore d'évaluation

- The War of The KnightsDocument3 pagesThe War of The KnightsJyotishmoy BoruahPas encore d'évaluation

- Flexmaster U.S.A.® Quick Release LS Series Clamp: Submittal DataDocument1 pageFlexmaster U.S.A.® Quick Release LS Series Clamp: Submittal DataLee ChorneyPas encore d'évaluation

- GF 2010-2011 - InglêsDocument140 pagesGF 2010-2011 - InglêsA R D100% (1)

- Pohon Industri Baja NasionalDocument1 pagePohon Industri Baja NasionalrossajnrPas encore d'évaluation

- Coliere Fixare Normafix NormettaDocument4 pagesColiere Fixare Normafix NormettaCirstea NicoletaPas encore d'évaluation

- Ground ResistorDocument2 pagesGround Resistorashoksince2005Pas encore d'évaluation

- Pin BrazingDocument2 pagesPin BrazingGlennSymingtonPas encore d'évaluation

- Innovative Refractory Technology For Coreless Induction Furnaces 1Document9 pagesInnovative Refractory Technology For Coreless Induction Furnaces 1UZAIR.KZPas encore d'évaluation

- 2003catalog PDFDocument25 pages2003catalog PDFPH "Pete" PetersPas encore d'évaluation

- 9734galva CoatDocument24 pages9734galva CoatAshok Kumar PillaiPas encore d'évaluation

- Pgi M 675 M 775 M 678 GS 3Document6 pagesPgi M 675 M 775 M 678 GS 3Juan Carlos Enríquez BarragánPas encore d'évaluation

- Steel Frame InnovationDocument6 pagesSteel Frame InnovationKeanu Joseph VelascoPas encore d'évaluation

- Extrusion Press PDFDocument2 pagesExtrusion Press PDFRobert25% (4)

- Super AlloysDocument13 pagesSuper Alloyshgahagohod100% (1)

- Die Cast Chill VentsDocument6 pagesDie Cast Chill VentsSunil SharmaPas encore d'évaluation

- Pickling and PassivationDocument2 pagesPickling and PassivationJignesh ShahPas encore d'évaluation

- Binder1 MixturesDocument12 pagesBinder1 Mixturesjomabi0% (1)

- Civil Affairs Handbook Belgium Section 8Document124 pagesCivil Affairs Handbook Belgium Section 8Robert ValePas encore d'évaluation

- Introducing Taps: Colour Band Machine Taps Hand Taps Pipe TapsDocument16 pagesIntroducing Taps: Colour Band Machine Taps Hand Taps Pipe TapsNadia AlvaradoPas encore d'évaluation

- Ufgs 33 52 90.00 20Document22 pagesUfgs 33 52 90.00 20pradanangkpPas encore d'évaluation

- ACI351.1R 99 DigitalDocument18 pagesACI351.1R 99 DigitalAlejandro TrujilloPas encore d'évaluation