Académique Documents

Professionnel Documents

Culture Documents

Conbextra Ep300 PDF

Transféré par

Ua AnyanhunTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Conbextra Ep300 PDF

Transféré par

Ua AnyanhunDroits d'auteur :

Formats disponibles

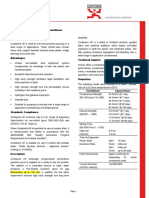

Conbextra EP300* constructive solutions

Low exotherm, epoxy resin free flow grout

Uses Properties

Suitable for use where heavy, dynamic or mobile loads are 23C 40C 50C

encountered. Particularly well suited to applications where Compressive strength

long working time and/or low exotherm properties are required BS6319 Part2:1983 :

3 days 75N/mm2 - -

! Grouting under reciprocating or rotating equipment

7 days 82N/mm2 100N/mm2 110N/mm2

! Heavy crane/transporter rails Tensile strength

BS6319 Part 7: 1983 :

! High speed turbines and centrifuges

7 days - 11N/mm 2 12.5N/mm2

! Grouting over long distances or in thick sections Flexural strength

BS 6319 Part 3: 1983:

! All applications under conditions of high ambient

7 days - 30N/mm 2 30N/mm 2

temperature

Density : 1950 kg/m

Pot life : 50 mins at 40C

Advantages

90 mins at 30C

! Low creep characteristics under sustained loading. 240 mins at 20C

Chemical resistance: Oil, grease, fats, most chemicals,

! Resistant to repetitive dynamic loads.

mild acids and alkalis, fresh and

! Non-shrink and hence ensures complete surface contact sea water.

and bond.

Note: Consult the local Fosroc Office when exposure to

! High compressive, tensile and flexural strengths. solvents or concentrated chemicals is anticipated.

! Withstands a wide range of chemicals.

Specification

Description Supplier specification

Conbextra EP300 is a low exotherm material which is All epoxy resin grouting where shown on the contract

particularly suitable where long working time is needed; for documents, shall be carried out using Conbextra EP300

large gaps (up to 300 mm) or for grouting at high ambient manufactured by Fosroc and used in accordance with the

temperatures (up to 55C). manufacturer's current data sheet.

Conbextra EP300 is a three component system consisting Performance specification

of base resin, liquid hardener and specially graded inert fillers.

All epoxy resin grouting where shown on the contract

documents must be carried out with a factory packed product.

Technical support

The hardened grout must have strengths exceeding:

Fosroc offers a comprehensive range of high performance,

Compressive strength : 80 N/mm2 at 7 days

high quality construction products all backed by BS 5750

Tensile strength : 10 N/mm2 at 7 days

certification. Fosroc offers a technical support package to

Flexural strength : 27 N/mm2 at 7 days

specifiers and contractors as well as technical advice from

staff with unrivalled experience in the industry. The storage, handling and placement of the grout must be in

strict accordance with the manufacturer's instructions.

Conbextra EP300*

Conbextra EP300*

Instructions for use Foundation surface

Preparation This must be free from oil, grease, or any loosely adherent

material. If the concrete surface is defective or has laitence, it

Underplate grouting

must be cut back to a sound base. Bolt holes or fixing pockets

The unrestrained surface area of the grout must be kept to a must be blown clean of any dirt or debris.

minimum. Generally, the gap between the perimeter

Base plate

formwork and the plate edge should not exceed 75 mm on

the pouring side and 25 mm on the opposite side. Formwork If delay is likely before placing steel base plates, it is

on the flank sides should be kept tight to the plate edge. Air recommended that the underside and edges are coated with

pressure relief holes should be provided to allow venting of Nitoprime 25* to prevent rust formation and ensure bonding

any isolated high spots. with the Conbextra EP10 grout. All metal surfaces should be

cleaned to a bright finish in accordance with Swedish Standard

Formwork

SA 2 or equal. Nitoprime 25 can be applied directly onto

The formwork should be constructed to be leak proof as newly cleaned steel surfaces even if they are damp.

Conbextra EP300 is a free flow grout. This can be achieved

Mixing

by using foam rubber strip or mastic sealant beneath the

constructed formwork and between joints. Loss of grout Pour all the contents of the hardener pack into the base

once the material is placed, but not hardened, will result in container. Mix using a slow speed power mixer until

incomplete filling of the gap. homogeneous.

For free flow grout conditions, it is essential to provide a Pour all the resultant liquid into a container with a capacity of

hydrostatic head of grout. To achieve this a feeding hopper 20 - 25 litres. Add all the filler provided and mix using a slow

should be used - please consult your local Fosroc office for speed power mixer for two minutes or until a uniform colour is

more details. achieved in the grout.

Placing

The mixed grout should be poured steadily from one side only

to eliminate the entrapment of air.

Typical on-plate shutter system

Continuous grout flow is essential.

Removable hopper: for larger pours the grout may be hand

placed or pumped into a removable hopper (trough) Sufficient grout must be available prior to starting.

The time taken to pour a batch should be regulated to the time

taken to prepare the next batch.

Flow characteristics

The maximum distance of flow is governed by the gap

thickness, the head of grout applied and the ambient

temperature.

Cleaning

All tools and equipment should be cleaned immediately after

use with Fosroc Solvent 102*. Spillages should be absorbed

with sand or sawdust and disposed in accordance with local

regulations.

Conbextra EP300 - Page 2 of 4

Conbextra EP300*

Low temperature working Precautions

Whilst the performance of Conbextra EP300 at low Health and safety

temperatures is assured, application under such conditions

Conbextra EP300 contains resins which may cause

can sometimes be difficult. It is therefore suggested that, for

sensitisation by skin contact. Avoid contact with skin and eyes

temperatures below 25C, the following guidelines are

and inhalation of vapour. Wear suitable protective clothing,

adopted:

gloves and eye/face protection. Barrier creams provide

(i) Store unmixed materials in a warm(preferably additional skin protection. Should accidental skin contact occur,

temperature controlled) environment. remove immediately with a resin removing cream, followed by

(ii) Keep mixing and placing equipment warm, arranging soap and water. Do not use solvent. In case of contact with

protection if necessary. It is especially important to keep eyes, rinse immediately with plenty of clean water and seek

warm those surfaces of the equipment which will come medical advice. If swallowed seek medical attention

into direct contact with the material itself. immediately - do not induce vomiting.

(iii) Try to eliminate application in the coldest time of the day, Fire

and certainly avoid application at night.

Fosroc Solvent 102 is flammable. Keep away from sources of

(iv) Minimum temperature of the mixed material to be 25 C ,

Ignition. No smoking. In the event of fire extinguish with CO2 or

and loading shall only be allowed 72 hours after pouring.

foam. Do not use a water jet.

Limitations Flash points

- Grouts should not be placed in any unrestrained situation, Fosroc Solvent 102 : 33C

i.e. base plate plinths, etc. Failure to comply may lead to For additional information see relevant Material Safety Data

crack development in the grout. Sheet.

- At temperatures below 25C the cure rate may be slow, but

will go to completion provided the temperature remains

above 5C.

- The cured grout, which is resistant to frost and sub-zero

temperatures, is most suited for ambient temperatures in

the range of 25 to 55C.

Estimating

Supply

Conbextra EP300 : 14 litre packs

Storage

All Conbextra EP300 has a shelf life of 12 months if kept in dry

conditions at 20C. If stored at high temperatures the shelf life

will be reduced.

Conbextra EP300 - Page 3 of 4

Conbextra EP300*

Additional Information

Fosroc manufactures a wide range of complementary

products which include :

! waterproofing membranes & waterstops

! joint sealants & filler boards

! cementitious & epoxy grouts

! specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and

refurbishment of damaged concrete. Fosrocs Systematic

Approach to concrete repair features the following :

! hand-placed repair mortars

! spray grade repair mortars

! fluid micro-concretes

! chemically resistant epoxy mortars

! anti-carbonation/anti-chloride protective coatings

! chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard

Conditions for the Supply of Goods and Service

Head Office

Al Gurg Fosroc telephone: (+9714) 2858606 fax: (+9714) 2859649 email: agf@fosroc.com

LLC Regional offices

Dubai, Al Gurg Fosroc telephone: 285 8787 fax: 285 2023 email: dubai@fosroc.com

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17735454 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 771 5080 fax: 771 7554 email: oman@fosroc.com

Qatar, Tadmur telephone: 413628 fax: 440812 email: qatar@fosroc.com

UAE/0426/01/C

Vous aimerez peut-être aussi

- A41 Construction MethodologyDocument15 pagesA41 Construction MethodologyCasfeta technical official Tayomi100% (1)

- A41 Construction MethodologyDocument15 pagesA41 Construction MethodologyCasfeta technical official Tayomi100% (1)

- Nondestructive Inspection of Hull Welds 2002Document71 pagesNondestructive Inspection of Hull Welds 2002Henry GelvisPas encore d'évaluation

- Density of Materials Bulk Materials.: Unit Conversion Tool - DownloadDocument10 pagesDensity of Materials Bulk Materials.: Unit Conversion Tool - DownloadUa AnyanhunPas encore d'évaluation

- Geotextiles and Geomembranes HandbookD'EverandGeotextiles and Geomembranes HandbookT.S. IngoldÉvaluation : 5 sur 5 étoiles5/5 (1)

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamPas encore d'évaluation

- Guide To Good Industry Practice LPG Cylinder Filling FV2 PDFDocument60 pagesGuide To Good Industry Practice LPG Cylinder Filling FV2 PDFMarco CetiPas encore d'évaluation

- API5L 45th Edition Specification For Line Pipe For WebsiteDocument6 pagesAPI5L 45th Edition Specification For Line Pipe For WebsiteRaja Ram yadav0% (1)

- Low exotherm epoxy grout for heavy loadsDocument4 pagesLow exotherm epoxy grout for heavy loadsSAJEED MOHAMMADPas encore d'évaluation

- Conbextra_EP300Document4 pagesConbextra_EP300m.elsanee.cubicPas encore d'évaluation

- Fosroc Conbextra EP300: Constructive SolutionsDocument4 pagesFosroc Conbextra EP300: Constructive SolutionsVincent JavatePas encore d'évaluation

- Low Exotherm Epoxy Grout for Heavy LoadsDocument4 pagesLow Exotherm Epoxy Grout for Heavy Loadsabhay_joshi2002Pas encore d'évaluation

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument1 pageConbextra EP10 : High Strength, Epoxy Resin GroutminedataPas encore d'évaluation

- High strength epoxy grout for heavy duty applicationsDocument2 pagesHigh strength epoxy grout for heavy duty applicationszulfikarPas encore d'évaluation

- 10 Conbextra EP10Document2 pages10 Conbextra EP10ahmad wildaanPas encore d'évaluation

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicPas encore d'évaluation

- Conbextra EP10: High Strength, Epoxy Resin GroutDocument3 pagesConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajPas encore d'évaluation

- High Strength Epoxy Grout for Heavy LoadsDocument2 pagesHigh Strength Epoxy Grout for Heavy LoadsAcho SupraholicPas encore d'évaluation

- TDS Conbextra EP10M IndiaDocument2 pagesTDS Conbextra EP10M Indiasyed AffanPas encore d'évaluation

- TDS-Conbextra-EP10M-IndiaDocument2 pagesTDS-Conbextra-EP10M-IndiaBabla SPas encore d'évaluation

- Conbextra EP10 (M)Document2 pagesConbextra EP10 (M)abhay_joshi2002Pas encore d'évaluation

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavatePas encore d'évaluation

- Nitomortar ELDocument4 pagesNitomortar ELMansoor AliPas encore d'évaluation

- High Strength, Low Viscous Epoxy Injection GroutDocument2 pagesHigh Strength, Low Viscous Epoxy Injection Groutraahul_nPas encore d'évaluation

- Fosroc Nitomortar EL: Constructive SolutionsDocument4 pagesFosroc Nitomortar EL: Constructive SolutionsVincent JavatePas encore d'évaluation

- TDS-Conbextra-EP10-IndiaDocument3 pagesTDS-Conbextra-EP10-IndiaBabla SPas encore d'évaluation

- Conbextra EP120 TDS PDFDocument3 pagesConbextra EP120 TDS PDFzulfikarPas encore d'évaluation

- Conbextra EP75 PDFDocument4 pagesConbextra EP75 PDFsaroat moongwattanaPas encore d'évaluation

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaPas encore d'évaluation

- TDS Conbextra EP10 LV IndiaDocument2 pagesTDS Conbextra EP10 LV IndiaAnanth KumarPas encore d'évaluation

- Fosroc Conbextra HF precision groutDocument4 pagesFosroc Conbextra HF precision groutThrtThrthPas encore d'évaluation

- Non-shrink precision groutDocument4 pagesNon-shrink precision groutEngr.Mohammed KhaledPas encore d'évaluation

- Conbextra HFDocument4 pagesConbextra HFm.elsanee.cubicPas encore d'évaluation

- High strength epoxy resin grout for heavy duty applicationsDocument4 pagesHigh strength epoxy resin grout for heavy duty applicationsHamkarPas encore d'évaluation

- High strength epoxy grout for heavy duty applicationsDocument4 pagesHigh strength epoxy grout for heavy duty applicationsVikas Singh ChandelPas encore d'évaluation

- Conbextra EP150 UAEDocument4 pagesConbextra EP150 UAEjasonPas encore d'évaluation

- Conbextra_EP75_PlusDocument4 pagesConbextra_EP75_Plusm.elsanee.cubicPas encore d'évaluation

- Conbextra HF: Shrinkage Compensated Cementitious Precision GroutDocument4 pagesConbextra HF: Shrinkage Compensated Cementitious Precision GroutbinodPas encore d'évaluation

- Conbextra HESEDocument4 pagesConbextra HESEm.elsanee.cubicPas encore d'évaluation

- Epoxy resin free flow grout for heavy duty applicationsDocument4 pagesEpoxy resin free flow grout for heavy duty applicationsFeri Oktara IrawanPas encore d'évaluation

- Fosroc Conbextra EP75: Constructive SolutionsDocument2 pagesFosroc Conbextra EP75: Constructive SolutionsmangjitPas encore d'évaluation

- Conbextra UW: Constructive SolutionsDocument4 pagesConbextra UW: Constructive SolutionstalatzahoorPas encore d'évaluation

- Fosroc Conbextra EPGP: Constructive SolutionsDocument2 pagesFosroc Conbextra EPGP: Constructive SolutionsVincent JavatePas encore d'évaluation

- TDS Renderoc LAXtra India3Document2 pagesTDS Renderoc LAXtra India3ARCHANA GUPTAPas encore d'évaluation

- Conbextra HF - High Strength Shrinkage Compensated GroutDocument4 pagesConbextra HF - High Strength Shrinkage Compensated Groutabhay_joshi2002Pas encore d'évaluation

- Conbextra EP75 PDFDocument3 pagesConbextra EP75 PDFKhaerul SidikPas encore d'évaluation

- Conbextra EPGPDocument2 pagesConbextra EPGPm.elsanee.cubicPas encore d'évaluation

- Fosroc Renderoc HS repair mortar guideDocument2 pagesFosroc Renderoc HS repair mortar guideMuhammed KunnappillyPas encore d'évaluation

- TDS Renderoc LAXtra IndiaDocument2 pagesTDS Renderoc LAXtra IndiaSHAIK ASIMUDDINPas encore d'évaluation

- Conbextra EP10 (M) PDFDocument2 pagesConbextra EP10 (M) PDFBinoy Sankar SarkerPas encore d'évaluation

- TDS Renderoc UW India3Document3 pagesTDS Renderoc UW India3ARCHANA GUPTAPas encore d'évaluation

- Conbextra Ep40Document3 pagesConbextra Ep40talatzahoorPas encore d'évaluation

- Conbextra EP40 UAEDocument2 pagesConbextra EP40 UAEjasonPas encore d'évaluation

- Fosroc Renderoc Laxtra Plus: Constructive SolutionsDocument2 pagesFosroc Renderoc Laxtra Plus: Constructive SolutionsVincent Javate0% (1)

- Nitobond EP: Epoxy Resin Concrete Bonding AgentDocument3 pagesNitobond EP: Epoxy Resin Concrete Bonding AgentDinesh HastakPas encore d'évaluation

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusMansoor AliPas encore d'évaluation

- Fosroc Conbextra HF PLUS High Strength GroutDocument4 pagesFosroc Conbextra HF PLUS High Strength GroutVincent JavatePas encore d'évaluation

- High-strength heat resistant cement groutDocument4 pagesHigh-strength heat resistant cement groutSHAIK ASIMUDDINPas encore d'évaluation

- Nitocote EpuDocument4 pagesNitocote EpumohamedbossilyPas encore d'évaluation

- Conbextra EBG (M)Document4 pagesConbextra EBG (M)abhay_joshi2002Pas encore d'évaluation

- Nitoproof 600 UAEDocument4 pagesNitoproof 600 UAECharles FernandesPas encore d'évaluation

- Fosroc Renderoc Laxtra: Constructive SolutionsDocument2 pagesFosroc Renderoc Laxtra: Constructive SolutionsVincent JavatePas encore d'évaluation

- Conbextra EBG (M) : Epoxy Resin Bearing GroutDocument3 pagesConbextra EBG (M) : Epoxy Resin Bearing GroutGangu Gangaraju N BPas encore d'évaluation

- TDS Nitofill EPLV BFLDocument2 pagesTDS Nitofill EPLV BFLanandswarupPas encore d'évaluation

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- World Health Organization Global COVID-19 Report - April 2Document13 pagesWorld Health Organization Global COVID-19 Report - April 2CityNewsTorontoPas encore d'évaluation

- Wilo Pump DatasheetsDocument32 pagesWilo Pump DatasheetsmanoPas encore d'évaluation

- World Health Organization Global COVID-19 Report - April 2Document13 pagesWorld Health Organization Global COVID-19 Report - April 2CityNewsTorontoPas encore d'évaluation

- Install Aspen One V8.4 HysysDocument22 pagesInstall Aspen One V8.4 HysysUa Anyanhun100% (2)

- 079 088Document10 pages079 088منير أحمدPas encore d'évaluation

- 2015 June 02 SIMOGEAR For Attendees PDFDocument44 pages2015 June 02 SIMOGEAR For Attendees PDFUa AnyanhunPas encore d'évaluation

- Windows Printer Test PageDocument1 pageWindows Printer Test PageUa AnyanhunPas encore d'évaluation

- Install Aspen One V8.4 HysysDocument22 pagesInstall Aspen One V8.4 HysysUa Anyanhun100% (2)

- Einstellung Stromregelkarte SRK 418 - SRK 16 Neutral - GBDocument2 pagesEinstellung Stromregelkarte SRK 418 - SRK 16 Neutral - GBUa AnyanhunPas encore d'évaluation

- Einstellung Stromregelkarte SRK 418 - SRK 16 Neutral - GBDocument2 pagesEinstellung Stromregelkarte SRK 418 - SRK 16 Neutral - GBUa AnyanhunPas encore d'évaluation

- Downloaded From WWW - ETTV.tvDocument1 pageDownloaded From WWW - ETTV.tvtushar shuklaPas encore d'évaluation

- 1 SMDocument9 pages1 SMaaPas encore d'évaluation

- Sikadur 42 - PDSDocument2 pagesSikadur 42 - PDSUa AnyanhunPas encore d'évaluation

- Telescoping Chs RhsDocument3 pagesTelescoping Chs RhsvgteePas encore d'évaluation

- Wa000 PDFDocument52 pagesWa000 PDFUa AnyanhunPas encore d'évaluation

- API5L 45th Edition Specification For Line Pipe For WebsiteDocument16 pagesAPI5L 45th Edition Specification For Line Pipe For WebsiteUa AnyanhunPas encore d'évaluation

- New Tariff Rate BEDCDocument12 pagesNew Tariff Rate BEDCAsemota OghoghoPas encore d'évaluation

- E33 Epoxy Grout Technical Data SheetDocument2 pagesE33 Epoxy Grout Technical Data SheetUa AnyanhunPas encore d'évaluation

- Wa000Document14 pagesWa000Ua AnyanhunPas encore d'évaluation

- CET code livestock and meat products guideDocument234 pagesCET code livestock and meat products guideUa AnyanhunPas encore d'évaluation

- Niagara Gas consultation records for HDD projectDocument26 pagesNiagara Gas consultation records for HDD projectUa AnyanhunPas encore d'évaluation

- Chapter - 87 Import DutyDocument6 pagesChapter - 87 Import DutyJubril AkinwandePas encore d'évaluation

- Building Beam PrinciplesDocument7 pagesBuilding Beam PrinciplesUa AnyanhunPas encore d'évaluation

- Armorgrout 100Document3 pagesArmorgrout 100Ua AnyanhunPas encore d'évaluation