Académique Documents

Professionnel Documents

Culture Documents

How To Use This Manual: Sizes 370, 1420-1760/2760 Types HFD25 & HFDD25 (Page 1 of 6)

Transféré par

jose_cruzTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

How To Use This Manual: Sizes 370, 1420-1760/2760 Types HFD25 & HFDD25 (Page 1 of 6)

Transféré par

jose_cruzDroits d'auteur :

Formats disponibles

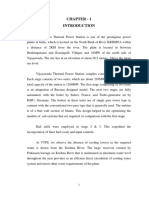

Falk Fluid Couplings Installation and Maintenance Instructions

Sizes 370, 1420-1760/2760 Types HFD25 & HFDD25 (Page 1 of 6)

How to Use This Manual FILL PLUG PERIMETER

For HFD25 & HFDD25 (Sizes 370, & 1420 thru 1760 and 392F (200C) FASTENERS

2760), use this manual in conjunction with Disc Coupling HF INPUT

HF OUTPUT

manual 478-210. ADAPTER

ADAPTER

This manual provides detailed instructions on installation, DISC COUPLING

maintenance and parts identification. Use the following Table OUTPUT ADAPTER

of Contents to locate required information.

Table of Contents

General Information . . . . . . . . . . . . . . . . . Page 1

Recommended Fluids . . . . . . . . . . . . . . . . Page 1

Installation . . . . . . . . . . . . . . . . . . . . . Page 2 ORIFICE SEAL

Orifice Plugs PLUG (1000 DISC COUPLING

(Sizes 1420 and larger) . . . . . . . . . . . . . . . Page 4 SERIES ONLY) ADAPTER BOLT &

Fusible Plugs . . . . . . . . . . . . . . . . . . . . Page 5 DELAY FILL LOCKNUT

Startup and Trouble Shooting . . . . . . . . . . . . Page 6 CHAMBER DRAIN PLUG

Figure 1 284F (140C)

Fluid Coupling Data Record . . . . . . . . . . . . . Page 6

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS not restrict free flow of air, but the portion of the guard in line

MANUAL FOR OPTIMUM PERFORMANCE AND TROUBLE with fusible plugs must be solid construction. Observe all

FREE SERVICE. safety rules when installing or servicing couplings.

CAUTION: DO NOT PAINT fluid coupling. Painting will reduce

INTRODUCTION fluid coupling thermal heat dissipation characteristics.

Falk Type HF fluid couplings are designed for horizontal

operation. Falk disc couplings provide limited end float, CAUTION: DO NOT spray water on a hot fluid coupling, as

without mechanical stops, for most applications where a this may result in cracking of aluminum components.

limited end float coupling is required. Refer to Factory for

coupling operation other than horizontal or for restricted IDENTIFICATION:

limited end float requirements.

Coupling size and M.O. Number (Mfg Order Number) are

Each fluid coupling is shipped from Rexnord with an angle finder stamped on the perimeter of the coupling. Where Rexnord has

(P/N 1224653). Simply place the angle finder on the filler plug been provided application data (HP, speed, start factor, driven

boss and rotate the coupling to the required fill angle as equipment), the coupling will also include an orange label on

instructed in the Fill Fluid Coupling section of these instructions. the perimeter, indicating the approximate fill quantity in fluid

ounces, and the correct fill angle. Provide coupling size and

Maximize Performance & Life M.O. number when ordering spare parts.

The performance and life of couplings depend largely upon Disc Coupling Refer to disc coupling service manual,

how you install and maintain them. Before installing couplings, 478-210.

make certain that foundations of equipment to be connected Fluid Coupling Size and Type are stamped on coupling

meet manufacturers requirements. Check for soft foot. The use perimeter. Refer to the Factory for replacement parts.

of stainless steel shims is recommended. Measuring

misalignment and positioning equipment within alignment

tolerances is simplified with an alignment computer. These Keep Records for Future Reference

calculations can also be done graphically or mathematically. Future maintenance of the fluid coupling can be greatly

It is recommended that final alignment be checked using simplified by keeping good records. It is strongly suggested

either an alignment computer or graphical analysis. Both that the Fluid Coupling Data Record, Table 7, be completed

methods allow the incorporation of cold offsets, which will and stored in the maintenance files.

compensate for shaft position changes due to thermal growth.

WARNING: Lock out starting switch of prime mover and remove RECOMMENDED FLUIDS

all external loads from drive before installing or servicing The following specifications and fluids listed in Table 1 apply to

couplings. Falk fluid couplings. Refer to Falk for use of fire resistant fluids.

NOTE: Fluids listed are typical products ONLY and should not be

WARNING: Opening of drain plugs, filler plugs or metering construed as exclusive recommendations.

orifice seal plugs of a fluid coupling should be done after the

ISO Viscosity Grade, Petroleum Oils (R & O) . . . . . . . 46

coupling has cooled down. When opening the plugs of a warm

or hot fluid coupling is absolutely necessary, place a rag over ISO Viscosity Grade, Synthetic Oils. . . . . . . . . . . . 32

the plug/plug hole, and loosen the plug slowly to relieve any Viscosity at 104F(40C) 46 cSt (215 SSU)

internal pressure. Viscosity Index Equal to or greater than 95.

WARNING: Consult applicable local and national safety Pour Point Must be 5F(3C) lower than minimum

codes for proper guarding of rotating members. Guard must ambient starting temperature.

Rexnord Industries, LLC, Coupling Group 528-270

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone : 262-796-4060 June 2006

Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 7-96

Installation and Maintenance Instructions Falk Fluid Couplings

(Page 2 of 6) Types HFD25 & HFDD25 Sizes 370, 1420-1760/2760

Flash Point 400F(204C) when using 140C and/or TABLE 2 Type HF Perimeter Fastener Size

180C fusible plugs. & Tightening Torques/Threaded

Flash Point 425F (218C) when using 200C fusible Rod Diameter

plugs at both fill and drain holes. COUPLING 1760

370 1420 1480 1584 1660

Specific Gravity 0.87 SIZE 2760

Antioxidant and Anti-foaming Additives Torque

lb-ft 33 33 33 88 81 140

Size

M10 x 80 M10 x 80 M10 x 80 M14 x 100 M14 x 120 M16 x 160

TABLE 1 Fluids & Operating Temperatures (mm)

Threaded

Petroleum Oils (R & O) Rod Dia-in .375 .500 .625

For Ambient Temperatures 20F to 125F (-6C to 52C)

Manufacturer Fluid

Amoco Oil Company American Industrial Oil 46

BP Oil Company HL-C46 Lifting

Chevron Products Company Hydraulic Oil AW 46 Remove two perimeter fasteners (metric) approximately 90

Exxon Company, USA Teresstic 46

Mobil Oil Corporation Mobil Fluid 424 apart. Insert threaded rod (Table 2) with washers and nuts,

Petro-Canada Products Harmony 46 then sling coupling as shown in Figure 2.

Shell Oil Company Turbo T 46

Texaco Lubricants Company Rando Oil HD 46

76 Lubricants Company 76 Unax AW 46

Petroleum Oils (R & O)

For Ambient Temperatures -20F to 125F (-28C to 52C)

Manufacturer Fluid

Amoco Oil Company American Industrial Oil 46

Mobil Oil Corporation Mobilfluid 424

Synthetic Oils and Synthetic Transmission Fluids

For Ambient Temperatures -40F to 125F (-40C to 52C)

Manufacturer Fluid

Conoco Incorporated Syncon R&O 32

Exxon Company, USA Teresstic SHP 32

Mobil Oil Corporation SHC 624

Texaco Lubricants Company Pinnacle 32

Mobil Oil Corp. Synthetic ATF

Chevron Synthetic All Weather THF

Citgo Transgard Fluid 250

Automatic Transmission Fluids (Dexron or Mercon Oils, etc.)

For Ambient Temperatures -40F to 125F (-40C to 52C)

NOTICE: Automatic Transmission Fluids below can only

be used with two 140C fusible plugs

Mobil Multi-purpose ATF

Texaco (Havoline) Mercon/Dexron-III or ATF Figure 2

Citgo Transgard ATF,Type F

ATF Type A and Type Dexron II, llD, llE, lll, Mercon M-891205 and M-921253

Key Installation Tips

l Do not exceed specified tightening torques for fusible

Annual Maintenance plugs at fill and drain holes (Step 4D). Excessive

1. Check shaft coupling alignment on a regular basis. tightening may strip aluminum threads.

Excessive misalignment will transfer damaging loads to the l Mount the fluid coupling as shown in Figure 4, the

connected equipment and may cause failure. output adapter side of the coupling must be connected

2. An annual check of the coupling and fluid is recommended. to the driven equipment. Attaching the output adapter

For extreme or unusual operating conditions, or when the side of the fluid coupling to the driver (usually a motor)

coupling is subjected to overheating, check the coupling will result in degraded performance, or in some cases

and fluid more frequently. Overheated fluid which becomes inadequate performance.

dark in color and gives off a burnt odor, must be changed. l After initial installation, store clamping bolts so they are

Fluid suppliers can test coupling fluid samples periodically available if the fluid coupling should need to be

and recommend economical change periods based on the removed.

rate of degradation. Continuous operating temperature l Carefully follow the instructions in this manual.

must not exceed 212F (100C).

3. Check outer blades of discpacks near bushings for fatigue

cracks. Discpacks can be checked while coupling is in INSTALLATION

operation by using a strobe light. Replace cracked discpacks Only standard mechanics tools, torque wrenches, feeler

per disc coupling service manual and recheck alignment. A gauges, straight edges and a bevel protractor with spirit level

slight bowing or S like distortion is normal. or angle finder (P/N 1224653) are required to install Falk

4. Check tightening torques of all drive bolts. fluid couplings.

528-270 Rexnord Industries, LLC, Coupling Group

June 2006 5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060

Supersedes 7-96 Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com

Falk Fluid Couplings Installation and Maintenance Instructions

Sizes 370, 1420-1760/2760 Types HFD25 & HFDD25 (Page 3 of 6)

The discpack drive bolts have been Factory tightened to the D. Evenly tighten bolts 1 1/2 turns from Finger Tight to

required elongation indicated in Manual 478-210. compress discpacks. DO NOT OVER TIGHTEN.

INTERFERENCE FIT HUBS Unless otherwise specified, Discpacks are now modestly compressed to aid the

Falk disc couplings are furnished for an interference fit without subsequent assembly process.

set screw. Heat hubs to a maximum 275F (135C) using an

oven, torch, induction heater or an oil bath.

PLASTIC

When an oxy-acetylene or blow torch is used, use an excess SPACER

acetylene mixture, as well as a rose bud tip. Mark hubs near TUBE CLAMPING

the center of their length in several places on hub body with a BOLT

temperature sensitive crayon, 275F (135C) melt

temperature. Direct flame towards hub bore using constant

INPUT OR

motion to avoid overheating an area. COUPLING

OUTPUT

ADAPTER

WARNING: If an oil bath is used, the oil must have a flash ADAPTER

point of 350F (177C) or higher. Do not rest hubs on the

bottom of the container. Do not use an open flame in a Figure 3a

combustible atmosphere or near combustible materials.

CLAMPING

CLEARANCE FIT HUBS Clean all parts using a BOLT

non-flammable solvent. Check hubs, shafts and keyways for INPUT OR

OUTPUT COUPLING

burrs. Do not heat clearance fit hubs. Install keys, mount hubs ADAPTER ADAPTER

with flange face flush with shaft end or as otherwise specified

and tighten set screws.

Figure 3b

1. Install Type FD Shaft Hubs (A-Hubs)

A. Lock out starting switch of prime mover. DISC COUPLING

ADAPTER BOLT

B. Determine required distance between shaft ends (BE) & LOCKNUT

from Table 3.

C. Install Type FD shaft hubs (A-Hubs) on the driving shaft

and driven shaft, and align the disc coupling A-Hubs per

A-HUB

instructions found in the disc coupling service manual. Figure 3c

E. Position fluid coupling assembly between disc coupling

TABLE 3 Disc Coupling Clamp Bolt Size hubs as close to the centerline as possible, Figure 4.

FLUID DISC

BE Disc Coupling Clamping Bolt F. With fluid coupling suspended from the sling, align the

Adapter Bolt No. Size holes of the disc coupling A-Hubs with the holes in the

COUPLING COUPLING

SIZE SIZE HFD25 HFDD25 Tightening (Grade 5 or Better)

adapters, and insert the adapter bolts on both sides

Torque lb-ft See Figure 3

(Figure 3c).

370 190 15.60 16.98 12 (6) .3125-18UNC x 1.375 H

1420 190 17.12 20.23 12 (6) .3125-18UNC x 1.375 H G. Slowly remove clamping bolts between coupling

1480 340 19.50 22.92 25 (6) .3750-20UNC x 1.750 adapters and input/output adapters to decompress the

1584 625 22.18 26.00 43 (6) .3125-18UNC x 2.000 discpacks. Make sure disc coupling A-Hubs are

1660 1080 25.25 29.58 103 (6) .3750-16UNC x 2.250

1760/2760 1700 28.88 33.72 103 (6) .3750-16UNC x 2.500 properly seated in adapter registers (see Figure 3c).

H Socket head cap screws. Store clamping bolts so they are available if the fluid

Hex head cap screws. coupling should need to be removed.

2. Install Type HFD25 or HFDD25 Fluid Coupling

A. The fluid coupling is shipped with input and output

adapters, discpacks and coupling adapters assembled

as shown in Figure 1, Page 1.

B. Remove clamping bolts and plastic spacer tubes on both

ends between coupling adapter and input/output

adapter, see Figure 3a. Properly discard spacer tubes

while keeping the clamping bolts for use in the following

steps.See Table 3 for clamping bolt size and number.

CAUTION: Plastic spacer tubes must be removed from

coupling at time of installation.

C. Re-insert clamping bolts on both ends between coupling

adapter and input/output adapter as shown in Fig. 3b.

Figure 4

Rexnord Industries, LLC, Coupling Group 528-270

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone : 262-796-4060 June 2006

Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 7-96

Installation and Maintenance Instructions Falk Fluid Couplings

(Page 4 of 6) Types HFD25 & HFDD25 Sizes 370, 1420-1760/2760

H. Install locknuts and tighten bolts/locknuts on output

side first according to the required adapter bolt

tightening torque specified in Table 3. Repeat for input

side.

CAUTION: Clamping bolts must be removed from

coupling before operation.

I. Reinstall perimeter fasteners and washers. Tighten to

torque specified in Table 2, Page 2

J. Recheck final alignment per disc coupling service

manual.

3. Fill Fluid Coupling

Figure 6

A. Rotate fluid coupling until fill plug is on top and remove

the fill plug, (both fill and drain plugs have metric

threads). See Figure 1, Page 1. NOTE: Coupling can

be filled through either the fill or the drain plugs.

0 0

E

B. Fill with the required amount of fluid. Fill information is

GL

0 0

50 N

found on the orange label that is affixed to the coupling

F A

50 LE

NG

O ILL

perimeter. Where no orange label is present, refer to L A 0

F

FIL F 10

fluid coupling Selection Guide 521-110 for fill data. O

Fluid must meet the specifications listed in Table 1.

Do not remove orange fluid fill label that is affixed to HIGH

the coupling perimeter. In cases where no orange label LEVEL 100

OF FILL LOW LEVEL

is affixed, a blank label is furnished. Fill out the blank

OF FILL

orange label once proper fill date has been

determined, then affix that label to the coupling.

C. Before reinstalling fill plug, check fill angle as described Figure 7

in the following step. Also, heed fill plug tightening

instructions, Step 4D.

5. Orifice Plugs (Sizes 1420 through 1760 and 2760 ,

4. Check Fill Angle Types HFD & HFDD only)

A. Refer to fluid fill label described in previous step for The 1000 Series fluid couplings contain 3 orifice plugs (metric

required fill angle. threaded) located near the outer part of the casing. They are

B. Use either an angle finder or a bevel protractor with located behind three metric hex socket seal plugs (see Figure

spirit level set for the required fill angle, and place it on 8). The function of these orifice plugs is to meter the fluid

flat boss of filler hole as shown in Figure 5. exiting from the delay fill chamber into the working circuit of

the fluid coupling. These plugs are initially furnished with a

C. Slowly rotate fluid coupling until the required fill angle

2.5mm hole (Sizes 1420-1660HF) and 3.5mm on Sizes 1760

is achieved, Figure 6. Fluid must appear at the lip of

and 2760, which results in acceptable starting times for most

the hole. Add or drain fluid until level is correct. Figure applications. Should the application require increased or

7 shows fill angle examples. reduced starting times, refer to Table 4 for other orifice hole

D. Reinstall fill plug with seal ring and tighten to require sizes and their estimated effect on starting time. These

torque: Sizes 370-1660, 33 lb-ft (44.75 Nm); Sizes estimates are based on the change in flow rate for the fluid to

1760/2760, 59lb-ft (80.00 Nm). DO NOT EXCEED exit the delay fill chamber. Couplings are furnished with a

SPECIFIED TIGHTENING TORQUE, as aluminum spare set of orifice plugs (undrilled).

threads may strip. CAUTION: Increasing the starting time can result in

overheating the fluid coupling and blowing the fusible plugs.

Refer to Table 5 for orifice, seal plugs sizes, tightening torques,

FILL ANGLE

and required metric hex Allen wrench sizes. Apply anti-seize

compound to the orifice plugs prior to their assembly. This will

assist in the event of future removal. Typical compounds (or

equal) are as follows:

Loctite Anti-Seize Thread Compound #767

Dow Corning 1000 High Temperature Anti-Seize Paste

Figure 5

528-270 Rexnord Industries, LLC, Coupling Group

June 2006 5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060

Supersedes 7-96 Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com

Falk Fluid Couplings Installation and Maintenance Instructions

Sizes 370, 1420-1760/2760 Types HFD25 & HFDD25 (Page 5 of 6)

ORIFICE PLUG

SEAL WASHER TABLE 5 Orifice & Seal Plug Sizes mm

Orifice Plug DIN 906 Seal Plug DIN 908 Seal Washer

DIN 7603

CPLG. SIZE Thread Hex Key Thread Hex Key Type A

Size Size Size Size Copper

1420 1/8R BSPT 5 mm 18 x 1.5 mm 10 mm 18 x 22 x 1.5 mm

1480 1/4R BSPT 6 mm 18 x 1.5 mm 10 mm 18 x 22 x 1.5 mm

SEAL 1584 3/8R BSPT 8 mm 22 x 1.5 mm 12 mm 22 x 27 x 1.5 mm

PLUG 1660 3/8R BSPT 8 mm 22 x 1.5 mm 12 mm 22 x 27 x 1.5 mm

1760/2760 1/2R BSPT 10 mm 27 x 2.0 mm 17 mm 27 x 32 x 2.0 mm

6. Fusible Plugs

A. Fusible plugs in the fill or drain holes have solder cores that

Figure 8 melt at the temperatures shown in Figure 1, Page 1. One

extra 284F (140C) plug is furnished with each coupling.

B. If solder in fusible plug melts due to overheating from

TABLE 4 Fluid Coupling Starting Times stalling or overloading, refer to Table 6, Page 6 and

Estimated Starting Time % of Original correct the cause of overheating.

Orifice Hole Diameter

1420HF 1660HF 1760HF/2760HF CAUTION: DO NOT replace fusible plugs with solid plugs.

3/64" (0.0469) 440 860 Use of solid plugs can result in coupling failure from

1/16" (0.0625) 250 490 overheating unless used in conjunction with a thermal trip

5/64" (0.0781) 160 310 switch. Refer to the Factory for thermal trip switch feature.

3/32" (0.0937) 110 220

2.5mm (0.0984) 100 200 C. Replace fusible plug as instructed in Step 4D.

7/64" (0.1094) 80 160

1/8" (0.1250) 60 120 D. Refill coupling with clean fluid as instructed in Steps 3 and 4.

3.5mm (0.1380) 50 100

5/32" (0.1562) 40 80

3/16" (0.1875) 30 50

Rexnord Industries, LLC, Coupling Group 528-270

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone : 262-796-4060 June 2006

Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 7-96

Installation and Maintenance Instructions Falk Fluid Couplings

(Page 6 of 6) Types HFD25 & HFDD25 Sizes 370, 1420-1760/2760

TABLE 6 Startup & Trouble Shooting

Problem Possible Cause Solution

Drive motor defective or Check motor connection, speed, amperage

incorrectly connected. draw and power draw.

Driven machine jammed. Check driven machine and remove jam.

Power consumption exceeds coupling H

capacity at specified fill angle.

Driven shaft fails to reach specified speed.

Coupling over or under filled. Re-check fill angle per Step 4.

Correct source of leakage and re-check fill

Coupling leaking.

angle per Step 4.

Size 1420HFD, HFDD, and larger Orifice

Clean orifice plug hole or use larger hole.

plug hole plugged.

Coupling under filled. Re-check fill angle per Step 4.

Enlarge orifice hole size (See Table 4 for

Size 1420HFD, HFDD, and larger Orifice

estimated

plug hole too small or plugged.

start time reduction) or clean plugged holes.

Fusible plugs melt. Correct source of leakage and re-check fill

Coupling leaking.

angle per Step 4.

Driven machine jammed. Check driven machine and remove jam.

Power consumption exceeds coupling H

capacity at specified fill angle.

Re-align per instructions in shaft coupling

Incorrect shaft coupling alignment.

service manual.

Incorrect shaft coupling alignment due Check HOT alignment and adjust to

to thermal growth. compensate for thermal growth.

Correct cause of wear and replace worn

Coupling vibration exceeds acceptable limits. Worn shaft coupling parts.

parts.

Loose foundation, shaft coupling or

Check and tighten fasteners accordingly.

adapter fasteners.

Return fluid coupling to Factory for

Damaged fluid coupling bearing.

bearing replacement.

H Increase fluid fill by decreasing fill angle in 5 increments to a minimum of 50 for HFD or 60 for HFDD. If drive shaft still does not reach specified speed, refer to the

Factory.

TABLE 7 Fluid Coupling Data Record

Equipment Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor/Brake Hp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . @ . . . . . . . . . Input RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Coupling Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fill Angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . Degrees. Fill Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fl. Oz.

Fluid Used (Mfg & Fluid Designation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Falk M.O. Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . .

528-270 Rexnord Industries, LLC, Coupling Group

June 2006 5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060

Supersedes 7-96 Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com

Vous aimerez peut-être aussi

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)D'EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Évaluation : 1 sur 5 étoiles1/5 (3)

- PT Tech HPTO12HXX-XXX Power Take OffDocument27 pagesPT Tech HPTO12HXX-XXX Power Take OffRonald100% (5)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003D'EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Évaluation : 5 sur 5 étoiles5/5 (1)

- 163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualDocument4 pages163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualCagPas encore d'évaluation

- BRADEN PD 12 WINCH Parts ListDocument28 pagesBRADEN PD 12 WINCH Parts Listhebert perezPas encore d'évaluation

- ENVOY RAZOR-regulator-valve-service-manualDocument37 pagesENVOY RAZOR-regulator-valve-service-manualDon SheensPas encore d'évaluation

- Acoples HidraulicosDocument34 pagesAcoples Hidraulicososcarlopez12345Pas encore d'évaluation

- Bucket Elevator Design and OperationDocument39 pagesBucket Elevator Design and OperationLarry Washington100% (1)

- 528 410 Falk True Torque Type HF41, HF42, Sizes 185 420, 1420 Fluid Couplings Installation ManualDocument6 pages528 410 Falk True Torque Type HF41, HF42, Sizes 185 420, 1420 Fluid Couplings Installation ManualrpazbPas encore d'évaluation

- HF Couplings IM-ManualDocument6 pagesHF Couplings IM-ManualCancio FlorezPas encore d'évaluation

- Tech 1440 ManDocument23 pagesTech 1440 ManRiski Kurniawan67% (3)

- 163-130 - Falk Drive One Type DH3, Sizes M1130-M1210 Shaft Drives - Parts ManualDocument4 pages163-130 - Falk Drive One Type DH3, Sizes M1130-M1210 Shaft Drives - Parts ManualCagPas encore d'évaluation

- 163 132 Falk Drive One Type DH3, Sizes M1220 M1250 Shaft Drives Parts ManualDocument4 pages163 132 Falk Drive One Type DH3, Sizes M1220 M1250 Shaft Drives Parts ManualLazzarus Az Gunawan100% (1)

- C5122Document12 pagesC5122apisituPas encore d'évaluation

- RYCO Hydraulics Product Technical Manual RHY-RHC0707AUSDocument444 pagesRYCO Hydraulics Product Technical Manual RHY-RHC0707AUSAdiya PurevjavPas encore d'évaluation

- 357 Series Control Valves (Obsolete Product)Document17 pages357 Series Control Valves (Obsolete Product)Yogurtu NngePas encore d'évaluation

- 163-110 - Falk Drive One Type DHC1, Sizes M1130-M1190 Shaft Drives - Parts ManualDocument4 pages163-110 - Falk Drive One Type DHC1, Sizes M1130-M1190 Shaft Drives - Parts ManualCagPas encore d'évaluation

- IOM Manual C132355.SflbDocument14 pagesIOM Manual C132355.SflbVenkat SubramanianPas encore d'évaluation

- Technical Bulletin: AudcoDocument12 pagesTechnical Bulletin: AudcoHrushikesh ReddyPas encore d'évaluation

- Service LubricatorsDocument52 pagesService LubricatorsmecambPas encore d'évaluation

- Underwing Nozzles: Carter Ground FuelingDocument54 pagesUnderwing Nozzles: Carter Ground FuelingHenryPas encore d'évaluation

- Operating & Installation Instruction PRVDocument16 pagesOperating & Installation Instruction PRVNguyễn SángPas encore d'évaluation

- LIT2299 Rev 10 PD12C Parts ListDocument28 pagesLIT2299 Rev 10 PD12C Parts ListYuliana Andrea Zapata RubioPas encore d'évaluation

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasDocument20 pagesOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonPas encore d'évaluation

- Disc Coupling Installation and Maintenance GuideDocument4 pagesDisc Coupling Installation and Maintenance Guidemarcelo castilloPas encore d'évaluation

- Pneumatic Valves - Viking Lite Series - Catalogue PDE2658TCUKDocument24 pagesPneumatic Valves - Viking Lite Series - Catalogue PDE2658TCUKDinda MaharaniPas encore d'évaluation

- 163 332 Falk Drive One Type DB, Sizes M1120 M1250 Right Angle Shaft Conveyor Drives Parts ManualDocument4 pages163 332 Falk Drive One Type DB, Sizes M1120 M1250 Right Angle Shaft Conveyor Drives Parts ManualnoviyanthyPas encore d'évaluation

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekPas encore d'évaluation

- PA Service ManualDocument140 pagesPA Service ManualaudiolabgaPas encore d'évaluation

- Sree TB 0002Document12 pagesSree TB 0002Tanmoy DuttaPas encore d'évaluation

- H - Series - Manual - Master - FIL MN 10 20 - Euro - EN FR ES PT DE RU - FINALDocument138 pagesH - Series - Manual - Master - FIL MN 10 20 - Euro - EN FR ES PT DE RU - FINALvipequi50Pas encore d'évaluation

- Valves Brochure2015Document48 pagesValves Brochure2015lcandoPas encore d'évaluation

- Foster Couplers 2004Document36 pagesFoster Couplers 2004Carlos Arturo Martinez SalcedoPas encore d'évaluation

- MUL ACS880 01 Quick Inst Guide R1 R3 Rev G ScrresDocument86 pagesMUL ACS880 01 Quick Inst Guide R1 R3 Rev G ScrresQuy HoangPas encore d'évaluation

- RRV2090 DV-515Document50 pagesRRV2090 DV-515Victor Javelosa Azuelo Jr.Pas encore d'évaluation

- Pioneer 1722Document61 pagesPioneer 1722telkonPas encore d'évaluation

- Coates Pump ManualDocument17 pagesCoates Pump ManualFergiKalesaranPas encore d'évaluation

- Serie FF PDFDocument3 pagesSerie FF PDFYanderier RiveraPas encore d'évaluation

- D601000439 Man 001Document25 pagesD601000439 Man 001Riski KurniawanPas encore d'évaluation

- 4.06 Eh 10M Triple Combi BopDocument20 pages4.06 Eh 10M Triple Combi BopKerman BaezPas encore d'évaluation

- 990178-Quick-Start-Guide-GMXa-EN-ES-IT-PT-webDocument64 pages990178-Quick-Start-Guide-GMXa-EN-ES-IT-PT-webDugPigeonPas encore d'évaluation

- Pka-Rp60Kal - TH Pka-Rp71Kal - TH PKA-RP100KAL - TH: Service ManualDocument32 pagesPka-Rp60Kal - TH Pka-Rp71Kal - TH PKA-RP100KAL - TH: Service ManualВладимир НаумычPas encore d'évaluation

- Explosive Atmospheres Brochure 3AUA0000037223 REVC en LowresDocument98 pagesExplosive Atmospheres Brochure 3AUA0000037223 REVC en LowresQIUPEILINPas encore d'évaluation

- TCM Torque SB96 7DDocument14 pagesTCM Torque SB96 7DИван КоньковPas encore d'évaluation

- D Series Installation&Maintenance PDFDocument56 pagesD Series Installation&Maintenance PDFPablo GarcíaPas encore d'évaluation

- Compresor 5120Document32 pagesCompresor 5120Cesar GongoraPas encore d'évaluation

- H SeriesDocument23 pagesH SeriesHanissa MorilloPas encore d'évaluation

- 21 PDFDocument22 pages21 PDFMaltin SelmanllariPas encore d'évaluation

- Viking Air Relief ValveDocument2 pagesViking Air Relief ValveSyed AsimPas encore d'évaluation

- Model QRNG 340 Model QRNG 340 Model QRNG 340 Model QRNG 340 Model QRNG 340Document22 pagesModel QRNG 340 Model QRNG 340 Model QRNG 340 Model QRNG 340 Model QRNG 340roalcalo_uanPas encore d'évaluation

- Fisher Volume BoosterDocument16 pagesFisher Volume Boosterpawank_kswnPas encore d'évaluation

- Service Manual: PKA-M60KA - TH PKA-M71KA - TH PKA-M100KA - TH Pka-M60Kal - TH Pka-M71Kal - TH PKA-M100KAL - THDocument40 pagesService Manual: PKA-M60KA - TH PKA-M71KA - TH PKA-M100KA - TH Pka-M60Kal - TH Pka-M71Kal - TH PKA-M100KAL - THcryogen11Pas encore d'évaluation

- 1 - Manual Sutorbilt Legend 2-5, SB-7-621 V5 10-05Document42 pages1 - Manual Sutorbilt Legend 2-5, SB-7-621 V5 10-05Sandro Renteros LimaPas encore d'évaluation

- FR700 Series Owner's ManualDocument60 pagesFR700 Series Owner's ManualmetasPas encore d'évaluation

- Texas Oil Tools: "EH34" 3.06" 10M Quad BOPDocument32 pagesTexas Oil Tools: "EH34" 3.06" 10M Quad BOPjose perozo100% (2)

- Hose and Fittings PDFDocument106 pagesHose and Fittings PDFchak1729Pas encore d'évaluation

- Pumy-P60nkmu Techservice Och502b 05-13Document114 pagesPumy-P60nkmu Techservice Och502b 05-13Marco RualesPas encore d'évaluation

- F84L Series Liquid Relief Valve Installation ManualDocument15 pagesF84L Series Liquid Relief Valve Installation ManualMoe MozhganPas encore d'évaluation

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004D'EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Évaluation : 3 sur 5 étoiles3/5 (1)

- Op Amps: Design, Application, and TroubleshootingD'EverandOp Amps: Design, Application, and TroubleshootingÉvaluation : 5 sur 5 étoiles5/5 (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Voith Fluid Couplings Constant FillDocument14 pagesVoith Fluid Couplings Constant Fillmanoj983100% (1)

- Fluid Coupling (Scoop Type) PST - Rating - SelectionDocument2 pagesFluid Coupling (Scoop Type) PST - Rating - Selectionpravash2526100% (1)

- Fluid CouplingsDocument20 pagesFluid CouplingsMd Mehbub SamratPas encore d'évaluation

- Ratlam Diesel Shed Training ReportDocument29 pagesRatlam Diesel Shed Training Reporter_manojpanchal100% (3)

- 1791 e Cr417 en GPK Smart Connection Technology For Voith Turbo Fluid CouplingsDocument2 pages1791 e Cr417 en GPK Smart Connection Technology For Voith Turbo Fluid CouplingsLazar MihailPas encore d'évaluation

- Major Training Report ON: Bharat Heavy Electricals Limited Bhopal (M.P.)Document63 pagesMajor Training Report ON: Bharat Heavy Electricals Limited Bhopal (M.P.)pariposhPas encore d'évaluation

- Technical Specification FOR Material Handling System: SPECIFICATION NO.: SPCL-T495/GRAFIX/A-100/GEN-Rev05Document33 pagesTechnical Specification FOR Material Handling System: SPECIFICATION NO.: SPCL-T495/GRAFIX/A-100/GEN-Rev05anindya.basu859217Pas encore d'évaluation

- 221 e cr240 en Hydrodynamic-Variable-Speed-Drives PDFDocument12 pages221 e cr240 en Hydrodynamic-Variable-Speed-Drives PDFcarlosloucaoPas encore d'évaluation

- 518 STD USA Centrifuge Manual Part 90-90-061-RevADocument109 pages518 STD USA Centrifuge Manual Part 90-90-061-RevAkanwarPas encore d'évaluation

- FLUDEXDocument50 pagesFLUDEXkingPas encore d'évaluation

- TEch MaNUalDocument190 pagesTEch MaNUalDavid Chalker82% (22)

- Discrete Manufacturing & Process Industries SolutionsDocument28 pagesDiscrete Manufacturing & Process Industries SolutionsSajin RayPas encore d'évaluation

- Vishnu Chaudhary HydraulicsDocument17 pagesVishnu Chaudhary Hydraulicsvishnu chaudharyPas encore d'évaluation

- Automobile VTU Syllabus For 6th SemesterDocument22 pagesAutomobile VTU Syllabus For 6th SemesterprabhuswamygsPas encore d'évaluation

- How Does Torque Converter WorkDocument6 pagesHow Does Torque Converter WorkJZM GulfPas encore d'évaluation

- Failure Analysis and Design Modification of Oil Cooler in Boiler Feed PumpDocument78 pagesFailure Analysis and Design Modification of Oil Cooler in Boiler Feed Pumpsai kiranPas encore d'évaluation

- Automotive Transmission NewDocument147 pagesAutomotive Transmission NewhodvmkvecautoPas encore d'évaluation

- Operation and Maintenance of Hydraulic Coupling Reverse Reducing Gear BoxDocument13 pagesOperation and Maintenance of Hydraulic Coupling Reverse Reducing Gear BoxCristian QuinteroPas encore d'évaluation

- Term Paper On Fluid Coupling and Torques Converter Converted 1Document24 pagesTerm Paper On Fluid Coupling and Torques Converter Converted 1OLUBABA100% (3)

- Catalogo Rotofluid Eng PDFDocument40 pagesCatalogo Rotofluid Eng PDFsoulpowertibuPas encore d'évaluation

- Module No 1 :automobile Engineering (Mumbai University)Document78 pagesModule No 1 :automobile Engineering (Mumbai University)Vaibhav Vithoba Naik100% (4)

- DMI Automobile Engineering NotesDocument23 pagesDMI Automobile Engineering NotesYuvaraj SamuvelPas encore d'évaluation

- Transmission Unit 3Document103 pagesTransmission Unit 3Ram SaacePas encore d'évaluation

- Automatic TransmissionDocument18 pagesAutomatic TransmissionMarissa LaingPas encore d'évaluation

- Free Samples - Amie - Chapters - Mining Pumps and Power Transmission Sec B Mining MachineryDocument26 pagesFree Samples - Amie - Chapters - Mining Pumps and Power Transmission Sec B Mining MachineryNgatcha Ralain BryanPas encore d'évaluation

- Variable Speed Fluid Coupling - SCDocument7 pagesVariable Speed Fluid Coupling - SCRavikanth AluriPas encore d'évaluation

- Unit-2-Automobile EnggDocument23 pagesUnit-2-Automobile EnggPrashant BhumireddyPas encore d'évaluation

- Falk Parallel-Shaft Gear Drives - Horizontal or Vertical Mounting Falk Right-Angle Shaft Gear Drives - Horizontal or Vertical MountingDocument8 pagesFalk Parallel-Shaft Gear Drives - Horizontal or Vertical Mounting Falk Right-Angle Shaft Gear Drives - Horizontal or Vertical MountingIgnacio J VidalPas encore d'évaluation

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)