Académique Documents

Professionnel Documents

Culture Documents

LifeMax DLN Fact Sheet

Transféré par

faisalnadimCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

LifeMax DLN Fact Sheet

Transféré par

faisalnadimDroits d'auteur :

Formats disponibles

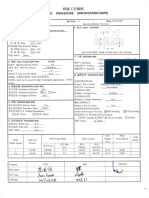

GE Power & Water

Power Generation Services

Dry Low NOx 2.6+ Combustion System

9FA/9FB Gas Turbines fact sheet

Evolving economic and regulatory requirements continue The DLN 2.6+ combustion system also serves as a foundation for

impacting the operational needs of todays gas turbines. Demand additional solutions, including GE Energys OpFlex* suite, an

for renewable resources, operational flexibility and higher fuel advanced controls platform designed to improve operational

prices are driving increasing needs for cyclic operation. In performance. The OpFlex AutoTune solution, for example,

addition to delivering lower NOx and CO emissions performance, enables continuous, reliable turbine operation with up to +/-20%

GE Energys Dry Low NOx (DLN) 2.6+ combustion system is variation of Modified Wobbe Index (MWI) for 9FA and +/-10%

designed to expand operational flexibility so you can meet your variation of MWI for 9FB. Additionally, DLN 2.6+ technology helps

power demand needs while reducing operational costs. The DLN enhance your availability to the grid by extending combustion

2.6+ combustion system is available for 9FA and 9FB gas inspection intervals to 24,000 hours or 900 starts.

turbines, including the 9FB.05 which shares the same combustor

With more than 75 million hours of DLN operation, and over

architecture.

23 million hours at or below 9 ppm NOx, GE has the expertise

DLN 2.6+ technology can broaden your operational flexibility by to help you meet your emissions and broader operational

combining attributes of the DLN 2+ and DLN 2.6 combustion objectives. The DLN 2.6+ combustion system is available with

systems, resulting in a design with six fuel nozzles instead of five. new 9FA or 9FB gas turbines, and can be installed during a

This configuration allows for asymmetric fuel flow that provides combustion, hot gas path, or major inspection for existing units.

additional control of the combustion system, and lower NOx

emissions; sub-15 ppm NOx (30 mg/z) on 9FA units, 15 ppm NOx

(30 mg/Nm3) on 9FB.03, and 25 ppm NOx (50 mg/Nm3) on 9FB.05

units with potential to achieve 15 ppm NOx (15 mg/Nm3). This

technology has accumulated more than 1,000,000 fired hours

and 18,000 fired starts.

fact sheet

Benefits Features

Satisfies increasingly stringent emission regulations Patented combustion system, more than 1,000,000 operating

Increased availability through extended combustion inspection hours on more than 70 gas turbines

intervals of 24,000 hours or 900 starts Mark* Ve and Mark VI solutions

Lower fuel costs, as much as $1.5 million per year, while Packaging and controls changes, including piping, manifold, and

maintaining emission compliance fuel skid redesigns; option for compliance to PED, ATEX, machinery

Turndown down to 35% of gas turbine load safety, low voltage, and EMC European Union directives

Fuel flexibility for various fuel grades Enhanced combustion liner geometry and fuel nozzle

Reduced off-peak cycling requirements, resulting in fewer starts Tuning valves, cloth seals, dynamics reduction, and flame stability

technologies contribute to the reduction of can-to-can variation

Faster dispatch capability

and combustion dynamics

Serves as a platform for adding OpFlex advanced

Field tunable by controlling the fuel split to the combustion zones

controls solutions

Continuous dynamics monitoring and remote DLN tuning

Reduced startup emissions

Applicability

This upgrade offering is available for all 9FA and 9FB gas turbines

equipped with DLN 2.0 or DLN 2+ combustion systems, and on new

9FA and 9FB gas turbines. The DLN 2.6+ combustion system can be

configured to burn either natural gas only, or as a dual fuel system

capable of burning either natural gas or distillate oil.

For more information, contact your GE Energy sales representative

or visit www.ge.com/energy.

* Trademark of the General Electric Company.

2013, General Electric Company. All rights reserved.

GEA14358D (07/2013)

Vous aimerez peut-être aussi

- Sourcing Secerets Ali-BabaDocument5 pagesSourcing Secerets Ali-BabafaisalnadimPas encore d'évaluation

- How To Search Product HuntingDocument5 pagesHow To Search Product HuntingShadab FaysalPas encore d'évaluation

- ATT03 Pages From HTGD693025V9019 Disassembly of The Intermediate Bearing PedestalDocument16 pagesATT03 Pages From HTGD693025V9019 Disassembly of The Intermediate Bearing PedestalfaisalnadimPas encore d'évaluation

- Operating Manual: BHIKKI 1180MW CCPP Project Serve OnlyDocument62 pagesOperating Manual: BHIKKI 1180MW CCPP Project Serve OnlyfaisalnadimPas encore d'évaluation

- Divertor DamperDocument53 pagesDivertor DamperfaisalnadimPas encore d'évaluation

- Rdlo / Rdlo V: Axially Split Volute Casing PumpDocument24 pagesRdlo / Rdlo V: Axially Split Volute Casing PumpfaisalnadimPas encore d'évaluation

- M26831 - NEW - (For IGV N VSV) - 5 - 18Document36 pagesM26831 - NEW - (For IGV N VSV) - 5 - 18faisalnadimPas encore d'évaluation

- Goat Fattening Farm 450 Animals Rs. 7.35 Million Mar-2018Document25 pagesGoat Fattening Farm 450 Animals Rs. 7.35 Million Mar-2018Ashat Ul Haq100% (1)

- ALLWEIR NTT40 PumpDocument12 pagesALLWEIR NTT40 PumpfaisalnadimPas encore d'évaluation

- Heatexchangers 140603082139 Phpapp01Document67 pagesHeatexchangers 140603082139 Phpapp01esamhamadPas encore d'évaluation

- How To Create Store On FacebookDocument20 pagesHow To Create Store On FacebookfaisalnadimPas encore d'évaluation

- WPS P008Document1 pageWPS P008faisalnadimPas encore d'évaluation

- General Overhead Crane Maintenance GuideDocument18 pagesGeneral Overhead Crane Maintenance GuidefaisalnadimPas encore d'évaluation

- Exercise 3: Problem StatementDocument2 pagesExercise 3: Problem StatementfaisalnadimPas encore d'évaluation

- Symbols PDFDocument2 pagesSymbols PDFKuttappa I GPas encore d'évaluation

- p92 & t23 - Esope France, 2004Document1 pagep92 & t23 - Esope France, 2004faisalnadimPas encore d'évaluation

- Guidelines 0n Pump Vibration First Edition Final July 2013Document17 pagesGuidelines 0n Pump Vibration First Edition Final July 2013ridzim4638Pas encore d'évaluation

- Guidelines 0n Pump Vibration First Edition Final July 2013Document17 pagesGuidelines 0n Pump Vibration First Edition Final July 2013ridzim4638Pas encore d'évaluation

- Weekly preventive maintenance scheduleDocument2 pagesWeekly preventive maintenance schedulefaisalnadimPas encore d'évaluation

- Biomass Pretreatment: Mats Galbe Dept. Chemical Engineering Lund UniversityDocument57 pagesBiomass Pretreatment: Mats Galbe Dept. Chemical Engineering Lund UniversityfaisalnadimPas encore d'évaluation

- 2006 j6Document12 pages2006 j6faisalnadimPas encore d'évaluation

- Performance Monitoring Guidelines For Power PlantsDocument1 pagePerformance Monitoring Guidelines For Power PlantsKeyur Patel0% (1)

- Calculation of Thermal Stress and Fatigue Life of 1000 MW Steam Turbine RotorDocument6 pagesCalculation of Thermal Stress and Fatigue Life of 1000 MW Steam Turbine RotorLe Anh TuanPas encore d'évaluation

- p92 & t23 - Esope France, 2004Document13 pagesp92 & t23 - Esope France, 2004adityadhPas encore d'évaluation

- Fuel Oil System DescriptionDocument11 pagesFuel Oil System DescriptionfaisalnadimPas encore d'évaluation

- 4 Types of Heat Exchanger Failures ArticleDocument6 pages4 Types of Heat Exchanger Failures ArticleAamir KhanPas encore d'évaluation

- 5 ImpactsDocument8 pages5 ImpactsfaisalnadimPas encore d'évaluation

- Real Time Water Wash System of Gas Turbine in Power PlantDocument4 pagesReal Time Water Wash System of Gas Turbine in Power PlantfaisalnadimPas encore d'évaluation

- I.G.V Openning and Closing CurveDocument3 pagesI.G.V Openning and Closing CurveHussam Baiee100% (3)

- 5 ImpactsDocument60 pages5 ImpactsfaisalnadimPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- National University of Singapore MEMS energy harvesters paperDocument11 pagesNational University of Singapore MEMS energy harvesters paperEdmund ChongPas encore d'évaluation

- Hvac FormulaeDocument5 pagesHvac FormulaeanishPas encore d'évaluation

- Soal B.ing 36-50Document6 pagesSoal B.ing 36-50fathurPas encore d'évaluation

- Chemistry Set 9Document21 pagesChemistry Set 9s_adhyaPas encore d'évaluation

- 06074L4 - ChargersEU (CEF21)Document1 page06074L4 - ChargersEU (CEF21)wirelesssoulPas encore d'évaluation

- Jenny Gas Fired Steam Cleaner: Solving Individual Cleaning Problems WorldwideDocument2 pagesJenny Gas Fired Steam Cleaner: Solving Individual Cleaning Problems WorldwidePawan SehrawatPas encore d'évaluation

- 40594-P25-A12B-2 LamarcheDocument28 pages40594-P25-A12B-2 LamarchemoisesPas encore d'évaluation

- Cheema Boiler Limited: Presented To: MR - Deepak Bhandari (Document32 pagesCheema Boiler Limited: Presented To: MR - Deepak Bhandari (angenious100% (1)

- ATA 24 Electrical Power L1Document40 pagesATA 24 Electrical Power L1jimbokhepelPas encore d'évaluation

- Problems and Solutions Physical Chemistry by LAIDLERDocument1 919 pagesProblems and Solutions Physical Chemistry by LAIDLERMohammad Khaled75% (4)

- Exam Jhs 2Document7 pagesExam Jhs 2Aleah Mae Villanueva MagnoPas encore d'évaluation

- Renewable Energy: Issam Salhi, Saïd Doubabi, Najib Essounbouli, Abdelaziz HamzaouiDocument9 pagesRenewable Energy: Issam Salhi, Saïd Doubabi, Najib Essounbouli, Abdelaziz HamzaouiSantiago GPas encore d'évaluation

- Familiarization of Electrical Lab EquipmentDocument4 pagesFamiliarization of Electrical Lab EquipmentBlaze firePas encore d'évaluation

- Fdd60s (TNK JKT) 2020Document1 pageFdd60s (TNK JKT) 2020hareudangPas encore d'évaluation

- SIMATIC S7-200: Digital ModulesDocument3 pagesSIMATIC S7-200: Digital ModuleszeeshanPas encore d'évaluation

- Dialnet CalculationOfMarineAirConditioningSystemsBasedOnEn 6769359Document15 pagesDialnet CalculationOfMarineAirConditioningSystemsBasedOnEn 6769359Om Parkash SharmaPas encore d'évaluation

- B.sc. Electronics Honours SyllabusDocument10 pagesB.sc. Electronics Honours Syllabussiddhartharay007Pas encore d'évaluation

- MCB Specification Bsen60898Document6 pagesMCB Specification Bsen60898jayswamiiPas encore d'évaluation

- Selection of Circuit BreakersDocument12 pagesSelection of Circuit BreakersPrudhvi RajPas encore d'évaluation

- Electrical One Line Diag PDFDocument5 pagesElectrical One Line Diag PDFahs beinPas encore d'évaluation

- PTC B1.1 Notes - Sub Module 15.12 (Air Systems)Document27 pagesPTC B1.1 Notes - Sub Module 15.12 (Air Systems)sohail aviatorPas encore d'évaluation

- ICT - Battery Backup Module PDFDocument2 pagesICT - Battery Backup Module PDFmahavirochanaPas encore d'évaluation

- Motorpact CatalogDocument108 pagesMotorpact CatalogtangouzePas encore d'évaluation

- Physics Formula and Notes For Class 12 CBSE Board Chapter 7 ALTERNATING CURRENTDocument11 pagesPhysics Formula and Notes For Class 12 CBSE Board Chapter 7 ALTERNATING CURRENTrahulPas encore d'évaluation

- High School Science Lesson on Volcanoes and Geothermal EnergyDocument6 pagesHigh School Science Lesson on Volcanoes and Geothermal EnergyNoemi ZablanPas encore d'évaluation

- Syllabus Teaching Science IIDocument11 pagesSyllabus Teaching Science IILiezl May Galicia-Perez100% (2)

- Resume Someswara Prasad K.MDocument3 pagesResume Someswara Prasad K.MkalyangudluruPas encore d'évaluation

- Advantages and Disadvantages of Ocean Thermal Energy Conversion (OTECDocument6 pagesAdvantages and Disadvantages of Ocean Thermal Energy Conversion (OTECJopiePas encore d'évaluation

- Experiment:8 Aim: Find Out Moisture, Volatile Matter and Ash Content in FuelDocument3 pagesExperiment:8 Aim: Find Out Moisture, Volatile Matter and Ash Content in FuelDhruv RanaPas encore d'évaluation

- Experiment in Physics2: Simple Power GeneratorDocument4 pagesExperiment in Physics2: Simple Power GeneratorJerico LausinPas encore d'évaluation