Académique Documents

Professionnel Documents

Culture Documents

An-PP-001 Turboexpander Design Features

Transféré par

Sobhy GendykhelaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

An-PP-001 Turboexpander Design Features

Transféré par

Sobhy GendykhelaDroits d'auteur :

Formats disponibles

AP P L I C A T I O N NOTE

Turboexpander-Compressor

Design Features

AN-PP-001 January 2002 Rev. 1

1.0 TURBOEXPANDER-COMPRESSORS

Mafi-Trench Corporation (MTC) turboexpander-compressors, or expanders are currently in operation around the

world in natural gas processing, dew point control, ethylene production, and power recovery applications. The

design speed and wheel diameters are selected to provide optimum aerodynamic performance for the turboexpander

as well as its booster compressor.

1.1 TURBOEXPANDER DESIGN

The expander compressor consists of three basic sections: (See Figure 1.1.)

1. The expander section with inlet and discharge flanges

2. The rotating assembly or center section.

3. The compressor section with inlet and discharge flanges.

FIGURE 1.1

AN-PP-001 Rev. 1 Page 1 of 5

1.1.1 INLET GUIDE VANES

The inlet guide vanes regulate mass flow admission to the expander. They are designed to provide zero

blow-by, positive actuation and high efficiency over a broad operating range. This is accomplished by utilizing

a unique proprietary mechanism incorporating a pressure actuated sealing ring. This design eliminates side

leakage and prevents nozzle galling.

The mechanism is designed to withstand full expander inlet pressure and can be adjusted to control admission

over the range of approximately 0 to 125% of the design mass flowrate. A pneumatic actuator with integral

positioner controls the guide vane opening. A control air signal causes the actuator to adjust the inlet guide

vane opening to compensate for changes in process conditions.

KEY DESIGN BENEFIT:

Non-Galling design provides more reliable and accurate process control.

VIEW FROM BEARING HOUSING

VIEW FROM OUTLET FLANGE

AN-PP-001 Rev. 1 Page 2 of 5

1.1.2 IMPELLERS

Mafi-Trench expander and compressor wheels are machined from solid

plate, bar or forgings for maximum strength and integrity. Brazed wheels

are not permitted in the Mafi-Trench design. Critical design parameters

such as stress and bore growth are computed in-house using Finite Element

Analysis software. Mafi-Trench has designed wheels for operating tip

speeds in excess of 1500 fps (457 m/s).

Expander stage performance is predicted using Computational Fluid

Dynamic (CFD) modeling. In addition, every Mafi-Trench wheel is

vibration tested for blade and disc resonant frequencies and tuned as required to prevent any damaging

interactions.

KEY DESIGN BENEFIT:

Greatly increased impeller life

No restrictions on operating speeds

High efficiency designs

Sample of CFD analysis on

compressor wheel design

AN-PP-001 Rev. 1 Page 3 of 5

1.1.3 SHAFT / WHEEL ATTACHMENT

The expander-compressor shaft is designed to operate below the first bending critical speed and torsional

resonance. For oil-lubricated bearing designs, a flame plated band of aluminum alloy is applied to the shaft in

the area sensed by the vibration probes to eliminate the effect of electrical runout. This technique has been used

on hundreds of Mafi-Trench turbines with complete success. Wheels are attached to the shaft on a special

tapered profile, with cylindrical keys and keyways. This design avoids the stress concentrations associated with

splines, conventional square keyways, and tongue and groove wheel-to-shaft fits. In addition, wheels are

secured to the tapered ends of the shaft by a common center stretch rod which is pre-stressed during assembly.

This results in a constant preload on each wheel to insure contact between wheels and shaft at all extremes of

temperature and speed.

KEY DESIGN BENEFIT:

Fewer machine trips due to high vibration

Lower dynamic loads on bearings

Ease of assembly and disassembly

AN-PP-001 Rev. 1 Page 4 of 5

1.1.4 ADDITIONAL DESIGN DETAILS

A spring-loaded Teflon lip seal is used for sealing of cryogenic cases. This highly reliable seal is also pressure

actuated. Therefore, effective sealing is not dependent on torquing of case bolts. Elastomeric "O" rings are used

for sealing warm process casings and warm internal parts.

The compressor incorporates a parallel wall, vaneless diffuser which yields excellent off-design performance.

The process conditions induce thermal growth and/or shrinkage in the expander and compressor housing.

Therefore, the expander case is center-line mounted and the compressor case is allowed to move along the

center line of the machine. Allowable flange forces and moments are three times NEMA SM-23 requirements.

All rotating parts are dynamically balanced to the requirements of ISO 1940 G2.5 on precise electronic

balancing equipment to ensure smooth operation over the entire operating speed range.

1.1.5 SPECIAL TOOLS

A "shaft seal ring and wheel puller" and a "shaft seal ring mounting tool" are part of the standard equipment

supply. These are the only special tools required for assembly and disassembly of the Mafi-Trench

Expander-Compressor.

AN-PP-001 Rev. 1 Page 5 of 5

Vous aimerez peut-être aussi

- Mhi Integrally Geared CompressorsDocument6 pagesMhi Integrally Geared CompressorscandharePas encore d'évaluation

- Turboexpanders: CompressorsDocument4 pagesTurboexpanders: Compressorsdhanu_aquaPas encore d'évaluation

- 01 Intro&Theory GTDocument74 pages01 Intro&Theory GTHafiz Usman MahmoodPas encore d'évaluation

- Pump RotordynamicsDocument26 pagesPump RotordynamicsHalil İbrahim Küplü100% (1)

- Gas Turbine Simple Cycle SCRDocument20 pagesGas Turbine Simple Cycle SCRJung Kyung WooPas encore d'évaluation

- Compressor C65Document1 pageCompressor C65frdnPas encore d'évaluation

- Stepless Clearance Pocket: Oil & GasDocument4 pagesStepless Clearance Pocket: Oil & Gasshank100Pas encore d'évaluation

- Mitsubishi CompressorsDocument5 pagesMitsubishi Compressorsstavros7100% (1)

- Gas SealsDocument38 pagesGas SealskbogeshwaranPas encore d'évaluation

- Difference Between API 611 and API 612 - Mechanical Engineering SiteDocument8 pagesDifference Between API 611 and API 612 - Mechanical Engineering SiteAlfredo VelasquezPas encore d'évaluation

- TurboExpander ProcessDocument18 pagesTurboExpander ProcessdndudcPas encore d'évaluation

- Seal Oil DegassingDocument16 pagesSeal Oil DegassingLuis Eduardo Escalona HurtadoPas encore d'évaluation

- Axial & Centrifugal Compressor For LNG Services - GEDocument4 pagesAxial & Centrifugal Compressor For LNG Services - GETalwinder Singh100% (1)

- Centrifugal Compressors: Petroskills CourseDocument23 pagesCentrifugal Compressors: Petroskills CoursedeepikaPas encore d'évaluation

- Sonatrach COCE Operation Eng 2ggDocument409 pagesSonatrach COCE Operation Eng 2ggVijay Vishal100% (1)

- Brochure BHGEDocument44 pagesBrochure BHGEbederinadmlPas encore d'évaluation

- Compressor With Seal OilDocument7 pagesCompressor With Seal OilKamel NaimiPas encore d'évaluation

- Introduction To Rotor Dynamics Analysis As API Standard Related To Centrifugal Machines - Part V-Overview of API RP684 - Balancing of RotorsDocument9 pagesIntroduction To Rotor Dynamics Analysis As API Standard Related To Centrifugal Machines - Part V-Overview of API RP684 - Balancing of RotorsskakerPas encore d'évaluation

- Gas Turbine in Cairo North Power StationDocument38 pagesGas Turbine in Cairo North Power StationAbdul Moeed Kalson0% (1)

- Shell Turbo T32Document3 pagesShell Turbo T32Agustinus Bayu Dewanto100% (1)

- GTG - Know How Training 27 Feb 2013 - 1Document30 pagesGTG - Know How Training 27 Feb 2013 - 1aden mng100% (1)

- Dry Gas Versus Wet Gas Compressor Seals PDFDocument5 pagesDry Gas Versus Wet Gas Compressor Seals PDFMANSIPas encore d'évaluation

- Steam Amonia TurbineDocument21 pagesSteam Amonia TurbineLuis Alexandre MachadoPas encore d'évaluation

- Centrifugal Compressor Wet Seals RETROFIT - Seal Oil De-Gassing & Control Better Option - BPDocument23 pagesCentrifugal Compressor Wet Seals RETROFIT - Seal Oil De-Gassing & Control Better Option - BPVILLANUEVA_DANIEL2064Pas encore d'évaluation

- 5 Reciprocating Compressor SelectionDocument27 pages5 Reciprocating Compressor SelectionHazem RamdanPas encore d'évaluation

- Intro To Centrifugal Compressor ComponentsDocument7 pagesIntro To Centrifugal Compressor ComponentsMuhammad Ridhwan100% (2)

- Turbomachinery Selection Exploitation and MaintenanceDocument9 pagesTurbomachinery Selection Exploitation and MaintenanceMichael Chikwendu100% (1)

- Your Gas Compression ApplicationDocument26 pagesYour Gas Compression Applicationdhanu_aqua100% (1)

- Type PR Online Assurance Program: Success StoryDocument2 pagesType PR Online Assurance Program: Success Storyvarun sharmaPas encore d'évaluation

- Datum Compressor Cut PDFDocument1 pageDatum Compressor Cut PDFJ.SIVIRAPas encore d'évaluation

- Reactors RefineryDocument12 pagesReactors RefineryMartin SzijjartoPas encore d'évaluation

- 1 - Presentation CentrifugalDocument184 pages1 - Presentation CentrifugalHayder Wassela50% (2)

- 03 Product OverviewDocument44 pages03 Product OverviewMamdouh ElhanafyPas encore d'évaluation

- Hydrocom: High Energy Savings and Excellent ControllabilityDocument8 pagesHydrocom: High Energy Savings and Excellent Controllabilityrahilshah100Pas encore d'évaluation

- Hydrocarbon Turbo ExpandersDocument20 pagesHydrocarbon Turbo ExpandersPakde NdokPas encore d'évaluation

- 04 01 T6497 Prev Mainten A4 Color 2sided 2slides Each SideDocument18 pages04 01 T6497 Prev Mainten A4 Color 2sided 2slides Each SideDangolPas encore d'évaluation

- Natural GAs Compressor LubrcantsDocument34 pagesNatural GAs Compressor LubrcantsPrakash JoshiPas encore d'évaluation

- Technical TrainingDocument7 pagesTechnical Trainingjenz84rulez0% (1)

- 3 - Gas Turbine Overview 8.09Document25 pages3 - Gas Turbine Overview 8.09Sujeet Kumar100% (1)

- Reliability Improving Compressor DGS Seal Reliability 1602747938Document27 pagesReliability Improving Compressor DGS Seal Reliability 1602747938George V Thomas100% (1)

- Case Study SentinelDocument2 pagesCase Study Sentinelashumishra007Pas encore d'évaluation

- Troubleshooting Centrifugal Pumps July04!28!34Document7 pagesTroubleshooting Centrifugal Pumps July04!28!34ho-faPas encore d'évaluation

- Lm2500 ManifoldDocument2 pagesLm2500 ManifoldDenis JimenezPas encore d'évaluation

- February 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsDocument4 pagesFebruary 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsKarim MuhammedPas encore d'évaluation

- Technical Paper - SGT400 ASME 2002Document9 pagesTechnical Paper - SGT400 ASME 2002usaid saifullahPas encore d'évaluation

- Sundyne Pinnacle Centrifugal Compressor Data SheetDocument2 pagesSundyne Pinnacle Centrifugal Compressor Data SheethamedfazelmPas encore d'évaluation

- Compressor ManturboDocument6 pagesCompressor ManturboSubhasish MitraPas encore d'évaluation

- Thermodynamic Analysis of A Steam TurbineDocument3 pagesThermodynamic Analysis of A Steam TurbinePhil Engel100% (1)

- Guielines For Specifying and Evaluating New and Rerated Multistage Centrifugal Compressors - PAPERDocument18 pagesGuielines For Specifying and Evaluating New and Rerated Multistage Centrifugal Compressors - PAPERVILLANUEVA_DANIEL2064Pas encore d'évaluation

- Dry Gas Seals SiemensDocument11 pagesDry Gas Seals Siemensahbabar808Pas encore d'évaluation

- Crankshaft Failure in CompressorDocument12 pagesCrankshaft Failure in CompressorKristomiDerMarine-IngenieurPas encore d'évaluation

- Gas Engine FundamentalsDocument13 pagesGas Engine Fundamentalsherdin56Pas encore d'évaluation

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsD'EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahPas encore d'évaluation

- 01 Chemical ProcessDocument333 pages01 Chemical ProcessDavid ValladaresPas encore d'évaluation

- Bombas Centrífugas BlackmerDocument180 pagesBombas Centrífugas BlackmerGustavo Restrepo100% (1)

- Detailed DescriptionM75 M3502SDocument9 pagesDetailed DescriptionM75 M3502SbiberiusPas encore d'évaluation

- 1hd Fte EngineDocument43 pages1hd Fte EngineAnonymous DYKEYoH92% (13)

- HH150 Smanual - MasterDocument43 pagesHH150 Smanual - Masterjacklyn ade putra80% (5)

- XLR UserDemoDocument27 pagesXLR UserDemoSobhy GendykhelaPas encore d'évaluation

- XLR UserGuideDocument209 pagesXLR UserGuideSobhy GendykhelaPas encore d'évaluation

- TIA Selection Tool: Device Graphic With DetailsDocument3 pagesTIA Selection Tool: Device Graphic With DetailsSobhy GendykhelaPas encore d'évaluation

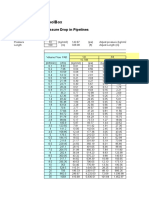

- The Engineering Toolbox: Compressed Air - Pressure Drop in PipelinesDocument6 pagesThe Engineering Toolbox: Compressed Air - Pressure Drop in PipelinesSobhy GendykhelaPas encore d'évaluation

- SCG Ie3000 PDFDocument1 230 pagesSCG Ie3000 PDFSobhy GendykhelaPas encore d'évaluation

- PDFDocument56 pagesPDFSobhy GendykhelaPas encore d'évaluation

- Siemens STLDocument272 pagesSiemens STLSobhy GendykhelaPas encore d'évaluation

- BOQ - Tubes and Fitting For Transmitters, Control Vlaves and Analyzers S/N DescriptionDocument2 pagesBOQ - Tubes and Fitting For Transmitters, Control Vlaves and Analyzers S/N DescriptionSobhy GendykhelaPas encore d'évaluation

- Fox Thermal Instruments, Inc.: Customer InformationDocument1 pageFox Thermal Instruments, Inc.: Customer InformationSobhy GendykhelaPas encore d'évaluation

- Parker AdaptersDocument62 pagesParker Adapterstoxicity23Pas encore d'évaluation

- KimiDocument10 pagesKimiSherminPas encore d'évaluation

- SSF Cooling TowersDocument30 pagesSSF Cooling TowersDhirendra Singh RathorePas encore d'évaluation

- Component Screening of Miconazole Nitrate Nanoemulsion: Research ArticleDocument8 pagesComponent Screening of Miconazole Nitrate Nanoemulsion: Research ArticleSiddhant YadavPas encore d'évaluation

- Sika Viscocrete: TechnologyDocument13 pagesSika Viscocrete: TechnologyacarthurPas encore d'évaluation

- Chapter 6-Rainwater HarvestingDocument20 pagesChapter 6-Rainwater HarvestingJpmega Civil StructuralPas encore d'évaluation

- Atomic Structure BWDocument47 pagesAtomic Structure BWShweta Saatish PandeyPas encore d'évaluation

- The Preparation of Potassium Tris (Oxalate) Ferrate (III) TrihydrateDocument8 pagesThe Preparation of Potassium Tris (Oxalate) Ferrate (III) Trihydrateapple33% (6)

- Storage Stability of A Processed Ginger PasteDocument2 pagesStorage Stability of A Processed Ginger PasteevelinPas encore d'évaluation

- Failure Analysis of Structural Steel Subjected To Long Term ExposureDocument13 pagesFailure Analysis of Structural Steel Subjected To Long Term ExposureDeepak wadgePas encore d'évaluation

- Fund - Elect DE52.Document355 pagesFund - Elect DE52.atashi baran mohantyPas encore d'évaluation

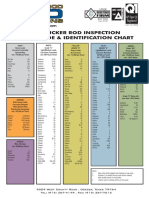

- Permian Rod Operations - Sucker Rod Identification Chart PDFDocument1 pagePermian Rod Operations - Sucker Rod Identification Chart PDFMinimaxou78Pas encore d'évaluation

- PHYS1002 Proposal 1Document2 pagesPHYS1002 Proposal 1MatthewGrovesPas encore d'évaluation

- SDS PAGE Troubleshooting GuideDocument12 pagesSDS PAGE Troubleshooting GuideBhavik ThakarPas encore d'évaluation

- AD-761 644 Structural and Force Diagrams of The Landing Gear V. L. Belskii, Et AlDocument42 pagesAD-761 644 Structural and Force Diagrams of The Landing Gear V. L. Belskii, Et Alebooks list1Pas encore d'évaluation

- NF6.1FX.2 Standard Compressor R134a 115-127V 60Hz: GeneralDocument2 pagesNF6.1FX.2 Standard Compressor R134a 115-127V 60Hz: Generalwilmer cantilloPas encore d'évaluation

- 2015 JC2 H2 Carboxylic Acids and Derivatives Part 1 Tutorial (Teachers) UpdatedDocument18 pages2015 JC2 H2 Carboxylic Acids and Derivatives Part 1 Tutorial (Teachers) UpdatedJohnPas encore d'évaluation

- DD ValveDocument8 pagesDD ValveJunnaid NissarPas encore d'évaluation

- SEFADocument56 pagesSEFAhg66Pas encore d'évaluation

- Rydlyme: The Solution To Your Water Scale ProblemsDocument4 pagesRydlyme: The Solution To Your Water Scale Problemswq3erwqerwerPas encore d'évaluation

- Calibration Uncertainty: NS, Krogsh/'ljvej 51Document6 pagesCalibration Uncertainty: NS, Krogsh/'ljvej 51KhalidPas encore d'évaluation

- h2 Physics DefinitionsDocument7 pagesh2 Physics DefinitionsJerald LimPas encore d'évaluation

- Agricultural Waste Conversion ToDocument6 pagesAgricultural Waste Conversion ToyemresimsekPas encore d'évaluation

- Sodium Hexameta Phosphate e CHB 038Document1 pageSodium Hexameta Phosphate e CHB 038Wasif KarimPas encore d'évaluation

- Spider SilkDocument5 pagesSpider SilkimranPas encore d'évaluation

- Life Cycle AssessmentDocument11 pagesLife Cycle AssessmentAsniIbrahimPas encore d'évaluation

- DJ 10 CM Plate: MJ MJDocument9 pagesDJ 10 CM Plate: MJ MJredspidey13100% (2)

- Oil & Gas Academy Petroleum Schools BrochureDocument54 pagesOil & Gas Academy Petroleum Schools BrochureOilGasAcademy80% (15)

- 03 Lewabrane Manual System Design 03Document13 pages03 Lewabrane Manual System Design 03zamijakaPas encore d'évaluation

- Practical No 10Document4 pagesPractical No 10Muhammad JahanzaibPas encore d'évaluation