Académique Documents

Professionnel Documents

Culture Documents

Cleaning Storage Tanks Safely

Transféré par

Eslam Ismaeel50%(2)50% ont trouvé ce document utile (2 votes)

477 vues5 pagesThis document provides requirements for cleaning storage tanks. It applies to storage tanks for hydrocarbons, chemicals, and effluent including underground and refrigerated tanks. Managers and contract holders are responsible for following these requirements. The requirements establish controls and procedures to manage risks like fire, explosion, asphyxiation, and static electricity during tank cleaning. Businesses must implement the requirements by December 31, 2013.

Description originale:

Cleaning of Storage Tanks

Titre original

2- Cleaning of Storage Tanks

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides requirements for cleaning storage tanks. It applies to storage tanks for hydrocarbons, chemicals, and effluent including underground and refrigerated tanks. Managers and contract holders are responsible for following these requirements. The requirements establish controls and procedures to manage risks like fire, explosion, asphyxiation, and static electricity during tank cleaning. Businesses must implement the requirements by December 31, 2013.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

50%(2)50% ont trouvé ce document utile (2 votes)

477 vues5 pagesCleaning Storage Tanks Safely

Transféré par

Eslam IsmaeelThis document provides requirements for cleaning storage tanks. It applies to storage tanks for hydrocarbons, chemicals, and effluent including underground and refrigerated tanks. Managers and contract holders are responsible for following these requirements. The requirements establish controls and procedures to manage risks like fire, explosion, asphyxiation, and static electricity during tank cleaning. Businesses must implement the requirements by December 31, 2013.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

Cleaning of Storage Tanks

Shell HSSE & SP Control Framework Mandatory

Personal Safety Manual Restricted

Version 2, December 2009

Purpose

To manage the Risks associated with the cleaning of Storage Tanks.

Who is this for?

Managers; and

Contract Holders.

What situations are/are not covered

This manual section applies to:

Storage Tanks for hydrocarbons, chemicals and effluent, including underground and

refrigerated tanks.

This manual section does not apply to:

Cavern storage; and

Pressure vessels.

Requirements

The Manager is Accountable for requirements 1 to 3:

1. Apply the Hierarchy Of Control as follows:

First: Minimise the need for or reduce the frequency of tank cleaning.

Second: Use Online Cleaning methods that do not require the opening of, or entry into,

tanks.

Third: Use mechanical cleaning options that do not require people to enter tanks.

Fourth: Allow personnel entry and manual cleaning of tanks where supported by a

documented Risk Assessment. Reference Confined Space Work.

2. Establish and maintain Procedures for tank cleaning in accordance with

Internationally Recognised Standards.

2.1. Procedures must include:

2.1.1. Pre-cleaning inspection to assess the tank contents and roof condition.

2.1.2. Precautions during gas freeing to include vehicle and personnel access

restrictions, control of ignition sources and weather conditions.

2.1.3. Emergency Response arrangements during tank cleaning.

3. Apply the Permit to Work for all tank cleaning and recognise, as a minimum, the

Hazards:

o fire and explosion;

o toxic substances and asphyxiation;

o static electricity due to steam and water jetting and grit blasting; and

o pyrophoric scale.

The Contract Holder is Accountable for requirement 4:

4. Select a specialist Contractor for tank cleaning in line with Contractor HSSE

Management.

Implementation Deadlines

Businesses must now implement requirements of this manual section as soon as practicable,

with risk-based prioritisation against other activities.

Gap assessment and closure plan: Developed by the Businesses

Latest date: June 30, 20010

Requirements into effect: Developed by the Businesses

Latest date: December 31, 2013

Assurance Protocol

Requirement in manual Key Words Survey Questions Field

section Observatio

ns

&

Document

ation,

Testing

Purpose Cleaning Review tank

To manage the Risks associated tanks cleaning

with the cleaning of storage records

tanks. Contractor

documentat

Who is this for? ion

Managers; and Interview

Contract Holders. Managers,

Contract

What situations are/are not Holders

covered?

This manual section applies to:

Storage tanks for

hydrocarbons, chemicals

and effluent, including

underground and

refrigerated tanks.

This manual section does not

apply to:

cavern storage; and

pressure vessels.

The Manager is Accountable for requirements 1-3 below:

Requirement in manual Key Words Survey Questions Field

section Observatio

ns

&

Document

ation,

Testing

1. Apply the Hierarchy of Control How have you assessed Risks Inspect

Control as follows: Hierarchy during tank cleaning operations planned

First: Minimise the need for Application and applied the Hierarchy of maintenanc

or reduce the frequency of Control to minimise them? e schedules

tank cleaning. Tank

Second: Use Online cleaning

Cleaning methods that do Risk

not require the opening of, Assessment

or Entry into, tanks. documents

Third: Use mechanical Method

cleaning options that do not Statements

require people to enter / Job

tanks. Hazard

Fourth: Allow personnel Analysis

Entry and manual cleaning

of tanks where supported

by a documented Risk

Assessment. Reference

Confined Space Work.

2. Establish and Maintain Tank

Procedures for tank cleaning

cleaning in accordance Procedures

with Internationally

Recognised Standards.

2.1. Procedures must Procedures What are the local Procedures Inspect gas

include: Standards for tank cleaning operations, free

2.1.1. Pre-cleaning what do they cover and how certificates

Inspection to are they documented? Review

assess the tank How do you know that your Emergency

contents and roof local Procedures comply with all Response

condition. appropriate Internationally Plans and

recognised standards? equipment

2.1.2. Precautions during

gas freeing to

include vehicle and

personnel access

restrictions,

control of ignition

sources and

weather

conditions.

2.1.3. Emergency

Response

arrangements

during tank

cleaning.

3. Apply the Permit to Work PTW How does your Permit to Work Review

Requirement in manual Key Words Survey Questions Field

section Observatio

ns

&

Document

ation,

Testing

for all tank cleaning and (PTW) system cover work on actual PTW

recognise, as a tank cleaning operations? to ensure

minimum, the Hazards: What Hazards are recognised compliance

o fire and explosion; and what Controls does the with

o toxic substances and PTW require? requirement

asphyxiation; s outlined in

o static electricity due to section 3

steam and water jetting

and grit blasting; and

o pyrophoric scale.

The Contract Holder is Accountable for requirement 4 below:

Requirement in manual Key Words Survey Questions Field

section Observatio

ns

&

Document

ation,

Testing

4. Select a competent Contractor How do you select your tank Review

Contractor for tank selection cleaning Contractors and assess contract

cleaning, in line with their Competence? documentat

Contractor HSSE ion

Management. Pre-

selection

assessment

s and

Competenc

e

documentat

ion,

including

licences

Vous aimerez peut-être aussi

- Confined Space Safety Presentation OSDocument25 pagesConfined Space Safety Presentation OSSajjad AfzalPas encore d'évaluation

- Chemical Hazard Bulletin: OPT D 1127Document1 pageChemical Hazard Bulletin: OPT D 1127HaleemUrRashidBangashPas encore d'évaluation

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document5 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)bryanPas encore d'évaluation

- Confined Space Entry: Maurice Sanders Qhse Consultant 973-3-697-9344 966-50-365-7914Document26 pagesConfined Space Entry: Maurice Sanders Qhse Consultant 973-3-697-9344 966-50-365-7914Suhail Adil100% (1)

- Asphalt CHBDocument1 pageAsphalt CHBShahidPas encore d'évaluation

- Hydrojetting SafetyDocument5 pagesHydrojetting SafetyHeryPas encore d'évaluation

- Tank Cleaning Check List1Document1 pageTank Cleaning Check List1Ali AbdoulayePas encore d'évaluation

- Work Permit SystemDocument69 pagesWork Permit SystemMuhammad Tariq88% (8)

- NSRP Project: Confined Space Entry CertificateDocument1 pageNSRP Project: Confined Space Entry CertificateThanh Tung DongPas encore d'évaluation

- JSA - Blasting - EXTERNALDocument13 pagesJSA - Blasting - EXTERNALAzad pravesh khanPas encore d'évaluation

- ELECTRICAL SAFETY CHECKLISTDocument1 pageELECTRICAL SAFETY CHECKLISTnlt_admin100% (1)

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocument23 pagesJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDPas encore d'évaluation

- COSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsDocument2 pagesCOSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsPaulSwinbankPas encore d'évaluation

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocument23 pagesJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDPas encore d'évaluation

- Safety Presentation - AramcoDocument11 pagesSafety Presentation - AramcoMang Doros EsquilloPas encore d'évaluation

- Tank CleaningDocument24 pagesTank CleaningVipin Somasekharan100% (4)

- JSA - Chemical CleaningDocument4 pagesJSA - Chemical CleaningkrshhPas encore d'évaluation

- CSE Awareness TrainingDocument12 pagesCSE Awareness TrainingjahanzaibPas encore d'évaluation

- JSA HCK MOC Hot Tap Drilling Rev1Document6 pagesJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDocument1 pageHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (2)

- Common Snakes and Scorpions - EnglishDocument8 pagesCommon Snakes and Scorpions - Englishshamroz khanPas encore d'évaluation

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajPas encore d'évaluation

- 0006 - 007-Reporting of Contractor On-Job Injuries Occupational Illnesses PDFDocument10 pages0006 - 007-Reporting of Contractor On-Job Injuries Occupational Illnesses PDFIssac JohnPas encore d'évaluation

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityjoshuaPas encore d'évaluation

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Safety Hazards Associated With Oil and Gas Extraction ActivitiesDocument13 pagesSafety Hazards Associated With Oil and Gas Extraction ActivitiesAnonymous y1pIqcPas encore d'évaluation

- Ventilation For Confined SpaceDocument6 pagesVentilation For Confined SpaceWONG TSPas encore d'évaluation

- Confined SpaceDocument16 pagesConfined SpaceAbdul Moeed KalsonPas encore d'évaluation

- Petroleum-Loading Unloading Top LoadingDocument4 pagesPetroleum-Loading Unloading Top LoadingLakshmi BalaPas encore d'évaluation

- Emergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTDocument3 pagesEmergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTSyifa Ula HamidyaPas encore d'évaluation

- 9 Use of Hand Roller Compactor SafetyDocument2 pages9 Use of Hand Roller Compactor SafetyarchiePas encore d'évaluation

- 185 Eng PDFDocument1 page185 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

- 5.5.6-5 PTW Monthly Audit FormDocument1 page5.5.6-5 PTW Monthly Audit FormRizwanButtPas encore d'évaluation

- Tank Cleaning ConsiderationsDocument1 pageTank Cleaning ConsiderationsAdele PollardPas encore d'évaluation

- PPE CampaignDocument9 pagesPPE CampaignAbdulKatherPas encore d'évaluation

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document10 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)mozammilPas encore d'évaluation

- CSM by AramcoDocument3 pagesCSM by AramcoSharifullahPas encore d'évaluation

- JHA ANALYSIS SCALE REMOVAL VESSELDocument2 pagesJHA ANALYSIS SCALE REMOVAL VESSELRiyadh SalehPas encore d'évaluation

- Rig Specific Emergency Response Plan Rev1Document33 pagesRig Specific Emergency Response Plan Rev1bilou100% (1)

- Sinai Field Drilling HSE Survey ChecklistDocument5 pagesSinai Field Drilling HSE Survey ChecklistnadyPas encore d'évaluation

- 01 Camp G.I. 0298 - 010Document73 pages01 Camp G.I. 0298 - 010iftikhar ahmadPas encore d'évaluation

- Cutting HandlingDocument25 pagesCutting HandlingWalid AmdouniPas encore d'évaluation

- Job Safety Analysis - Work SheetDocument4 pagesJob Safety Analysis - Work Sheetrickie7809Pas encore d'évaluation

- Safety Talk On-Safety During ShutdownDocument10 pagesSafety Talk On-Safety During Shutdownchakri4all100% (1)

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- Method Statement DPE GL1 Cooling Water Line CleaningDocument15 pagesMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaPas encore d'évaluation

- 658 - Eng - Sigma Phenguard 935 BaseDocument1 page658 - Eng - Sigma Phenguard 935 BasetariquePas encore d'évaluation

- Confined Space Entry Rescue Plan 1Document11 pagesConfined Space Entry Rescue Plan 1patrick ruwonaPas encore d'évaluation

- Tank Cleaning ProcessDocument7 pagesTank Cleaning ProcessgbogboiwePas encore d'évaluation

- Confined Space Entry Procedure for OCCPL Hyco ProjectDocument8 pagesConfined Space Entry Procedure for OCCPL Hyco ProjectKrishna Kumar SasidharanPas encore d'évaluation

- TANK REPAIR SAFETY STEPSDocument19 pagesTANK REPAIR SAFETY STEPSPerwez21100% (1)

- Confined SpaceDocument31 pagesConfined SpacegshdavidPas encore d'évaluation

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SPas encore d'évaluation

- JSA Excavation for Sabkha Water Filling StationDocument5 pagesJSA Excavation for Sabkha Water Filling StationDelta akathehuskyPas encore d'évaluation

- 3263 - Transfer of Diesel JSA-R76!02!202-01Document1 page3263 - Transfer of Diesel JSA-R76!02!202-01cmrig74Pas encore d'évaluation

- Indian Oil and Gas Canada Drilling Waste ChecklistDocument12 pagesIndian Oil and Gas Canada Drilling Waste Checklistsami NaPas encore d'évaluation

- Part I - 04 Work Permit SystemDocument7 pagesPart I - 04 Work Permit Systemsalah abddayemPas encore d'évaluation

- RA Hydro JettingDocument16 pagesRA Hydro Jettingnaveed100% (3)

- ConstructioRiskAssessment of Riser InstallationDocument13 pagesConstructioRiskAssessment of Riser InstallationMario JacobsonPas encore d'évaluation

- NDT Penetran ProcedureDocument15 pagesNDT Penetran ProcedureBayu PutraPas encore d'évaluation

- SDP Reflective AccountDocument1 pageSDP Reflective AccountEslam IsmaeelPas encore d'évaluation

- 2 Dynamicsofecosystem 121129013419 Phpapp01Document35 pages2 Dynamicsofecosystem 121129013419 Phpapp01Eslam IsmaeelPas encore d'évaluation

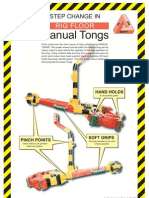

- Tong SafetyDocument1 pageTong SafetyAhmad Ghazee67% (3)

- PMP Question Bank PDFDocument16 pagesPMP Question Bank PDFRyan Li67% (15)

- Fa 248 1003 PDFDocument168 pagesFa 248 1003 PDFEslam IsmaeelPas encore d'évaluation

- 01 EcologyDocument26 pages01 EcologyEslam IsmaeelPas encore d'évaluation

- ISO 45001 and Its Power For GoodDocument1 pageISO 45001 and Its Power For GoodEslam IsmaeelPas encore d'évaluation

- HSE FRM-18 HSE Flyer PDFDocument1 pageHSE FRM-18 HSE Flyer PDFEslam IsmaeelPas encore d'évaluation

- HSE AbbreviationsDocument1 pageHSE AbbreviationsEslam IsmaeelPas encore d'évaluation

- Aramco Test PDFDocument13 pagesAramco Test PDFEslam IsmaeelPas encore d'évaluation

- Injury Statistics SheetDocument4 pagesInjury Statistics SheetEslam IsmaeelPas encore d'évaluation

- Drill Floor Safety - ArabicDocument22 pagesDrill Floor Safety - ArabicEslam IsmaeelPas encore d'évaluation

- Drill floor safety best practicesDocument22 pagesDrill floor safety best practicesPaul100% (2)

- Over 60Document1 pageOver 60Eslam IsmaeelPas encore d'évaluation

- Tong SafetyDocument1 pageTong SafetyAhmad Ghazee67% (3)

- Lenovo BranchesDocument3 pagesLenovo BranchesEslam IsmaeelPas encore d'évaluation

- Verification Request FormDocument2 pagesVerification Request FormEslam IsmaeelPas encore d'évaluation

- Auditor/Lead Auditor Training Course: Based On OHSAS 18001:2007Document69 pagesAuditor/Lead Auditor Training Course: Based On OHSAS 18001:2007Eslam IsmaeelPas encore d'évaluation

- Theory Slides 3Document86 pagesTheory Slides 3Eslam IsmaeelPas encore d'évaluation

- Radiographic TestingDocument47 pagesRadiographic TestingsmrndrdasPas encore d'évaluation

- Radiation RADocument480 pagesRadiation RAEslam IsmaeelPas encore d'évaluation

- Drilling Course Introduction To CementingDocument14 pagesDrilling Course Introduction To CementingEslam IsmaeelPas encore d'évaluation

- Theory Slides 2Document59 pagesTheory Slides 2Eslam IsmaeelPas encore d'évaluation

- Contractor Companies Listed With Adce PDFDocument12 pagesContractor Companies Listed With Adce PDFEslam Ismaeel100% (1)

- Theory Slides 1Document82 pagesTheory Slides 1Eslam IsmaeelPas encore d'évaluation

- Industrial-Process Control Valves: BSI Standards PublicationDocument22 pagesIndustrial-Process Control Valves: BSI Standards PublicationEslam Ismaeel100% (1)

- Battleships + Carriers of The Terran Confederation - Wing CommanderDocument7 pagesBattleships + Carriers of The Terran Confederation - Wing CommanderknavealphaPas encore d'évaluation

- Pani Panchayat Operational ManualDocument168 pagesPani Panchayat Operational ManualPreeti SubudhiPas encore d'évaluation

- EN 1000x2 Machine SpecificationsDocument4 pagesEN 1000x2 Machine SpecificationsvinodraiengPas encore d'évaluation

- Protect Tanks From Overpressure and Vacuum PDFDocument7 pagesProtect Tanks From Overpressure and Vacuum PDFJohn SmithPas encore d'évaluation

- SC 15TW-Stainless Steel 13Document44 pagesSC 15TW-Stainless Steel 13roherneville100% (1)

- Black Dragon Ninjitsu Espionage Level 2 Camp HandbookDocument15 pagesBlack Dragon Ninjitsu Espionage Level 2 Camp HandbookRon CollinsPas encore d'évaluation

- FM 100-2-3 The Soviet Army - Troops, Organization, and EquipmentDocument454 pagesFM 100-2-3 The Soviet Army - Troops, Organization, and EquipmentBob Andrepont100% (8)

- Memoir 44 Memoir 44 Guia de Regras Com 102983Document7 pagesMemoir 44 Memoir 44 Guia de Regras Com 102983Mandarini SilvaPas encore d'évaluation

- Panzer Aces No.29Document66 pagesPanzer Aces No.29Joppito100% (10)

- Use of Eductors With Ballast Water Management Systems Making Use of Active SubstancesDocument7 pagesUse of Eductors With Ballast Water Management Systems Making Use of Active Substancesmister_no34Pas encore d'évaluation

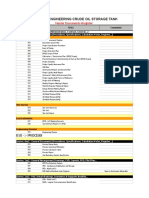

- Crude Oil Storage Tank MDRDocument5 pagesCrude Oil Storage Tank MDRAtty Atty50% (2)

- FortressDocument36 pagesFortressCarlos Mejia Fernandez100% (16)

- Denmark Team 1 List 2Document3 pagesDenmark Team 1 List 2Pablo GallegoPas encore d'évaluation

- SP ArtilleryDocument96 pagesSP ArtilleryPETR SMITH100% (2)

- Total Warfare ChangesDocument12 pagesTotal Warfare ChangesPanchito VillaPas encore d'évaluation

- Soviet Operational Art and Tactics in the 1930sDocument36 pagesSoviet Operational Art and Tactics in the 1930sCan't hidePas encore d'évaluation

- 1944 22Document217 pages1944 22nofail eastPas encore d'évaluation

- European Ground ForcesDocument115 pagesEuropean Ground Forcesjb2ookworm100% (8)

- Arsenal For Agression - Armored Vehicles of The Warsaw PactDocument90 pagesArsenal For Agression - Armored Vehicles of The Warsaw PactType99100% (17)

- British Commando 4345Document6 pagesBritish Commando 4345donpeppe1Pas encore d'évaluation

- Filler and Drain Plugs GuideDocument5 pagesFiller and Drain Plugs Guidemetin metinPas encore d'évaluation

- Nato and Warsaw Pact Force ComparisonDocument64 pagesNato and Warsaw Pact Force ComparisonKoen van den Bos100% (4)

- '65rules - Unofficial - With FAQ and ErrataDocument25 pages'65rules - Unofficial - With FAQ and ErrataChristopher MillerPas encore d'évaluation

- Ernst BarkmannDocument3 pagesErnst BarkmannFrederique FortierPas encore d'évaluation

- Steel Battalion Line of Contact Field ManualDocument38 pagesSteel Battalion Line of Contact Field ManualDecker LenardPas encore d'évaluation

- Walk Through and Weapon Desc EDF 2017Document17 pagesWalk Through and Weapon Desc EDF 2017Busted11290Pas encore d'évaluation

- Scale Military Modeler International 2017 07Document100 pagesScale Military Modeler International 2017 07Prplknite100% (5)

- P36 IngDocument29 pagesP36 IngES4891100% (1)

- Soviet Military Power 1981Document102 pagesSoviet Military Power 1981Anonymous UjXZ18NQxrPas encore d'évaluation

- Forces Flames of War ListDocument3 pagesForces Flames of War ListbenitoPas encore d'évaluation