Académique Documents

Professionnel Documents

Culture Documents

Trench Box Install Guide Rev A1

Transféré par

AnuDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Trench Box Install Guide Rev A1

Transféré par

AnuDroits d'auteur :

Formats disponibles

UNCONTROLLED WHEN PRINTED

go to www.mgf.ltd.uk for latest version

GENERAL

Current health and safety legislation requires

that construction equipment users formulate

a site specific Safe System of Work (SSoW)

to undertake the works they are proposing.

This document is intended to provide

TOP sufficient product specific guidance on

handling, installing, maintaining and

removing MGF equipment to allow the SSoW

to be compiled. It should always be read in

conjunction with the product specific

technical files and the site specific design

information (including any residual risks to be

managed on site) provided by MGF or

others.

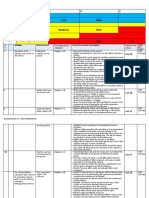

A B C D

Users of this equipment should be both

BASE B Telescopic struts adjusted to required width C

familiar with and competent in its use. MGF

A Assemble by laying panels flat Second panel lowered onto struts D Box lifted into vertical can provide toolbox talks and training

using MGF 4-leg chains provided and locked into position within panel pockets and locked into position before position for use material / advice on request.

using pins and retaining clips provided releasing chains

MGF excavation systems can be supplied

with a full range of site safety products and

ancillaries. These products are designed to

comply with current best practice and meet

the requirements of the Lifting Operations &

Lifting Equipment Regulations, Work at

Height Regulations and the Confined Spaces

Regulations.

STRUT

For MGF contact details or further

information visit www.mgf.ltd.uk

SAFETY TIPS

ASSEMBLY 1. If used in very weak, problematic or

E F G G saturated ground always ensure a site

specific temporary works design is provided.

E Excavate to max 1.0m below ground F Lower Base into excavation G Dig and push Base to Base depth advancing in maximum 300mm increments by pushing

2. Always inspect lifting points prior to every

level (if site conditions permit) and release chains each panel down using excavator bucket avoiding damage to lifting points or panel lifting operation and ensure all personnel are

well clear of operation.

3. Box should never be flown above the

base of the excavation by more than 150mm

(subject to a risk assessment).

4. Only access the box via a suitable

secured ladder placed within the box. Never

enter via the ends/faces of an unsupported

excavation.

5. Always ensure all pins and retaining clips

Standard Duty Heavy Duty are correctly fitted prior to use.

4-Leg Chain Extraction Chain

H I I J 6. If box becomes stuck in the ground only

use designated extraction chains to release

ANCILLARIES H Lower Top onto Base and connect together I Dig and push assembled box to box depth / required depth J On achieving final depth batter back open each corner at a time. N.B. Extraction loads

to form single box ensuring all 4 top to base of up to 50Te can be generated.

if additional top required repeat steps H to I ends. Install ladder and edge protection.

connection points are fully secured NB. MGF Endsafe panels can be used in 7. Do not allow personnel to enter the box

lieu of a batter whilst excavator is moving box.

8. Always ensure the box is evenly

Maintenance

K

supported by the ground on opposite faces to

avoid boxes becoming unstable.

Prior to permitting entry always ensure:- 9. Always work from a position of safety.

Avoid working above on an unsupported

edge, an unprotected edge or under a

Panels are installed plumb, square and suspended load.

level to each other

10. Very heavy equipment to be installed by

competent groundwork contractors only.

All components are fitted and show no

11. Take care to avoid accidently striking

signs of damage or distress struts or using struts for lifting/moving the

Telescopic Strut Strut Pocket Lifting/Extraction box.

Connection Connection Point Safe means of access/egress is provided

from within the box IF IN DOUBT ASK!

L Removal

LINE OF

TRENCH BOXES Removal is a reverse of installation

ensuring material is backfilled and Guidance for Safe

compacted as extraction proceeds. Systems of Work:

MANHOLE BOX Trench Boxes

Drawing No. Rev

GSSW/02.1A A1

Connector Pin 100 Thick Top to Base Drop 60 Thick Top to Base Fork Date of first issue

and R-Clip Down Connection Connection 06.03.12

Vous aimerez peut-être aussi

- Method Statement For Workshop Activities RevDocument4 pagesMethod Statement For Workshop Activities RevEmadHassanPas encore d'évaluation

- Demolition 4 PDFDocument19 pagesDemolition 4 PDFazrulPas encore d'évaluation

- HOLLOW-CORE SLAB SYSTEMS Information ManDocument36 pagesHOLLOW-CORE SLAB SYSTEMS Information ManEng.wissam Safaa100% (1)

- Tender Submission: Tender Evaluation: G Force Client: S&S Sdn. Bhd. Project:Mars Lander/Rover Date:17/09/2017 RevisionDocument49 pagesTender Submission: Tender Evaluation: G Force Client: S&S Sdn. Bhd. Project:Mars Lander/Rover Date:17/09/2017 Revisionapi-372696692Pas encore d'évaluation

- Technical Note TN 073 Self Compacting ConcreteDocument4 pagesTechnical Note TN 073 Self Compacting ConcreteKhaja MohiddinPas encore d'évaluation

- MST For REINFORCEMENT WORKSDocument6 pagesMST For REINFORCEMENT WORKSsudhir patkarPas encore d'évaluation

- Lo 2 - DemolitionDocument29 pagesLo 2 - DemolitionEng Stephen ArendePas encore d'évaluation

- Preliminary Construction Management PlanDocument84 pagesPreliminary Construction Management PlanjibooryPas encore d'évaluation

- Annex 06 - UNOPS Minimum Health and Safety Requirements For ContractorsDocument57 pagesAnnex 06 - UNOPS Minimum Health and Safety Requirements For Contractorsabdu al enabPas encore d'évaluation

- Stage 1 Demolition Method StatementDocument27 pagesStage 1 Demolition Method StatementPaul OchiengPas encore d'évaluation

- Construction of Prefabricated CulvertsDocument2 pagesConstruction of Prefabricated CulvertsJonah ScottPas encore d'évaluation

- 2 - Risk Assessment HeightsDocument15 pages2 - Risk Assessment HeightsXozanPas encore d'évaluation

- Anti TermiteDocument19 pagesAnti TermiteAjoy McPas encore d'évaluation

- Fischer Technical DataDocument6 pagesFischer Technical DataAnonymous CgJzschPas encore d'évaluation

- Technical Data Sheet For Hilti HIT HY 200Document39 pagesTechnical Data Sheet For Hilti HIT HY 200ValeriuPas encore d'évaluation

- ScaffoldingDocument21 pagesScaffoldingKrm ChariPas encore d'évaluation

- A Guide To Commissioning Scaffold Design: 1 of 6 June 2020Document6 pagesA Guide To Commissioning Scaffold Design: 1 of 6 June 2020Matthew PowellPas encore d'évaluation

- Temporary Works (Cbe3033) SyllabusDocument10 pagesTemporary Works (Cbe3033) SyllabusTony FungPas encore d'évaluation

- Technical Comment - Wall Formwork - CommentsDocument19 pagesTechnical Comment - Wall Formwork - CommentsYazan AmlehPas encore d'évaluation

- Part R10 Construction of EarthworksDocument10 pagesPart R10 Construction of EarthworksCK TangPas encore d'évaluation

- Construction MethodologyDocument15 pagesConstruction MethodologyLorens RiezaPas encore d'évaluation

- Demolition Protocol 2008Document32 pagesDemolition Protocol 2008dragosgiligorPas encore d'évaluation

- Work Procedure For CCB Scaffolding - FinalDocument80 pagesWork Procedure For CCB Scaffolding - FinalLeo PascualPas encore d'évaluation

- Safety in Design Risk RegisterDocument1 pageSafety in Design Risk Registerchayan83Pas encore d'évaluation

- TI 801-02 Volume 2 - Statement of WorkDocument81 pagesTI 801-02 Volume 2 - Statement of WorkMohamed FathiPas encore d'évaluation

- Demolition Risk AssessmentDocument4 pagesDemolition Risk AssessmentNIJESHPas encore d'évaluation

- CHS Method StatementDocument3 pagesCHS Method StatementjatinPas encore d'évaluation

- TWf2020.01 - Management of Scaffolding - 8 September 2020 - FINALDocument26 pagesTWf2020.01 - Management of Scaffolding - 8 September 2020 - FINALMohamed AdelPas encore d'évaluation

- Ms Block WorksDocument3 pagesMs Block WorksjaladeepPas encore d'évaluation

- Prop En1065 C-D35Document1 pageProp En1065 C-D35alessandroPas encore d'évaluation

- Formenta Product CatalogueDocument28 pagesFormenta Product CatalogueEmanuel KrznarPas encore d'évaluation

- Swedish Scaffolding Standard DraftDocument38 pagesSwedish Scaffolding Standard DraftcisyabPas encore d'évaluation

- Trench SafetyDocument61 pagesTrench SafetyRestie TeanoPas encore d'évaluation

- BS 1139Document0 pageBS 1139Anuj ShahiPas encore d'évaluation

- Checklist - DemolitionDocument2 pagesChecklist - DemolitionRommel Carlo Largado100% (1)

- Scaffolding SafetyDocument4 pagesScaffolding Safetyrguy3223Pas encore d'évaluation

- Demolition Method Statement: ClientDocument86 pagesDemolition Method Statement: ClientEngr Nissar KakarPas encore d'évaluation

- RC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutDocument3 pagesRC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutAnonymous ze9ag1Pas encore d'évaluation

- Ms Working PlatformDocument4 pagesMs Working Platformmohd solihin bin mohd hasan100% (1)

- Method Statement of Crossing Box CulvertDocument2 pagesMethod Statement of Crossing Box CulvertNur EmalinPas encore d'évaluation

- Manar Cup Lock SystemDocument54 pagesManar Cup Lock Systemtarek.filePas encore d'évaluation

- Glenbrook Rd. Demolition and Disposal PlanDocument56 pagesGlenbrook Rd. Demolition and Disposal PlanBruno CarvalheiroPas encore d'évaluation

- Cpc07e-Ms-str-0010 Method of Statement For Installation of BridgeDocument13 pagesCpc07e-Ms-str-0010 Method of Statement For Installation of BridgeMariam MousaPas encore d'évaluation

- Safe Design StructuresDocument27 pagesSafe Design Structurespaul machariaPas encore d'évaluation

- Code of Practice-FormworkDocument32 pagesCode of Practice-FormworkChung Yiung YungPas encore d'évaluation

- City of Durban Standard Engineering Specification Part C - Concrete WorkDocument33 pagesCity of Durban Standard Engineering Specification Part C - Concrete WorkLuke Jabulani ReidPas encore d'évaluation

- Chapter 26 - Scaffolding GuidelineDocument32 pagesChapter 26 - Scaffolding GuidelineCharlyn Burce MadridPas encore d'évaluation

- Cranes and Derricks 1926550Document13 pagesCranes and Derricks 1926550Alex BravoPas encore d'évaluation

- Climbing FormworkDocument4 pagesClimbing FormworkAshwin B S RaoPas encore d'évaluation

- Temporary Works BS5975-2019 Overview of The RevsionDocument23 pagesTemporary Works BS5975-2019 Overview of The RevsionRichard Sleeman100% (1)

- PERI UP Brochure Rosett Flex 03-2011 (792144) - Shoring DetailsDocument52 pagesPERI UP Brochure Rosett Flex 03-2011 (792144) - Shoring Detailswawen03Pas encore d'évaluation

- Demolition WorksDocument26 pagesDemolition WorksKholer BurgmanPas encore d'évaluation

- Progress Report No. 2-Dhangadhi PDFDocument6 pagesProgress Report No. 2-Dhangadhi PDFIrah IrakihdaPas encore d'évaluation

- Specification of Safety NetDocument5 pagesSpecification of Safety Netdeepak_023Pas encore d'évaluation

- C4M Mivan FormworkDocument3 pagesC4M Mivan Formworkmanohar reddyPas encore d'évaluation

- 6.method Statement Steel Erection and CladdingDocument4 pages6.method Statement Steel Erection and Claddingشاز إياسPas encore d'évaluation

- 2 Finishing Works Method Statement For Building ConstructionDocument15 pages2 Finishing Works Method Statement For Building ConstructionElxao XanPas encore d'évaluation

- (Soluciones Minería) PC05IPTT01BDocument2 pages(Soluciones Minería) PC05IPTT01BSheryl Calderón CoroseoPas encore d'évaluation

- Safety Vest InformationDocument2 pagesSafety Vest InformationSyafiq KhalilPas encore d'évaluation

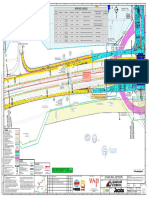

- Mark Up DRG - ABDocument1 pageMark Up DRG - ABAnuPas encore d'évaluation

- Construction NOC Drawing - TL27, TLB7, TLB8 & TLB9Document1 pageConstruction NOC Drawing - TL27, TLB7, TLB8 & TLB9AnuPas encore d'évaluation

- C0306 JBL Eut Ca 0309 AaDocument26 pagesC0306 JBL Eut Ca 0309 AaAnuPas encore d'évaluation

- Layout For 1600Ø GRP Drainage Line: EX. DB17/1Document1 pageLayout For 1600Ø GRP Drainage Line: EX. DB17/1AnuPas encore d'évaluation

- Drainage Line Network - R921/1BDocument2 pagesDrainage Line Network - R921/1BAnuPas encore d'évaluation

- Hexamoll Dinch English MSDSDocument8 pagesHexamoll Dinch English MSDSMohammed Tanjil Morshed remonPas encore d'évaluation

- HSE Inspection Report-10Document14 pagesHSE Inspection Report-10najihahPas encore d'évaluation

- Emergency Preparedness and Response ProcedureDocument2 pagesEmergency Preparedness and Response ProcedurednmulePas encore d'évaluation

- Shifting: Full Body Harness, Helmet, Safety Shoes, Reflecting Jacket, Goggels, Hand Gloves, Life LineDocument3 pagesShifting: Full Body Harness, Helmet, Safety Shoes, Reflecting Jacket, Goggels, Hand Gloves, Life LineJEPL C/o Yasho Industries LtdPas encore d'évaluation

- Code of Conduct: Golder Is Committed To High Standards of Ethical Behavior in The Conduct of Its BusinessDocument3 pagesCode of Conduct: Golder Is Committed To High Standards of Ethical Behavior in The Conduct of Its BusinessCésarAugustoGuevaraColmenaresPas encore d'évaluation

- Warrior 800 Operations Manual Revision 4 (En)Document334 pagesWarrior 800 Operations Manual Revision 4 (En)ALEJO100% (3)

- HR ProjectDocument61 pagesHR ProjectAzizMBA100% (2)

- Abstract - of The BOCW Act, 1996Document9 pagesAbstract - of The BOCW Act, 1996sameer9.patelPas encore d'évaluation

- 8878 NMO ROHS Leaflet in Blue and Updated FINALDocument2 pages8878 NMO ROHS Leaflet in Blue and Updated FINALDaniel Jun KimPas encore d'évaluation

- Module-39 Quality of Work LifDocument15 pagesModule-39 Quality of Work LifSuman KunduPas encore d'évaluation

- Material Safety Data Sheet Cat High Speed Ball Bearing Grease (NLGI #2)Document7 pagesMaterial Safety Data Sheet Cat High Speed Ball Bearing Grease (NLGI #2)aldo velasco100% (1)

- CF4000 - Tech Data Sheet - FINALDocument5 pagesCF4000 - Tech Data Sheet - FINALJuan SePas encore d'évaluation

- Bradley CurveDocument21 pagesBradley Curveajm7Pas encore d'évaluation

- Manufacturer SDSDocument19 pagesManufacturer SDSTwinkle ChokshiPas encore d'évaluation

- Lotrène® Q TR-144: Safety Data SheetDocument11 pagesLotrène® Q TR-144: Safety Data SheetlyesPas encore d'évaluation

- Teleworking Risks and PreventionDocument32 pagesTeleworking Risks and Preventionelena martinPas encore d'évaluation

- 7 Things You'd Better KnowDocument5 pages7 Things You'd Better KnowtechnojourneePas encore d'évaluation

- CE Declaration of ConformityDocument2 pagesCE Declaration of Conformitymaria cristina ristagnoPas encore d'évaluation

- Manual For Measuring Occupational Electric and Magnetic Field ExposuresDocument150 pagesManual For Measuring Occupational Electric and Magnetic Field Exposuresyuber14102100% (2)

- Asignment For Tej ShoesDocument39 pagesAsignment For Tej ShoesAyush Tiwari100% (1)

- Rowena R. Marasigan BSN, RNDocument3 pagesRowena R. Marasigan BSN, RNAMINAH JULIANNA MARASIGANPas encore d'évaluation

- Safety Orientation - New EmployeeDocument4 pagesSafety Orientation - New EmployeeMattPas encore d'évaluation

- Grade 10 TLEDocument3 pagesGrade 10 TLEJhobhel Christopher Galivo100% (1)

- Pour Point Depressant SDSDocument4 pagesPour Point Depressant SDSBasil GeorgePas encore d'évaluation

- When Tragedy Strikes Supply Chain: A Case Study On Rana PlazaDocument5 pagesWhen Tragedy Strikes Supply Chain: A Case Study On Rana PlazaAvishek BhattacherjeePas encore d'évaluation

- Manual Handling Solutions You Can HandleDocument38 pagesManual Handling Solutions You Can HandleBex FerridayPas encore d'évaluation

- Ohs Resources For Cts 1Document3 pagesOhs Resources For Cts 1api-491433072Pas encore d'évaluation

- Dangerous Goods Emergency Response ChartDocument1 pageDangerous Goods Emergency Response ChartMinh NguyenPas encore d'évaluation

- LATICRETE 317 SDS - US EnglishDocument7 pagesLATICRETE 317 SDS - US Englishpetersom 93Pas encore d'évaluation

- UNILUBE CHAIN BAR Medium-SDSDocument5 pagesUNILUBE CHAIN BAR Medium-SDSa3.msaputraPas encore d'évaluation