Académique Documents

Professionnel Documents

Culture Documents

The Yielding of Fasteners Duirng Tightening PDF

Transféré par

Aristotle Medina0 évaluation0% ont trouvé ce document utile (0 vote)

153 vues2 pages1. The document summarizes a landmark 1975 paper by Peter Gill that proved yielding of fasteners during tightening is advantageous, not detrimental to clamping force.

2. Gill demonstrated that tightening bolts well beyond yield does not reduce their ability to exert clamping force on joint members under service loads.

3. The paper showed that high pretension from beyond-yield tightening improves bolt fatigue resistance, load transfer through friction, and resistance to loosening.

Description originale:

Titre original

The yielding of fasteners duirng tightening.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce document1. The document summarizes a landmark 1975 paper by Peter Gill that proved yielding of fasteners during tightening is advantageous, not detrimental to clamping force.

2. Gill demonstrated that tightening bolts well beyond yield does not reduce their ability to exert clamping force on joint members under service loads.

3. The paper showed that high pretension from beyond-yield tightening improves bolt fatigue resistance, load transfer through friction, and resistance to loosening.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

153 vues2 pagesThe Yielding of Fasteners Duirng Tightening PDF

Transféré par

Aristotle Medina1. The document summarizes a landmark 1975 paper by Peter Gill that proved yielding of fasteners during tightening is advantageous, not detrimental to clamping force.

2. Gill demonstrated that tightening bolts well beyond yield does not reduce their ability to exert clamping force on joint members under service loads.

3. The paper showed that high pretension from beyond-yield tightening improves bolt fatigue resistance, load transfer through friction, and resistance to loosening.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Reprinted from Distributors Link Magazine

About the Author/WAYNE WALLACE

Wayne Wallace is the president of Applied Bolting Technology Products. The

company provides bolting consulting services and manufactures direct tension

indicating washers from its base in Ludlow, Vermont. Wallace is a member of the

Research Council on Structural Connections, a director of the Bolting Technol-

ogy Council, and author of numerous papers on the practical aspects of quality

assurance in structural bolting. He can be reached by fax at 802-228-7204, or e-

mail at wallace@appliedbolting.com.

The Yielding of Fasteners During Tightening

Wayne Wallace reminds us of Peter Gills landmark 1975 Paper

A round 1985, I once remarked to Doc Morrow, then

Stelco's head of fastener manufacturing in

Canada, that structural bolts MUST be tensioned be-

Some . . . fee/ that when a bolt is tightened we// beyond

yield it loses its abi/ity to exert a clamping force on the

joint members. We can show that this is not the case.

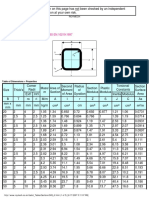

yond yield. Was this all right, I asked, in his opinion? Doc In Figure 1 line OYXU is the load extension graph for

was among the fastener greats at Stelco at the time, like a bolt in a joint, and line OJ is the load deformation line

Ian Park (in my opinion, the best self-taught fastener manu- for the joint members. We now imagine that tightening

facturing metallurgist ever), Errol Alexander (the has been taken wel/ beyond yield point Y and up to a

Alexander model for thread stripping), and others. clamping force P where the bolt and joint member con-

Doc, whom I never knew by any other name, showed ditions are those shown at X and J respectively After

me a paper written by Peter Gill of GKN Fasteners Ltd., tightening, the joint members can only lose compres-

for the answer. Peter was then a senior researcher at sive load by losing some of their compressive strain, i.e.

GKN, a very large British bolt manufacturer, and whom by increasing in thickness. In order to increase in thick-

I have since learned, was internationally respected for ness they would have to push out against the bolt and

technical application information on bolts. nut and so increase the extension of the bolt. This would

In this landmark paper on the subject, probably writ- require a pushing load, which would have to be main-

ten around 1975, Gill pointed out and proved that yield- tained at levels along the line XU. But the joint mem-

ing of fasteners during tightening is, in fact, advanta- bers cannot exert loads at these levels. They can only

geous. Also, he not only proves the theory on paper, but exert loads at levels along the lower line XF. This is be-

he demonstrates it by means of devising a jig in which cause when their compressive strain decreases, their

he torques a bolt almost to breaking and then applying compressive load falls from J towards 0 and XF is par-

external tension. The paper is elegant in its simplicity, a//e/ to JO.

and should be known and understood by anybody who It could be shown by a similar argument that the bolt

wrestles with the sometimes perplexing questions sur- of course cannot lose tension by squeezing the plates.

rounding bolting applications. Squeezing the plates requires an increasing load (ar-

Rather than writing a new paper on this same sub- row G), whereas the bolt can on/y exert a decreasing

ject, I thought it would be interesting for readers of Link load (arrow H).

to read or re-read Gills paper, presented here in abbre- Thus, apart from small relaxation losses, a bolt tight-

viated form, along with a few comments of mine. ened beyond yield is able to retain its induced tension.

Here goes Peter Gill:

1. Introduction - In the design of load carrying parts, Wallace again:

it is a generalrule to make sure that yielding will not Note what Gill is saying here. Tighten a bolt WAY

occur under service loading. Usually, then, the yield load past yield, that is, almost to the breaking point, and it

level of all-important parts is known or is closely esti- will exist in its environment as a stable system acting

mated. The designer then ensures that these levels ex- and reacting with and against the plates it clamps to-

ceed the service loads by a suitable factor of safety so gether. Note how clear is his explanation. None of those

that the only deformations to be anticipated are the usual confusing bolt diagrams you see in many papers where

minute elastic ones, which are negligible. the bolt stiffness and the clamped joint stiffness are rep-

In the.. . specification of tightening procedures, an resented by intersecting lines forming a triangle. Gill

important exception can be made to this rule. This is presents the bolt/joint clamp force/extension line (lines

because shank yielding during tightening is not only al- OYXU and OJ) on the same base line, as equal and

lowable - it is in most cases, advantageous. opposite for true strain compatibility, which is of course

2. Retention of bolt load after yield at tightening -

the only logical way to present them. The two act as a a DTI, which deforms plastically as the bolt is tightened,

system, after all. improves or softens the bolt response to external load

Here is a summary of the other comments and con- because it assures beyond yield tightening, and is eas-

clusions Gill makes in this classic paper. ily inspectable because of the relatively large deforma-

Under service load, the (yielded) bolt is able to per- tion as the DTI bumps compress.

form as though it had never yielded at all. Gill again with his final conclusions:

Tightening beyond yield does not affect the ability of Several advantages are obtained when the fasten-

the bolt to withstand the effects of subsequent service ing is designed in this way, i.e., with yield occurring in

loading on the joint. the nut, washer. or head rather than in the shank.

High pretensions are good for joint performance be- 1. The reduction in fastener stiffness reduces the fa-

cause: tigue loading to which the bolt is subjected under re-

1. Improved resistance to bolt fatigue. peated joint service loads.

2. Shear loads will be taken by friction at the mating 2. Any desired /eve/ of bolt pre-tension can be ob-

surfaces of the joint members. tained irrespective of bolt yield strength.

3. Resistance to loosening. 3. Although the turn of nut" method is simple to use,

4. Tightening to yield simplifies the tightening method subsequent inspection for correct bolt tension can be

("If the bolt does not break during tightening it will not difficult. In the case of a compressible element inspec-

fracture in subsequent service"). tion is easy. and on/y involve gauging the height of the

Having shown that yield is allowable in the shanks of bumps ... edited bv Wallace.

bolts it follows that it is also allowable in other elements 4. Yielding of the shank is sometimes undesirable,

of the fastenings, i.e., the bolt head, the washer, and e.g., when repeated tightening is anticipated.

the nut...The amount of yield movement can be gauged 5. Over-yield tightening means a low factor of safety

or measured to inspect that the desired load has been during tightening but a high factor of safety in subse-

reached. In the better-designed devices a considerable quent service.

yield movement can occur at substantially uniform load 6. Tightening below yield means a high factor of safely

and this removes the need for critical inspection methods. during tightening, but a low factor of safety during sub-

sequent service.

Wallace again: Write or e-mail wallace@appliedbolting.com if you

Note what Gill is saying here. The presence of (say) want a copy of Peter Gills entire paper. 0

4 i

0

COMPRESSIVE BOLT EXTENSION

.

DEFORMATION

OF JOINT MEMBERS

GILL: FIGURE 1

Vous aimerez peut-être aussi

- YieldingDocument2 pagesYieldingtyjmtyjmPas encore d'évaluation

- An Introduction To The Design and Behavior of Bolted Joints - ExcerptsDocument50 pagesAn Introduction To The Design and Behavior of Bolted Joints - ExcerptsThiagoCarvalhoPas encore d'évaluation

- Chapter 2Document6 pagesChapter 2udomPas encore d'évaluation

- Fatigue TestingDocument10 pagesFatigue TestingMuhammed SulfeekPas encore d'évaluation

- Twi Fatigure TestingDocument13 pagesTwi Fatigure TestingchungndtPas encore d'évaluation

- Theory Q'sDocument5 pagesTheory Q'sChachi CPas encore d'évaluation

- Bolt Torque DeterminationDocument11 pagesBolt Torque DeterminationRatna Giridhar Kavali100% (1)

- Turn of The Nut For Anchor BoltsDocument8 pagesTurn of The Nut For Anchor BoltsshannonPas encore d'évaluation

- Specifications: StructuralDocument4 pagesSpecifications: StructuralThaung Myint OoPas encore d'évaluation

- Unit 11 Structural Components: Alms Ob/ectlves Lntroductlon Structures and Thelr ComponentsDocument6 pagesUnit 11 Structural Components: Alms Ob/ectlves Lntroductlon Structures and Thelr ComponentsSohanPas encore d'évaluation

- Threaded Fasteners For FSAE PDFDocument27 pagesThreaded Fasteners For FSAE PDFMarcelo Delgado100% (1)

- Factor Bolted JointsDocument42 pagesFactor Bolted JointsOliver Kraus100% (1)

- Valve Live Loading Using Belleville SpringDocument6 pagesValve Live Loading Using Belleville SpringBruno ManzettiPas encore d'évaluation

- Wisdom:: WeldingDocument5 pagesWisdom:: WeldingSathish KumarPas encore d'évaluation

- Questions & Answers: Webinar: Expansion Joints in CAESAR IIDocument3 pagesQuestions & Answers: Webinar: Expansion Joints in CAESAR IIMina MagdyPas encore d'évaluation

- Lecture 3 & 4 Structural Steel Design MuDocument26 pagesLecture 3 & 4 Structural Steel Design MuPenelope MalilwePas encore d'évaluation

- Torque PDFDocument3 pagesTorque PDFicetesterPas encore d'évaluation

- Stab 1 E 2015Document16 pagesStab 1 E 2015Eugeniu PrisacariPas encore d'évaluation

- Bolted Connection FatigueDocument12 pagesBolted Connection FatigueMahfuzur Rahman100% (1)

- Locking FastnersDocument3 pagesLocking FastnersRip_BarPas encore d'évaluation

- Reuse of Fasteners Rev 2017-02-21Document3 pagesReuse of Fasteners Rev 2017-02-21amnestyresearchSMLPas encore d'évaluation

- VSrinivas - Discussion Topics - 22-3-2011Document2 pagesVSrinivas - Discussion Topics - 22-3-2011scribd049Pas encore d'évaluation

- Fasteners: The ESG ReportDocument4 pagesFasteners: The ESG ReportAnton SurviyantoPas encore d'évaluation

- Bolting Basics ExplainedDocument8 pagesBolting Basics ExplainedMarc AnmellaPas encore d'évaluation

- PV Newsletter - Volume 2012 Issue 7Document8 pagesPV Newsletter - Volume 2012 Issue 7Hari PurwitoPas encore d'évaluation

- How Do I Determine Bolt Torque For Flanged Connections - GasketsDocument4 pagesHow Do I Determine Bolt Torque For Flanged Connections - GasketsNataraj MohanPas encore d'évaluation

- Bolt Design Calc SheetDocument19 pagesBolt Design Calc SheetMarshalPas encore d'évaluation

- Mat Chapter 31Document27 pagesMat Chapter 31hemant_durgawalePas encore d'évaluation

- The Basics of Bolted JointsDocument2 pagesThe Basics of Bolted Jointshitesh_tilalaPas encore d'évaluation

- Course Name: CE 3130: Steel Structures DesignDocument25 pagesCourse Name: CE 3130: Steel Structures Designcarlomonsalve1Pas encore d'évaluation

- Modulo 4 CM 19 09 2020Document25 pagesModulo 4 CM 19 09 2020carlomonsalve1Pas encore d'évaluation

- Lessons From Crane RunwaysDocument5 pagesLessons From Crane Runwaysdicktracy11Pas encore d'évaluation

- Preloaded Bolt Assemblies: Steel Industry Guidance NotesDocument2 pagesPreloaded Bolt Assemblies: Steel Industry Guidance NotesaikalessPas encore d'évaluation

- Unit 8 Design of Beams PDFDocument28 pagesUnit 8 Design of Beams PDFveenuPas encore d'évaluation

- Welds - Static and Fatigue Strength - IiDocument27 pagesWelds - Static and Fatigue Strength - IiOuseppachan Ambooken100% (1)

- How Do I Determine Bolt Torque For Flanged ConnectionsDocument6 pagesHow Do I Determine Bolt Torque For Flanged Connectionsloq100% (1)

- BigBoltArticle BlendulfDocument5 pagesBigBoltArticle BlendulfDominicPas encore d'évaluation

- Structural Design: Information SheetDocument4 pagesStructural Design: Information SheetVRKVRK10Pas encore d'évaluation

- The Reinforcement of Steel ColumnsDocument5 pagesThe Reinforcement of Steel Columnsprinkesh barodiyaPas encore d'évaluation

- Buckling Analysis of Cylindrical ShellsDocument4 pagesBuckling Analysis of Cylindrical ShellsVPN NetworkPas encore d'évaluation

- Torque InstructionsDocument13 pagesTorque Instructionsjfrench_62000Pas encore d'évaluation

- Fastener FatigueDocument14 pagesFastener FatigueiodabaotPas encore d'évaluation

- Structural Connections - Scia5203: Unit - IDocument77 pagesStructural Connections - Scia5203: Unit - IVignesh DhuruvanPas encore d'évaluation

- (Kiot) : Design of Steel and Timber StructureDocument53 pages(Kiot) : Design of Steel and Timber Structurebini1221Pas encore d'évaluation

- Converting Static FrictionDocument16 pagesConverting Static FrictionJuanSebastianAlonsoPas encore d'évaluation

- Flange LeakageDocument29 pagesFlange Leakagevrindk80% (5)

- Lab 3 - Ex2 - Deflection of Beams Instructions 2022Document13 pagesLab 3 - Ex2 - Deflection of Beams Instructions 2022fmcanespy018Pas encore d'évaluation

- Bolted Connections (Prying Force)Document16 pagesBolted Connections (Prying Force)Ivan Hadzi BoskovicPas encore d'évaluation

- Cover Plate Welding Details 2008aug by BlodgettDocument3 pagesCover Plate Welding Details 2008aug by BlodgettJim StreitmatterPas encore d'évaluation

- Bolt Behaviour Basic ConceptsDocument3 pagesBolt Behaviour Basic ConceptsAnonymous GE8mQqxPas encore d'évaluation

- Lecture 7-Unrestrained BeamDocument42 pagesLecture 7-Unrestrained BeamRaimi Suhaimi100% (1)

- Joining Composites: Drilling Holes in The Composite For Fasteners Will Greatly Reduce Its StrengthDocument6 pagesJoining Composites: Drilling Holes in The Composite For Fasteners Will Greatly Reduce Its StrengthwalterPas encore d'évaluation

- Remaining Life Evaluation of Coke DrumsDocument15 pagesRemaining Life Evaluation of Coke DrumsRohit KalePas encore d'évaluation

- Job Knowledge 78Document3 pagesJob Knowledge 78Mehmet Soysal100% (1)

- 6 4uDocument7 pages6 4uElsayed Salah HamoudaPas encore d'évaluation

- What Is Snug-Tightened PDFDocument2 pagesWhat Is Snug-Tightened PDFMartín50% (2)

- BucklingDocument7 pagesBucklingMohammad BurhanPas encore d'évaluation

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910D'EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Pas encore d'évaluation

- (Asce) ST 1943-541X 0002284Document12 pages(Asce) ST 1943-541X 0002284Sergio Alejandro barreiroPas encore d'évaluation

- JSE Lignos Etal 2019Document13 pagesJSE Lignos Etal 2019faisaladePas encore d'évaluation

- Sustainability Metrics For Performance Based Seismic Bridge ResponseDocument12 pagesSustainability Metrics For Performance Based Seismic Bridge ResponseAristotle MedinaPas encore d'évaluation

- Effect of Seismic Load History On Deformation Limit States For Longitudinal Bar Buckling in RC Circular ColumnsDocument13 pagesEffect of Seismic Load History On Deformation Limit States For Longitudinal Bar Buckling in RC Circular ColumnsAristotle MedinaPas encore d'évaluation

- Seismic Performance of Axially Restrained Reinforced Concrete Frame BeamsDocument12 pagesSeismic Performance of Axially Restrained Reinforced Concrete Frame BeamsAristotle MedinaPas encore d'évaluation

- Variability in Seismic Collapse Probabilities of Solid - and Coupled-Wall BuildingsDocument17 pagesVariability in Seismic Collapse Probabilities of Solid - and Coupled-Wall BuildingsAristotle MedinaPas encore d'évaluation

- Column Base Connections For Hollow Steel Sections Seismic Performance and Strength ModelsDocument13 pagesColumn Base Connections For Hollow Steel Sections Seismic Performance and Strength ModelsAristotle MedinaPas encore d'évaluation

- An Engineering Application of Earthquake Early Warning ePAD-Based Decision Framework For Elevator ControlDocument10 pagesAn Engineering Application of Earthquake Early Warning ePAD-Based Decision Framework For Elevator ControlAristotle MedinaPas encore d'évaluation

- Connections and Fatigue Behaviour of Precast Insulated PanelDocument169 pagesConnections and Fatigue Behaviour of Precast Insulated PanelAristotle MedinaPas encore d'évaluation

- Structures: Engineering AdvanceDocument22 pagesStructures: Engineering AdvanceJuan Camilo Laguna OrtizPas encore d'évaluation

- MyPUBLICATIONAMM 857 195Document6 pagesMyPUBLICATIONAMM 857 195nasru hajiPas encore d'évaluation

- Finite Element Analysis of Thin Precast Concrete Sandwich PanelsDocument6 pagesFinite Element Analysis of Thin Precast Concrete Sandwich PanelsAristotle MedinaPas encore d'évaluation

- Reference #03 - JR-403 Sandwich Wall PanelsDocument61 pagesReference #03 - JR-403 Sandwich Wall PanelsAristotle MedinaPas encore d'évaluation

- The Yielding of Fasteners Duirng Tightening PDFDocument2 pagesThe Yielding of Fasteners Duirng Tightening PDFAristotle MedinaPas encore d'évaluation

- British Steel SectionsDocument6 pagesBritish Steel SectionsAristotle MedinaPas encore d'évaluation

- Guide To Accelerated Conditioning Protocols For Durability Assessment of Internal and External Fiber-Reinforced Polymer (FRP) ReinforcementDocument16 pagesGuide To Accelerated Conditioning Protocols For Durability Assessment of Internal and External Fiber-Reinforced Polymer (FRP) ReinforcementAristotle Medina100% (1)

- How A Bolt WorksDocument6 pagesHow A Bolt WorksAristotle MedinaPas encore d'évaluation

- Metric Bolt Properties, Grades, and StrengthDocument8 pagesMetric Bolt Properties, Grades, and StrengthAristotle MedinaPas encore d'évaluation

- Universal Beams To BS4 Part 1 - 1993Document3 pagesUniversal Beams To BS4 Part 1 - 1993Aristotle MedinaPas encore d'évaluation

- EFunda - Torque and Tension in BoltsDocument2 pagesEFunda - Torque and Tension in BoltsAristotle MedinaPas encore d'évaluation

- SP e PDFDocument40 pagesSP e PDFAristotle MedinaPas encore d'évaluation

- HP UsDocument1 pageHP UsAristotle MedinaPas encore d'évaluation

- Chemical and Mechanical PropertiesDocument5 pagesChemical and Mechanical PropertiesAristotle MedinaPas encore d'évaluation

- Universal Beams To BS4 Part 1 - 1993Document3 pagesUniversal Beams To BS4 Part 1 - 1993Aristotle MedinaPas encore d'évaluation

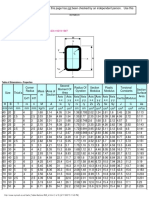

- Square Hollow Sections - Cold FormedDocument5 pagesSquare Hollow Sections - Cold FormedAristotle MedinaPas encore d'évaluation

- Rectangular Hollow Sections - Hot FormedDocument5 pagesRectangular Hollow Sections - Hot FormedAristotle MedinaPas encore d'évaluation

- Square Hollow Sections - Hot FormedDocument5 pagesSquare Hollow Sections - Hot FormedAristotle MedinaPas encore d'évaluation

- Unequal Angles To en 10056-1 - 1998Document3 pagesUnequal Angles To en 10056-1 - 1998Aristotle MedinaPas encore d'évaluation

- Rectangular Hollow Sections - Coled FormedDocument5 pagesRectangular Hollow Sections - Coled FormedAristotle MedinaPas encore d'évaluation

- Statistical Mechanics: Lecture A0: Phase TransitionsDocument5 pagesStatistical Mechanics: Lecture A0: Phase TransitionsTushar GhoshPas encore d'évaluation

- Black Box Software Testing: Introduction To Test DocumentationDocument29 pagesBlack Box Software Testing: Introduction To Test DocumentationMohamed SaleemPas encore d'évaluation

- Lesson 1 - Section 5.1 - Chemical and Physical ChangeDocument4 pagesLesson 1 - Section 5.1 - Chemical and Physical ChangeshanlbyPas encore d'évaluation

- Ground Water Recharge Techniques 2Document141 pagesGround Water Recharge Techniques 2Ravi Bhushan SharmaPas encore d'évaluation

- Lecture Notes For Week Ten Mechanics of Chain DrivesDocument11 pagesLecture Notes For Week Ten Mechanics of Chain DrivesJohn KimaniPas encore d'évaluation

- Ultimate ESAS Data Bank CompilationDocument19 pagesUltimate ESAS Data Bank CompilationVea ValcorzaPas encore d'évaluation

- Fracture Toughness Evaluation of WC-Co Alloys by Indentation TestingDocument12 pagesFracture Toughness Evaluation of WC-Co Alloys by Indentation TestingFjodorSergPas encore d'évaluation

- Composite For Innovative Wind TurbineDocument25 pagesComposite For Innovative Wind TurbineSuraj MoodPas encore d'évaluation

- Charpy Impact TestDocument3 pagesCharpy Impact TestRamana IkkurthiPas encore d'évaluation

- 117BH - Ceramic Science and Technology PDFDocument8 pages117BH - Ceramic Science and Technology PDFvenkiscribd444Pas encore d'évaluation

- 1Document9 pages1MurtadhaPas encore d'évaluation

- KomdisDocument4 pagesKomdisGading cacaPas encore d'évaluation

- Infineon TLE9104SH DataSheet v01 - 31 ENDocument35 pagesInfineon TLE9104SH DataSheet v01 - 31 ENMohamed AbdulmaksoudPas encore d'évaluation

- 99929Document20 pages99929Tamer Moustafa100% (2)

- Drafting Technology Y2Document202 pagesDrafting Technology Y2Anderson MarantanPas encore d'évaluation

- Oracle IdeasDocument45 pagesOracle Ideashamdy2001Pas encore d'évaluation

- Washer Dryer: Owner'S ManualDocument29 pagesWasher Dryer: Owner'S ManualThai FuizaiPas encore d'évaluation

- Platespin User GuideDocument17 pagesPlatespin User GuideEbitomo Anthony TobiPas encore d'évaluation

- Exhibitor 35804 PDFDocument36 pagesExhibitor 35804 PDFulton1237624Pas encore d'évaluation

- Soil Test Report KolhapurDocument35 pagesSoil Test Report Kolhapuryedida viswanadhPas encore d'évaluation

- Fruit Recognition Deep LearningDocument53 pagesFruit Recognition Deep Learningsaran20099Pas encore d'évaluation

- LG ART COOL AC Manual - Owner - Eng - Lmo240c - 20120307165905Document28 pagesLG ART COOL AC Manual - Owner - Eng - Lmo240c - 20120307165905ACERGYPas encore d'évaluation

- Abdelmoumene ChapterDocument2 pagesAbdelmoumene Chapterab__ismPas encore d'évaluation

- Perry 02Document2 pagesPerry 02Thaly MejiaPas encore d'évaluation

- Galvanic Cathodic Protection For Power Transmission Tower Grillage FoundationsDocument6 pagesGalvanic Cathodic Protection For Power Transmission Tower Grillage FoundationsMA100% (1)

- Advances in Thermal Design of Heat Ex ChangersDocument530 pagesAdvances in Thermal Design of Heat Ex ChangersBabbare Voltaire100% (3)

- Pivot PointDocument22 pagesPivot Pointjanderclanderpeich100% (1)

- QUALICOAT Specifications 16th Edition Updated VersionDocument86 pagesQUALICOAT Specifications 16th Edition Updated VersionСтанислав ПодольскийPas encore d'évaluation

- MYG Varistors Data SheetDocument4 pagesMYG Varistors Data SheetPedro Giménez100% (1)

- 7) Progress PaymentDocument5 pages7) Progress Paymentkerwin jayPas encore d'évaluation