Académique Documents

Professionnel Documents

Culture Documents

Grinding Wheel Replacement

Transféré par

Ashok SureshTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Grinding Wheel Replacement

Transféré par

Ashok SureshDroits d'auteur :

Formats disponibles

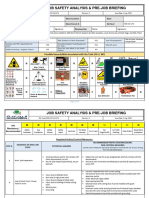

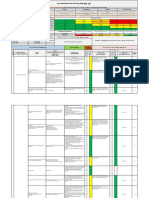

Job Safety Analysis Form

JSA #: Prepared by:

Procedure Reference: Reviewed & Approved by:

Job Description: Replace grinding wheel on bench grinder Unit Name: Date:

Responsibilities:

Tasks: Break the job Hazards: What hazards did you find for

Step Controls: Who will be

down into a logical each task?

# What controls are in place or will you put in place? responsible for each

sequence of steps

of those controls?

Verify Bench grinder is Electrical shock Pull the plug out from the socket

not plugged in Pull the plug not the cord Mechanic

1

Remove the old / Eye and abrasion injury Press and hold locking pin and loosen the nut using proper spanner Mechanic

damaged wheel from Wear eye protection and work gloves

the Bench grinder using

wheel opening tool

2

Inspect the new Crack on the wheel Do not use wheels which have been dropped or otherwise damaged. Mechanic

grinding wheel for date Grinding wheel RPM not matching with Do not use a grinding wheel that has rated less speed than the speed

of manufacturing date , the bench grinder speed of the bench grinder.

manufacturer, Improper size and shape Check the speed governing device in the bench grinder for proper

compatibility and the functioning.

mounting flanges for

good condition

3

Install new wheel and Wheel may drop down and get Do not use wheels which have been dropped Mechanic

tighten the nut using damaged. Tighten nut only enough to hold the wheel firmly

proper tool Using excessive pressure when

mounting can damage the wheel

4

Tick and discuss

the lifesaving rules

which are related

to the job during

meeting

Job Safety Analysis Form

Check cord, plug, Damaged cord and plug Repair or replace, if found damaged

wheel guard etc. for Wheel guard missing or not adjusted Install wheel guard/adjust as required. Mechanic

damage properly

5

Tick and discuss

the lifesaving rules

which are related

to the job during

meeting

Vous aimerez peut-être aussi

- Annual Tool Box Meeting Plan ScheduleDocument3 pagesAnnual Tool Box Meeting Plan Scheduletoxicity23Pas encore d'évaluation

- E-Fact 14 - Hazards and Risks Associated With Manual Handling in The WorkplaceDocument10 pagesE-Fact 14 - Hazards and Risks Associated With Manual Handling in The WorkplaceDeby Damayanti SupardiPas encore d'évaluation

- WEEKLY EHS REPORTDocument15 pagesWEEKLY EHS REPORTBryt PaintsilPas encore d'évaluation

- JSA-174.Confined Space EntryDocument3 pagesJSA-174.Confined Space Entryghazi4u100% (1)

- Department of Health.: Occupational Health & Safety PolicyDocument10 pagesDepartment of Health.: Occupational Health & Safety PolicyMuhammad SaeedPas encore d'évaluation

- 06-F02 Training Needs AnalysisDocument36 pages06-F02 Training Needs AnalysisSn AhsanPas encore d'évaluation

- PTW Tracking Log: Allied Engineering Construction Sdn. Bhd. Urc Engineering Sdn. BHDDocument1 pagePTW Tracking Log: Allied Engineering Construction Sdn. Bhd. Urc Engineering Sdn. BHDviniPas encore d'évaluation

- Inspection - Forms - Lanyard - Body HardnessDocument1 pageInspection - Forms - Lanyard - Body Hardnesspetrus jacobPas encore d'évaluation

- Grinding SafetyDocument19 pagesGrinding Safetyjaykotak12345Pas encore d'évaluation

- Contractor EHS Requirements StandardDocument25 pagesContractor EHS Requirements Standardamitbanerjee51Pas encore d'évaluation

- Site safety inspection ladder scaffold checklistDocument1 pageSite safety inspection ladder scaffold checklistRickPas encore d'évaluation

- Declaration Penalty Matrix PDFDocument3 pagesDeclaration Penalty Matrix PDFrohit jaiswalPas encore d'évaluation

- EHS is Everyone’s ResponsibilityDocument88 pagesEHS is Everyone’s ResponsibilityMarthaPas encore d'évaluation

- Sercel Hse PolicyDocument1 pageSercel Hse PolicyddwererPas encore d'évaluation

- Chemicals Can: Safe Handling of ChemicalsDocument1 pageChemicals Can: Safe Handling of ChemicalsJavier Quintero SaavedraPas encore d'évaluation

- SAB Defensive Driving Driver's HandbookDocument20 pagesSAB Defensive Driving Driver's HandbookaymenmoatazPas encore d'évaluation

- 5 Years Road Map: Objectives TargetDocument3 pages5 Years Road Map: Objectives TargetRajesh VermaPas encore d'évaluation

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathPas encore d'évaluation

- Work Equipment ChecklistDocument4 pagesWork Equipment ChecklistcddesignsPas encore d'évaluation

- EHS Inspection ReportDocument7 pagesEHS Inspection ReportchepurthiPas encore d'évaluation

- 2 Consequence Management ProcedureDocument10 pages2 Consequence Management ProcedureriyazaliPas encore d'évaluation

- Risk Assessment: Kitchen - HomeDocument5 pagesRisk Assessment: Kitchen - HomesonofoddinPas encore d'évaluation

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabPas encore d'évaluation

- 8.8 5 Respiratory Protection Management Measures (At HSSE P 8 43V0 2022) ReleaseDocument14 pages8.8 5 Respiratory Protection Management Measures (At HSSE P 8 43V0 2022) ReleaseGeyko RuslanPas encore d'évaluation

- JSA 06 (Rebar Assembly Work)Document8 pagesJSA 06 (Rebar Assembly Work)abdulthahseen007100% (1)

- Safe Manual Handling BookletDocument17 pagesSafe Manual Handling Bookletbilo1984Pas encore d'évaluation

- Crane Safety Tool Box TalkDocument2 pagesCrane Safety Tool Box Talksathees4329Pas encore d'évaluation

- First Aid Kit Inspection Check List FormDocument1 pageFirst Aid Kit Inspection Check List Formmuhammad imtiazPas encore d'évaluation

- 3 Hazard CommunicationDocument9 pages3 Hazard CommunicationAlaa AllamPas encore d'évaluation

- JSa For Glass FixingDocument17 pagesJSa For Glass FixingShekh BabulPas encore d'évaluation

- Specific Risk Assessment: Project: Construction of Bonifacio Global City - Ortigas Center Road Link ProjectDocument12 pagesSpecific Risk Assessment: Project: Construction of Bonifacio Global City - Ortigas Center Road Link Projectjason cepadaPas encore d'évaluation

- Incidents By Root Causes Tools Equipment TrainingDocument5 pagesIncidents By Root Causes Tools Equipment TrainingvictorPas encore d'évaluation

- Noise Awarness TrainingDocument12 pagesNoise Awarness TrainingSafety SteelallyPas encore d'évaluation

- HSE Training MatrixDocument3 pagesHSE Training MatrixNasrullah JanPas encore d'évaluation

- P.S.E Engineering & Construction Pte LTD Vehicle Pre-Start ChecklistDocument5 pagesP.S.E Engineering & Construction Pte LTD Vehicle Pre-Start ChecklistWunna LwinPas encore d'évaluation

- OHSAS180012007 Health Safety Management System ManualDocument36 pagesOHSAS180012007 Health Safety Management System ManualCandra Wae Lah100% (3)

- SOP For Tree Cutting at HPCL UNNAODocument3 pagesSOP For Tree Cutting at HPCL UNNAOamankumar100% (1)

- Check-List Hse: Evaluation (+) : Ok (-) : Not Ok ( ) : N/ADocument3 pagesCheck-List Hse: Evaluation (+) : Ok (-) : Not Ok ( ) : N/AKouroufia Diaby GassammaPas encore d'évaluation

- RISK ASSESSMENT FOR SWRO PLANT FOUNDATION WORKDocument7 pagesRISK ASSESSMENT FOR SWRO PLANT FOUNDATION WORKabhinav djPas encore d'évaluation

- Safety Practices for Compressed Gas CylindersDocument4 pagesSafety Practices for Compressed Gas CylindersjeyesbelmenPas encore d'évaluation

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- Lathe Operation SafetyDocument1 pageLathe Operation Safetymustafa_staj8367Pas encore d'évaluation

- Hazard Communication and Chemical Safety Guideline: ApprovalDocument14 pagesHazard Communication and Chemical Safety Guideline: ApprovalJayson S. VerdeflorPas encore d'évaluation

- Ar Intp Bab 3 - 94Document1 pageAr Intp Bab 3 - 94IqbalStra25Pas encore d'évaluation

- QHSE DashboardDocument5 pagesQHSE DashboardParure DoréePas encore d'évaluation

- Monthly Safety ReportDocument2 pagesMonthly Safety ReportPrakash PalaiPas encore d'évaluation

- Jsa SMDB Maintenence...Document3 pagesJsa SMDB Maintenence...ASLAM MULANIPas encore d'évaluation

- Health and Safety Risk AssessmentDocument10 pagesHealth and Safety Risk AssessmentAnwar MohamedPas encore d'évaluation

- 11 - Drilling Machine ChecklistDocument1 page11 - Drilling Machine ChecklistAfzal AkhtarPas encore d'évaluation

- Daily Site Inspection ChecklistDocument2 pagesDaily Site Inspection ChecklistRavi thokalPas encore d'évaluation

- Safe Lifting Procedure 2Document6 pagesSafe Lifting Procedure 2angelaPas encore d'évaluation

- PRO-00861 Corporate Safety - Cranes and Lifting Equipment Safety ProcedureDocument30 pagesPRO-00861 Corporate Safety - Cranes and Lifting Equipment Safety ProcedureGustavo Alonso BerettaPas encore d'évaluation

- HSE Manual NRC GroupDocument65 pagesHSE Manual NRC GroupPurnomo JarodPas encore d'évaluation

- January HSE Management PlanDocument1 pageJanuary HSE Management PlanMohammed AhmedPas encore d'évaluation

- Accident Investigation: Introduction To EffectiveDocument28 pagesAccident Investigation: Introduction To EffectiveBabbooPas encore d'évaluation

- EHS PlanDocument37 pagesEHS PlanVishal TiwariPas encore d'évaluation

- Near Miss or Injury ReportingDocument1 pageNear Miss or Injury ReportingIgor PetkovPas encore d'évaluation

- QY360 Blasting Wheel Operation ManualDocument15 pagesQY360 Blasting Wheel Operation ManualDecho KrachevPas encore d'évaluation

- NPS - Unit 102 ScopeDocument2 pagesNPS - Unit 102 ScopeAshok SureshPas encore d'évaluation

- Kemper Catalog FlowControl Oct2013Document20 pagesKemper Catalog FlowControl Oct2013jesdcp7Pas encore d'évaluation

- Belzona 5111: Instructions For UseDocument2 pagesBelzona 5111: Instructions For UsePedro RuizPas encore d'évaluation

- Third Party Inspection ScopeDocument1 pageThird Party Inspection ScopeAshok SureshPas encore d'évaluation

- BD-28 (B24) IomDocument39 pagesBD-28 (B24) Iomkrishan_raj_1Pas encore d'évaluation

- ShowdocwDocument7 pagesShowdocwFahad KhanPas encore d'évaluation

- Technical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarDocument2 pagesTechnical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarAshok SureshPas encore d'évaluation

- P16MBA3Document4 pagesP16MBA3Ashok SureshPas encore d'évaluation

- P16MBA4Document2 pagesP16MBA4Ashok SureshPas encore d'évaluation

- Drilling Chokes BrochureDocument12 pagesDrilling Chokes BrochureAshok SureshPas encore d'évaluation

- Demco DM Iom PDFDocument24 pagesDemco DM Iom PDFAshok SureshPas encore d'évaluation

- Adapter CouplingDocument48 pagesAdapter CouplingIan_SmythPas encore d'évaluation

- Briggs & Stratton Small Engine Reassembly Visual GuideDocument40 pagesBriggs & Stratton Small Engine Reassembly Visual GuideAshok SureshPas encore d'évaluation

- Demco DM Iom PDFDocument24 pagesDemco DM Iom PDFAshok SureshPas encore d'évaluation

- Choke Maintnance PDFDocument42 pagesChoke Maintnance PDFbtrasla9023Pas encore d'évaluation

- Masts/Derricks/Substructures: Api RP 4GDocument12 pagesMasts/Derricks/Substructures: Api RP 4GegyinspectoryahooPas encore d'évaluation

- Cost Breakup For SGS Second PumpDocument1 pageCost Breakup For SGS Second PumpAshok SureshPas encore d'évaluation

- PVCMC 0501 Us PDFDocument40 pagesPVCMC 0501 Us PDFAshok SureshPas encore d'évaluation

- Pressure Control EquipmentDocument169 pagesPressure Control EquipmentAshok SureshPas encore d'évaluation

- 4th 120316074120 Phpapp02Document27 pages4th 120316074120 Phpapp02Ahmed ghPas encore d'évaluation

- BD-28 (B24) IomDocument39 pagesBD-28 (B24) Iomkrishan_raj_1Pas encore d'évaluation

- Welded Flanged Spool Design CalculationDocument1 pageWelded Flanged Spool Design CalculationAshok SureshPas encore d'évaluation

- Cameron Part Numbering SystemDocument10 pagesCameron Part Numbering SystemAshok SureshPas encore d'évaluation

- 12 Drilling PreventersDocument82 pages12 Drilling PreventersDavid Kusuma100% (1)

- Fastener HandoutDocument32 pagesFastener HandoutRaifan RaizerPas encore d'évaluation

- Ailgent Vs Pro - BrochureDocument6 pagesAilgent Vs Pro - BrochureTasha MorrisPas encore d'évaluation

- Stainless Steel Sheet Metal SpecificationsDocument2 pagesStainless Steel Sheet Metal SpecificationsAshok SureshPas encore d'évaluation

- Vciom 06204 enDocument19 pagesVciom 06204 enAshok SureshPas encore d'évaluation

- Hercules Production Solutions Catalog PDFDocument28 pagesHercules Production Solutions Catalog PDFPedro Antonio Mejia SuarezPas encore d'évaluation

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizPas encore d'évaluation

- SBJD Rnp-X-Rwy-18 Iac 20210520Document1 pageSBJD Rnp-X-Rwy-18 Iac 20210520Thiago MirandaPas encore d'évaluation

- Goal 2020 UpdatedDocument192 pagesGoal 2020 UpdatedVishalPas encore d'évaluation

- Beech 1900: Professional Pilot and Technician Training ProgramsDocument11 pagesBeech 1900: Professional Pilot and Technician Training ProgramsCarlos Daniel Tantacalle BonifacioPas encore d'évaluation

- B737NG Inspections Guide. TRAINING ONLYDocument31 pagesB737NG Inspections Guide. TRAINING ONLYMihalcea CristianPas encore d'évaluation

- HLO Helicopter Landing OfficerDocument136 pagesHLO Helicopter Landing OfficerMauricio MendezPas encore d'évaluation

- Type Acceptance Report: Cirrus SR20, SR22 and SR22TDocument17 pagesType Acceptance Report: Cirrus SR20, SR22 and SR22TPhilPas encore d'évaluation

- Company Maintenance Manual Lionair (JT) Vs Batikair (Id)Document34 pagesCompany Maintenance Manual Lionair (JT) Vs Batikair (Id)Siti Rizka FauziyahPas encore d'évaluation

- VVCT Terminal Charts and Arrival ProceduresDocument12 pagesVVCT Terminal Charts and Arrival ProceduresNguyen MinhPas encore d'évaluation

- Weight and Balance Manual: Reference: VJC A330-300 Fleet WBM Issue Date: 09 Mar 22Document456 pagesWeight and Balance Manual: Reference: VJC A330-300 Fleet WBM Issue Date: 09 Mar 22Hung Nguyen100% (1)

- 1953 3 EngDocument29 pages1953 3 EngTatePas encore d'évaluation

- TCDS EASA - IM - .A.090 - PA34-220T - Issue 7Document15 pagesTCDS EASA - IM - .A.090 - PA34-220T - Issue 7Anggarda Bagus SejatiPas encore d'évaluation

- Jenis Pesawat Kapasitas MTOW (KG)Document7 pagesJenis Pesawat Kapasitas MTOW (KG)AtengPas encore d'évaluation

- A31SO - Rev13 Embraer 120Document12 pagesA31SO - Rev13 Embraer 120Jonnathan LudeñaPas encore d'évaluation

- Easa - Ad - 2019-0067R1 - 1 (Ali 53-11-05 - SB 53-1410)Document4 pagesEasa - Ad - 2019-0067R1 - 1 (Ali 53-11-05 - SB 53-1410)Alejandro RamirezPas encore d'évaluation

- Aircraft Major Structural Stresses Copy of DiscussionDocument34 pagesAircraft Major Structural Stresses Copy of DiscussionangeloPas encore d'évaluation

- Structures Training Manual Rev0Document52 pagesStructures Training Manual Rev0andiee trader100% (2)

- Aircraft Weighing ReportsDocument31 pagesAircraft Weighing ReportsEdwar ZulmiPas encore d'évaluation

- Part 39Document17 pagesPart 39mohamedkhderPas encore d'évaluation

- Component Maintenance Manual With Illustrated Parts List Main Landing Gear Brake Assembly Part Number 2-1707Document170 pagesComponent Maintenance Manual With Illustrated Parts List Main Landing Gear Brake Assembly Part Number 2-1707TAR AEROLINEAS100% (1)

- AFM SyphaxDocument1 078 pagesAFM SyphaxnashPas encore d'évaluation

- AOPA Lesson PlansDocument33 pagesAOPA Lesson PlansKostas RossidisPas encore d'évaluation

- Record of Construction and Equipment for Oil TankersDocument8 pagesRecord of Construction and Equipment for Oil TankersNestor MospanPas encore d'évaluation

- Hyd y Resr Over HeatDocument2 pagesHyd y Resr Over HeatSuman BajracharyaPas encore d'évaluation

- 22 Autopilot TB20Document84 pages22 Autopilot TB20Lu CasaPas encore d'évaluation

- Vertical IndicatorDocument9 pagesVertical IndicatorKent Louie RocabertePas encore d'évaluation

- Assembly Manual: Semi Scale Yak-54S, ARF 73"Document45 pagesAssembly Manual: Semi Scale Yak-54S, ARF 73"mohamed sidkyPas encore d'évaluation

- SB 24 056 01Document3 pagesSB 24 056 01Bony KlausPas encore d'évaluation

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Yuri SilvaPas encore d'évaluation

- A380: Development of The Flight Controls: Claude LELAIEDocument5 pagesA380: Development of The Flight Controls: Claude LELAIEJerome Cardenas TablacPas encore d'évaluation

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument5 pagesAlert Operators Transmission - Aot: Customer Services DirectorateEray KoçPas encore d'évaluation