Académique Documents

Professionnel Documents

Culture Documents

BR PDF

Transféré par

Oscar VillaseñorTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BR PDF

Transféré par

Oscar VillaseñorDroits d'auteur :

Formats disponibles

BRAKES

SECTION

BRAKE SYSTEM

BR B

E

CONTENTS

SERVICE INFORMATION ............................ 2 2WD : Removal and Installation ..............................15 BR

2WD : Inspection .....................................................15

PRECAUTIONS ................................................... 2

Precaution for Supplemental Restraint System 4WD ............................................................................16

G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- 4WD : Removal and Installation ..............................17

SIONER" ................................................................... 2 4WD : Inspection .....................................................17

Precaution for Brake System .................................... 2

BRAKE BOOSTER ........................................... 19 H

PREPARATION ................................................... 3 On-vehicle Service ..................................................19

Commercial Service Tool .......................................... 3 Removal and Installation .........................................19

VACUUM LINES ............................................... 21 I

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................. 4 Removal and Installation KA24DE ..........................21

NVH Troubleshooting Chart ...................................... 4 Inspection ................................................................21

Removal and Installation YD25DDTi .......................22 J

BRAKE PEDAL AND BRACKET ........................ 5 Inspection ................................................................22

Removal and Installation ........................................... 5

Inspection .................................................................. 5 FRONT DISC BRAKE ....................................... 23

K

Adjustment ................................................................ 6 Component ..............................................................23

Pad Replacement ....................................................23

BRAKE FLUID ..................................................... 7 Caliper Removal and Installation .............................24

Checking Brake Fluid Level ...................................... 7 Caliper Disassembly and Assembly ........................25 L

Checking Brake Line ................................................. 7 Brake Burnishing Procedure ....................................26

Changing Brake Fluid ................................................ 7

Bleeding Brake System ............................................. 7 REAR DRUM BRAKE ....................................... 27 M

Component ..............................................................27

BRAKE PIPING AND HOSE ............................... 9 Inspection ................................................................28

Hydraulic Circuit ........................................................ 9 Removal and Installation .........................................28

Front and Rear Brake Piping and Hose .................. 10 Wheel Cylinder Disassembly an Assembly .............31 N

Inspection ................................................................ 11

SERVICE DATA AND SPECIFICATIONS

MASTER CYLINDER .........................................12 (SDS) ................................................................. 32 O

Component .............................................................. 12 General Specification ..............................................32

Removal and Installation ......................................... 12 Load Sensing Valve .................................................32

Disassembly and Assembly .................................... 13 Disc Brake ...............................................................32

P

Drum Brake .............................................................32

LOAD SENSING VALVE ....................................15 Brake Pedal .............................................................32

Brake Booster ..........................................................33

2WD ........................................................................... 15

Revision: September 2009 BR-1 2010 D22 LCV

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005783008

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution for Brake System INFOID:0000000005473022

Use brake fluid DOT 3.

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

To clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

Never use mineral oils such as gasoline or kerosene. They

will ruin rubber parts of hydraulic system.

Use flare nut wrench when removing and installing brake

tubes.

SBR686C

Always torque brake lines when installing.

Burnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing

pads or linings, or if a soft pedal occurs at very low mileage. Refer to BR-26, "Brake Burnishing Pro-

cedure".

WARNING:

Clean brakes with a vacuum dust collector to minimize risk of health hazard from powder caused by

friction.

Revision: September 2009 BR-2 2010 D22 LCV

PREPARATION

< SERVICE INFORMATION >

PREPARATION

A

Commercial Service Tool INFOID:0000000005473023

B

Tool name Description

1 Flare nut crowfoot Removing and installing each brake piping

2 Torque wrench a: 10 mm (0.39 in)

C

NT360

Brake fluid pressure gauge Measuring brake fluid pressure E

BR

NT151 G

Revision: September 2009 BR-3 2010 D22 LCV

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart INFOID:0000000005473024

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

FFD-6, RFD-6,

BR-23, BR-23

FSU-5, RSU-4

BR-23, BR-23

BR-25, BR-28

\BR-28

BR-27

BR-24

BR-25

FAX-4

FAX-4

WT-3

PR-4

PS-5

Reference page

Linings or pads - uneven wear

Linings or pads - damaged

Rotor or drum deformation

Rotor or drum imbalance

Rotor thickness variation

Rotor or drum deflection

Return spring damaged

Rotor or drum damage

PROPELLER SHAFT

Rotor or drum runout

Rotor or drum rust

Drum out of round

Possible cause

Shims damaged

DIFFERENTIAL

ROAD WHEEL

DRIVE SHAFT

SUSPENSION

and SUSPECTED PARTS

STEERING

TIRES

AXLE

Noise

Symptom BRAKE Shake

Shimmy, Judder

: Applicable

Revision: September 2009 BR-4 2010 D22 LCV

BRAKE PEDAL AND BRACKET

< SERVICE INFORMATION >

BRAKE PEDAL AND BRACKET

A

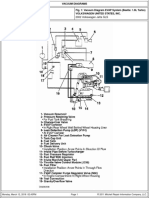

Removal and Installation INFOID:0000000005473025

BR

J

AWFIA0387GB

1. Fulcrum shaft 2. Pedal bracket 3. Stop lamp switch K

4. Return spring 5. Snap pin 6. Brake pedal

7. Clevis pin

* Replace plastic stopper located at the end of the clevis pin if deformed or damaged L

Inspection INFOID:0000000005473026

M

Check brake pedal for following items.

Brake pedal bend

Clevis pin deformation

Crack of any welded portion N

Crack or deformation of clevis pin stopper

P

SBR997

Revision: September 2009 BR-5 2010 D22 LCV

BRAKE PEDAL AND BRACKET

< SERVICE INFORMATION >

Adjustment INFOID:0000000005473027

Check brake pedal free height from metal panel.

H : Free height (Refer to BR-32, "Brake Pedal".)

D : Depressed height (Refer to BR-32, "Brake

Pedal".)

Under force of 490 N (50 kg, 110 lb) with engine

running

C : Clearance between pedal stopper and

threaded end of stop lamp switch [0.3 - 1.0 mm

(0.012 - 0.039 in)]

A : Pedal free play [1.0 - 3.0 mm (0.039 - 0.118

in)]

SBR278AB

If necessary, adjust brake pedal free height.

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

Make sure that tip of input rod stays inside.

2. Loosen lock nut and adjust clearance C with stop lamp switch

respectively, then tighten lock nuts.

3. Check pedal free play.

Make sure that stop lamp is off when pedal is released.

4. Check brake pedal depressed height while engine is running.

If lower than specification, check for leaks, air in system, or

damage to components (master cylinder, wheel cylinder, etc.). SBR930

Then make necessary repairs.

Revision: September 2009 BR-6 2010 D22 LCV

BRAKE FLUID

< SERVICE INFORMATION >

BRAKE FLUID

A

Checking Brake Fluid Level INFOID:0000000005473028

Check fluid level in reservoir tank. It should be between MAX and B

MIN lines on reservoir tank.

If fluid level is extremely low, check brake system.

If the brake warning lamp comes on, check brake fluid level switch

and parking brake switch. C

SBR451D E

Checking Brake Line INFOID:0000000005473029

CAUTION: BR

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

1. Check brake lines (tubes and hoses) for cracks, deterioration G

and other damage. Replace any damaged parts.

2. Check for oil leakage by fully depressing brake pedal while

engine is running. H

I

SBR389C

Changing Brake Fluid INFOID:0000000005473030

J

CAUTION:

Refill with new brake fluid DOT 3.

Always keep fluid level higher than minimum line on reservoir K

tank.

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted L

areas, wash it away with water immediately.

1. Clean inside of reservoir tank, and refill with new brake fluid.

2. Connect a vinyl tube to each air bleeder valve. M

3. Drain brake fluid from each air bleeder valve by depressing

brake pedal. SBR419C

N

4. Refill until brake fluid comes out of each air bleeder valve.

Use same procedure as in bleeding hydraulic system to refill brake fluid.

Refer to BR-7, "Bleeding Brake System".

O

Bleeding Brake System INFOID:0000000005473031

CAUTION:

P

Revision: September 2009 BR-7 2010 D22 LCV

BRAKE FLUID

< SERVICE INFORMATION >

Carefully monitor brake fluid level at master cylinder during

bleeding operation.

If master cylinder is suspected to have air inside, bleed air

from master cylinder first. Refer to BR-12, "Removal and

Installation".

Fill reservoir with new brake fluid DOT 3. Make sure it is full

at all times while bleeding air out of system.

Place a container under master cylinder to avoid spillage of

brake fluid.

Turn ignition switch OFF and disconnect the ABS connector

or battery cable.

SBR995

Bleed air in the following order.

- Left rear brake

- Right rear brake

- Left front brake

- Right front brake

- ABS Actuator and Electric Unit

1. Connect a transparent vinyl tube to air bleeder valve.

2. Fully depress brake pedal several times.

3. With brake pedal depressed, open air bleeder valve to release

air.

4. Close air bleeder valve.

5. Release brake pedal slowly.

6. Repeat steps 2. through 5. until clear brake fluid comes out of air

bleeder valve.

7. Tighten air bleeder.

SBR419C

Air bleeder : 7 - 9 Nm (0.7 - 0.9 kg-m, 61 - 78 in-lb)

Revision: September 2009 BR-8 2010 D22 LCV

BRAKE PIPING AND HOSE

< SERVICE INFORMATION >

BRAKE PIPING AND HOSE

A

Hydraulic Circuit INFOID:0000000005473032

BR

I

AWFIA0389GB

1. Front brake 2. Five-way connector 3. Three-way connector J

4. Rear brake 5. Load sensing valve 6. Master cylinder

Three-way connector (engine

7. Brake booster 8. Front

compartment)

K

31.4 (3.2, 23) 16.2 (1.7, 12)

Revision: September 2009 BR-9 2010 D22 LCV

BRAKE PIPING AND HOSE

< SERVICE INFORMATION >

AWFIA0390GB

1. Front brake 2. 4-way connector 3. Three way connector (axle)

4. Rear brake 5. Load sensing valve (LSV) 6. Master cylinder

Three way connector (engine compart-

7. Brake booster 8. 9. ABS actuator and electric unit

ment)

31.4 (3.2, 23) 16.2 (1.7, 12) Front

Front and Rear Brake Piping and Hose INFOID:0000000005473033

REMOVAL

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

All hoses must be free from excessive bending, twisting and

pulling.

1. Connect vinyl tube to air bleeder valve.

2. Drain brake fluid from each air bleeder valve by depressing

brake pedal.

3. Remove flare nut connecting brake tube and hose, then with-

draw lock spring.

SBR992

4. Cover openings to prevent entrance of dirt whenever discon-

necting brake line.

INSTALLATION

CAUTION:

Revision: September 2009 BR-10 2010 D22 LCV

BRAKE PIPING AND HOSE

< SERVICE INFORMATION >

Refill with new brake fluid DOT 3.

Never reuse drained brake fluid. A

1. Tighten all flare nuts and connecting bolts.

2. Refill until new brake fluid comes out of each air bleeder valve.

3. Bleed air. Refer to BR-7, "Bleeding Brake System". B

SBR686C

D

Inspection INFOID:0000000005473034

Check brake lines (tubes and hoses) for cracks, deterioration and other damage. Replace any damaged parts.

E

BR

Revision: September 2009 BR-11 2010 D22 LCV

MASTER CYLINDER

< SERVICE INFORMATION >

MASTER CYLINDER

Component INFOID:0000000005473035

AWFIA0391GB

1. Reservoir cap 2. Oil filter (w/ABS) 3. Float

4. Reservoir tank 5. Seal 6. Cylinder body

7. O-ring 8. Piston stopper (w/ABS) 9. Secondary piston assembly

Primary piston assembly (w/

10. Primary piston assembly 11. Stopper cap 12.

ABS)

Secondary piston assembly (w/ Brake fluid level switch (if

13. 14.

ABS) equipped)

Removal and Installation INFOID:0000000005473036

REMOVAL

CAUTION:

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

In the case of brake fluid leakage from the master cylinder, disassemble the cylinder. Then check

piston cups for deformation and scratches and replace necessary parts.

1. Connect a vinyl tube to air bleeder on brakes.

2. Drain brake fluid from each air bleeder, depressing brake pedal to empty fluid from master cylinder.

3. Disconnect brake fluid level switch.

4. Remove flare nuts.

5. Remove master cylinder nuts.

INSTALLATION

CAUTION:

Revision: September 2009 BR-12 2010 D22 LCV

MASTER CYLINDER

< SERVICE INFORMATION >

Refill with new brake fluid DOT 3.

Never reuse drained brake fluid. A

1. Place master cylinder onto brake booster and secure master

cylinder nuts lightly.

2. Tighten master cylinder nuts. B

3. Fill reservoir tank with new brake fluid.

4. Plug all ports on master cylinder with fingers to prevent air suc-

tion while releasing brake pedal. C

5. Have driver depress brake pedal slowly several times until no air

comes out of master cylinder. ABR190

6. Fit brake lines to master cylinder. D

7. Tighten flare nuts. Refer to BR-9, "Hydraulic Circuit".

8. Bleed air from brake system. Refer to BR-7, "Bleeding Brake System".

E

Disassembly and Assembly INFOID:0000000005473037

DISASSEMBLY BR

1. If necessary, remove brake fluid level switch.

2. Bend claws of stopper cap outward.

G

SBR938A

J

3. Remove piston assemblies.

NOTE:

If it is difficult to remove secondary piston assembly, gradually

K

apply compressed air through fluid outlet.

4. Draw out reservoir tank.

L

M

SBR939A

INSPECTION AFTER DISASSEMBLY

N

Master cylinder

Check master cylinder inner wall for pin holes and scratches. Replace if damaged.

Piston O

Check the piston cup for damage. Replace the piston if damage is found.

ASSEMBLY

CAUTION: P

Never use mineral oils such as kerosene or gasoline during the cleaning and assembly process.

Make sure there is no foreign material such as dirt and dust on the inner cylinder wall, piston and

cup seal.

Be careful not to damage the parts with a service tool when assembling.

Do not drop parts. Do not use dropped parts.

Revision: September 2009 BR-13 2010 D22 LCV

MASTER CYLINDER

< SERVICE INFORMATION >

1. Insert secondary piston assembly (C). Then insert primary pis-

ton assembly (D).

CAUTION:

Pay attention to direction of piston cups in figure. Also,

insert pistons squarely to avoid scratches on cylinder bore.

A: Without ABS

B: With ABS

C: Secondary piston

D: Primary piston

AWFIA0421GB

2. Install stopper cap.

NOTE:

Before installing stopper cap, ensure that claws are bent inward.

3. Push reservoir tank seals into cylinder body.

4. Push reservoir tank into cylinder body.

5. If necessary, install brake fluid level switch.

SBR940A

Revision: September 2009 BR-14 2010 D22 LCV

LOAD SENSING VALVE

< SERVICE INFORMATION >

LOAD SENSING VALVE

A

2WD

2WD : Removal and Installation INFOID:0000000005473038

B

BR

SBR964D

J

CAUTION:

Always use a flare nut wrench to remove brake tube. Be careful not to damage flare nut and brake

tube. Also, use flare nut torque wrench for brake tube installation and tightening to the specified K

torque. Refer to BR-9, "Hydraulic Circuit".

Refill with new brake fluid DOT 3.

Never reuse drained brake fluid.

L

REMOVAL

1. Drain brake fluid.

2. Using a suitable tool, remove flare nut on brake tubes from load sensing valve. M

NOTE:

Cover brake line connections/openings to protect them from foreign material such as dust or dirt.

3. Remove bolts to remove load sensing valve. N

INSTALLATION

Installation is in the reverse order of removal.

After installation perform the following: bleed air from brake line. Refer to BR-7, "Bleeding Brake System", O

and check mounting length L of sensor spring. Refer to BR-32, "Load Sensing Valve".

2WD : Inspection INFOID:0000000005473039

P

INSPECTION

1. With the vehicle in unladen condition, a person should sit in driver's seat at the rear. Then he/she should

get out of car gently. (This is to stabilize suspension deflection.)

NOTE:

Unladen condition: with full coolant, lubricant, 6 to 8 litters of fuel, spare tire, jack, and hand tools loaded.

Revision: September 2009 BR-15 2010 D22 LCV

LOAD SENSING VALVE

< SERVICE INFORMATION >

2. Press load sensing valve against stopper bolt. Check if center-to-center length L between adjusting ref-

erence hole and reference pin is as specified below.

Length L : 163.4 mm (6.43 in)

If measurement is outside the standard, perform following;

loosen bolt of sensor spring bracket. By moving sensor spring

bracket, adjust so that the length L comes into specified

range.

3. Connect brake fluid pressure tester (special service tool) to

bleed valves of front caliper and rear wheel cylinder.

4. Bleed air from brake fluid pressure tester (special service tool).

5. With brake pedal depressed, check brake fluid pressure at front

caliper and rear wheel cylinder. The respective measurements

should be as specified in the table below.

SFIA0245E

6. Under condition of step 2 above, adjust rear shaft weight with

weights to obtain 163.4 mm (6.43 in) as length L. Then, check

brake fluid pressure as described in step 5 above. If measure-

ments are outside the standards, replace load sensing valve

main body.

BRA0515D

Standard

Front caliper brake fluid Rear wheel cylinder brake fluid pressure kPa (bar, kg/cm2, psi)

pressure 2WD

kPa (bar, kg/cm2, psi) unladen loaded

3236 - 4217 (32.36 - 42.17, 33 - 43, 3923 5884 (39.2 - 58.8, 40 - 60,

4,904 (49.0, 50, 711)

469 - 611) 569 - 853)

4119 - 5100 (41.1 - 57.0, 42 - 52, 597 6375 - 8336 (64.0 - 83.4, 65 - 85, 924

9,807 (98.1, 100, 1422)

- 739) - 1209

7. After inspection, remove brake fluid pressure tester (special service tool) and bleed air. Refer to BR-7,

"Bleeding Brake System".

4WD

Revision: September 2009 BR-16 2010 D22 LCV

LOAD SENSING VALVE

< SERVICE INFORMATION >

4WD : Removal and Installation INFOID:0000000005473040

BR

SBR966D

I

CAUTION:

Always use a flare nut wrench to remove brake tube. Be careful not to damage flare nut and brake

tube. Also, use flare nut torque wrench for brake tube installation and tightening to the specified J

torque. Refer to BR-9, "Hydraulic Circuit".

Refill with new brake fluid DOT 3.

Never reuse drained brake fluid.

K

REMOVAL

1. Drain brake fluid.

2. Using a suitable tool, remove flare nut on brake tubes from load sensing valve. L

NOTE:

Cover brake line connections/openings to protect them from foreign material such as dust or dirt.

3. Remove bolts to remove load sensing valve. M

INSTALLATION

Installation is in the reverse order of removal.

After installation perform the following: bleed air from brake line. Refer to BR-7, "Bleeding Brake System", N

and check mounting length L of sensor spring. Refer to BR-32, "Load Sensing Valve".

4WD : Inspection INFOID:0000000005473041

O

INSPECTION

1. With the vehicle in unladen condition, a person should sit in driver's seat at the rear. Then he/she should P

get out of car gently. (This is to stabilize suspension deflection.)

NOTE:

Unladen condition: with full coolant, lubricant, 6 to 8 litters of fuel, spare tire, jack, and hand tools loaded.

2. Press load sensing valve against stopper bolt. Check if center-to-center length L between adjusting ref-

erence hole and reference pin is as specified below.

Length L : 163.4 mm (6.43 in)

Revision: September 2009 BR-17 2010 D22 LCV

LOAD SENSING VALVE

< SERVICE INFORMATION >

If measurement is outside the standard, perform following;

loosen bolt of sensor spring bracket. By moving sensor spring

bracket, adjust so that the length L comes into specified

range.

3. Connect brake fluid pressure tester (special service tool) to

bleed valves of front caliper and rear wheel cylinder.

4. Bleed air from brake fluid pressure tester (special service tool).

5. With brake pedal depressed, check brake fluid pressure at front

caliper and rear wheel cylinder. The respective measurements

should be as specified in the table below.

SFIA0245E

6. Under condition of step 2 above, adjust rear shaft weight with

weights to obtain 163.4 mm (6.43 in) as length L. Then, check

brake fluid pressure as described in step 5 above. If measure-

ments are outside the standards, replace load sensing valve

main body.

BRA0515D

Standard

Rear wheel cylinder brake fluid pressure kPa (bar, kg/cm2, psi)

Front caliper brake fluid pressure

4WD

kPa (bar, kg/cm2, psi)

unladen loaded

1765 - 2746 (18.0 - 27.5, 18 - 28, 3923 - 5884 (39.2 - 58.8, 40 -

4,904 (49.0, 50, 711)

256 - 398) 60, 569 - 853)

2648 - 3629 (26.5 - 36.3, 27 - 37, 6865 - 8924 68.7 - 89.2, 71 - 91,

9,807 (98.1, 100, 1422)

384 - 526) 995 - 1294)

7. After inspection, remove brake fluid pressure tester (special service tool) and bleed air. Refer to BR-7,

"Bleeding Brake System".

Revision: September 2009 BR-18 2010 D22 LCV

BRAKE BOOSTER

< SERVICE INFORMATION >

BRAKE BOOSTER

A

On-vehicle Service INFOID:0000000005473042

OPERATING CHECK B

Depress brake pedal several times with engine off. After exhaust-

ing vacuum, make sure there is no change in pedal stroke.

C

E

SBR002A

Depress brake pedal, then start engine. If pedal goes down BR

slightly, operation is normal.

SBR365AA

I

AIRTIGHT CHECK

Start engine, and stop it after one or two minutes. Depress brake pedal several times slowly. Booster is air-

tight if pedal stroke is less each time. J

Depress brake pedal while engine is running, and stop engine with pedal depressed. The pedal stroke

should not change after holding pedal down for 30 seconds.

K

Removal and Installation INFOID:0000000005473043

REMOVAL

L

CAUTION:

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

Be careful not to deform or bend brake pipes during removal of booster. M

INSPECTION AFTER REMOVAL

1. Apply vacuum of 66.7 kPa (500 mmHg, 19.69 inHg) to brake N

booster with a hand vacuum pump.

2. Add preload of 19.6 N (2.0 kg, 4.4 lb) to output rod length.

3. Check output rod length. O

Output : 10.275 - 10.525 mm (0.4045 - 0.4144 in)

rod length P

ABR875

INSTALLATION

CAUTION:

Revision: September 2009 BR-19 2010 D22 LCV

BRAKE BOOSTER

< SERVICE INFORMATION >

Be careful not to deform or bend brake pipes during installa-

tion of booster.

Replace clevis pin if damaged.

Refill with new brake fluid DOT 3.

Never reuse drained brake fluid.

Take care not to damage brake booster mounting bolt thread

when installing. Due to the narrow angle of installation, the

threads can be damaged by the dash panel.

1. Before fitting booster, temporarily adjust clevis to dimension

shown.

SBR116BE

A : 160 mm (6.30 in)

2. Fit booster, then secure mounting nuts (brake pedal bracket to brake booster) lightly.

3. Connect brake pedal and booster input rod with clevis pin.

4. Secure brake booster nuts.

Brake booster nuts : 14.2 Nm (1.4 kg-m, 10 ft-lb)

5. Install master cylinder. Refer to BR-12, "Removal and Installation".

6. Adjust brake pedal height and free play. Refer to BR-6, "Adjustment".

7. Secure lock nut for clevis.

Lock nut : 19 Nm (1.9 kg-m, 14 ft-lb)

8. Bleed air. Refer to BR-7, "Bleeding Brake System".

SBR930

Revision: September 2009 BR-20 2010 D22 LCV

VACUUM LINES

< SERVICE INFORMATION >

VACUUM LINES

A

Removal and Installation KA24DE INFOID:0000000005473044

D

AWFIA0404GB

1. Check valve A. To engine B. To brake booster

E

CAUTION:

When installing vacuum hoses, pay attention to the following points.

BR

Do not apply any oil or lubricants to vacuum hose with check

valve.

Insert vacuum tube into vacuum hose as shown.

Install vacuum hose with internal check valve, paying atten- G

tion to its direction.

I

SBR225B

Inspection INFOID:0000000005473045

J

VISUAL INSPECTION

Check vacuum lines and connections for airtightness, improper attachment, chafing and deterioration.

CHECK VALVE INSPECTION K

Check vacuum with a vacuum pump.

L

Connect to booster side Vacuum should exist.

Connect to engine side Vacuum should not exist.

M

N

SBR844B

Revision: September 2009 BR-21 2010 D22 LCV

VACUUM LINES

< SERVICE INFORMATION >

Removal and Installation YD25DDTi INFOID:0000000005473046

AWFIA0405GB

1. Check valve A. To engine B. To brake booster

CAUTION:

Because vacuum hose contains a check valve, it must be

installed in the correct position. Refer to the stamp to confirm

correct installation. Brake booster will not operate normally if

the hose is installed in the wrong direction.

Insert vacuum hose at least 24 mm (0.94 in).

Do not use lubricating oil during assembly.

SBR225B

Inspection INFOID:0000000005473047

VISUAL INSPECTION

Check for correct assembly, damage and deterioration.

CHECK VALVE INSPECTION

Airtightness Inspection

Check vacuum with a handy vacuum pump.

When connected to the booster side (1):

Vacuum should decrease within 1.3 kPa (10 mm-

Hg, 0.39 inHg) for 15 seconds under a vacuum of

66.7 kPa (500 mmHg, 19.69 inHg).

When connected to the engine side (2):

Vacuum should not exist.

Replace vacuum hose assembly if vacuum hose and check valve

are malfunctioning. SFIA0210E

Revision: September 2009 BR-22 2010 D22 LCV

FRONT DISC BRAKE

< SERVICE INFORMATION >

FRONT DISC BRAKE

A

Component INFOID:0000000005473048

BR

G

AWFIA0406GB

1. Main pin 2. Pin boot 3. Torque member bolt

4. Torque member 5. Shim cover (if equipped) 6. Inner shim

H

7. Inner pad 8. Pad retainer 9. Outer pad

10. Outer shim 11. Connecting bolt 12. Copper washer

13. Main pin bolt 14. Bleed valve 15. Cylinder body

I

16. Piston seal 17. Piston 18. Piston boot

A. Apply to sliding portion B. Bake fluid R. Rubber grease

J

Pad Replacement INFOID:0000000005473049

WARNING: K

Clean brakes with a vacuum dust collector to minimize the hazard of airborne particles or other mate-

rials.

CAUTION: L

When cylinder body is open, do not depress brake pedal, or piston will pop out.

Be careful not to damage piston boot or get oil on rotor. Always replace shims when replacing pads.

If shims are rusted or show peeling of the rubber coat, replace them with new shims.

It is not necessary to remove connecting bolt except for disassembly or replacement of caliper M

assembly. In this case, suspend cylinder body with wire so as not to stretch brake hose.

Burnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing

pads or linings, or if a soft pedal occurs at very low mileage. Refer to BR-26, "Brake Burnishing Pro- N

cedure".

1. Remove reservoir cap.

2. Remove lower main pin bolt. O

SBR081A

Revision: September 2009 BR-23 2010 D22 LCV

FRONT DISC BRAKE

< SERVICE INFORMATION >

3. Rotate cylinder body upward. Remove pad retainers, inner and

outer shims and shim cover (if equipped).

Standard pad thickness : 10 mm (0.39 in)

Pad wear limit : 2 mm (0.079)

CAUTION:

Carefully monitor brake fluid level because brake fluid will

return to reservoir tank when pushing back pistons.

SBR010B

Caliper Removal and Installation INFOID:0000000005473050

REMOVAL

WARNING:

Clean brake pads with a vacuum dust collector to minimize the hazard of airborne particles or other

materials.

CAUTION:

Suspend caliper assembly with wire so as not to stretch brake hose.

Remove torque member bolts and connecting bolt.

NOTE:

It is not necessary to remove connecting bolt except for disassembly

or replacement of caliper assembly. In this case, suspend caliper

assembly with wire so as not to stretch brake hose.

SBR083A

INSTALLATION

CAUTION:

Refill with new brake fluid DOT 3.

Never reuse drained brake fluid.

1. Install caliper assembly and brake hose. Align protrusion on

brake hose with slot on caliper assembly.

2. Bleed air. Refer to BR-7, "Bleeding Brake System".

SBR084A

Revision: September 2009 BR-24 2010 D22 LCV

FRONT DISC BRAKE

< SERVICE INFORMATION >

Caliper Disassembly and Assembly INFOID:0000000005473051

A

DISASSEMBLY

WARNING:

Do not place your fingers in front of piston. B

CAUTION:

Do not scratch or score cylinder wall.

Front disc brake uses plastic pistons. Handle them carefully. C

1. Push out piston and dust covers with compressed air. Use a

wooden block so that both pistons come out evenly.

2. Remove piston seal with a suitable tool. D

BR

SBR085A

INSPECTION AFTER DISASSEMBLY

G

Cylinder Body

Check inside surface of cylinder for score, rust, wear, damage and presence of foreign objects. If any of the

above conditions are observed, replace cylinder body. H

Minor damage from rust or foreign objects may be eliminated by polishing surface with a fine emery paper.

Replace cylinder body if necessary.

CAUTION:

Use brake fluid to clean. Never use mineral oil. I

Piston

CAUTION:

Piston sliding surface is plated. Do not polish with emery paper J

even if rust or foreign objects are stuck to sliding surface.

SBR177C

M

Main Pin, Main Pin Bolt and Pin Boot

Check for wear, cracks, rust and other damage. Replace if any of the above conditions are observed.

N

DISC ROTOR INSPECTION

Runout

1. Check rotor runout using a dial indicator. O

Make sure that wheel bearing axial end play is within the speci-

fications before measuring. Refer to FAX-5, "Front Wheel Bear-

ing". P

Maximum rotor runout : 0.07 mm (0.0028 in)

2. If the rotor runout is out of specification, find minimum rotor

runout position as follows:

a. Remove nuts and rotor from wheel hub.

b. Shift the rotor one hole and secure rotor to wheel hub with nuts. SBR089A

Revision: September 2009 BR-25 2010 D22 LCV

FRONT DISC BRAKE

< SERVICE INFORMATION >

c. Measure runout.

d. Repeat steps a. to c. so that minimum rotor runout position can be found.

3. If the rotor runout is still out of specification, turn rotor with on-car brake lathe (MAD, DL-8700, AMMCO

700 and 705 or equivalent).

Thickness

Rotor repair limit (mini- : Minimum thickness 24.0

mum thickness mm (0.945)

Thickness variation (At : Maximum 0.02 mm

least 8 positions) (0.0008 in)

If thickness variation exceeds the specification, turn rotor with on-car

brake lathe.

SBR090A

ASSEMBLY

1. Insert piston seal into groove on cylinder body.

2. With piston boot fitted to piston, insert piston boot into groove on

cylinder body and install piston.

CAUTION:

Lubricate with new brake fluid before installing pistons into

cylinder body.

SBR178C

3. Properly secure piston boot.

CAUTION:

Secure dust seal properly.

SBR179CA

Brake Burnishing Procedure INFOID:0000000005473052

Burnish the brake contact surfaces according to the following procedure after refinishing or replacing drums or

rotors, after replacing pads or linings, or if a soft pedal occurs at very low mileage.

CAUTION:

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31 MPH).

2. Use medium brake pedal/foot effort to bring the vehicle to a complete stop from 50 km/h (31 MPH). Adjust

brake pedal/foot pressure such that vehicle stopping time equals 3 to 5 seconds.

3. To cool the brake system, drive the vehicle at 50 km/h (31 MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3, 10 times or more to complete the burnishing procedure.

Revision: September 2009 BR-26 2010 D22 LCV

REAR DRUM BRAKE

< SERVICE INFORMATION >

REAR DRUM BRAKE

A

Component INFOID:0000000005473053

LT26 B

BR

I

AWFIA0407GB

1. Shoe hold pin 2. Plug 3. Shoe hold pin J

4. Back plate 5. Air bleeder cap 6. Air bleeder

7. Cylinder body 8. Piston cup 9. Piston

10. Dust cover 11. Spring 12. Wheel cylinder K

13. Pin 14. Adjusting lever 15. Toggle lever

16. Washer 17. Retainer clip 18. Retainer spring

19. Spring seat 20. Shoe hold spring 21. Retainer L

22. Shoe (leading side) 23. Adjuster 24. Shoe (trailing side)

Brake grease Front B Brake fluid

M

R Rubber grease

Revision: September 2009 BR-27 2010 D22 LCV

REAR DRUM BRAKE

< SERVICE INFORMATION >

LT30

AWFIA0408GB

1. Shoe hold pin 2. Plug 3. Back plate

4. Shoe (leading side) 5. Air bleeder 6. Spring

7. Piston cup 8. Piston 9. Boot

10. Retainer ring 11. Toggle lever 12. Wave washer

13. Shoe (trailing side) 14. Adjuster 15. Boot

16. Piston 17. Piston cup 18. Wheel cylinder

19. Adjuster lever 20. Spring seat 21. Shoe hold spring

22. Retainer 23. Adjuster spring 24. Return spring (upper)

25. Return spring (lower) Brake grease Front

B Brake fluid R Rubber grease

Inspection INFOID:0000000005473054

WHEEL CYLINDER

Check wheel cylinder for leakage.

Check for wear, damage and loose conditions.

Replace if any such condition exists.

ABR370

Removal and Installation INFOID:0000000005473055

REMOVAL

WARNING:

Clean brake lining with a vacuum dust collector to minimize the hazard of airborne asbestos or other

materials.

CAUTION:

Make sure parking brake lever is released completely.

Revision: September 2009 BR-28 2010 D22 LCV

REAR DRUM BRAKE

< SERVICE INFORMATION >

1. Release parking brake lever fully, then remove drum.

If drum is hard to remove, the following procedures should be A

carried out.

a. Remove plug. Then shorten adjuster to make clearance

between brake shoe and drum. B

SBR280B

D

b. Install two bolts as shown. Tighten the two bolts gradually.

BR

G

SBR093A

2. After removing shoe hold pin by rotating retainer, remove lead-

H

ing shoe then remove trailing shoe. Remove spring by rotating

shoes.

CAUTION:

Be careful not to damage wheel cylinder piston boots. I

Be careful not to damage parking brake cable when sepa-

rating it.

3. Remove adjuster. J

4. Disconnect parking brake cable from toggle lever.

CAUTION:

Be careful not to damage parking brake cable when sepa- ABR369

K

rating it.

5. Remove retainer clip with a suitable tool. Then separate toggle

lever and brake shoe (trailing side).

L

ABR408

INSPECTION AFTER REMOVAL O

Drum

Revision: September 2009 BR-29 2010 D22 LCV

REAR DRUM BRAKE

< SERVICE INFORMATION >

Maximum inner diameter (Repair limit)

LT26 : 261.5 mm (10.30 in)

LT30 : 296.5 mm (11.67 in)

Contact surface should be fine finished with No. 120 to 150 emery

paper.

Using a drum lathe, lathe brake drum if it shows scoring, partial

wear or stepped wear.

After brake drum has been completely reconditioned or replaced,

check drum and shoes for proper contact pattern. SBR095A

Lining

Check lining thickness.

Standard lining thickness

LT26 : 5.5 mm (0.217)

LT30 : 5.8 mm (0.228 in)

Lining wear limit (A)

LT26 : 1.5 mm (0.059 in)

LT30 : 1.5 mm (0.059 in)

SBR021A

INSTALLATION

NOTE:

Always perform shoe clearance adjustment.

Burnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing pads or lin-

ings, or if a soft pedal occurs at very low mileage. Refer to BR-26, "Brake Burnishing Procedure".

1. Fit toggle lever to brake shoe (trailing side) with retainer clip.

SBR092B

2. Shorten adjuster by rotating it.

Pay attention to direction of adjuster.

Wheel Screw Depression

Left Left-hand thread Yes

Right Right-hand thread No

3. Connect parking brake cable to toggle lever.

4. Installation is in the reverse order of removal.

CAUTION:

SBR217B

Revision: September 2009 BR-30 2010 D22 LCV

REAR DRUM BRAKE

< SERVICE INFORMATION >

Be careful not to damage wheel cylinder piston boots.

A

BR

G

WFIA0085E

5. Adjust shoe-to-drum clearance.

H

6. Install brake drum.

7. When installing new wheel cylinder or overhauling wheel cylin-

der, bleed air. Refer to BR-7, "Bleeding Brake System".

I

8. Adjust parking brake. Refer to PB-4, "Adjustment".

ABR917

K

Wheel Cylinder Disassembly an Assembly INFOID:0000000005473056

Check all internal parts for wear, rust and damage. Replace if nec-

L

essary.

Pay attention not to scratch cylinder when installing pistons.

WFIA0084E

O

Revision: September 2009 BR-31 2010 D22 LCV

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specification INFOID:0000000005473057

Unit: mm (in)

Applied model KA24DE YD25DDTi

Brake model CL28VD

Cylinder bore diameter number of pistons 42.8 (1.685) x 2

Front brake Pad 146.6 x 48.5 x 10

Length width thickness (5.77 x 1.909 x 0.39)

Rotor outer diameter thickness 260 x 26 (10.2 x 1.02)

Brake model LT26 LT30

Cylinder bore diameter 22.22 (7/8)

Rear brake 249.6 x 40 x 5.5 (9.83 x 1.57 x 296.5 x 50 x 6.1 (11.65 x 1.97

Lining length width thickness

0.217) x 0.240)

Drum inner diameter 260.0 (10.23) 295.0 (11.61)

Master cylinder Bore diameter 25.40 (1)

Booster model M195T M215T

Brake booster Pri: 205 (8.07) Pri: 230 (9.06)

Diaphragm diameter

Sec: 180 (7.09) Sec: 205 (8.07)

Recommended brake fluid DOT 3

Load Sensing Valve INFOID:0000000005473058

LOAD SENSING VALVE

Load Sensing Valve spring length spring lenght "L" (center to center) 163.4 mm (6.43 in)

Disc Brake INFOID:0000000005473059

Unit: mm (in)

Brake model CL28VD

Wear limit minimum thickness 2.0 (0.079)

Pad

Standard pad thickness 10 (0.39)

Rotor repair limit Minimum thickness 24.0 (0.945)

Rotor runout Maximum 0.07 (0.0028)

Rotor thickness variation Maximum 0.02 (0.0008)

Drum Brake INFOID:0000000005473060

Unit: mm (in)

Brake model LT26 LT30

Minimum thickness 1.5 (0.059)

Lining wear limit

Standard thickness 5.5 (0.217) 5.8 (0.228)

Maximum inner diameter 261.5 (10.30) 296.5 (11.67)

Drum repair limit

Out-of-round limit 0.03 (0.0012)

Brake Pedal INFOID:0000000005473061

Unit: mm (in)

Transmission M/T

Free height H* 191 - 201(7.52 - 7.91)

Revision: September 2009 BR-32 2010 D22 LCV

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION >

Depressed height D

105 (4.13)

[under force of 490 N (50 kg, 110 lb) with engine running] A

Clearance C between pedal stopper and threaded end of stop lamp switch or ASCD

0.3 - 1.0 (0.012 - 0.039)

brake switch

Pedal free play At pedal pad 1.0 - 3.0 (0.039 - 0.118) B

*: Measured from surface of metal floor to pedal pad

Brake Booster INFOID:0000000005473062 C

Unit: mm (in)

Output rod length 10.275 - 10.525 (0.4045 - 0.4144) D

BR

Revision: September 2009 BR-33 2010 D22 LCV

Vous aimerez peut-être aussi

- Brake System: SectionDocument33 pagesBrake System: SectionEduardo ColinPas encore d'évaluation

- Brake System: SectionDocument32 pagesBrake System: SectionAnonymous 64HDY7IiN0Pas encore d'évaluation

- Versa 2012Document42 pagesVersa 2012erodriguez101Pas encore d'évaluation

- Brake System: SectionDocument23 pagesBrake System: SectionSteven AmadorPas encore d'évaluation

- Brake System: SectionDocument41 pagesBrake System: SectionalvarodvPas encore d'évaluation

- Brake System: SectionDocument48 pagesBrake System: SectionjonathanPas encore d'évaluation

- Brake System: SectionDocument42 pagesBrake System: SectionDozer KamilPas encore d'évaluation

- Nissan NRDocument41 pagesNissan NRServicio KorazaPas encore d'évaluation

- Brake System: SectionDocument128 pagesBrake System: SectionFerri JiPas encore d'évaluation

- Brake System: SectionDocument24 pagesBrake System: SectionmadurangaPas encore d'évaluation

- Brake System: SectionDocument110 pagesBrake System: SectionJumadi AlkutsPas encore d'évaluation

- Brake System: SectionDocument42 pagesBrake System: SectionLuis Alfonso Ortiz ESpinosaPas encore d'évaluation

- Brake System: SectionDocument34 pagesBrake System: SectionHawkar SuleimanPas encore d'évaluation

- Brake System: SectionDocument127 pagesBrake System: SectionLuis GarcíaPas encore d'évaluation

- Brake System: SectionDocument51 pagesBrake System: SectionsKardoPas encore d'évaluation

- Brake System: SectionDocument46 pagesBrake System: SectionRavishka SilvaPas encore d'évaluation

- Brake System: SectionDocument124 pagesBrake System: SectionArdy LauPas encore d'évaluation

- Brake System: SectionDocument137 pagesBrake System: SectionEgoro KapitoPas encore d'évaluation

- Steering System: SectionDocument32 pagesSteering System: Sectiongiancarlo sanchezPas encore d'évaluation

- Brake System: SectionDocument51 pagesBrake System: Sections.e. e.p.Pas encore d'évaluation

- BR PDFDocument47 pagesBR PDFSofyanPas encore d'évaluation

- BR PDFDocument34 pagesBR PDFewald51Pas encore d'évaluation

- Brake System: SectionDocument65 pagesBrake System: SectionRuhu royPas encore d'évaluation

- Brake System: SectionDocument56 pagesBrake System: SectionJorgeEnriqueJaramilloPas encore d'évaluation

- ST PDFDocument30 pagesST PDFronaldPas encore d'évaluation

- Infiniti FX BC ManualDocument32 pagesInfiniti FX BC ManualMarius DeacPas encore d'évaluation

- Brake System: SectionDocument47 pagesBrake System: Sectionصالح الدوسريPas encore d'évaluation

- Brake System: SectionDocument20 pagesBrake System: SectionYB MOTOR Nissan - Datsun SpecialistPas encore d'évaluation

- Steering System: SectionDocument34 pagesSteering System: SectionederengPas encore d'évaluation

- Brake System: SectionDocument52 pagesBrake System: SectionOscar GonzálezPas encore d'évaluation

- Brake System: SectionDocument32 pagesBrake System: SectionedgarPas encore d'évaluation

- Brake System: SectionDocument89 pagesBrake System: SectionRosarioPas encore d'évaluation

- Brake System: SectionDocument36 pagesBrake System: SectionWilmer QuiñonezPas encore d'évaluation

- Brake System BRDocument49 pagesBrake System BRciro_svPas encore d'évaluation

- BR PDFDocument58 pagesBR PDFronaldPas encore d'évaluation

- Brake System NISSAN B16Document51 pagesBrake System NISSAN B16Alex HernandezPas encore d'évaluation

- Steering System: SectionDocument31 pagesSteering System: SectioncesarPas encore d'évaluation

- Brake System: SectionDocument49 pagesBrake System: SectionjasleenPas encore d'évaluation

- BR 1Document43 pagesBR 1Petter VillarroelPas encore d'évaluation

- Brake System: SectionDocument46 pagesBrake System: SectionDiego496Pas encore d'évaluation

- Brake System: SectionDocument58 pagesBrake System: SectionTimPas encore d'évaluation

- Brake System BRDocument58 pagesBrake System BRciroPas encore d'évaluation

- Brake System: SectionDocument32 pagesBrake System: SectionDorusPas encore d'évaluation

- Brembo 350zDocument52 pagesBrembo 350zLucasPas encore d'évaluation

- Brake SystemDocument41 pagesBrake Systemhenry_zambranoPas encore d'évaluation

- Brake System: SectionDocument49 pagesBrake System: Sectiongiancarlo sanchezPas encore d'évaluation

- Brake System: SectionDocument69 pagesBrake System: SectionEgoro KapitoPas encore d'évaluation

- Brake System (Section BR)Document46 pagesBrake System (Section BR)ramon chilianPas encore d'évaluation

- Sistema de Frenos Nissan Patrol 2016Document54 pagesSistema de Frenos Nissan Patrol 2016Hendrick CepedaPas encore d'évaluation

- Brake System: SectionDocument59 pagesBrake System: Sectionibnu malkanPas encore d'évaluation

- Brake System: SectionDocument34 pagesBrake System: SectionJBPas encore d'évaluation

- BR MuranoDocument54 pagesBR MuranoZatovonirina RazafindrainibePas encore d'évaluation

- Brake System: SectionDocument36 pagesBrake System: SectionOscar Jhonyffer Pereda RiscoPas encore d'évaluation

- BR PDFDocument37 pagesBR PDFmatias villanueva martinezPas encore d'évaluation

- Brake System: SectionDocument36 pagesBrake System: Sectionfearimus1Pas encore d'évaluation

- Steering System: SectionDocument38 pagesSteering System: SectionMaiChiVuPas encore d'évaluation

- Brake System: SectionDocument34 pagesBrake System: SectionМиша ШаулаPas encore d'évaluation

- Infinity Brake SystemDocument34 pagesInfinity Brake SystemAlex WellmanPas encore d'évaluation

- Brake System: SectionDocument200 pagesBrake System: SectionhuusonbachkhoaPas encore d'évaluation

- Teardowns: Learn How Electronics Work by Taking Them ApartD'EverandTeardowns: Learn How Electronics Work by Taking Them ApartPas encore d'évaluation

- Codigo P076aDocument6 pagesCodigo P076aOscar VillaseñorPas encore d'évaluation

- Campaña de Bateria de Carro ElectricoDocument3 pagesCampaña de Bateria de Carro ElectricoOscar VillaseñorPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- ZED-BULL Installation ExplainDocument7 pagesZED-BULL Installation ExplainHerciu Andreea RoxanaPas encore d'évaluation

- 1 8Document1 page1 8Oscar VillaseñorPas encore d'évaluation

- Dongle User Manual V1.3Document5 pagesDongle User Manual V1.3Eduardo Alvarez HuizaPas encore d'évaluation

- Instrument Panel: SectionDocument14 pagesInstrument Panel: SectionOscar Villaseñor100% (1)

- Lu PDFDocument28 pagesLu PDFOscar VillaseñorPas encore d'évaluation

- Manual Steering System: SectionDocument21 pagesManual Steering System: SectionOscar VillaseñorPas encore d'évaluation

- Lan System: SectionDocument44 pagesLan System: SectionOscar VillaseñorPas encore d'évaluation

- Lighting System: SectionDocument42 pagesLighting System: SectionOscar VillaseñorPas encore d'évaluation

- BRC PDFDocument74 pagesBRC PDFOscar VillaseñorPas encore d'évaluation

- Ma PDFDocument51 pagesMa PDFOscar VillaseñorPas encore d'évaluation

- Glasses, Window System & Mirrors: SectionDocument42 pagesGlasses, Window System & Mirrors: SectionOscar VillaseñorPas encore d'évaluation

- Di PDFDocument53 pagesDi PDFOscar VillaseñorPas encore d'évaluation

- Front Final Drive: SectionDocument32 pagesFront Final Drive: SectionOscar VillaseñorPas encore d'évaluation

- Fsu PDFDocument45 pagesFsu PDFOscar VillaseñorPas encore d'évaluation

- Ei PDFDocument32 pagesEi PDFOscar VillaseñorPas encore d'évaluation

- BL PDFDocument67 pagesBL PDFOscar VillaseñorPas encore d'évaluation

- FL PDFDocument21 pagesFL PDFOscar VillaseñorPas encore d'évaluation

- Ex PDFDocument6 pagesEx PDFOscar VillaseñorPas encore d'évaluation

- Engine Cooling System: SectionDocument47 pagesEngine Cooling System: SectionOscar VillaseñorPas encore d'évaluation

- Fax PDFDocument27 pagesFax PDFOscar VillaseñorPas encore d'évaluation

- B D A C E F G H I J K L: Transmission/ TransaxleDocument9 pagesB D A C E F G H I J K L: Transmission/ TransaxleOscar Villaseñor100% (1)

- CL PDFDocument19 pagesCL PDFOscar VillaseñorPas encore d'évaluation

- Audio, Visual & Telephone System: SectionDocument13 pagesAudio, Visual & Telephone System: SectionOscar VillaseñorPas encore d'évaluation

- Acc PDFDocument5 pagesAcc PDFOscar Villaseñor100% (1)

- Boletin Codigo 722 y 720 Sensor de VelocidadDocument3 pagesBoletin Codigo 722 y 720 Sensor de VelocidadOscar VillaseñorPas encore d'évaluation

- Diagram AsDocument3 pagesDiagram AsOscar VillaseñorPas encore d'évaluation

- John Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)Document17 pagesJohn Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)laopaodunPas encore d'évaluation

- NCJ May 2011Document102 pagesNCJ May 2011techkasambaPas encore d'évaluation

- Subsea Production System - OverviewDocument24 pagesSubsea Production System - OverviewMuhammad NursalamPas encore d'évaluation

- Finder PSG Engineered Products Brochure L PDFDocument20 pagesFinder PSG Engineered Products Brochure L PDFGeorge_Wabag_2014Pas encore d'évaluation

- Bombas - para Uso QuimicosDocument2 pagesBombas - para Uso QuimicosmatallanaparedesPas encore d'évaluation

- 2 Simulating A Diesel Engine Using A Sector Mesh: Data ProvidedDocument16 pages2 Simulating A Diesel Engine Using A Sector Mesh: Data ProvidedmohanPas encore d'évaluation

- Evinrude 115 Direct Injection ManualDocument62 pagesEvinrude 115 Direct Injection ManualKonstantinos Karakoulas67% (3)

- Auriga 23 KWDocument48 pagesAuriga 23 KWGino Cid CamposPas encore d'évaluation

- Introduction To Steam Engine 1Document4 pagesIntroduction To Steam Engine 1Aiman SherdilPas encore d'évaluation

- DCU Trainingfor New EngineersDocument44 pagesDCU Trainingfor New EngineersDipankar Phukan50% (2)

- Velocity StringsDocument2 pagesVelocity StringsDedy DayatPas encore d'évaluation

- Tentative Rules For Gas Ready ShipsDocument10 pagesTentative Rules For Gas Ready ShipsMung Duong XuanPas encore d'évaluation

- Ic Engine SyllabusDocument2 pagesIc Engine SyllabusMadhurjya SaikiaPas encore d'évaluation

- Hydraulic Pulley PullerDocument4 pagesHydraulic Pulley PullerTanvi KhuranaPas encore d'évaluation

- EHS Questions 1Document21 pagesEHS Questions 1Fahd KhanPas encore d'évaluation

- KomatsuDocument868 pagesKomatsujeffersson joel paredes paucar100% (1)

- Manual De12t p126Document184 pagesManual De12t p126javed samaa100% (1)

- Development of Double Gear Fuel Pump For Heat Management ImprovementDocument9 pagesDevelopment of Double Gear Fuel Pump For Heat Management ImprovementkangsungjinPas encore d'évaluation

- 2012 CatalogDocument352 pages2012 Catalogartie1969100% (1)

- BC600XLDocument4 pagesBC600XLAbu Mariam0% (1)

- Eaton - 9 SpeedDocument16 pagesEaton - 9 SpeedHenry GramajoPas encore d'évaluation

- Low Volatile Doosan BabcockDocument22 pagesLow Volatile Doosan BabcockKUNALJAY100% (1)

- Linde H50Document1 203 pagesLinde H50Николай МозговPas encore d'évaluation

- Dp200 Workshop ManualDocument123 pagesDp200 Workshop ManualAnderson London95% (20)

- Coating CardDocument15 pagesCoating CardAnton Thomas PunzalanPas encore d'évaluation

- Biomass JCV 2017Document49 pagesBiomass JCV 2017Kevin Carmona Toral100% (1)

- Understand Real World Problems in EjectorDocument8 pagesUnderstand Real World Problems in EjectorEdgar Enrique Diaz Marquina100% (1)

- LIQUIDATION #1 MAY15-JUNE19 (00000002)Document6 pagesLIQUIDATION #1 MAY15-JUNE19 (00000002)Hanabishi RekkaPas encore d'évaluation

- Apag 20240319Document33 pagesApag 20240319Евгений КондратенкоPas encore d'évaluation

- Structures and Land Rig Mobilization ST-1: IADC Drilling ManualDocument3 pagesStructures and Land Rig Mobilization ST-1: IADC Drilling ManualHussainPas encore d'évaluation