Académique Documents

Professionnel Documents

Culture Documents

OFT2-CAD-Simulationssoftware Für Hydraulik Und Pneumatik OFT2-CAD-Simulationssoftware Für Hydraulik Und Pneumatik

Transféré par

Gabriel García GutiérrezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

OFT2-CAD-Simulationssoftware Für Hydraulik Und Pneumatik OFT2-CAD-Simulationssoftware Für Hydraulik Und Pneumatik

Transféré par

Gabriel García GutiérrezDroits d'auteur :

Formats disponibles

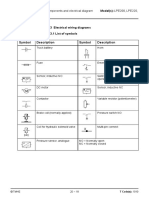

Operation of Valves

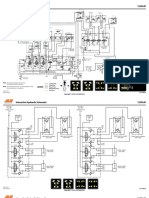

Logic Function Truth Logic Pneumatic Symbols Electrical Symbols Manual Operation Mechanical Pneumatic Electrical

Table Graphical

General Spring button

Symbols symbol

Plunger

valve

Pneumatic Electrical

A

AND E1 E2 A E1

A

E2 E1

E1 Pneumatic

0 0 0 E1

& Electrical, hand-assisted,

0 1 0

A

E2 Push button spring centred

1 0 0

E2 A Roller tappet Ball valve Pivot operation,

E1

E2

A or knob automatic control

1 1 1

E2

A A Roller and Throttle Different pistons Electrical,

OR E1 E2 A

E1 E2

E1 Lever lever valve external control

E1 E2

0 0 0 E1

1 A

0 1 1 E2 A

1 0 1 E1

E2 A

1 1 1

E2

Line throttle

Pedal Spring valve Pneumatic Spring

NAND A Electrical,

E1 E2 A

E1 & E1 E2 spring centred

0 0 1 A Detent, maintains Pneumatic and

0 1 1 E2

1 0 1 specified position mechanical Springs

1 1 0 E1 E2 A

NOR E1 E2 A

A

E1

0

0

0

1

1

0

E1

1 A Compressed air production Flow valves Pressure valves Stop (check) valves

E2 E2

1 0 0

E1 E2 A

and conditioning

1 1 0 Check valve,

Spring loaded

Air pressure source Flow control Pressure

A

EQUIVALENCE E1 E2 A E1 E1

valve, adjustable regulator valve

Non-return

0 0 1 E1

check valve,

0 1 0 E2

= A E2 Air service unit

1 0 0 Flow control lockable

1 1 1 E2

A Pressure

valve with relief valve Twin pressure valve

Filter direct exhaust

A (logical AND)

EXCLUSIVE-OR E1 E2 A E1 E1

(EOR) 0

0

0

1

0

1

E1

=1 A E2 Filter with Throttle check Pressure Shuttle valve

E2

1 0 1

E2 water trap valve, adjustable switch (logical OR)

1 1 0 A

Filter with automatic Rapid exhaust

INHIBITION E1 E2 A A

water trap valve

E1

AND-NOT 0

0

0

1

0

0

E1

& A E2

E2 E2

1 0 1 E1 Mist Lubricator

1 1 0 A

IMPLICATION E1 E2 A

IF-THEN 0 0 1 E1

1 A E1

A E1 E2 Control valves Cylinder Other Symbols

0 1 1 E2

1 0 0 E2

1 1 1 A

Single-acting cylinder, Silencer

2/2 Control valve spring return

EQUALITY A

E1 A E1

0 0 E1 1 A E1 3/2 Control valve, Double-acting cylinder Pressure indicator

1 1 Neutral position closed with singlepiston rod

Omegon Teachware. All rights reserved.

Pressure gauge

3/2 Control valve, Double-acting cylinder

INVERSION A Flow-through in with non-contact

E1

NOT E1

0

A

1 E1 1 A E1 neutral position signal source Differential

1 0 pressure gauge

A

Double-acting cylinder

4/2 Control valve with adjustable stroke

Air receiver

cushioning at both ends

MEMORY E1 K1 K1 K1

A B 5/2 Control valve,

(Flip-Flop) E1

S

A

B

E1 E2 Flow-through possible Double-acting cylinder Stop (check) valve

E2

R E2

in both directions with non-contact signal

K1 A B source and end cushioning

Direct air exhaust

5/3 Control valve, Double-acting cylinder

Mid position closed with double-ended piston rod Separate air exhaust

Double-acting cylinder

OFT2-CAD-Simulationssoftware without piston rod Rotary drive

fr Hydraulik und Pneumatik

www.en.omesim.com

Vous aimerez peut-être aussi

- Processing Station Assembly InstructionsDocument18 pagesProcessing Station Assembly InstructionsAbraham PerezPas encore d'évaluation

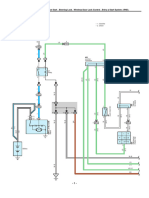

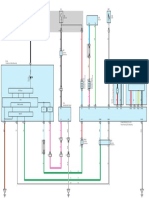

- Toyota Hilux 2018 Overall EWD Engine - Hybrid System Engine Control (1GD-FTV, 2GD-FTV)Document10 pagesToyota Hilux 2018 Overall EWD Engine - Hybrid System Engine Control (1GD-FTV, 2GD-FTV)gabrielzinho43100% (3)

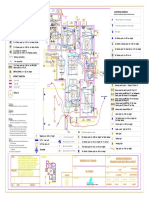

- Electrical Wiring DigramDocument15 pagesElectrical Wiring DigramSunilMurkikarPas encore d'évaluation

- CIROS Robotics Manual - FESTODocument88 pagesCIROS Robotics Manual - FESTOJulian Guillermo Cifuentes CifuentesPas encore d'évaluation

- MR-J2S-S099 - Specifications and Instruction Manual BCN-B11127-478 (01.02) PDFDocument84 pagesMR-J2S-S099 - Specifications and Instruction Manual BCN-B11127-478 (01.02) PDFDoDuyBacPas encore d'évaluation

- Your Source For Ac & DC Motor ControlDocument128 pagesYour Source For Ac & DC Motor ControlJordan Moreira ValdezPas encore d'évaluation

- Manual MPS-PA Compact Workstation EN PDFDocument72 pagesManual MPS-PA Compact Workstation EN PDFstoka seljacka0% (1)

- Festo Electrical, Pneumatic and Logic SymbolsDocument1 pageFesto Electrical, Pneumatic and Logic SymbolsAvtomatika Kole Nehtenin50% (2)

- 8Q-IAI - A321 - Cabin and Emergency Equipment Layout - Rev 05 - SignedDocument1 page8Q-IAI - A321 - Cabin and Emergency Equipment Layout - Rev 05 - SignedMugilanPas encore d'évaluation

- Simbologia PDFDocument1 pageSimbologia PDFMartin Abraham Perez UriasPas encore d'évaluation

- SoMove 2.x Installation NotesDocument8 pagesSoMove 2.x Installation NotesPaulJohnPosadasGimenaPas encore d'évaluation

- Festo-Sensors For Handling and ProcessingDocument238 pagesFesto-Sensors For Handling and ProcessingRevi AdikharismaPas encore d'évaluation

- Mohamed Youssef: Control EngineerDocument2 pagesMohamed Youssef: Control EngineerMohamed Youssef100% (1)

- Maintenance Manual: Fanuc Ac Spinole ServoDocument152 pagesMaintenance Manual: Fanuc Ac Spinole Servovasiliy vasilievichPas encore d'évaluation

- Ecad Chapter 1 Jun2020Document18 pagesEcad Chapter 1 Jun2020Azlan AzizPas encore d'évaluation

- CR750, CR751 - Instruction Manual (Ethernet Function) BFP-A3379-0 (03.15)Document82 pagesCR750, CR751 - Instruction Manual (Ethernet Function) BFP-A3379-0 (03.15)ayxworks eurobotsPas encore d'évaluation

- FESTODocument24 pagesFESTOSetiawan Lux ExhaustPas encore d'évaluation

- Worksheet Data Rep and Intro C++Document4 pagesWorksheet Data Rep and Intro C++Neena SharmaPas encore d'évaluation

- A14b-0076-B001 Input UnitDocument2 pagesA14b-0076-B001 Input UnitMilan RadosavljevicPas encore d'évaluation

- Computer Applications in Power Systems: By: DB&DGDocument106 pagesComputer Applications in Power Systems: By: DB&DGNatinaelPas encore d'évaluation

- GB HandlingDocument22 pagesGB HandlingDiego Mayorga100% (1)

- Schéma Électrique Hamos EKS1031-0 - 610881 PENA Metaux - 20.07.2020 - REV1Document162 pagesSchéma Électrique Hamos EKS1031-0 - 610881 PENA Metaux - 20.07.2020 - REV1MeyerPas encore d'évaluation

- Model PA1/PA3/SA1/SA2/SA3/SA5/ SB/SB2/SB3/SB4/SB5/SB6/SB7/ SC/SC3/SC4/NB/NB2/NB6Document506 pagesModel PA1/PA3/SA1/SA2/SA3/SA5/ SB/SB2/SB3/SB4/SB5/SB6/SB7/ SC/SC3/SC4/NB/NB2/NB6Mr TechPas encore d'évaluation

- ISO 05456-2-1996 ScanDocument10 pagesISO 05456-2-1996 ScanLuigiPas encore d'évaluation

- Avanza 2013 ABS-01-01Document3 pagesAvanza 2013 ABS-01-01jazuka autoPas encore d'évaluation

- 28 Corolla / AurisDocument1 page28 Corolla / AurisvarenziaPas encore d'évaluation

- 005 - Electrical Wiring DiagramsDocument20 pages005 - Electrical Wiring DiagramsNgo Ngoc TuPas encore d'évaluation

- Manual TekaDocument7 pagesManual TekaJAVIPas encore d'évaluation

- Diagrama ABS AvanzaDocument4 pagesDiagrama ABS AvanzaGERARDO CESSAPas encore d'évaluation

- Someflu - FP .NP .16.01.ENDocument2 pagesSomeflu - FP .NP .16.01.ENBANGU SONNYPas encore d'évaluation

- 2015 Creta G 1.6 Mpi A-T-DiagramDocument1 page2015 Creta G 1.6 Mpi A-T-DiagramJimmy Durand LunaPas encore d'évaluation

- Wiring DiagramDocument1 pageWiring DiagramBayu IsmoyoPas encore d'évaluation

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksPas encore d'évaluation

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksPas encore d'évaluation

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksPas encore d'évaluation

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksPas encore d'évaluation

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksPas encore d'évaluation

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksPas encore d'évaluation

- Ower Teering: Vortex Control ValveDocument8 pagesOwer Teering: Vortex Control ValveMarlene Sanmartin MazaPas encore d'évaluation

- Capacitor Bank - AsbuitDocument5 pagesCapacitor Bank - AsbuitJamaludin MuhamadPas encore d'évaluation

- Regulacija 24 VDocument2 pagesRegulacija 24 Vsandra1833Pas encore d'évaluation

- Pre FinalDocument1 pagePre FinalMacoy NaagPas encore d'évaluation

- Rev3 PDFDocument36 pagesRev3 PDFEd PokusaPas encore d'évaluation

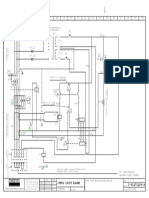

- Title: Arm Uk LTD Ali Baba 12 Auto/Man DRAWING No: 960202-1Document1 pageTitle: Arm Uk LTD Ali Baba 12 Auto/Man DRAWING No: 960202-1LaurentEunicePas encore d'évaluation

- Varun Valanjeri Electrical Layout-3Document1 pageVarun Valanjeri Electrical Layout-3ANOOP R NAIRPas encore d'évaluation

- لقطة شاشة 2022-11-17 في 11.27.29 صDocument1 pageلقطة شاشة 2022-11-17 في 11.27.29 صHur AliPas encore d'évaluation

- C15 and C18 Generator SetDocument4 pagesC15 and C18 Generator Setspider blackPas encore d'évaluation

- B - 1250AJP - Interactive Hyd SchemDocument4 pagesB - 1250AJP - Interactive Hyd SchemJoão M. de MirandaPas encore d'évaluation

- TDN-P1 - Tde-P1Document1 pageTDN-P1 - Tde-P1juan carlos quispe quispePas encore d'évaluation

- E A C B F H L J D G N: Consulting Engineers Fahim, Nanji & Desouza (PVT.) LTDDocument1 pageE A C B F H L J D G N: Consulting Engineers Fahim, Nanji & Desouza (PVT.) LTDMine FollowerPas encore d'évaluation

- Rav4 Ess-RhdDocument26 pagesRav4 Ess-RhdMyo Myint HtwePas encore d'évaluation

- Fault Switch 14: Driver Power Window InopDocument4 pagesFault Switch 14: Driver Power Window InopLong HàPas encore d'évaluation

- Ad-2 LFQTDocument8 pagesAd-2 LFQTgaspard.courte59Pas encore d'évaluation

- Electric Dropbolt Manual: EB200NLWDocument4 pagesElectric Dropbolt Manual: EB200NLWMuhamad Ilham Fatchu RezaPas encore d'évaluation

- 12 Hilux: Stop LightDocument1 page12 Hilux: Stop LightautocomtrucksPas encore d'évaluation

- 12 Hilux: Stop LightDocument1 page12 Hilux: Stop LightautocomtrucksPas encore d'évaluation

- Eps SDocument1 pageEps Sbryan floresPas encore d'évaluation

- PDF Adem 3 Ecm Installed On Cat and Perkins 2300 - CompressDocument3 pagesPDF Adem 3 Ecm Installed On Cat and Perkins 2300 - CompressIchal Jelmis JhePas encore d'évaluation

- Sandvik: Control Circuit DiagramDocument1 pageSandvik: Control Circuit Diagramyongsheng xiaoPas encore d'évaluation

- Layout MCC CP8danCP9-A3 IFRDocument1 pageLayout MCC CP8danCP9-A3 IFRabut tirtaPas encore d'évaluation

- Unit 07 Self-Test Chemistry Self TestDocument2 pagesUnit 07 Self-Test Chemistry Self TestOluwatusin Ayo OluwatobiPas encore d'évaluation

- More Practice Multiple ChoiceDocument3 pagesMore Practice Multiple ChoiceHiPas encore d'évaluation

- K46 ManualDocument8 pagesK46 ManualDavid KasaiPas encore d'évaluation

- Trigonometric Ratios LPDocument3 pagesTrigonometric Ratios LPjoshgarciadlt100% (2)

- Data Structures and Other Objects Using C++, Third Edition, by Michael Main and Walter SavitchDocument6 pagesData Structures and Other Objects Using C++, Third Edition, by Michael Main and Walter SavitchMd Rubaiyat BhuiyanPas encore d'évaluation

- An4879 Introduction To Usb Hardware and PCB Guidelines Using Stm32 Mcus StmicroelectronicsDocument26 pagesAn4879 Introduction To Usb Hardware and PCB Guidelines Using Stm32 Mcus StmicroelectronicsBulentPas encore d'évaluation

- PistonDocument7 pagesPistongauravarora93100% (1)

- ITECH1000 Assignment1 Specification Sem22014Document6 pagesITECH1000 Assignment1 Specification Sem22014Nitin KumarPas encore d'évaluation

- JNJNKDocument11 pagesJNJNKjatin gargPas encore d'évaluation

- VT300 User ManualDocument21 pagesVT300 User ManualLuvPas encore d'évaluation

- Pipe Clamp For Sway Bracing TOLCODocument1 pagePipe Clamp For Sway Bracing TOLCOEdwin G Garcia ChPas encore d'évaluation

- Fire Dynamic Damper Installation InstructionsDocument18 pagesFire Dynamic Damper Installation InstructionsJohnMerrPas encore d'évaluation

- Microprocessor I - Lecture 01Document27 pagesMicroprocessor I - Lecture 01Omar Mohamed Farag Abd El FattahPas encore d'évaluation

- IK Gujral Punjab Technical University: 1. Electric ChargeDocument12 pagesIK Gujral Punjab Technical University: 1. Electric ChargeJashandeep KaurPas encore d'évaluation

- Infinera Ds Isfp Timedivision Multiplexing ModulesDocument3 pagesInfinera Ds Isfp Timedivision Multiplexing ModulesAnonymous bpf0OZSd9Pas encore d'évaluation

- Audio Evolution Mobile User Manual For AndroidDocument336 pagesAudio Evolution Mobile User Manual For AndroidkbalazsPas encore d'évaluation

- L4 Subdivision of PlotsDocument20 pagesL4 Subdivision of PlotsKenny BoatPas encore d'évaluation

- Projector Spec 8040Document1 pageProjector Spec 8040Radient MushfikPas encore d'évaluation

- College of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurDocument24 pagesCollege of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurPooja SahuPas encore d'évaluation

- Epson WorkForce Pro WF-C878-879RDocument8 pagesEpson WorkForce Pro WF-C878-879Rsales2 HARMONYSISTEMPas encore d'évaluation

- Chapter 3Document23 pagesChapter 3pganoelPas encore d'évaluation

- NumpyDocument23 pagesNumpymuzammil jawedPas encore d'évaluation

- PythagorasDocument109 pagesPythagorasaditya00012Pas encore d'évaluation

- Optimization of Decarbonization On Steel IndustryDocument28 pagesOptimization of Decarbonization On Steel Industrymsantosu000Pas encore d'évaluation

- Flexenclosure Esite Brochure PDFDocument5 pagesFlexenclosure Esite Brochure PDFajdCruisePas encore d'évaluation

- KD-131 Asme Viii Div3Document2 pagesKD-131 Asme Viii Div3comar85Pas encore d'évaluation

- BASF Snap Fit Design GuideDocument24 pagesBASF Snap Fit Design Guideomerscheen100% (6)

- Silicon Controlled RectifierDocument38 pagesSilicon Controlled RectifierPaoPas encore d'évaluation

- Sentinel Visualizer 6 User GuideDocument227 pagesSentinel Visualizer 6 User GuideTaniaPas encore d'évaluation

- MoazzamMaqsood Transcript PDFDocument3 pagesMoazzamMaqsood Transcript PDFmoazzam maqsoodPas encore d'évaluation