Académique Documents

Professionnel Documents

Culture Documents

BusDuct PM Check List

Transféré par

Muhammad Akif Naeem0 évaluation0% ont trouvé ce document utile (0 vote)

2K vues3 pagesBus Duct Maintenance Check List

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentBus Duct Maintenance Check List

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

2K vues3 pagesBusDuct PM Check List

Transféré par

Muhammad Akif NaeemBus Duct Maintenance Check List

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

JUBAIL UNITED PETROCHEMICAL COMPANY Garinll

Dominant failure mode :

FAILURE

Order No.

Checkst Tile 7 checks no

Cheek ti f Med

[' Soe tckics Geant en Medium 7” | MeT-CHL-EE-00056-05

| Function T Bepartment fev. Wo:

Technical Engineering Support 03

Department (Electrical)

‘Approved By Date Approved Page No:O1 of O3

ESD Sr. 02/12/2014 |

Manager/

GM Maintenance len Doar

TAGNo. TAG DESCRIPTION ]

Frequency : 5Y MEDIUM / LOW VOLTAGE | Job execution Date: |

BUSDUCT |

BUS BAR INSULATION [era Notification /

1.0 MAINTENANCE GUIDELINES

+ Refer Work Instruction No. MET-WIN-EE-00058-05

- Carry out the following checks (CHKS), cleaning (CLN) and repair as required.

+ Completed activities should be marked by "Y" for YES and,

" for NO.

For any activity not applicable, put "NA" for Not Applicable in Remarks column.

Note: Maintenance of Bus-Ducts shall be carried out during available

opportunity or Shut-downs.

Sr.No DESCRIPTION

CHKS/ CLN

COMPLETED

REPAIR

REQUIRED

REPAIR

COMPLETED | REMARKS

YES

No | YES [NO | YES | NO

1 | Is the equipment

isolated electrically and

‘SWP obtained

| Master

| card No.

‘SWP No.

Identify the Bus duct to.

be taken for

maintenance and

barricade it from live

bus duct,

Clean bus duct from

3 | dust/dirt by vacuum

cleaner

(Open bus duct covers _

and Inspect Visually for

abnormality/overheating

Prepared by; Sadanandan Sudheer

Stat Electrical Engineer- ESD

Date: 02/12/2014

Reviewed by : Majdi Al Faraj

Elewical Manager “ESD

7 [Date : 02/12/2014

Page No: 02 of 04

[[Date: 02/12/2014 | Rev. No: 03

] Check bus bar cca ]

5 | Connections for

tightness by using

torque wrench.

Check bus bar support

© | insulators for crack and

damage

| Check bus bar

7 ‘| Separator |

shrouds/barriers for any

tracking :

Check space heaters |

g_| continuity by resistance

check, measure its

resistance and record

in table 2.0.

Check space heater ]

supply junction box

connections for

looseness and seal the |

‘openings.

Check continuity with

10 | earthing grid and

connection of earthing

strip for looseness...

a1_| Check for breather

assembly for any | |

damage and do cleaning a iets

Check for proper wall

12 | sealing around bus

ducts wherever |

applicable A

13 _ | Check bus duct |

supporting frame

structure.

‘Check for sign of

14 | overheating ,

discoloration of bus bar

joints and sign of |

moisture ingress el

Carryout bus bar | Refer last

conductivity test on bus test

15 __ bars joints and record in values and

| table 3.0. shall not

differ

negatively

by 5%

16 | Check the space heater | |

resistance and record

Measure bus bar

17 | insulation resistance |

and record values in

table 4.0 MEE AE lee J

__2.0__ Space Heater Thermostat Settings:

Page No: 03 of 04

Rev. Ne

Sr. | Space Heater Resistance of Thermostat setting | Actual | pe nary

No_| identification __| space heater __| (Expected value) _| value _| Rem"

Bus Bar Conductive Test Results: a

Rg [Joint Identification Number | Phase A Phase B Phase C

megger for MV)

Description hn h to | B-ph to

| Ground | Ground

Insulation Resistance Measurement ( Use 500V megger for LV / 5 KV

5.0 General Remark:

Any general observation made while performing maintenance or during test

should be recorded below.

Performed by

Name

Signature :

Date

Reviewed by

Name :

Signature:

Date :

Y” Put tick mark in the status box once this tag related SAP

order / Notification

technically completed.

Vous aimerez peut-être aussi

- New Product DevelopmentDocument23 pagesNew Product DevelopmentMuhammad Akif NaeemPas encore d'évaluation

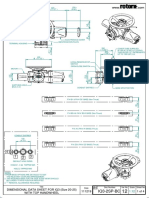

- IQ3-2SP-BC: A4 1 of 4 Dimensional Data Sheet For Iq3 (Size 20-25) With Top Handwheel 111219Document4 pagesIQ3-2SP-BC: A4 1 of 4 Dimensional Data Sheet For Iq3 (Size 20-25) With Top Handwheel 111219Muhammad Akif NaeemPas encore d'évaluation

- LED Bulb Quotation-A Model and T ModelDocument2 pagesLED Bulb Quotation-A Model and T ModelMuhammad Akif NaeemPas encore d'évaluation

- TR PM Check ListDocument5 pagesTR PM Check ListMuhammad Akif NaeemPas encore d'évaluation

- 300B0000 IQT Basic StandardDocument2 pages300B0000 IQT Basic StandardSri100% (2)

- Basic Terms To Get StartDocument3 pagesBasic Terms To Get StartMuhammad Akif NaeemPas encore d'évaluation

- Circuit diagram of a remote control system with a transformer and power supply detailsDocument2 pagesCircuit diagram of a remote control system with a transformer and power supply detailshassan hassanPas encore d'évaluation

- Sss Module: Transformer Tapping OptionsDocument2 pagesSss Module: Transformer Tapping OptionsMuhammad Akif NaeemPas encore d'évaluation

- 304d2000 2Document2 pages304d2000 2campana02Pas encore d'évaluation

- University of Wales External ProgramDocument13 pagesUniversity of Wales External ProgramMuhammad Akif NaeemPas encore d'évaluation

- VC PM Check ListDocument4 pagesVC PM Check ListMuhammad Akif NaeemPas encore d'évaluation

- S 1481Document2 pagesS 1481Muhammad Akif NaeemPas encore d'évaluation

- Ampacities of Insulated Conductors (From NEC Table 310 16)Document2 pagesAmpacities of Insulated Conductors (From NEC Table 310 16)Muhammad Akif NaeemPas encore d'évaluation

- QC INSPECTOR ElectricalDocument3 pagesQC INSPECTOR ElectricalMuhammad Akif Naeem100% (2)

- InTech - Power System and Substation Automation PDFDocument28 pagesInTech - Power System and Substation Automation PDFMuhammad Akif NaeemPas encore d'évaluation

- Switchboards InspectionDocument72 pagesSwitchboards InspectionMuhammad Akif NaeemPas encore d'évaluation

- Best Practice Manual-TransformersDocument46 pagesBest Practice Manual-Transformerschandrakanth0083396Pas encore d'évaluation

- Tabla Awg A mm2Document1 pageTabla Awg A mm2Francisco HernandezPas encore d'évaluation

- Transformer Maintenance and Acceptance TestDocument62 pagesTransformer Maintenance and Acceptance TestSatish NurukurthiPas encore d'évaluation

- Manual LV MotorsDocument26 pagesManual LV MotorsMuhammad Akif NaeemPas encore d'évaluation

- 03 - OSN EquipmentDocument73 pages03 - OSN EquipmentMuhammad HarisPas encore d'évaluation

- ABB Substation Condition Monitoring ScheduleDocument16 pagesABB Substation Condition Monitoring ScheduleRey Arthur100% (1)

- 01 - SDH (Synchronous Digital Hierarchy)Document85 pages01 - SDH (Synchronous Digital Hierarchy)Muhammad Akif NaeemPas encore d'évaluation

- P6 102 Manual CNS Printer Friendly FormatDocument222 pagesP6 102 Manual CNS Printer Friendly FormatGökhan UtangaçPas encore d'évaluation

- Optical Fiber TrainingDocument181 pagesOptical Fiber TrainingMuhammad HarisPas encore d'évaluation

- 1st 3 Lecs PM NotesDocument21 pages1st 3 Lecs PM NotesMuhammad Akif NaeemPas encore d'évaluation

- 3BSE045753 L H en 800xa Its All About Control Config. Poster 700x500 MMDocument1 page3BSE045753 L H en 800xa Its All About Control Config. Poster 700x500 MMMuhammad Akif NaeemPas encore d'évaluation

- 17 GSMDocument72 pages17 GSMMuhammad Akif NaeemPas encore d'évaluation

- Application Form Procees-Prodaug14Document1 pageApplication Form Procees-Prodaug14محمد فصیح آفتابPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)