Académique Documents

Professionnel Documents

Culture Documents

Tpi Cv01a 0

Transféré par

Waris La Joi WakatobiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tpi Cv01a 0

Transféré par

Waris La Joi WakatobiDroits d'auteur :

Formats disponibles

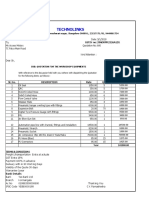

14 Agust 2015 19:32 Conveyor Design Summary Page 1/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Conveyed Material

Material Description COAL Surcharge Angle 30 deg

Low Bulk Density 800 kg/m3 Angle of Repose 45 deg

High Bulk Density 900 kg/m3 Material Lump size 50 mm

Conveyor Data

Conveying Distance 106,36 m Design Capacity 250 tonnes/hr

Nett Lift / Lower (-) 20,41 m Belt Speed 2,5 m/s

Belt Details

Belt Width Selected 650 mm Calculated Belt % Full 68,4 %

Belt Class & Run Safety Factor 315/3 11,41 Top Cover Thickness 5 mm

Belt Rated Tension 31,5 kN/m Bottom Cover Thickness 3 mm

Belt Total Length 225,0 m Belt Mass 8,41 kg/m

Belt Tensions and Power Calculations CEMA

Effective Tens. Fully Loaded 9,74 kN Belt Power - Empty Belt 8,01 kW

Maximum Tension Tmax 17,94 kN Belt Power - Inclines Loaded 23,99 kW

Minimum Tension Tmin 7,98 kN Belt Power - Declines Loaded 8,75 kW

Sag Tension 1,5 % 3,55 kN Belt Power - Fully Loaded 24,35 kW

Takeup Type Vertical Gravity Drive Efficiency 90,0 %

Takeup Mass 1800 kg Absorbed Power Fully Loaded 27,06 kW

Takeup Pulley Belt Tension 8,83 kN Installed Motor Power 37 kW

Carry and Return Idlers

Carry Idler Trough Angle 35 Return Idler Trough Angle 0

Carry Idler Spacing 1,2 m Return Idler Spacing 3 m

Carry Idler No Rolls x Dia 3 x 89 mm Return Idler No Rolls x Dia 1 x 89 mm

Dynamics and Miscellaneous Data

Startup Factor - Fully Loaded 150 % CEMA Temperature Factor Kt 1,00

Startup Factor - Empty 150 % Total Braking Torque LSS 0,00 kNm

Starting Time - Fully Loaded 1,64 sec Stop Time - Loaded, Braking 1,89 sec

Starting Time - Empty 0,64 sec Stop Time - Loaded, Coasting 1,89 sec

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Conveyor Sections - Input Data Page 2/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Station / Sectio

Section Section Cap- Ten Idler Skirt Friction

Length Lift X co- Y co- Z co- acity Adj. Spacing Length No. of Factor

Station Description m m ord m ord m ord m tph kN m m Scrapers Input

1 Tail 0,55 -0,06 0,00 0,00 0,00 0 0,60 0,0000

2 Int. Pt 0,60 -0,02 0,55 0,00 0,12 0 0,60 0,0000

3 Hopper 11,10 0,00 1,15 0,00 0,10 250 0,30 0,0000

4 Int. Pt 6,42 0,00 12,25 0,00 0,10 250 1,20 4,00 0,0000

5 Int. Pt 84,34 20,40 18,67 0,00 0,10 250 1,20 0,0000

6 Int. Pt 3,99 0,00 100,50 0,00 20,50 250 1,20 0,0000

7 Int. Pt 0,51 0,01 104,49 0,00 20,50 250 0,60 0,0000

8 Drive 0,28 0,07 105,00 0,00 20,30 0 3,00 1 0,0000

9 Snub 1,87 0,00 104,67 0,00 20,03 0 3,00 1 0,0000

10 Bend 4,13 -4,13 102,80 0,00 19,99 0 3,00 1 0,0000

11 Takeup 4,13 4,13 102,47 0,00 15,86 0 3,00 0,0000

12 Bend 1,61 -0,02 102,15 0,00 19,99 0 3,00 1 0,0000

13 Int. Pt 84,34 -20,40 100,54 0,00 20,15 0 3,00 0,0000

14 Int. Pt 18,45 -0,08 18,71 0,00 -0,25 0 3,00 0,0000

15 Snub 0,26 0,15 0,26 0,00 -0,19 0 3,00 1 0,0000

Totals: 222,57 0,06 0,00 4,00 5

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Takeup & Drive Traction Calculation Page 3/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Drive Torque Start-up Factor Loaded 150 % Takeup Pulley Belt Tension 8,83 kN

Drive Torque Start-up Factor Empty 150 % Takeup Mass 1800 kg

Running Starting Braking

Drive Fully Empty Fully Empty Fully Empty

Number Loaded Belt Loaded Belt Loaded Belt

Drive No. 1 Drive

Pulley No. 8 Lagging Type Rubber Rubber Rubber

Wrap Angle 192 192 192 192 192 192

Co-efficient of Friction 0,25 0,25 0,35 0,35 0,35 0,35

Drive Factor Cw 0,763 0,763 0,448 0,448 0,448 0,448

Calculated Belt Tension T1 kN 17,94 11,42 27,02 23,07 10,06 9,23

Calculated Belt Tension T2 kN 8,27 8,27 8,93 7,8 8,68 8,49

Minimum Required T2 kN 7,38 2,4 8,1 6,84 0,62 0,33

Surplus T2 Tension (T1-T2) kN 0,89 5,87 0,83 0,96 8,06 8,16

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Tension Calculations - Summary Run / Start Page 4/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Drive Torque Start-up Factor Loaded 150 %

Drive Torque Start-up Factor Empty 150 % Takeup Mass 1800 kg

Running Starting Braking Coasting

Fully Inclines Declines Fully Fully Fully

Loaded Empty Loaded Loaded Loaded Empty Loaded Empty Loaded Empty

Station Tension Tension Tension Tension Tension Tension Tension Tension Tension Tension

No kN kN kN kN kN kN kN kN kN kN

1 Tail 8,32 8,32 8,32 8,32 10,36 13,51 6,55 7,34 6,55 7,34

2 Int. Pt 8,37 8,37 8,37 8,37 10,55 13,94 6,47 7,32 6,47 7,32

3 Hopper 8,37 8,37 8,37 8,37 10,57 13,98 6,45 7,31 6,45 7,31

4 Int. Pt 8,99 8,76 8,93 8,93 12,13 15,55 6,27 7,49 6,27 7,49

5 Int. Pt 9,22 8,83 9,12 9,12 12,76 15,94 6,15 7,49 6,15 7,49

6 Int. Pt 17,86 11,37 17,76 11,66 26,66 22,78 10,22 9,22 10,22 9,22

7 Int. Pt 17,93 11,41 17,80 11,70 26,97 23,02 10,07 9,23 10,07 9,23

8 Drive 17,94 11,42 17,81 11,71 27,02 23,07 10,06 9,23 10,06 9,23

9 Snub 8,53 8,53 8,53 8,53 9,21 8,09 8,93 8,75 8,93 8,75

10 Bend 8,85 8,85 8,85 8,85 9,64 8,70 9,15 9,01 9,15 9,01

11 Takeup 8,83 8,83 8,83 8,83 8,83 8,83 8,83 8,83 8,83 8,83

12 Bend 9,23 9,23 9,23 9,23 9,42 9,71 9,06 9,13 9,06 9,13

13 Int. Pt 9,54 9,54 9,54 9,54 9,89 10,43 9,24 9,37 9,24 9,37

14 Int. Pt 7,98 7,98 7,98 7,98 9,65 12,24 6,53 7,18 6,53 7,18

15 Snub 7,99 7,99 7,99 7,99 9,95 12,97 6,30 7,06 6,30 7,06

Minimum Ten 7,98 7,98 7,98 7,98 8,83 8,09 6,15 7,06 6,15 7,06

Maximum Ten 17,94 11,42 17,81 11,71 27,02 23,07 10,22 9,37 10,22 9,37

Effective Ten 9,74 3,21 9,60 3,50

Ave. Belt Ten 10,69 9,25 10,64 9,38 13,97 14,86 7,85 8,20 7,85 8,20

Belt Elong. m 0,408 0,167 0,4 0,189 0,957 1,105 -0,067 -0,008 -0,067 -0,008

T/up Travel m 0,204 0,084 0,2 0,094 0,478 0,552 -0,034 -0,004 -0,034 -0,004

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Belt Details Report Page 5/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Low BD = 800kg/m3 High BD = 900kg/m3

Conveyed Material Belt Speed & Capacity

Material Description COAL Belt Speed 2,5 m/s

Low Bulk Density 800 kg/m3 Belt Design Capacity Input 250 tonnes/hr

High Bulk Density 900 kg/m3 Section Loading Max Capacity 250 tonnes/hr

Surcharge Angle 30 deg Carry Idler Trough Angle 35

Angle of Repose 45 deg Belt Dimensions

Material Lump size 50 mm Top Cover Thickness 5 mm

Belt Make & Class Bottom Cover Thickness 3 mm

Belt Category Equel Korea Brand Belt Carcass Thickness 3,6 mm

Belt Description PLYLON-HI Belt Total Thickness 11,6 mm

Belt Class / Plies 315/3 3 Belt Total Belt Length (L) 225,0 m

Belt Reinforcement Fibre Fabric Time for 1 Revolution 90,0 sec

Belt Width Selected 650 mm Belt Load Area and Capacity at 800kg/m3

Belt Modulus 2070 kN/m Minimum Rec. Edge Distance 59 mm

Actual Edge Distance Low BD 100 mm

Load Burden Depth 113 mm

Load Burden Width 393 mm

Belt Tensions Belt Load Area at Minimum

Recommended Edge Distance 0,0508 m2

Belt Rated Tension / m width 31,5 kN/m

Calculated Tension / m width 27,6 kN/m Belt Load Area Utilised at Low

Belt Rated Tension for width 20,5 kN Bulk Density 0,0347 m2

Calculated Max Run Tension 17,94 kN Belt Actual % Full at Low BD 68,4 %

Minimum Tension Tmin 7,98 kN Belt Load Area and Capacity at 900kg/m3

Allowable Tension Rise, Starting 150 % Minimum Rec. Edge Distance 59 mm

Allowable Belt Tension, Starting 30,7 kN Actual Edge Distance High BD 111 mm

Actual Belt Tension, Starting 27,02 kN Belt Load Area Utilised at High

Bulk Density 0,0309 m2

Belt and Material Mass Belt Actual % Full at High BD 60,8 %

Belt Top Cover Mass 3,7 kg/m Flooded Belt Capacity at 900kg/m3

Belt Bottom Cover Mass 2,2 kg/m Flooded Belt Load Area at Zero

Edge Distance 0,0778 m2

Belt Carcass Mass 2,5 kg/m

Belt Mass Wb (per linear m) 8,4 kg/m Flooded Belt Capacity 630 tonnes/hr

Material Mass Wm 27,8 kg/m Flooded Belt Material Mass 70 kg/m

Total Mass (Wb + Wm) 36,2 kg/m

Total Belt Mass (Wb x L) 1892 kg

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Tension Calculations - Summary Belt Sag Page 6/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Allowable Belt Sag % Running 1,5 %

Allowable Belt Sag % Start / Stop 5 % Takeup Mass 1800 kg

Running Starting Braking Coasting

Fully Inclines Declines Fully Fully Fully

Loaded Empty Loaded Loaded Loaded Empty Loaded Empty Loaded Empty

Station Tension Tension Tension Tension Tension Tension Tension Tension Tension Tension

No kN kN kN kN kN kN kN kN kN kN

1 Tail 8,32 8,32 8,32 8,32 10,36 13,51 6,55 7,34 6,55 7,34

Idler Spacing m 0,60

Belt Sag % 0,07 0,07 0,07 0,07 0,06 0,05 0,09 0,08 0,09 0,08

2 Int. Pt 8,37 8,37 8,37 8,37 10,55 13,94 6,47 7,32 6,47 7,32

Idler Spacing m 0,60

Belt Sag % 0,07 0,07 0,07 0,07 0,06 0,04 0,1 0,08 0,1 0,08

3 Hopper 8,37 8,37 8,37 8,37 10,57 13,98 6,45 7,31 6,45 7,31

Idler Spacing m 0,30

Belt Sag % 0,16 0,04 0,16 0,16 0,13 0,02 0,21 0,04 0,21 0,04

4 Int. Pt 8,99 8,76 8,93 8,93 12,13 15,55 6,27 7,49 6,27 7,49

Idler Spacing m 1,20

Belt Sag % 0,59 0,14 0,6 0,6 0,44 0,08 0,85 0,17 0,85 0,17

5 Int. Pt 9,22 8,83 9,12 9,12 12,76 15,94 6,15 7,49 6,15 7,49

Idler Spacing m 1,20

Belt Sag % 0,58 0,14 0,58 0,14 0,42 0,08 0,87 0,17 0,87 0,17

6 Int. Pt 17,86 11,37 17,76 11,66 26,66 22,78 10,22 9,22 10,22 9,22

Idler Spacing m 1,20

Belt Sag % 0,3 0,11 0,3 0,46 0,2 0,05 0,52 0,13 0,52 0,13

7 Int. Pt 17,93 11,41 17,80 11,70 26,97 23,02 10,07 9,23 10,07 9,23

Idler Spacing m 0,60

Belt Sag % 0,15 0,05 0,15 0,05 0,1 0,03 0,26 0,07 0,26 0,07

8 Drive 17,94 11,42 17,81 11,71 27,02 23,07 10,06 9,23 10,06 9,23

Idler Spacing m 3,00

Belt Sag % 0,17 0,27 0,17 0,26 0,11 0,13 0,31 0,34 0,31 0,34

9 Snub 8,53 8,53 8,53 8,53 9,21 8,09 8,93 8,75 8,93 8,75

Idler Spacing m 3,00

Belt Sag % 0,36 0,36 0,36 0,36 0,34 0,38 0,35 0,35 0,35 0,35

10 Bend 8,85 8,85 8,85 8,85 9,64 8,70 9,15 9,01 9,15 9,01

Idler Spacing m 3,00

Belt Sag % 0,35 0,35 0,35 0,35 0,32 0,36 0,34 0,34 0,34 0,34

11 Takeup 8,83 8,83 8,83 8,83 8,83 8,83 8,83 8,83 8,83 8,83

Idler Spacing m 3,00

Belt Sag % 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Tension Calculations - Summary Belt Sag Page 7/30

Running Starting Braking Coasting

Fully Inclines Declines Fully Fully Fully

Loaded Empty Loaded Loaded Loaded Empty Loaded Empty Loaded Empty

Station Tension Tension Tension Tension Tension Tension Tension Tension Tension Tension

No kN kN kN kN kN kN kN kN kN kN

12 Bend 9,23 9,23 9,23 9,23 9,42 9,71 9,06 9,13 9,06 9,13

Idler Spacing m 3,00

Belt Sag % 0,34 0,34 0,34 0,34 0,33 0,32 0,34 0,34 0,34 0,34

13 Int. Pt 9,54 9,54 9,54 9,54 9,89 10,43 9,24 9,37 9,24 9,37

Idler Spacing m 3,00

Belt Sag % 0,32 0,32 0,32 0,32 0,31 0,3 0,33 0,33 0,33 0,33

14 Int. Pt 7,98 7,98 7,98 7,98 9,65 12,24 6,53 7,18 6,53 7,18

Idler Spacing m 3,00

Belt Sag % 0,39 0,39 0,39 0,39 0,32 0,25 0,47 0,43 0,47 0,43

15 Snub 7,99 7,99 7,99 7,99 9,95 12,97 6,30 7,06 6,30 7,06

Idler Spacing m 3,00

Belt Sag % 0,39 0,39 0,39 0,39 0,31 0,24 0,49 0,44 0,49 0,44

Minimum Ten 7,98 7,98 7,98 7,98 8,83 8,09 6,15 7,06 6,15 7,06

Maximum Sag 0,59 0,39 0,6 0,6 0,44 0,38 0,87 0,44 0,87 0,44

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Tension Calculations - Run Fully Loaded Page 8/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Takeup Mass 1800 kg

Tensions

Section Section Ten Material Skirt Scraper Section CEMA

Station / Pulley

Length Lift T1 Run T2 Run Tp Drive Adj. Accel. Friction Friction Effective Friction

Station m m kN kN Pulley Te kN kN kN kN kN Tension Factor

1 Tail 0,55 -0,06 8,32 8,37 0,05 0,00 0,016

2 Int. Pt 0,60 -0,02 8,37 8,37 0,00 0,016

3 Hopper 11,10 0,00 8,37 8,37 0,17 0,45 0,0179

4 Int. Pt 6,42 0,00 8,99 8,99 0,12 0,11 0,0237

5 Int. Pt 84,34 20,40 9,22 9,22 8,64 0,0215

6 Int. Pt 3,99 0,00 17,86 17,86 0,07 0,0215

7 Int. Pt 0,51 0,01 17,93 17,93 0,01 0,016

8 Drive 0,28 0,07 17,94 8,27 0,06 9,68 0,26 0,01 0,015

9 Snub 1,87 0,00 8,53 8,59 0,05 0,26 0,00 0,015

10 Bend 4,13 -4,13 8,85 8,90 0,05 0,26 -0,34 0,015

11 Takeup 4,13 4,13 8,83 8,88 0,05 0,35 0,015

12 Bend 1,61 -0,02 9,23 9,28 0,05 0,26 0,00 0,015

13 Int. Pt 84,34 -20,40 9,54 9,54 -1,56 0,0242

14 Int. Pt 18,45 -0,08 7,98 7,98 0,02 0,015

15 Snub 0,26 0,15 7,99 8,05 0,05 0,26 0,01 0,0242

Totals: 0,38 9,7 0,00 0,17 0,12 1,30 7,76

Maximum Tension 17,94 kN Total Effective Tension 9,74 kN

Minimum Tension 7,98 kN Total Belt Power (Te x V) 24,35 kW

Average Tension Fully Loaded 10,69 kN Belt Modulus 2070 kN/m

Average Tension Belt Stationary 8,25 kN Total Belt Length 225,00 m

Average Tension Difference 2,44 kN Belt Elastic Elongation 0,408 m

Takeup Movement 0,204 m

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Tension Calculations - Run Empty Page 9/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Station / Pulley Tensions

Section Section Ten Material Skirt Scraper Section CEMA

Length Lift T1 Run T2 Run Tp Drive Adj. Accel. Friction Friction Effective Friction

Station m m kN kN Pulley Te kN kN kN kN kN Tension Factor

1 Tail 0,55 -0,06 8,32 8,37 0,05 0,00 0,016

2 Int. Pt 0,60 -0,02 8,37 8,37 0,00 0,016

3 Hopper 11,10 0,00 8,37 8,37 0,39 0,0179

4 Int. Pt 6,42 0,00 8,76 8,76 0,07 0,0237

5 Int. Pt 84,34 20,40 8,83 8,83 2,54 0,0215

6 Int. Pt 3,99 0,00 11,37 11,37 0,04 0,0215

7 Int. Pt 0,51 0,01 11,41 11,41 0,01 0,016

8 Drive 0,28 0,07 11,42 8,27 0,06 3,15 0,26 0,01 0,015

9 Snub 1,87 0,00 8,53 8,59 0,05 0,26 0,00 0,015

10 Bend 4,13 -4,13 8,85 8,90 0,05 0,26 -0,34 0,015

11 Takeup 4,13 4,13 8,83 8,88 0,05 0,35 0,015

12 Bend 1,61 -0,02 9,23 9,28 0,05 0,26 0,00 0,015

13 Int. Pt 84,34 -20,40 9,54 9,54 -1,56 0,0242

14 Int. Pt 18,45 -0,08 7,98 7,98 0,02 0,015

15 Snub 0,26 0,15 7,99 8,05 0,05 0,26 0,01 0,0242

Totals: 0,37 3,15 0,00 1,30 1,53

Maximum Tension 11,42 kN Total Effective Tension 3,21 kN

Minimum Tension 7,98 kN Total Belt Power (Te x V) 8,01 kW

Average Tension Fully Loaded 9,25 kN Belt Modulus 2070 kN/m

Average Tension Belt Stationary 8,25 kN Total Belt Length 225,00 m

Average Tension Difference 1 kN Belt Elastic Elongation 0,167 m

Takeup Movement 0,084 m

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Tension Calculations - Run Inclines Loaded Page 10/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Station / Pulley Tensions

Section Section Ten Material Skirt Scraper Section CEMA

Length Lift T1 Run T2 Run Tp Drive Adj. Accel. Friction Friction Effective Friction

Station m m kN kN Pulley Te kN kN kN kN kN Tension Factor

1 Tail 0,55 -0,06 8,32 8,37 0,05 0,00 0,016

2 Int. Pt 0,60 -0,02 8,37 8,37 0,00 0,016

3 Hopper 11,10 0,00 8,37 8,37 0,17 0,39 0,016

4 Int. Pt 6,42 0,00 8,93 8,93 0,12 0,07 0,0207

5 Int. Pt 84,34 20,40 9,12 9,12 8,64 0,0215

6 Int. Pt 3,99 0,00 17,76 17,76 0,04 0,0207

7 Int. Pt 0,51 0,01 17,80 17,80 0,02 0,0163

8 Drive 0,28 0,07 17,81 8,27 0,05 9,55 0,26 0,01 0,015

9 Snub 1,87 0,00 8,53 8,59 0,05 0,26 0,00 0,015

10 Bend 4,13 -4,13 8,85 8,90 0,05 0,26 -0,34 0,015

11 Takeup 4,13 4,13 8,83 8,88 0,05 0,35 0,015

12 Bend 1,61 -0,02 9,23 9,28 0,05 0,26 0,00 0,015

13 Int. Pt 84,34 -20,40 9,54 9,54 -1,56 0,0242

14 Int. Pt 18,45 -0,08 7,98 7,98 0,02 0,015

15 Snub 0,26 0,15 7,99 8,05 0,05 0,26 0,01 0,0242

Totals: 0,38 9,68 0,00 0,17 0,12 1,30 7,76

Maximum Tension 17,81 kN Total Effective Tension 9,6 kN

Minimum Tension 7,98 kN Total Belt Power (Te x V) 23,99 kW

Average Tension Inclines Loaded 10,64 kN Belt Modulus 2070 kN/m

Average Tension Belt Stationary 8,25 kN Total Belt Length 225,00 m

Average Tension Difference 2,39 kN Belt Elastic Elongation 0,4 m

Takeup Movement 0,2 m

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Tension Calculations - Run Declines Loaded Page 11/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Station / Pulley Tensions

Section Section Ten Material Skirt Scraper Section CEMA

Length Lift T1 Run T2 Run Tp Drive Adj. Accel. Friction Friction Effective Friction

Station m m kN kN Pulley Te kN kN kN kN kN Tension Factor

1 Tail 0,55 -0,06 8,32 8,37 0,05 0,00 0,016

2 Int. Pt 0,60 -0,02 8,37 8,37 0,00 0,016

3 Hopper 11,10 0,00 8,37 8,37 0,17 0,39 0,0179

4 Int. Pt 6,42 0,00 8,93 8,93 0,12 0,07 0,0237

5 Int. Pt 84,34 20,40 9,12 9,12 2,54 0,0215

6 Int. Pt 3,99 0,00 11,66 11,66 0,04 0,0215

7 Int. Pt 0,51 0,01 11,70 11,70 0,01 0,016

8 Drive 0,28 0,07 11,71 8,27 0,06 3,44 0,26 0,01 0,015

9 Snub 1,87 0,00 8,53 8,59 0,05 0,26 0,00 0,015

10 Bend 4,13 -4,13 8,85 8,90 0,05 0,26 -0,34 0,015

11 Takeup 4,13 4,13 8,83 8,88 0,05 0,35 0,015

12 Bend 1,61 -0,02 9,23 9,28 0,05 0,26 0,00 0,015

13 Int. Pt 84,34 -20,40 9,54 9,54 -1,56 0,0242

14 Int. Pt 18,45 -0,08 7,98 7,98 0,02 0,015

15 Snub 0,26 0,15 7,99 8,05 0,05 0,26 0,01 0,0242

Totals: 0,38 9,7 0,00 0,17 0,12 1,30 7,76

Maximum Tension 11,71 kN Total Effective Tension 3,5 kN

Minimum Tension 7,98 kN Total Belt Power (Te x V) 8,75 kW

Average Tension Declines Loaded 9,38 kN Belt Modulus 2070 kN/m

Average Tension Belt Stationary 8,25 kN Total Belt Length 225,00 m

Average Tension Difference 1,13 kN Belt Elastic Elongation 0,189 m

Takeup Movement 0,094 m

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Conveyor Starting and Stopping Page 12/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

System Masses Input Data

Mass of Belt 1.892 kg Belt Speed 2,5 m/s

Mass of Material 2.954 kg Belt Rated Tension 31,5 kN/m

Carry Idler Equivalent Mass 832 kg Allow. Belt Start Tension Rise 150 %

Return Idler Equivalent Mass 50 kg Drive Inertia 0,284 kg-m2

Pulley Equivalent Mass 558 kg Total Braking Torque 0 kNm

Drive Equivalent Mass 1.069 kg Start-up Factor - Loaded 150 %

Total System Equivalent Mass 7.355 kg Start-up Factor - Empty 150 %

Installed Power 37 kW

Tensions and Accelerating Forces

Drive Efficiency (Average) 90 %

Effective Tens. Fully Loaded 9,74 kN

Effective Tension Empty 3,21 kN Stopping Times & Deceleration Rates

Total Braking Force 0,00 kN Stopping Time Loaded Braking 1,89 sec

Stopping Time Loaded Coasting 1,89 sec

Tension Available to Accelerate Conveyor

Stopping Time Empty Braking 3,43 sec

Accelerating Tension - Loaded 11,21 kN

Stopping Time Empty Coasting 3,43 sec

Accelerating Tension - Empty 17,09 kN

Deceleration - Loaded Braking -1,32 m/s2

Starting Times & Acceleration Rates

Deceleration - Loaded Coasting -1,32 m/s2

Starting Time - Fully Loaded 1,64 sec

Deceleration - Empty Braking -0,73 m/s2

Starting Time - Empty 0,64 sec

Deceleration - Empty Coasting -0,73 m/s2

Acceleration Rate - Loaded 1,52 m/s2

Accelerating Rate - Empty 3,88 m/s2 Stopping Distances & Discharge Volumes

Stopping Distance Loaded Braking 2,36 m

Belt Tension Rise Starting / Braking

Stopping Distance Loaded Coasting 2,36 m

Max Belt Tension, Start/Brake 27,02 kN

Stopping Distance Empty Braking 4,29 m

Belt Width 650 mm

Stopping Distance Empty Coasting 4,29 m

Maximum Belt Tension / width 41,57 kN/m

Belt Rated Tension / width 31,5 kN/m Discharge Mass, Braking 66 kg

Actual Max Tension, Start/Brake 132 % Discharge Mass, Coasting 66 kg

Discharge Volume, Braking 0,08 m3

Discharge Volume, Coasting 0,08 m3

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Conveyor Idler Details Report Page 13/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Carry Side Idlers Return Side Idlers

Idler Category Equel Korea Brand Equel Korea Brand

Idler Description 3 Roll Carry 1 Roll Flat Carry

Idler Design Belt Width 650 mm 650 mm

Idler Series - -

Drawing Number

Nominal Idler Spacing 1,2 m 3 m

Total Number of Idlers 146 10

Idler Price 0 0

Troughing Angle 35,0 deg 0,0 deg

Idler Shaft Diameter 20,0 mm 22,0 mm

Idler Bearing Diameter 20,0 mm 20,0 mm

Number of Idler Rolls 3 1

Idler Roll Diameter 89 mm 89 mm

Idler Rotation Speed 536 rpm 536 rpm

Roll Face Width 241 mm 741 mm

Roll Bearing Centres 186,8 mm 686,8 mm

Shaft Support Centres 267 mm 767 mm

Idler Support Fixing Width 900 mm 900 mm

Idlerset Rotating Mass 5,7 kg 5 kg

Idlerset Total Mass 16,7 kg 11,4 kg

Idler Vertical Misalignment Allowance 3,0 mm 5,0 mm

Dynamic Load Factor 1,09 1,40

Belt Deviation Load 1.000 N 500 N

Total Load on Centre Roll 1.334 N 955 N

Type of Bearing Ball Ball

Bearing Designation 6204 6204

Bearing Dynamic Load Rating C 12.700 N 12.700 N

Bearing L10h Life 214.532 hrs 585.283 hrs

Allowable Shaft Deflection at Bearing 8,00 min 10,00 min

Actual Shaft Deflection at Bearing 5,21 min 9,36 min

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Vertical Curve Radius Calculations Page 14/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

14 Agust 2015 19:32 Vertical Curve Radius Calculations Page 14/30

Belt Width 650 mm % Belt Mass for Lift-off Calculation 75 %

Belt Mass - New Belt 8,41 kg/m Curve Tension Safety Factor 1

Top Cover Mass - New Belt 3,67 kg/m Average Drive Torque Start-up Factor - Loaded 150 %

Bottom Cover Mass 2,2 kg/m Average Drive Torque Start-up Factor - Empty 150 %

Worn Belt Mass 6,31 kg/m Belt Modulus 2070 kN/m

Reduction of Top Cover Mass 57,3 % Belt Rated Tension 31,5 kN/m 20,8 kN

Conveyed Material Mass 27,78 kg/m Allowable Edge Tension - Running: 115 % Starting 150 %

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Vertical Curve Radius Calculations Page 15/30

Belt Width 650 mm % Belt Mass for Lift-off Calculation 75 %

Belt Mass - New Belt 8,41 kg/m Curve Tension Safety Factor 1

Top Cover Mass - New Belt 3,67 kg/m Average Drive Torque Start-up Factor - Loaded 150 %

Bottom Cover Mass 2,2 kg/m Average Drive Torque Start-up Factor - Empty 150 %

Worn Belt Mass 6,31 kg/m Belt Modulus 2070 kN/m

Reduction of Top Cover Mass 57,3 % Belt Rated Tension 31,5 kN/m 20,8 kN

Conveyed Material Mass 27,78 kg/m Allowable Edge Tension - Running: 115 % Starting 150 %

Station / Sectio Design

Vertical Running Starting Braking Largest

Load Curve Fully Loaded Empty Fully Loaded Empty Fully Loaded Empty Reqd.

Capacity Radius Tension Radius Radius

Curve Tension Radius Tension Radius Tension Radius Tension Radius Tension Radius

Station Type tonnes/hr m kN m kN m kN m kN m kN m kN m m

1 Tail 8,32 8,32 10,36 13,51 6,55 7,34

2 Int. Pt Concave 8,37 8,37 10,55 13,94 6,47 7,32

Belt Tension at Curve kN 8,37 8,37 10,55 13,94 6,47 7,32

Min. Concave Lift Off Radius 135 135 171 225 105 118 225

Min. Edge Tension Radius 13 13 11 8 17 15

Max. Centre Tension Radius 4 4 4 6 3 3

3 Hopper 250 8,37 8,37 10,57 13,98 6,45 7,31

4 Int. Pt 250 8,99 8,76 12,13 15,55 6,27 7,49

5 Int. Pt Concave 250 9,22 8,83 12,76 15,94 6,15 7,49

Belt Tension at Curve kN 9,22 8,83 12,76 15,94 6,15 7,49

Min. Concave Lift Off Radius 149 143 206 258 99 121 258

Min. Edge Tension Radius 12 13 9 7 18 15

Max. Centre Tension Radius 4 4 5 7 3 3

6 Int. Pt Convex 250 17,86 11,37 26,66 22,78 10,22 9,22

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Vertical Curve Radius Calculations Page 16/30

Belt Width 650 mm % Belt Mass for Lift-off Calculation 75 %

Belt Mass - New Belt 8,41 kg/m Curve Tension Safety Factor 1

Top Cover Mass - New Belt 3,67 kg/m Average Drive Torque Start-up Factor - Loaded 150 %

Bottom Cover Mass 2,2 kg/m Average Drive Torque Start-up Factor - Empty 150 %

Worn Belt Mass 6,31 kg/m Belt Modulus 2070 kN/m

Reduction of Top Cover Mass 57,3 % Belt Rated Tension 31,5 kN/m 20,8 kN

Conveyed Material Mass 27,78 kg/m Allowable Edge Tension - Running: 115 % Starting 150 %

Station / Sectio Design

Vertical Running Starting Braking Largest

Load Curve Fully Loaded Empty Fully Loaded Empty Fully Loaded Empty Reqd.

Capacity Radius Tension Radius Radius

Curve Tension Radius Tension Radius Tension Radius Tension Radius Tension Radius

Station Type tonnes/hr m kN m kN m kN m kN m kN m kN m m

Belt Tension at Curve kN 17,86 11,37 26,66 22,78 10,22 9,22

146

Min. Edge Tension Radius 20 9 -36 146 8 8

Max. Buckling Radius 4 7 2 3 8 9

Belt Edge Tension Rise at Curve kN 0 0 0 0 0 0

Total Edge Tension at Curve kN and % 17,86 86% 11,37 55% 26,66 128% 22,78 110% 10,22 49% 9,22 44%

Centre Tension at Curve kN 17,86 11,37 26,66 22,78 10,22 9,22

7 Int. Pt Concave 250 17,93 11,41 26,97 23,02 10,07 9,23

Belt Tension at Curve kN 17,93 11,41 26,97 23,02 10,07 9,23

Min. Concave Lift Off Radius 290 184 436 372 163 149 436

Min. Edge Tension Radius 6 10 4 5 11 12

Max. Centre Tension Radius 10 5 -16 106 4 4

8 Drive 17,94 11,42 27,02 23,07 10,06 9,23

9 Snub 8,53 8,53 9,21 8,09 8,93 8,75

10 Bend 8,85 8,85 9,64 8,7 9,15 9,01

11 Takeup 8,83 8,83 8,83 8,83 8,83 8,83

12 Bend 9,23 9,23 9,42 9,71 9,06 9,13

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Vertical Curve Radius Calculations Page 17/30

Belt Width 650 mm % Belt Mass for Lift-off Calculation 75 %

Belt Mass - New Belt 8,41 kg/m Curve Tension Safety Factor 1

Top Cover Mass - New Belt 3,67 kg/m Average Drive Torque Start-up Factor - Loaded 150 %

Bottom Cover Mass 2,2 kg/m Average Drive Torque Start-up Factor - Empty 150 %

Worn Belt Mass 6,31 kg/m Belt Modulus 2070 kN/m

Reduction of Top Cover Mass 57,3 % Belt Rated Tension 31,5 kN/m 20,8 kN

Conveyed Material Mass 27,78 kg/m Allowable Edge Tension - Running: 115 % Starting 150 %

Station / Sectio Design

Vertical Running Starting Braking Largest

Load Curve Fully Loaded Empty Fully Loaded Empty Fully Loaded Empty Reqd.

Capacity Radius Tension Radius Radius

Curve Tension Radius Tension Radius Tension Radius Tension Radius Tension Radius

Station Type tonnes/hr m kN m kN m kN m kN m kN m kN m m

13 Int. Pt Convex 9,54 9,54 9,89 10,43 9,24 9,37

Belt Tension at Curve kN 9,54 9,54 9,89 10,43 9,24 9,37

9

Min. Edge Tension Radius 8 8 8 8 8 8

Max. Buckling Radius 9 9 8 8 9 9

Belt Edge Tension Rise at Curve kN 0 0 0 0 0 0

Total Edge Tension at Curve kN and % 9,54 46% 9,54 46% 9,89 48% 10,43 50% 9,24 44% 9,37 45%

Centre Tension at Curve kN 9,54 9,54 9,89 10,43 9,24 9,37

14 Int. Pt Concave 7,98 7,98 9,65 12,24 6,53 7,18

Belt Tension at Curve kN 7,98 7,98 9,65 12,24 6,53 7,18

Min. Concave Lift Off Radius 129 129 156 198 105 116 198

Min. Edge Tension Radius 14 14 12 9 17 16

Max. Centre Tension Radius

15 Snub 7,99 7,99 9,95 12,97 6,3 7,06

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Viscoelastic Friction Factor Report Page 18/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Viscoelastic Calculations Input Data

Belt Rubber Description Rubber description ... Carry Idler Centre Roll Dia 139 mm

Top Cover Dynamic Modulus E' 6 N/mm2 Carry Idler Centre Roll Drag 2 N

Top Cover Dynamic Loss Factor Tan(delta) 0,13 Carry Idler Wing Roll Dia 139 mm

Belt Top Cover Temperature 30 deg C Carry Idler Wing Roll Drag 2 N

Rolling Resistance Factor RRF Top 0,072 RRF Bot. 0,072 Return Idler Centre Roll Dia 139 mm

Bottom Cover Dynamic Modulus E' 6 N/mm2 Return Idler Centre Roll Drag 2 N

Bot Cover Dynamic Loss Factor Tan(delta) 0,131 Return Idler Wing Roll Dia 139 mm

Belt Bottom Cover Temperature 30 deg C Return Idler Wing Roll Drag 2 N

Belt & Material Flexure Adjustment factor 1 Idlerset Skew Angle 0,5 deg

Belt has Turnover on Return Run Idlerset Forward Tilt angle 0,5 deg

Station / Section friction factor f (loaded) Empty

Total Indentation Matl.& Belt Idler Drag Idler Skew & Tilt

Loaded Indent Indent Freq Flexure Flexure Drag Drag Tilt Tilt Empty

Section Idler Friction factor factor uency friction friction factor factor friction friction Friction

No Length Spacing factor f fi % rad/s fm % fr % ft % factor f

1 0,55 0,60 0,0160 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0160

2 0,60 0,60 0,0160 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0160

3 11,10 0,30 0,0179 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0160

4 6,42 1,20 0,0237 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0207

5 84,34 1,20 0,0215 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0188

6 3,99 1,20 0,0215 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0207

7 0,51 0,60 0,0160 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0160

8 0,28 3,00 0,0150 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0150

9 1,87 3,00 0,0150 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0150

10 4,13 3,00 0,0150 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0150

11 4,13 3,00 0,0150 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0150

12 1,61 3,00 0,0150 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0150

13 84,34 3,00 0,0242 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0242

14 18,45 3,00 0,0150 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0150

15 0,26 3,00 0,0242 0,00000 0,0 0 0,00000 0,0 0,00000 0,0 0,00000 0,0 0,0242

Totals: 222,57 0,06 0,00 4,00 5

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Conveyor Belt Resonance Report Page 19/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Carry Roll Diameter 89 mm Belt Speed 2,5 m/s

Return Roll Diameter 89 mm Takeup Mass 1800 kg

Belt Resonance +/- Tolerance 10 %

Station / Sectio Running Fully Loaded Belt Resonance

Critical Critical Idler

Start End Belt Transverse Idler Roll Section Idler Idler Spacing

Belt Belt Wave Frequency Excitation Idler Spacing Spacing within

Mode

Station Description

Tension Tension Range Frequency Spacing Start End +/- 10%

kN kN Hz to Hz Hz m m m m

1 Tail 8,37 8,37 26,13 26,12 8,94 0,6 1,75 1,75 OK

2 Int. Pt 8,37 8,99 26,12 27,09 8,94 0,6 1,75 1,82 OK

3 Hopper 8,37 9,22 24,66 25,95 8,94 0,3 0,83 0,87 OK

4 Int. Pt 8,99 17,86 6,4 9,14 8,94 1,2 0,86 1,23 Caution 1

5 Int. Pt 9,22 17,93 6,49 9,16 8,94 1,2 0,87 1,23 Caution 1

6 Int. Pt 17,86 17,94 9,14 9,16 8,94 1,2 1,23 1,23 Caution 1

7 Int. Pt 17,93 8,53 18,31 12,45 8,94 0,6 1,23 0,84 Caution 1/2

8 Drive 8,27 8,85 5,19 5,37 8,94 3 1,74 1,8 OK

9 Snub 8,59 8,83 5,29 5,37 8,94 3 1,78 1,8 OK

10 Bend 8,9 9,23 5,39 5,49 8,94 3 1,81 1,84 OK

11 Takeup 8,88 9,54 5,38 5,58 8,94 3 1,81 1,87 OK

12 Bend 9,28 7,98 5,5 5,1 8,94 3 1,85 1,71 OK

13 Int. Pt 9,54 7,99 5,58 5,1 8,94 3 1,87 1,71 OK

14 Int. Pt 7,98 8,32 5,1 5,21 8,94 3 1,71 1,75 OK

15 Snub 8,05 8,32 5,12 5,21 8,94 3 1,72 1,75 OK

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Takeup Travel Report Page 20/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Takeup Travel

Takeup Type Vertical Gravity

Auto Calc Takeup Mass

Takeup Mass step increment 200 kg

Max no. of Calc Increments 100

Takeup Mass kg (Manual 2700 kg

Input)

Takeup Mass Calculated 1800 kg

Takeup Travel Estimate

Safety Margin Top + 1 m

Belt Splice Allowance + 1 m

Dynamic Travel Up + 1 m

Dynamic Travel Down + 1 m

Safety Margin Bottom + 1 m

Thermal Expansion Distance

Minimum Site Temperature 15 deg

Maximum Site Temperature 45 deg

Belt Expansion co-efficient

1,17E-05

m/m per degree C

Total Belt Length 225,00 m

Thermal Expansion Distance + 0,051 m

Permanent Belt Stretch

Permanent Stretch co-

0,3 %

efficient % of Belt Length

Permanent Belt Stretch 0,435 m

Distance +

Total Takeup Travel Distance 5,49 m

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Drive Details Report Page 21/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Drive No. 1 Drive Pulley No. 8

Drive Description Pulley Condition Wet

Load Share on Drive Pulley 100 % Pulley Lagging Type Rubber

Starting Torque Factor, Fully Loaded 150 % Belt Wrap Angle 192

Starting Torque Factor, Empty 150 % Coefficient of Friction, Running 0,25

Number of Motors on Drive Pulley 1 Drive Factor Cw, Running 0,76

Motor Description Electric Motor Coefficient of Friction, Starting 0,35

Motor Power Rating 37 kW Drive Factor Cw, Starting 0,45

Motor Voltage 380 Volts Pulley and Shaft Dimensions

Gearbox Description - Pulley Shell Diameter 418 mm

Drive Efficiency 90 % Pulley Lagging Thickness 12 mm

Pulley Outside Diameter 442 mm

Pulley Shaft Diameter at Hub 115 mm

Pulley Shaft Diameter at Brg 100 mm

High Speed Coupling Pulley and Belt Speed

HS Coupling Make No Selection Motor Full Load Speed 1465 rpm

HS Coupling Model Required Gearbox Ratio 13,562 :1

Low Speed Coupling Selected Gearbox Ratio 16 :1

LS Coupling Make No Selection Required Pulley Speed 108,02 rpm

LS Coupling Model Calculated Pulley Speed for Reducer 91,56 rpm

Brake Required Belt Speed 2,5 m/s

Brake Location High Speed Calculated Belt Speed 2,12 m/s

Low Speed Brake Torque Input 0 kNm Drive Inertia

Equiv HS Brake Torque 0 Nm Motor Inertia 0,284 kg-m2

Holdback High Speed Coupling Inertia 0 kg-m2

Static Analysis Runback Force Fv 5560 N High Speed Brake Disc Inertia 0 kg-m2

Static Analysis Horizontal Force Fh 4180 N Flywheel Inertia 0 kg-m2

Calculated Holdback Torque 767 Nm Gearbox Inertia (HSS) 0 kg-m2

Holdback Required (Yes / No) Yes Fv>Fh/2 Total Drive Inertia 0,284 kg-m2

Holdback Torque 3 x Motor FLT 9813 Nm Total Drive Equivalent Mass 1069 kg

Holdback Make No Selection

Holdback Model

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Drive Motor Details Report Page 22/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Drive No. 1 Drive Pulley No. 8

Drive Description Total Motor Power on Drive 37 kW

Number of Motors on Drive Pulley 1 Absorbed Power at Pulley 24,35 kW

Motor Category Metric Motor Drive Efficiency 90 %

Motor Description Electric Motor Absorbed Power at Motor 27,06 kW

Motor Power Rating 37 kW Motor Full Load Speed 1465 rpm

Motor Voltage 380 Volts Motor Full Load Torque 241 Nm

Number of poles 4 Motor Full Load Current 73 Amps

Motor Frame Size D225S Motor Efficiency @ Duty Point 90,9 %

Motor Shaft Diameter 60 mm Motor Power Factor @ Duty Pt 0,8

Motor Shaft Height 225 mm Mass of Motor 310 kg

Motor Inertia 0,284 kg-m2

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Drive Fluid Coupling Details Report Page 23/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Drive No. 1 Drive Pulley No. 8

Drive Description Coupling Size

Number of Motors on Drive Pulley 1 Motor Power Rating 37 kW

Selection Mode Manual Motor Full Load Speed 1465 rpm

Coupling Category Coupling Rated Slip 0 %

Coupling Description No Selection - Direct Drive Peak Torque % 0 % FLT

Coupling Power Rating 0 kW Run-up Torque % (2 sec) 0 % FLT

Min. Required Ramping Time sec Coupling Output Speed 1465 rpm

Max Starting Time 0 sec Mass of Coupling 0 kg

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Drive Gearbox Details Report Page 24/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Drive No. 1 Drive Pulley No. 8

Drive Description Motor Power Rating 37 kW

Number of Motors on Drive Pulley 1 Motor Full Load Speed 1465 rpm

Selection Mode Manual Motor Torque @ FL Speed 241 Nm

Gearbox Category - Motor Torque at Pulley Speed 3271 Nm

Gearbox Description - Gearbox Rated Torque 18000 Nm

Type - Service Factor Required 1,86

Size 250 Service Factor Calculated 5,5

Code

Plus Speed Selection Tolerance 5 %

Ratio 16

Minus Speed Selection Tolerance 5 %

Number of Stages

Fluid Coupling Slip 0 %

Design Efficiency (Input) 90 % Required Gearbox Ratio 13,562 :1

Gearbox Actual Efficiency 96 % Selected Gearbox Ratio 16 :1

Maximum Input Shaft Speed 2000 rpm Required Pulley Speed 108,02 rpm

Minimum Input Shaft Speed 0 rpm Calculated Pulley Speed for Reducer 91,56 rpm

Input Shaft Diameter 70 mm Required Belt Speed 2,5 m/s

Output Shaft Diameter 125 mm Calculated Belt Speed 2,12 m/s

Gearbox Inertia kg-m2 Mass of Gearbox 495 kg

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Brake Details Report Page 25/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Drive / Brake No. 1 Drive Pulley No. 8

Description Brake Location High Speed

Load Share on Drive Pulley 100 % Disc Material Mild Steel

Brake Category Disc Diameter 600 mm

Brake Description No Selection Disc Thickness 30 mm

Caliper BSFH 206 Co-eff of Friction (Pad-Disc) 0,4

Number of Motors on Drive Pulley 1

Caliper Clamping Force Minimum 6000 N

Brake Selection Input Data Caliper Clamping Force Maximum 8300 N

Low Speed Brake Torque Input 0 kNm Pad offset Width W 60 mm

Equiv HS Brake Torque 0 Nm Maximum Air Gap 3 mm

Design Braking Torque Input 1000 Nm Recommended working airgap is 1mm

Selected Brake's Torque Rating 1063 Nm Disc Initial Speed 1480 rpm

Design Stopping Time 10,0 sec Disc Moment of Inertia 3,0 kg-m2

Consecutive No of Stops 3 Required Gearbox Ratio 13,562 :1

Average No of Stops 6 Drive Efficiency 90 %

Ambient Temperature 40 deg C Mass of Caliper 26 kg

Disc Temperature after stops 74 deg C Brake Caliper Price $0,00

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Shaft Coupling Report Page 26/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Drive No. 1 Drive Pulley No. 8

Drive Description Motor Power Rating 37 kW

Load Share on Drive Pulley 100 % Motor Full Load Speed 1465 rpm

Starting Torque Factor, Fully Loaded 150 % Motor Torque @ FL Speed 241 Nm

Starting Torque Factor, Empty 150 % Motor Torque at Pulley Speed 3271 Nm

Number of Motors on Drive Pulley 1 Pulley Shaft Diameter at Brg 100 mm

Drive Efficiency 90 %

High Speed Coupling Low Speed Coupling

HS Coupling Category LS Coupling Category

HS Coupling Make No Selection LS Coupling Make No Selection

HS Coupling Model LS Coupling Model

Coupling Type Coupling Type

Coupling Torque Rating 0 Nm Coupling Torque Rating 0 Nm

Service Factor Required 3,5 Service Factor Required 3,5

Service Factor Calculated 0 Service Factor Calculated 0

Maximum Shaft Bore 0 mm Maximum Shaft Bore 0 mm

Minimum Shaft Bore 0 mm Minimum Shaft Bore 0 mm

Maximum Rotation Speed 0 rpm Maximum Rotation Speed 0 rpm

High Speed Coupling Inertia 0 kg-m2 Low Speed Coupling Inertia 0 kg-m2

Drawing Number Drawing Number

High Speed Coupling Mass 0 kg Low Speed Coupling Mass 0 kg

High Speed Coupling Price 0 Low Speed Coupling Price 0

Fluid Coupling

Direct Drive

Fluid Coupling No Selection - Direct Drive

Fluid Coupling Size

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Conveyor Pulley Shafts Page 27/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Station / Sectio Resul- Calculated Selected

T1 T2 tant T1

Shaft Wrap Run Run Start Defl. Dt. Shaft Brg Brg Shaft

Length Angle Force Dia Dia Dia Dia Ctrs Mass

Station Description mm deg kN kN kN kN mm mm mm mm mm kg

1 Tail 1320 180,0 8,3 8,4 16,6 10,4 78,4 75,7 80 75 1070 52

8 Drive UK 101 1420 190,0 17,9 8,3 26,1 27,0 87,8 95,4 115 100 1070 116

9 Snub 15C 1260 11,0 8,5 8,6 1,6 9,2 43,9 34,9 50 50 1070 19

10 Bend 11B 1310 90,0 8,8 8,9 12,5 9,6 73,1 68,9 75 70 1070 45

11 Takeup 1320 180,0 8,8 8,9 17,7 8,8 79,6 77,2 80 75 1070 52

12 Bend 11B 1310 90,0 9,2 9,3 13,0 9,4 73,8 69,8 75 70 1070 45

15 Snub 15C 1260 18,0 8,0 8,0 2,5 9,9 48,8 40,3 50 50 1070 19

Designers Comments * Denotes manual pulley shaft dimensions entered

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Conveyor Pulleys Page 28/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Station / Sectio

Face Shaft Brg Shaft Brg Wrap Pulley Pulley & Mom of

Shell Lagging Width Length Ctrs Dia Dia Angle Speed Shaft Inertia

Station Description Dia mm mm mm mm mm mm mm deg rpm Mass kg kgm2

1 Tail 350 0 750 1320 1070 80 75 180,0 136,4 167 2,5

8 Drive 418 12 750 1420 1070 115 100 190,0 108,0 298 6,2

9 Snub 273 0 750 1260 1070 50 50 11,0 174,9 92 1,0

10 Bend 350 0 750 1310 1070 75 70 90,0 136,4 161 2,5

11 Takeup 350 0 750 1320 1070 80 75 180,0 136,4 167 2,5

12 Bend 350 0 750 1310 1070 75 70 90,0 136,4 161 2,5

15 Snub 273 0 750 1260 1070 50 50 18,0 174,9 92 1,0

Designers Comments * Denotes manual pulley dimensions entered

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Conveyor Pulley Dimensions Page 29/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Station / Sectio

Face Shaft Brg Shaft Brg Belt Pulley & Mom of

Shell Lagging OD Width Length Ctrs Dia Dia Width Shaft Inertia

Station Description Dia mm mm mm mm mm mm mm mm mm Mass kg kgm2

1 Tail 350 0 350 750 1320 1070 80 75 650 167 2,5

8 Drive 418 12 442 750 1420 1070 115 100 650 298 6,2

9 Snub 273 0 273 750 1260 1070 50 50 650 92 1,0

10 Bend 350 0 350 750 1310 1070 75 70 650 161 2,5

11 Takeup 350 0 350 750 1320 1070 80 75 650 167 2,5

12 Bend 350 0 350 750 1310 1070 75 70 650 161 2,5

15 Snub 273 0 273 750 1260 1070 50 50 650 92 1,0

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

14 Agust 2015 19:32 Conveyor Pulleys Data Sheet Page 30/30

PT. BANGUN ARTA HUTAMA

Project Tanjung Power Indonesia Client Hyundai Engineering

Project No. Prepared By UJ

Conveyor No. BC01A-R0 Design Date 06 Agustus 2015

Station / Sectio

Face Brg Drive Wrap Pulley T1 T2 T1 T2

Shell Lagging Width Ctrs Power Angle Speed Run Run Start Start

Station Description Dia mm mm mm mm kW deg rpm kN kN kN kN

1 Tail 350 0 750 1070 180,0 136,4 8,32 8,37 13,51 13,88

Running Full Starting Empty

8 Drive 418 12 750 1070 37 190,0 108,0 17,94 8,27 27,02 8,93

Running Full Starting Full

9 Snub 273 0 750 1070 11,0 174,9 8,53 8,59 9,21 9,34

Running Full Starting Full

10 Bend 350 0 750 1070 90,0 136,4 8,85 8,9 9,64 9,81

Running Full Starting Full

11 Takeup 350 0 750 1070 180,0 136,4 8,83 8,88 8,83 9,2

Running Full Starting Empty

12 Bend 350 0 750 1070 90,0 136,4 9,23 9,28 9,71 10,09

Running Full Starting Empty

15 Snub 273 0 750 1070 18,0 174,9 7,99 8,05 12,97 13,23

Running Full Starting Empty

Designers Comments

G:\PT.TanjungPowerIndonesia\MechCalc\TPI-CV01A-R00 (UpdatePlan).xml Helix

Ver 6.0.15 Licenced to PT Bangun Arta Hutama Technologies

Vous aimerez peut-être aussi

- Helix Calculation Stage-1 CV 42 (R2) Approved - 230524 - 222556Document26 pagesHelix Calculation Stage-1 CV 42 (R2) Approved - 230524 - 222556Karthikeyan MallikaPas encore d'évaluation

- Conveyor Design Summary: Helix Technologies Pty LTDDocument23 pagesConveyor Design Summary: Helix Technologies Pty LTDmamatsulsPas encore d'évaluation

- Conveyor Design Summary: PT. Siko TechnoDocument37 pagesConveyor Design Summary: PT. Siko TechnoJoe GrosirPas encore d'évaluation

- HelixAllReportsDemo12 C3 OverlandDocument66 pagesHelixAllReportsDemo12 C3 OverlandSergio DiazPas encore d'évaluation

- Conveyor Design Summary: Copper Ore 1800 1800 30 15 100 MM 4860 Tonnes/hr 3 M/s 1800 8 MM 281 4 MMDocument20 pagesConveyor Design Summary: Copper Ore 1800 1800 30 15 100 MM 4860 Tonnes/hr 3 M/s 1800 8 MM 281 4 MMiman zareiePas encore d'évaluation

- Helix Delta-T6 Sample Report01Document29 pagesHelix Delta-T6 Sample Report01Khaleel PashaPas encore d'évaluation

- Calculasi Conveyor 7a & 8aDocument34 pagesCalculasi Conveyor 7a & 8adeni prastikoPas encore d'évaluation

- Sample - Catamaran Trim & Stability BookletDocument37 pagesSample - Catamaran Trim & Stability BookletNiranjan Kumar Injeti100% (1)

- C3048 PNJ CAL B 0002 B Conveyor 11 CV 01Document30 pagesC3048 PNJ CAL B 0002 B Conveyor 11 CV 01Joel MoorePas encore d'évaluation

- Conveyor Design Summary: Coal Bituminous 50 Mesh 870 800 45 30Document47 pagesConveyor Design Summary: Coal Bituminous 50 Mesh 870 800 45 30Boy AlfredoPas encore d'évaluation

- Helix T6 Calculation Conveyor 2500 TPHDocument31 pagesHelix T6 Calculation Conveyor 2500 TPHJoe GrosirPas encore d'évaluation

- ZC01-FD001-Feeder Load Calc 29092020Document10 pagesZC01-FD001-Feeder Load Calc 29092020dhiny.andrianiPas encore d'évaluation

- KonfigDocument10 pagesKonfigErfan.TPas encore d'évaluation

- Anexala0117s3021r 30373 45 1710210153Document2 pagesAnexala0117s3021r 30373 45 1710210153Valcu GabrielPas encore d'évaluation

- Helix ZC01-FD001 24092020Document9 pagesHelix ZC01-FD001 24092020achmatPas encore d'évaluation

- Structural Solutions of India: of Pile Lateral Load TestDocument6 pagesStructural Solutions of India: of Pile Lateral Load TestSatyaprakash PrasadPas encore d'évaluation

- Structural Solutions of India: of Pile Lateral Load TestDocument6 pagesStructural Solutions of India: of Pile Lateral Load TestSatyaprakash PrasadPas encore d'évaluation

- Conveyor Design Summary: Pt. Siko TechnoDocument8 pagesConveyor Design Summary: Pt. Siko TechnoachmatPas encore d'évaluation

- DTH - Martillo Zandvik TodozDocument39 pagesDTH - Martillo Zandvik TodozedwinPas encore d'évaluation

- Memoria de Calculo Cintas Transportadoras PDFDocument29 pagesMemoria de Calculo Cintas Transportadoras PDFluigimarlonePas encore d'évaluation

- Revised Final JK 30 MW Turbine Overhauling ReportDocument38 pagesRevised Final JK 30 MW Turbine Overhauling ReportRajesh GoladaPas encore d'évaluation

- CF-PSC-R-02A, 02B, 02C & 02D (Quartz)Document33 pagesCF-PSC-R-02A, 02B, 02C & 02D (Quartz)Harish KumarPas encore d'évaluation

- Stability Calculation - Immersing: Loadcase - Immersing Damage Case - IntactDocument6 pagesStability Calculation - Immersing: Loadcase - Immersing Damage Case - IntactfahmiPas encore d'évaluation

- Belt Den Design Calculations NeWDocument42 pagesBelt Den Design Calculations NeWIbz AjagbePas encore d'évaluation

- Fluid Mechanics: Mini Pelton Turbine KM31401: LAB IVDocument7 pagesFluid Mechanics: Mini Pelton Turbine KM31401: LAB IVBorromeo MathewPas encore d'évaluation

- Lateral 1stDocument15 pagesLateral 1stabhishekrajoriya00Pas encore d'évaluation

- Ramp - QuotationDocument2 pagesRamp - QuotationYASHPas encore d'évaluation

- DPR 27 Nov 23Document2 pagesDPR 27 Nov 23Pardeep SharmaPas encore d'évaluation

- Graf Load Test 2Document5 pagesGraf Load Test 2Faizul IzuanPas encore d'évaluation

- Impact of Jet Lab ReportDocument11 pagesImpact of Jet Lab ReportArrianna PeterPas encore d'évaluation

- ACFrOgBIkpx7Dwzv-Xx6ZaOiDCT X01mmvr6997C7YFLeSPSvNGp1sJUfMptWNElGapOzTipp1bPfi75M0jm N-WTW BaQO2j ry9XMUgIaIShs2m6qBE4Cmp8nvXdewANzCtt Kxar818CB4c9Document6 pagesACFrOgBIkpx7Dwzv-Xx6ZaOiDCT X01mmvr6997C7YFLeSPSvNGp1sJUfMptWNElGapOzTipp1bPfi75M0jm N-WTW BaQO2j ry9XMUgIaIShs2m6qBE4Cmp8nvXdewANzCtt Kxar818CB4c9Zie RenPas encore d'évaluation

- Form C: Type Test Verification ReportDocument10 pagesForm C: Type Test Verification ReportMadhushan DassanayakePas encore d'évaluation

- Voltage Limits:: Operating Problem Corrective Action FACTS ControllerDocument4 pagesVoltage Limits:: Operating Problem Corrective Action FACTS Controllerعبدا لصمدPas encore d'évaluation

- Start: Static Input Data (Beltanalyst™)Document8 pagesStart: Static Input Data (Beltanalyst™)Erlan OlveiraPas encore d'évaluation

- CF-EPF-R-03 & CF-EPF-R-04 (Crushed Revert)Document33 pagesCF-EPF-R-03 & CF-EPF-R-04 (Crushed Revert)Harish KumarPas encore d'évaluation

- Eas OostlDocument3 pagesEas OostlRayhan AlifaPas encore d'évaluation

- CF-EPF-R-03 & CF-EPF-R-04 (Quartz)Document33 pagesCF-EPF-R-03 & CF-EPF-R-04 (Quartz)Harish KumarPas encore d'évaluation

- Drivability Analysis For Sohar Refiniary PDFDocument11 pagesDrivability Analysis For Sohar Refiniary PDFuygarkoprucuPas encore d'évaluation

- HunasanahalliDocument2 pagesHunasanahalliumadevi1201Pas encore d'évaluation

- Annex I-1 Process Technical and Production Capacity-Rev01Document29 pagesAnnex I-1 Process Technical and Production Capacity-Rev01jackhuguesPas encore d'évaluation

- Motor 2.5 HP - ShakersDocument2 pagesMotor 2.5 HP - ShakersAlex SinissPas encore d'évaluation

- Parker Pneumatic Robust Air Motor - P1V-M: PDE2600PNUKDocument5 pagesParker Pneumatic Robust Air Motor - P1V-M: PDE2600PNUKZoran JankovPas encore d'évaluation

- Conveyor Calculation IS 11592Document2 pagesConveyor Calculation IS 11592Maknan SteelPas encore d'évaluation

- 512 - Ra-04 SesDocument2 pages512 - Ra-04 Sesshanivi vrindavanPas encore d'évaluation

- CF-PSC-R-02A, 02B, 02C & 02D (Crushed Revert)Document33 pagesCF-PSC-R-02A, 02B, 02C & 02D (Crushed Revert)Harish KumarPas encore d'évaluation

- CF-STD-R-01 (Blended)Document33 pagesCF-STD-R-01 (Blended)Harish KumarPas encore d'évaluation

- Financial AnalisysDocument12 pagesFinancial AnalisysMuhamad FajriPas encore d'évaluation

- Cti PDFDocument5 pagesCti PDFFarhan ShahPas encore d'évaluation

- Belt Conveyors With Shaft SizingDocument5 pagesBelt Conveyors With Shaft SizingArun Chopra100% (1)

- HD Est C30188 00 01Document81 pagesHD Est C30188 00 01NgapakGamingPas encore d'évaluation

- Invoice No: TVT/2018-19/143 Date: 1/3/2019 S.No Particular Hsn/Sac Qty. Unit Rate Amount CGST SGST Rate Amount Rate Amount TotalDocument12 pagesInvoice No: TVT/2018-19/143 Date: 1/3/2019 S.No Particular Hsn/Sac Qty. Unit Rate Amount CGST SGST Rate Amount Rate Amount TotalGURLEENPas encore d'évaluation

- Structural Solutions of India: of Pile Lateral Load TestDocument6 pagesStructural Solutions of India: of Pile Lateral Load TestSatyaprakash PrasadPas encore d'évaluation

- Structural Solutions of India: of Pile Lateral Load TestDocument6 pagesStructural Solutions of India: of Pile Lateral Load TestSatyaprakash PrasadPas encore d'évaluation

- Dunlop Conveyor Belt Design ManualDocument16 pagesDunlop Conveyor Belt Design ManualTabor TamiruPas encore d'évaluation

- Fuel and Payload Planner: Fuel Plan Trip DetailsDocument18 pagesFuel and Payload Planner: Fuel Plan Trip DetailsJavierPas encore d'évaluation

- Popeller Design PDFDocument25 pagesPopeller Design PDFcujat123Pas encore d'évaluation

- Calculo Banda TrasnportadoraDocument10 pagesCalculo Banda TrasnportadoraHugo Mario Ariza PalacioPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- British Commercial Computer Digest: Pergamon Computer Data SeriesD'EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesPas encore d'évaluation

- Technical Data Hino 700 ProfiaDocument5 pagesTechnical Data Hino 700 ProfiaWaris La Joi WakatobiPas encore d'évaluation

- 7300en PDFDocument9 pages7300en PDFWaris La Joi WakatobiPas encore d'évaluation

- Feeder Breaker Chain (Renold Chain) Double Pitch Sprocket DesignDocument1 pageFeeder Breaker Chain (Renold Chain) Double Pitch Sprocket DesignWaris La Joi Wakatobi0% (1)

- Operating Instructions: BA K295 EN 06.97Document45 pagesOperating Instructions: BA K295 EN 06.97Waris La Joi WakatobiPas encore d'évaluation

- Calc - Vibrating Screen Single Deck NPK1Document5 pagesCalc - Vibrating Screen Single Deck NPK1Waris La Joi WakatobiPas encore d'évaluation

- RUPEX Coupling RWNDocument26 pagesRUPEX Coupling RWNWaris La Joi WakatobiPas encore d'évaluation

- 7300en PDFDocument9 pages7300en PDFWaris La Joi WakatobiPas encore d'évaluation

- Operating Instructions: BA G298 EN 08.98Document39 pagesOperating Instructions: BA G298 EN 08.98Waris La Joi WakatobiPas encore d'évaluation

- 8702en PDFDocument32 pages8702en PDFWaris La Joi WakatobiPas encore d'évaluation

- ZAPEX CouplingDocument22 pagesZAPEX CouplingWaris La Joi WakatobiPas encore d'évaluation

- Installation GuideDocument15 pagesInstallation GuideWaris La Joi WakatobiPas encore d'évaluation

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIDocument10 pagesAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiPas encore d'évaluation

- Arpex CouplingDocument38 pagesArpex CouplingWaris La Joi WakatobiPas encore d'évaluation

- 8703en PDFDocument35 pages8703en PDFWaris La Joi WakatobiPas encore d'évaluation

- Survey of Cargo Handling ResearchDocument95 pagesSurvey of Cargo Handling ResearchWaris La Joi WakatobiPas encore d'évaluation

- Coefficient of Friction PDFDocument8 pagesCoefficient of Friction PDFWaris La Joi WakatobiPas encore d'évaluation

- Wire Rope Drum HoistDocument3 pagesWire Rope Drum HoistWaris La Joi WakatobiPas encore d'évaluation

- PARAMAX NEW Copy Rev2Document281 pagesPARAMAX NEW Copy Rev2Waris La Joi WakatobiPas encore d'évaluation

- Vertical Curve Radius Calculations: Pt. Vortex IndonesiaDocument4 pagesVertical Curve Radius Calculations: Pt. Vortex IndonesiaWaris La Joi WakatobiPas encore d'évaluation

- Trailing Chasis Axle R1Document62 pagesTrailing Chasis Axle R1Waris La Joi WakatobiPas encore d'évaluation

- List Mining CompanyDocument12 pagesList Mining CompanyWaris La Joi WakatobiPas encore d'évaluation