Académique Documents

Professionnel Documents

Culture Documents

Biofilm Removal and Chemical Sanitization of RO Systems - Pharmaceutical Guidelines

Transféré par

ASHOK KUMAR LENKATitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Biofilm Removal and Chemical Sanitization of RO Systems - Pharmaceutical Guidelines

Transféré par

ASHOK KUMAR LENKADroits d'auteur :

Formats disponibles

BiofilmRemovalandChemicalSanitizationofROSystems

Sanitization of the reverse osmosis water purification system and biofilm removal from water system.

To control microbial growth, RO systems must be chemically sanitized on a regular basis. Prior to sanitation it is important to chemically clean the firstpass

RO system. This will help to disrupt any biofilm that protects viable bacteria from contact with the sanitant. It also removes foulants that will react with and

chemically deplete the sanitizing agent.

Typically this is done in a twostep process. The first step commonly involves the use of an acid cleaner

such as citric acid to remove the inorganic foulants. Next, a highpH cleaner such as sodium hydroxide is

used in order to remove organic foulants. Then the system is sanitized with one of the following agents:

formaldehyde, hydrogen peroxide, or peracetic acid/hydrogen peroxide. It is important to consult the

manufacturer of the RO system to determine the correct concentrations of the chemicals that are

compatible with the membranes in the system, and always rinse with Purified Water before changing

chemicals.

Both cleaning and sanitation processes consist of four steps. First, the cleaning chemical is mixed with

permeate water in a cleaninplace ClP tank. Second, the chemical solution is recirculated through the RO

system for 15 to 30 minutes. Then, the system is left to soak for 20 to 30 minutes. The system should be

started once every 5 to 10 minutes for a short time to allow fresh solution to contact the membrane.

Finally, the system should be rinsed with permeate water until the residual cleaning

and/or sanitation chemicals have been removed.

Although the second pass of the RO does not typically require cleaning as frequently as the first pass, a regular cleaning and sanitation schedule should be

maintained. This schedule should be based on the microbial concentrations and samples collected from the permeate water from the secondpass RO

machine. When microbial concentrations in the permeate begin to rise steadily, sanitation should be conducted.

If peracetic acid or hydrogen peroxide are used to sanitize PA membranes, the membrane must be cleaned with an acid cleaner in order to remove free iron

and any other transitional metals; otherwise the membrane may be chemically damaged by the sanitation procedure. It is also important to make certain

that the sanitant is mixed with water that is free of chlorine. The membrane's exposure to the sanitant should not exceed one hour per week at the

recommended concentration level, or reduced membrane life may occur.

Related: Biocontamination Control Techniques for Purified Water System

Biofilm Removal

Biofilm is a common term used to describe the accumulation of microorganisms and their byproduct excretions onto surfaces of a water treatment

system. Because most microorganisms prefer to become attached to a surface, more and more microorganisms will adhere to the surfaces of a water

system. As microorganisms die, they become nutrient sources for other microorganisms. Over time, a film consisting of living and dead organisms will

form. A slimy cover called a glycocalyx surrounds the organisms and serves to trap nutrients from the water source and protect the organisms from

chemical destruction and biofilm removal.

Related: How to Remove the Pathogenic Bacteria from Water Systems

For biofilm removal, it is necessary to conduct a series of sanitation and cleaning steps. First, inorganic should be removed using a lowpH cleaner. Second,

any organic compound or dead microorganisms should be removed using a highpH cleaner such as sodium hydroxide. Third, a sanitation should be

conducted using a common sanitizing agent such as formaldehyde, chlorine, or peracetic acid/hydrogen peroxide. Then conduct a series of organic

cleaning cycles followed by sanitation cycles. Prior to changing chemicals, always flush with purified water. For severe, established biofilms, it may be

necessary to repeat this process 5 to 10 times. During each step, the sanitation agent should be in contact with the system for 15 to 30 minutes for an

effective biofilm removal.

Also see: Purified Water System Validation

Ankur Choudhary is India's first professional pharmaceutical blogger, author and founder of Pharmaceutical Guidelines, a widelyread pharmaceutical

blog since 2008. Signup for the free email updates for your daily dose of pharmaceutical tips.

Need Help: Ask Question

Offline

20082017 All rights reserved to Ankur Choudhary and data may not be reproduced on other websites. Designed by Pharmaceutical Guidelines.

Privacy Policy Disclaimer

Vous aimerez peut-être aussi

- Biofilm Removal and Chemical Sanitization of RO Systems - Pharmaceutical Guidelines PDFDocument1 pageBiofilm Removal and Chemical Sanitization of RO Systems - Pharmaceutical Guidelines PDFASHOK KUMAR LENKAPas encore d'évaluation

- Tugas Pertemuan 2 Air 2020Document4 pagesTugas Pertemuan 2 Air 2020Suci DwiPas encore d'évaluation

- How Reverse Osmosis Works: Conductivity MeterDocument21 pagesHow Reverse Osmosis Works: Conductivity MeterEricsson BotchweyPas encore d'évaluation

- Biocontamination Control Techniques For Purified Water SystemDocument4 pagesBiocontamination Control Techniques For Purified Water SystemAli KureishiPas encore d'évaluation

- Drinking Water DisinfectionDocument9 pagesDrinking Water DisinfectionWONG TSPas encore d'évaluation

- Biocontamination Control Techniques For Purified Water System - Pharmaceutical GuidelinesDocument1 pageBiocontamination Control Techniques For Purified Water System - Pharmaceutical GuidelinesASHOK KUMAR LENKAPas encore d'évaluation

- STP Dtd. 21.02.2023Document26 pagesSTP Dtd. 21.02.2023pragati dwivediPas encore d'évaluation

- The Benefits of Using Reverse Osmosis Water FiltersDocument2 pagesThe Benefits of Using Reverse Osmosis Water FiltersAlejandro GutierrezPas encore d'évaluation

- Switching To Water Based Cleaners in Repair and Maintenance Parts CleaningDocument10 pagesSwitching To Water Based Cleaners in Repair and Maintenance Parts CleaningukalPas encore d'évaluation

- Miscellaneous Treatment MethodsDocument25 pagesMiscellaneous Treatment Methodsjong LacPas encore d'évaluation

- Types of Purified Water Systems in Pharmaceuticals - Pharmaceutical GuidelinesDocument2 pagesTypes of Purified Water Systems in Pharmaceuticals - Pharmaceutical GuidelinesRandheer DubeyPas encore d'évaluation

- Ship Sewage Treatment ExplainedDocument6 pagesShip Sewage Treatment ExplainedGiorgi KandelakiPas encore d'évaluation

- BTPM AssignmentDocument15 pagesBTPM AssignmentAtharva DeshpandePas encore d'évaluation

- ChemDocument12 pagesChemguptaasmi17Pas encore d'évaluation

- Working of A Biological Sewage PlantDocument15 pagesWorking of A Biological Sewage PlantJose OrtegaPas encore d'évaluation

- Wastewater Treatment PlantDocument2 pagesWastewater Treatment PlantJerson RicafortPas encore d'évaluation

- STD 10 Water Security - Activity - 4 - (2ND Term)Document3 pagesSTD 10 Water Security - Activity - 4 - (2ND Term)shauryamusketeersPas encore d'évaluation

- Lesson 15 - Trickling FiltersDocument10 pagesLesson 15 - Trickling FiltersShane RodriguezPas encore d'évaluation

- Wastewater Treatment Process OverviewDocument148 pagesWastewater Treatment Process OverviewAilan TenGkuPas encore d'évaluation

- Textile Effluent TreatmentDocument6 pagesTextile Effluent TreatmentvenkatharunPas encore d'évaluation

- Biofilm RemovalDocument5 pagesBiofilm Removaledo wijayantoPas encore d'évaluation

- Health and Microbiology Surface DisinfectionDocument13 pagesHealth and Microbiology Surface DisinfectionHà Tuấn KiệtPas encore d'évaluation

- Types of Wastewater Treatment ProcessDocument6 pagesTypes of Wastewater Treatment Processvishal kashyapPas encore d'évaluation

- Managing Water and Air Quality Managing Water and Air QualityDocument20 pagesManaging Water and Air Quality Managing Water and Air QualityJin SiclonPas encore d'évaluation

- What Is An ETP PlantDocument12 pagesWhat Is An ETP PlantrohitPas encore d'évaluation

- Portable Rainwater PurificationDocument4 pagesPortable Rainwater PurificationCaera Mae VillaricoPas encore d'évaluation

- A) State and Describe Various Stages of A Biodegradation StudyDocument6 pagesA) State and Describe Various Stages of A Biodegradation StudyAbdulkadir AlbabaPas encore d'évaluation

- 14 The Water Purification ProcessDocument6 pages14 The Water Purification ProcessDennis Joel Ochoa MorochoPas encore d'évaluation

- ExamDocument9 pagesExamDileepa NeranjanaPas encore d'évaluation

- Membrane Cleaning 101 PDFDocument5 pagesMembrane Cleaning 101 PDFsamrickyPas encore d'évaluation

- Textile Waste Water Management: Course: Introduction To General Chemistry Course Code: CHE 101Document7 pagesTextile Waste Water Management: Course: Introduction To General Chemistry Course Code: CHE 101Ishtiaq Ahmed MugdhaPas encore d'évaluation

- Waste Water TreatmentDocument3 pagesWaste Water TreatmentShiladitya ChoudhuryPas encore d'évaluation

- Report of Educational VisitDocument5 pagesReport of Educational VisitHARSHADPas encore d'évaluation

- The Water Purification Process 2Document4 pagesThe Water Purification Process 2Yue YingPas encore d'évaluation

- Kutchen Tools CleaningDocument13 pagesKutchen Tools Cleaningmj yuPas encore d'évaluation

- Ballast Water Treatment SystemDocument4 pagesBallast Water Treatment Systemdipanshu tiwariPas encore d'évaluation

- Major Waste Water Treatment Processes: ETP, STP, CETP (38Document4 pagesMajor Waste Water Treatment Processes: ETP, STP, CETP (38r0466Pas encore d'évaluation

- Name of The Student: Sewage Treatment PlantDocument19 pagesName of The Student: Sewage Treatment PlantDharshanPas encore d'évaluation

- Hospital Wastewater and Its TreatmentDocument8 pagesHospital Wastewater and Its TreatmentDjHanna OlShopsPas encore d'évaluation

- A MICRO PROJECT ON "Prepare Report On Household Water Filtrations Unit"Document9 pagesA MICRO PROJECT ON "Prepare Report On Household Water Filtrations Unit"pmali1408Pas encore d'évaluation

- Determination of The CleaninDocument7 pagesDetermination of The Cleaninanil1Pas encore d'évaluation

- The Hygienic ChainDocument16 pagesThe Hygienic Chainpoli2cosPas encore d'évaluation

- Conventional Waste Water Treatment Process - Water ReuseDocument2 pagesConventional Waste Water Treatment Process - Water ReuseGeraldPas encore d'évaluation

- Treatment ProcessesDocument36 pagesTreatment ProcessesFree_Beating_HeartPas encore d'évaluation

- Chapter 5 Sewage Treatment PlantDocument3 pagesChapter 5 Sewage Treatment PlantJasleneDimarananPas encore d'évaluation

- Cleaning House BroilerDocument25 pagesCleaning House BroilerEmanuel Sergiu PanaPas encore d'évaluation

- The Hygienic ChainDocument16 pagesThe Hygienic ChainJosé GómezPas encore d'évaluation

- WHO's Guidelines On Water Quality Recommend: Treatment ProcesssDocument4 pagesWHO's Guidelines On Water Quality Recommend: Treatment ProcesssLaishram NirpenPas encore d'évaluation

- Haldia Institute of Technology Presentation For Environmental Sciences (MC - 401)Document12 pagesHaldia Institute of Technology Presentation For Environmental Sciences (MC - 401)subarna maitiPas encore d'évaluation

- Chlorine and Drinking Water TreatmentDocument4 pagesChlorine and Drinking Water TreatmentRajesh ChePas encore d'évaluation

- E. Coli A Report by Peter H. Gleick: Portable Rainwater: Filtration and PurificationDocument6 pagesE. Coli A Report by Peter H. Gleick: Portable Rainwater: Filtration and PurificationCaera Mae VillaricoPas encore d'évaluation

- STP Detail DesignDocument4 pagesSTP Detail DesignrspawaiyaPas encore d'évaluation

- Mail Today Pure and Safe?Document7 pagesMail Today Pure and Safe?atharnadim_osPas encore d'évaluation

- CleaningDocument2 pagesCleaningBiljana TausanovicPas encore d'évaluation

- Water Purifiers: RO vs UV vs Chemical - Which is Best and SafestDocument3 pagesWater Purifiers: RO vs UV vs Chemical - Which is Best and SafestssmaddiPas encore d'évaluation

- Waste and SanitationDocument45 pagesWaste and SanitationOkello GodfreyPas encore d'évaluation

- Waste Water TreatmentDocument7 pagesWaste Water TreatmentMuhammad SyafiqPas encore d'évaluation

- Aquaponics Bacteria: Importance of Bacterias in Aquaponics SystemD'EverandAquaponics Bacteria: Importance of Bacterias in Aquaponics SystemÉvaluation : 3 sur 5 étoiles3/5 (1)

- No-Fluff Swimming Pool Maintenance Guide for Beginners: Easy Steps to Maintain Water Chemistry, Eliminate Algae and Keep Your Pool SparklingD'EverandNo-Fluff Swimming Pool Maintenance Guide for Beginners: Easy Steps to Maintain Water Chemistry, Eliminate Algae and Keep Your Pool SparklingPas encore d'évaluation

- Mankind Pharma Limited Unit-Ii, Paonta Sahib .: 1.0 PowerDocument9 pagesMankind Pharma Limited Unit-Ii, Paonta Sahib .: 1.0 PowerASHOK KUMAR LENKA100% (1)

- Ajit Kumar Rout: Curriculam VitaeDocument3 pagesAjit Kumar Rout: Curriculam VitaeASHOK KUMAR LENKAPas encore d'évaluation

- Usp 1116 Usp 36 NF31S1 PDFDocument11 pagesUsp 1116 Usp 36 NF31S1 PDFASHOK KUMAR LENKAPas encore d'évaluation

- PLAN Vs ACHIEVEMENT (26.12.16) : Department: MicrobiologyDocument1 pagePLAN Vs ACHIEVEMENT (26.12.16) : Department: MicrobiologyASHOK KUMAR LENKAPas encore d'évaluation

- 2500Document4 pages2500ASHOK KUMAR LENKAPas encore d'évaluation

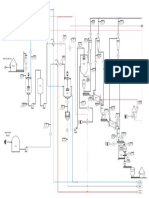

- Water System DrawingDocument1 pageWater System DrawingASHOK KUMAR LENKAPas encore d'évaluation

- 58 66 (Ajpr)Document9 pages58 66 (Ajpr)ASHOK KUMAR LENKAPas encore d'évaluation

- XL Laboratories Purchases PVDC Film from ACG PharmapackDocument1 pageXL Laboratories Purchases PVDC Film from ACG PharmapackASHOK KUMAR LENKAPas encore d'évaluation

- Job Descriptions Roles and ResponsibilitiesDocument7 pagesJob Descriptions Roles and ResponsibilitiesASHOK KUMAR LENKAPas encore d'évaluation

- Vap1.7 MSDSDocument10 pagesVap1.7 MSDSASHOK KUMAR LENKAPas encore d'évaluation

- List of Instru - EquipDocument2 pagesList of Instru - EquipASHOK KUMAR LENKAPas encore d'évaluation

- DayQuil Cold & Flu Relief LiquiCaps ReviewDocument1 pageDayQuil Cold & Flu Relief LiquiCaps ReviewASHOK KUMAR LENKAPas encore d'évaluation

- A4c - NAM Registration GuidelineDocument92 pagesA4c - NAM Registration GuidelineASHOK KUMAR LENKAPas encore d'évaluation

- 03-09-2017 Sorbitol Soluction 70%Document1 page03-09-2017 Sorbitol Soluction 70%ASHOK KUMAR LENKAPas encore d'évaluation

- Communications Officer 61-11 - JDDocument15 pagesCommunications Officer 61-11 - JDASHOK KUMAR LENKAPas encore d'évaluation

- 26.12.16 Revised Embossing Letter RequirementDocument4 pages26.12.16 Revised Embossing Letter RequirementASHOK KUMAR LENKAPas encore d'évaluation

- Requirement of Embossing Letter Details For Blister Packing Change PartsDocument2 pagesRequirement of Embossing Letter Details For Blister Packing Change PartsASHOK KUMAR LENKAPas encore d'évaluation

- AutoCAD Tutorial 002 PDFDocument54 pagesAutoCAD Tutorial 002 PDFskannanmecPas encore d'évaluation

- Annexure 01 Job Responsbility FormDocument1 pageAnnexure 01 Job Responsbility FormASHOK KUMAR LENKAPas encore d'évaluation

- XL - PC Report - 2,3,4,5,6 - Feb - 17Document84 pagesXL - PC Report - 2,3,4,5,6 - Feb - 17ASHOK KUMAR LENKAPas encore d'évaluation

- Amit ResumeDocument5 pagesAmit ResumeASHOK KUMAR LENKAPas encore d'évaluation

- Polysorb 85 - 70 - 00 RM COADocument2 pagesPolysorb 85 - 70 - 00 RM COAASHOK KUMAR LENKAPas encore d'évaluation

- Suppliers ListDocument3 pagesSuppliers ListASHOK KUMAR LENKAPas encore d'évaluation

- Stability: Basic CoarseDocument79 pagesStability: Basic CoarseASHOK KUMAR LENKAPas encore d'évaluation

- List of Instru - Equip.Document2 pagesList of Instru - Equip.ASHOK KUMAR LENKAPas encore d'évaluation

- 14MA GarciaDocument10 pages14MA GarciaMusab Hashmi100% (1)

- Job responsibility form templateDocument1 pageJob responsibility form templateASHOK KUMAR LENKAPas encore d'évaluation

- Nicotinamide COADocument2 pagesNicotinamide COAASHOK KUMAR LENKAPas encore d'évaluation

- Procurement: Balance Capacity Least Count Type of Balance No. of Items Placement Digit of Display RequirementDocument2 pagesProcurement: Balance Capacity Least Count Type of Balance No. of Items Placement Digit of Display RequirementASHOK KUMAR LENKAPas encore d'évaluation

- Peanut Oil COA AnalysisDocument2 pagesPeanut Oil COA AnalysisASHOK KUMAR LENKAPas encore d'évaluation

- D-Fog For GE Gas TurbinesDocument8 pagesD-Fog For GE Gas TurbinesarslanhamidPas encore d'évaluation

- Diked & Spill Protection: Dike Protection Fixed Mount Low Level Foam MakersDocument4 pagesDiked & Spill Protection: Dike Protection Fixed Mount Low Level Foam MakersAamerMAhmadPas encore d'évaluation

- MSDS Lithiumplex XP 1Document3 pagesMSDS Lithiumplex XP 1José BautistaPas encore d'évaluation

- Broiler House VentilationDocument30 pagesBroiler House VentilationPrestoneKPas encore d'évaluation

- Impacts of Tourism On Society PDFDocument7 pagesImpacts of Tourism On Society PDFgowthami m100% (1)

- Calpeda MXV-B Vertical Multistage PumpDocument6 pagesCalpeda MXV-B Vertical Multistage PumpWayne Seaman100% (1)

- 03 Jaer V2N2 PDFDocument6 pages03 Jaer V2N2 PDFAnonymous KzJcjGCJbPas encore d'évaluation

- SLS 614Document16 pagesSLS 614K S Kumara100% (8)

- Dafc Mars HabDocument45 pagesDafc Mars HabHungary UNHRC ShahPas encore d'évaluation

- CorrView Corrosion MonitorDocument2 pagesCorrView Corrosion MonitorMohsen KarimiPas encore d'évaluation

- Grundfos - SLV 80 80 75 2 51D CDocument11 pagesGrundfos - SLV 80 80 75 2 51D CBelen GelosPas encore d'évaluation

- Effect of Pile Foundation On Groundwater FlowDocument18 pagesEffect of Pile Foundation On Groundwater Flowu19n6735Pas encore d'évaluation

- Design Details of Sewage Treatment Plan With SBR PDFDocument8 pagesDesign Details of Sewage Treatment Plan With SBR PDFali ahmadiPas encore d'évaluation

- Indian Physical EnvironmentDocument43 pagesIndian Physical EnvironmentSudhakar Kothapalli100% (1)

- JETTY Preliminary Design ReportDocument137 pagesJETTY Preliminary Design Reporttsuak91% (11)

- GM 2016Document213 pagesGM 2016justusfr4ntzPas encore d'évaluation

- Cleaning Procedures For MoldDocument10 pagesCleaning Procedures For MoldOlaolu SaeedPas encore d'évaluation

- Wastewater Treatment Process of Maynilad Water ServicesDocument9 pagesWastewater Treatment Process of Maynilad Water ServicesEjay AbantePas encore d'évaluation

- Water Softeners Residential 9100SXT Valve Softeners US ManualDocument12 pagesWater Softeners Residential 9100SXT Valve Softeners US ManualPromagEnviro.comPas encore d'évaluation

- Frog Farming 00Document4 pagesFrog Farming 00api-3704111Pas encore d'évaluation

- Kabul DR - Shahid PDFDocument14 pagesKabul DR - Shahid PDFahabbasiPas encore d'évaluation

- Visio-PFD A3 Revisi - VSDXDocument1 pageVisio-PFD A3 Revisi - VSDXrani rafiPas encore d'évaluation

- Graphene Oxide and Its Application As An Adsorbent For Wastewater Treatment PDFDocument33 pagesGraphene Oxide and Its Application As An Adsorbent For Wastewater Treatment PDFThanh Nguyen100% (1)

- Assessing The Spatial Distribution of Groundwater Quality of Addis Ababa City by Using Geographical Information Systems.Document18 pagesAssessing The Spatial Distribution of Groundwater Quality of Addis Ababa City by Using Geographical Information Systems.Premier PublishersPas encore d'évaluation

- Analysis Modeling River Meandering Crosato2008PHDThesisDocument268 pagesAnalysis Modeling River Meandering Crosato2008PHDThesisPranavPas encore d'évaluation

- ME44001 17 18 S2 Tutorial 1Document30 pagesME44001 17 18 S2 Tutorial 1Tsz Chun YuPas encore d'évaluation

- Final Exam YOUTH 14 - V2 - Answer KeyDocument3 pagesFinal Exam YOUTH 14 - V2 - Answer KeyDanii ArbelaezPas encore d'évaluation

- Basi Calculation For Pump Tank SelectionDocument28 pagesBasi Calculation For Pump Tank SelectionSameera LakmalPas encore d'évaluation

- User Manual Project Registration v6Document23 pagesUser Manual Project Registration v6Sasta LalaPas encore d'évaluation

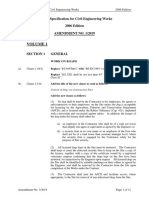

- General Specification For Civil Engineering Works 2006 Edition AMENDMENT NO. 1/2019Document11 pagesGeneral Specification For Civil Engineering Works 2006 Edition AMENDMENT NO. 1/2019ryanPas encore d'évaluation