Académique Documents

Professionnel Documents

Culture Documents

Oceanic HD856

Transféré par

Pedro DutraCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Oceanic HD856

Transféré par

Pedro DutraDroits d'auteur :

Formats disponibles

Erifon HD 856

BOP Control Fluid

Concentrate

General Description

Erifon HD856 is a fully synthetic BOP control fluid concentrate, formulated for

use at a dilution of 100:1 in fresh water, thus is extremely economical. It has

excellent stability, anti-wear and anti-corrosion properties, and is fully inhibited

to resist microbiological attack. Erifon HD856 has come to be regarded

worldwide as the leading BOP control fluid and is in use in systems on a large

number of installations.

High Dilution Ratio

As Erifon HD856 is used at a dilution ratio of 100:1 with fresh water, it is very

economical to use, even when BOP functions are operated frequently. Storage

space and supply costs are also minimized. The high operating dilution does not,

however, mean that performance has been compromised in any way. Erifon

HD856 contains a sophisticated additive package to ensure that the safety and

reliability of the BOP system are maintained.

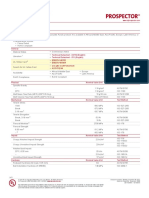

Physical Properties

Appearance Dark Blue, Slightly

Viscous Liquid

Viscosity (cS) @ -20C -4F 750

0C 32F 85

20C 68F 20

40C 104F 8

Pour Point (C)(F) -29C (-20F)

pH Value (Concentrate) 9.60

pH Value (@ 100:1 dilution) 9.3

Specific Gravity (15.6C) (60) 1.10

Max. Recommended Temp. (C) (F) 60C (140F)

MacDermid Offshore Solutions MacDermid Offshore Solutions

223 N. Brockman St. Cale Lane

Pasadena, TX 77506 New Springs, Wigan

Order Desk: (800) 521-2589 WN2 1JR, UK

Sales Office: (713) 472-5081 fax 2440 +44(1942) 501000 fax +44(1942) 501110

Email: offshoreorders@macdermid.com Email: wigansales@macdermid.com

Erifon HD856 Revised 10-5-07 Page 2

Material Compatibility Erifon HD856 is inhibited to prevent corrosion of ferrous metal alloys, even

when electrolytic effects prevail where multi-metal couples are encountered. The fluid will also have no

adverse effect on the seal and packing compounds generally used in the construction of BOP systems.

Paints of the cured epoxy, nylon or phenolic type may be used without being significantly affected by the

fluid. The painting of internal surfaces of hydraulic systems is not advised.

Anti-Wear Properties Considerable care has been taken to give Erifon

HD856 excellent anti-wear properties, particularly where metal-to-metal

rubbing contacts occur. This is of particular importance in modern control

systems using shear-seal valves with metal-to-metal sealing faces.

Stability Erifon HD856 represents a major breakthrough in BOP fluid stability. Earlier products were

liable to become unstable and degrade in a very short period of time if contaminated with seawater and/or

microorganisms such as bacteria or fungi. Erifon HD856 will tolerate contamination with moderate

amounts of seawater without suffering from precipitation, flocculation or phasing. It also contains a broad-

spectrum anti-microbiological package to minimize the effects of bacterial and fungal activity. This aspect

alone can greatly reduce BOP system maintenance and repair costs by preventing degradation in the

system which would otherwise lead to acid corrosion, abrasive wear and sludging.

Discharge into marine environments Erifon HD856 is included in the U.K. Notification Scheme

for the Selection of Chemicals For Use Offshore. The Centre for Environment, Fisheries and Aquaculture

Science has studied details of the chemical composition, biodegradability, bioaccumulation and the

toxicological affects on marine organisms and Erifon HD856 has been included in the Scheme as a

Category C product. This means that no notification is required provided that the discharge rate does not

exceed 10 tonnes per annum per installation.

Installation of Erifon HD856

Whether the fluid is installed in a new system, or one that is already in operation on another type of BOP

fluid, it is important to carry out an effective flushing operation to ensure freedom from microbiological and

other contaminants. Even new systems, particularly if they have been in storage for some time, can

contain contaminants that can severely inhibit the proper operation of even a high quality fluid like Erifon

HD856.

It should be stressed that carrying out a proper flushing and cleaning operation prior to installation will

greatly increase the life of the fluid, and may well result in substantial savings in equipment reconditioning

at a later date. The operator is urged to examine the condition of the equipment prior to fluid installation,

however, as no fluid, regardless of quality, can rectify system damage that has already taken place.

MacDermid Offshore Solutions MacDermid Offshore Solutions

223 N. Brockman St. Cale Lane

Pasadena, TX 77506 New Springs, Wigan

Order Desk: (800) 521-2589 WN2 1JR, UK

Sales Office: (713) 472-5081 fax 2440 +44(1942) 501000 fax +44(1942) 501110

Email: offshoreorders@macdermid.com Email: wigansales@macdermid.com

Erifon HD856 Revised 10-5-07 Page 3

The most effective method of flushing a system, especially where microbiological attack has already

occurred, is to use Erifon Systems Cleaner. Erifon Systems Cleaner is a highly effective treatment for use

in systems suffering from microbiological and other forms of contamination. Supplied as a concentrate, it

attacks a wide variety of microorganisms, breaks down sludge deposits and neutralizes acid degradation

products. It is also widely used to flush new control systems prior to fluid installation, improving fluid and

system service life.

New systems may be flushed using a 2% solution of Erifon Systems Cleaner in a 100:1 mix of Erifon

HD856 in fresh water. The solution should remain in the system for a period of between twenty-four and

forty-eight hours before being discarded and the system being recharged with fresh Erifon HD856.

Operational systems should be treated by adding the Erifon Systems Cleaner to the existing BOP fluid at

a level of 2%, and then cycling the system to ensure complete distribution of the Erifon Systems Cleaner

solution. After a period of between twenty-four and forty-eight hours, the system should be drained and

Erifon HD856 installed.

When flushing new or operational systems, particular attention must be given

to accumulators and pilot lines, as if these are not treated adequately they

could re-contaminate the entire system, and waste the entire flushing

operation.

The specific procedures necessary will vary from system to system.

MacDermids staff can offer detailed advice on the correct approach to be used

in particular circumstances.

Once Erifon HD856 has been successfully installed in a system, it is

recommended that advantage is taken of the MacDermid Fluid Monitoring

Service, as part of a planned maintenance program.

Fluid Maintenance

Erifon HD856 is designed for use at an operating dilution of 100:1 with fresh water. In general, it will work

satisfactorily at ratios of between 90:1 and 110:1. Outside these limits there will be penalties to be paid

either because of higher than necessary fluid costs, or a reduction in performance and system reliability.

The quality of water used is of great importance. Only fresh water should be used, preferably from the

installation's potable water system. It should not be assumed that potable water is automatically free of

potentially damaging microorganisms, as tests by Health Authorities are testing specifically for pathogens

(organisms which can cause illness), while others, which could cause fluid deterioration, could still be

present. The anti-microbiological package in Erifon HD856 is perfectly adequate to deal with fluid

contamination that enters the system by normal means (airborne, water splash, etc.) and will ensure long

fluid life, but no fluid or additive pack can cope with continuous ingression of micro-organisms via the

make-up water. It is preferable not to use drill water for make up, and seawater must never be used. If

any doubt exists as to the suitability of water supplies, samples may be submitted to MacDermid, and

these will be analyzed and a report and recommendations issued.

MacDermid Offshore Solutions MacDermid Offshore Solutions

223 N. Brockman St. Cale Lane

Pasadena, TX 77506 New Springs, Wigan

Order Desk: (800) 521-2589 WN2 1JR, UK

Sales Office: (713) 472-5081 fax 2440 +44(1942) 501000 fax +44(1942) 501110

Email: offshoreorders@macdermid.com Email: wigansales@macdermid.com

Erifon HD856 Revised 10-5-07 Page 4

At its normal dilution ratio of 100:1, Erifon HD856 may be used at temperatures down to 0 C(32F). For

lower temperature operation, it is necessary to add a pour point depressant to the system. MacDermid

provides a product, Erifon Stack Glycol, specifically for this purpose, and the chart on page 4 shows the

mix ratios of Erifon HD856, Erifon Stack Glycol and water to be used for various operating temperatures.

Pure glycols may be used as alternative pour point depressants, but commercially available antifreeze

formulations must be avoided due to the likely interaction between additives that could detrimentally affect

fluid performance.

LOW TEMPERATURE MIXING CHART

Freezing Point Erifon HD856 Erifon Stack Fresh Water

F (C) Parts Glycol Parts Parts

20 (-7) 1 15 84

0 (-18) 1 32 67

-20 (-29) 1 44 55

-30 (-34) 1 50 49

-40 (-40) 1 53 46

The most important aspects of maintaining Erifon HD856 are to ensure the correct dilution and, where

applicable, Stack Glycol level, and to keep the water supply free from microorganisms. Erifon HD856 is

extremely tolerant of all types of contamination, and this means that it will not deteriorate immediately

such contamination occurs. A planned program of maintenance can therefore provide advance warning

of system problems, allowing them to be dealt with before they have a significant effect on system safety

and reliability.

Surveys of service samples submitted to MacDermid for analysis under their Fluid Monitoring Service

show incorrect dilution to be the most frequent cause of fluid failure, closely followed by bacterial

contamination of the make-up water supply. Studying the rate of deterioration of these fluids suggests

that a program of sample checking every two to three months is generally adequate to provide sufficient

warning of impending problems. In certain circumstances, such as in particularly warm climates, or where

sub-standard supplies of water cannot be avoided, monthly checks are advantageous.

The taking of samples may be made easier by the installation of suitable sample ports at strategic points

about the system. It should be remembered that the sample taken would only be of use when analyzed if

it is representative of fluid within the system as a whole.

MacDermid Offshore Solutions MacDermid Offshore Solutions

223 N. Brockman St. Cale Lane

Pasadena, TX 77506 New Springs, Wigan

Order Desk: (800) 521-2589 WN2 1JR, UK

Sales Office: (713) 472-5081 fax 2440 +44(1942) 501000 fax +44(1942) 501110

Email: offshoreorders@macdermid.com Email: wigansales@macdermid.com

Erifon HD856 Revised 10-5-07 Page 5

LUBRICANT COMPARISON ON BAROID

EXTREME PRESSURE TESTER

50

Resultant Motor Load in lb-force

N

IO

N TIO

UT LU

40 L DI

DI :1

00 IO N

ER

0:

1 -1 UT

B DIL

AT

-5 D

UI 0 :1

W

A

D FL -5

30 UI IV

E C N

FL TIT UID TIO

FL

VE PE IVE DILU

TI M I T :1

TI CO ET 00

PE MP -1

20 M CO 56

CO D8

NH

RIFO

E

10

0 50 100 150 200 250 300 350 400

Applied Torque in inch-pounds

Information given in this publication is based upon technical data gained in our own and other Laboratories and is believed

to be true. However the material is used in conditions beyond our control thus we can assume no liability for results

obtained or damages incurred through the application of the date presented herein.

MacDermid Offshore Solutions MacDermid Offshore Solutions

223 N. Brockman St. Cale Lane

Pasadena, TX 77506 New Springs, Wigan

Order Desk: (800) 521-2589 WN2 1JR, UK

Sales Office: (713) 472-5081 fax 2440 +44(1942) 501000 fax +44(1942) 501110

Email: offshoreorders@macdermid.com Email: wigansales@macdermid.com

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Documents Resources MacDermid Erifon HD856 Issue 10 A4Document2 pagesDocuments Resources MacDermid Erifon HD856 Issue 10 A4Pedro DutraPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Otis Actuator h03548Document2 pagesOtis Actuator h03548Pedro Dutra100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Ocean Engineering 15512028 - Artikel 11 Pipa Bawah LautDocument6 pagesOcean Engineering 15512028 - Artikel 11 Pipa Bawah LautPedro DutraPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- ABREVIAÇÕES-Design Terms AbbreviationsDocument18 pagesABREVIAÇÕES-Design Terms AbbreviationsPedro DutraPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Lincoln Ap - 1 PDFDocument1 pageLincoln Ap - 1 PDFPedro DutraPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- PRS - Diverless Connection System - HorizontalDocument2 pagesPRS - Diverless Connection System - HorizontalPedro DutraPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- DTS - Connector CleanerDocument1 pageDTS - Connector CleanerPedro DutraPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Nylon11 Material DataDocument1 pageNylon11 Material DataPedro DutraPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- GE HY Kellyguard FS 080709 PDFDocument2 pagesGE HY Kellyguard FS 080709 PDFPedro Dutra100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- IWOCS SMS Intervention and Workover Control Systems DatasheetDocument1 pageIWOCS SMS Intervention and Workover Control Systems DatasheetPedro DutraPas encore d'évaluation

- Subsea Single Bolt ConnectorsDocument12 pagesSubsea Single Bolt ConnectorsPedro DutraPas encore d'évaluation

- MEG Throttle Valve Oceanneging CTV-HFDocument4 pagesMEG Throttle Valve Oceanneging CTV-HFPedro DutraPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Oceanic HD856Document5 pagesOceanic HD856Pedro DutraPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Patent Ucon Us8794336Document13 pagesPatent Ucon Us8794336Pedro DutraPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Trunnion Eng Final MensiDocument28 pagesTrunnion Eng Final MensiPedro DutraPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Casing Tables 2015Document64 pagesCasing Tables 2015JOSEPas encore d'évaluation

- Astm FundidosDocument2 pagesAstm FundidosPedro DutraPas encore d'évaluation

- Hydraulic Internal Seal Receptacle (HISR) : Product InformationDocument1 pageHydraulic Internal Seal Receptacle (HISR) : Product InformationPedro DutraPas encore d'évaluation

- Em Everslik® vs. Whitford XylanDocument2 pagesEm Everslik® vs. Whitford XylanPedro DutraPas encore d'évaluation

- Wellhead Requirements Vol 5Document27 pagesWellhead Requirements Vol 5Pedro DutraPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Em Everslik® vs. Whitford XylanDocument2 pagesEm Everslik® vs. Whitford XylanPedro DutraPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Wellhead Requirements Vol 5Document27 pagesWellhead Requirements Vol 5Pedro DutraPas encore d'évaluation

- Humidity HandbookDocument130 pagesHumidity HandbookPedro Dutra100% (1)

- MR 0175 Inquiries and ResponsesDocument25 pagesMR 0175 Inquiries and ResponsesPedro DutraPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Maxseal Solenoid Valve Ico4s 1-2 2-2 AutoDocument4 pagesMaxseal Solenoid Valve Ico4s 1-2 2-2 AutoPedro DutraPas encore d'évaluation

- 7862 TC1380Document8 pages7862 TC1380Pedro DutraPas encore d'évaluation

- Errata2 API 6A Ed20Document1 pageErrata2 API 6A Ed20Pedro DutraPas encore d'évaluation

- Norsok Standard M-501: Rev. 5, June 2004Document24 pagesNorsok Standard M-501: Rev. 5, June 2004Nelson Matos100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Chemistry of The Morphine Alkaloids Bentley (Oxford 1954) PDFDocument452 pagesThe Chemistry of The Morphine Alkaloids Bentley (Oxford 1954) PDFJim Leonard100% (2)

- Research Cold StorageDocument6 pagesResearch Cold StorageApivit MalichaiPas encore d'évaluation

- 4140 PDFDocument28 pages4140 PDFShariq KhanPas encore d'évaluation

- ACRYREX® CM-211: Chi Mei CorporationDocument3 pagesACRYREX® CM-211: Chi Mei CorporationPhuoc Thinh TruongPas encore d'évaluation

- ME309 Metallurgy and Material Science PDFDocument4 pagesME309 Metallurgy and Material Science PDFPremnath G100% (1)

- Tea Processing: How Leaves Become Black Tea in 4 StepsDocument27 pagesTea Processing: How Leaves Become Black Tea in 4 StepsSaidur Rahman KhanPas encore d'évaluation

- Welding Defects and PreventionDocument2 pagesWelding Defects and PreventionVicky SinghPas encore d'évaluation

- Booklet 2 Topic 1Document61 pagesBooklet 2 Topic 1Sarah Al ObaidanPas encore d'évaluation

- Manual ATN-1100 Automatic Kjeldahl Nitrogen Determination ApparatusDocument35 pagesManual ATN-1100 Automatic Kjeldahl Nitrogen Determination Apparatuschristopher lee mercadoPas encore d'évaluation

- Investigation of Failures of 230KV Copper Conductor BushingsDocument15 pagesInvestigation of Failures of 230KV Copper Conductor BushingscalripkenPas encore d'évaluation

- Vortex Quantum SeriesDocument34 pagesVortex Quantum SeriesmiguelcPas encore d'évaluation

- 85 TPH CFBC Boiler Operation and Maintenance ManualDocument152 pages85 TPH CFBC Boiler Operation and Maintenance ManualAamirMalik100% (1)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Chapter 11 Physical and ChemicalDocument49 pagesChapter 11 Physical and ChemicalJJ Almagro100% (1)

- Ganoderma laccase optimizationDocument9 pagesGanoderma laccase optimizationRajeshKumarPas encore d'évaluation

- United States Patent: (10) Patent No.: (45) Date of PatentDocument70 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentAnonymous DxaBg8fUEPas encore d'évaluation

- Prodinfo Antox-75-E Eng FinalDocument2 pagesProdinfo Antox-75-E Eng FinalKumar RamanPas encore d'évaluation

- CMB Chapter 15Document32 pagesCMB Chapter 15cyorogPas encore d'évaluation

- Ferritic and Martensitic Casting Materials SpecificationsDocument2 pagesFerritic and Martensitic Casting Materials SpecificationsSinan YıldızPas encore d'évaluation

- AWS D1.5 PQR TitleDocument1 pageAWS D1.5 PQR TitleNavanitheeshwaran SivasubramaniyamPas encore d'évaluation

- Us03cicv21 Unit3Document28 pagesUs03cicv21 Unit3ashokPas encore d'évaluation

- TIGAS Haldor TopsoeDocument25 pagesTIGAS Haldor TopsoeGabriele CentiPas encore d'évaluation

- Coconut Shell Based Activated Carbon W No Greeen House Gas EmissionDocument4 pagesCoconut Shell Based Activated Carbon W No Greeen House Gas Emissionmragul22Pas encore d'évaluation

- Green Inhibitors For Steel Corrosion in Acidic Environment - State of ArtDocument21 pagesGreen Inhibitors For Steel Corrosion in Acidic Environment - State of Artanisa sutifanyPas encore d'évaluation

- An Updated Review On IPQC Tests For Sterile and Non Sterile ProductsDocument12 pagesAn Updated Review On IPQC Tests For Sterile and Non Sterile ProductsJvnPas encore d'évaluation

- Recyclingand Reuseof TextileDocument47 pagesRecyclingand Reuseof TextileRey100% (1)

- Gas Dynamics-Rayleigh FlowDocument26 pagesGas Dynamics-Rayleigh FlowRahul100% (4)

- Characterization of Raw Wastewater From TanneriesDocument9 pagesCharacterization of Raw Wastewater From TanneriesMaliha CheemaPas encore d'évaluation

- Thermodynamics For EngineersDocument620 pagesThermodynamics For Engineersgsuresh40100% (8)

- Welds CracksDocument8 pagesWelds Cracksaltaf94Pas encore d'évaluation

- Adhesives: Standard Terminology ofDocument12 pagesAdhesives: Standard Terminology ofJOHN MARTINPas encore d'évaluation

- The Martha Manual: How to Do (Almost) EverythingD'EverandThe Martha Manual: How to Do (Almost) EverythingÉvaluation : 4 sur 5 étoiles4/5 (11)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterD'EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterÉvaluation : 4 sur 5 étoiles4/5 (467)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingD'EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingÉvaluation : 4 sur 5 étoiles4/5 (2993)

- Tortoise and Hare Decluttering: The Whats, Whys, and Hows of Every Angle of DeclutteringD'EverandTortoise and Hare Decluttering: The Whats, Whys, and Hows of Every Angle of DeclutteringÉvaluation : 4.5 sur 5 étoiles4.5/5 (51)

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritD'EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeD'EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (164)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.D'EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Évaluation : 4 sur 5 étoiles4/5 (17)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosD'EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosÉvaluation : 3.5 sur 5 étoiles3.5/5 (8)