Académique Documents

Professionnel Documents

Culture Documents

Unlined Pressure Conduits

Transféré par

percys99Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Unlined Pressure Conduits

Transféré par

percys99Droits d'auteur :

Formats disponibles

www.rockmass.

net

UNLINED PRESSURE CONDUITS - used in hydropower plants

by Arild Palmstrm, Ph.D.

RockMass as

An unlined pressure conduit is a tunnel or shaft, which is not lined to withstand internal water

pressures. As most rock have a very low permeability, water migrates into or out of a tunnel

depending on the relation between natural ground water pressure and the pressure in the tunnel. Lining

for rock support purpose is applied as necessary in sections having poor stability; average length of

such linings very seldom exceeds 5% of total tunnel length. Possible pervious zones encountered

during tunnelling are sealed by cement grouting to reduce possible loss of water.

The following conditions are important for a successful solution:

Low permeability of the rock material.

Low permeability or conductivity of the joints and fractures.

Virgin stress sufficiently high to prevent development of fractures or jacking along existing joints.

Physically and chemically stable rock masses.

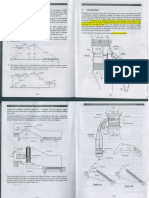

The early Norwegian hydropower plants were designed with a horizontal headrace tunnel and a

penstock on the surface as shown in Figure 1. Unlined water tunnels and shafts with pressures of any

significance came into use in Norway at the end of World War I in 1919. After the first four shafts

were built, no unlined pressure conduits were constructed until the mid fifties. From then on, a number

of shafts with steadily increasing pressure on unlined rock have been constructed (Figure 1). Starting

in the seventies, the shafts were often replaced by inclined pressure tunnels supplied with unlined air

cushion chambers in rock. The common layouts of shafts and tunnels are shown in Figure 1. The

choice of the actual layout is dependent upon topography, access and the need for secondary intakes.

The application of air cushion surge chambers for the unlined pressure tunnels is a further

development in the hydropower design and construction.

The design principles used for the first shafts are not known. In the fifties, several simple overburden

criteria were developed, having the common goal that the water pressure should be less than the

minimum principal rock stress. The

RESERVOIR

HWL

assumption was that this stress was

SURGE SHAFT

HEADRACE TUNNEL

the vertical stress (or a stress

PE

N ST

LAKE TAP

component with some angle to the

OC

K POWER STATION

vertical), depending on surface slope

or shaft inclination. The design was

done long before reliable stress

OLD SOLUTION WITH PENSTOCK

measurement techniques were

developed and accepted. Hence, the

SURGE SHAFT

HWL

RESERVOIR

HEADRACE TUNNEL design had to be based on theoretical

PR

LAKE TAP

E

SS

U

considerations and certain

RE POWER STATION

assumptions.

SH

AF

ACCESS TUNNEL

T

TAILRACE TUNNEL

Later, in the seventies, a finite

SOLUTION WITH PRESSURE SHAFT element model was developed and

complimented by design charts. One

RESERVOIR

HWL

AIR CUSHION

limitation of these charts was that

SURGE CHAMBER

LAKE TAP PRE

they are based on occurrence of high

SSUR POWER STATION

E TU

NNEL ACCESS TUNNEL horizontal stresses (which is common

in Scandinavia).

TAILRACE TUNNEL

SOLUTION WITH PRESSURE TUNNEL AND AIR CUSHION SURGE CHAMBER

FIGURE 1. DEVELOPMENT IN DESIGN OF UNLINED PRESSURE CONDUITS

www.rockmass.net

In the 1990s, powerful numerical analyses for computers were developed and refined. After these new

and more precise design tools came into use, problems with failures seem largely to have been

overcome. The increasingly common practise of checking the design values by in situ stress

measurements (of increasing better quality) has contributed to the successful construction and

operation of a number of high head conduits and air cushion surge chambers in the late seventies.

FIGURE 2. THE DEVELOPMENT OF UNLINED PRESSURE CONDUITS IN NORWAY

The main benefits using pressure shaft tunnel or pressure tunnel are:

No expensive lining (except of the last 20 50m steel lining).

Reduced number of construction adits.

Shorter tunnel system.

In addition, for pressure tunnels: shorter or no expensive shaft construction.

These features result in significant reduction in construction costs and often also shorter construction

time for the hydropower plant.

The highest static head on unlined rock today is 1050m for the Tyin power plant (see Figure 2),

constructed in 2004. The total length of unlined pressure conduits in Norway is not known exactly, but

is estimated to exceed 2000 km.

Vous aimerez peut-être aussi

- New SRF Values For Moderately Jointed RocksDocument12 pagesNew SRF Values For Moderately Jointed RocksArpan NandyPas encore d'évaluation

- Coyne Et Al 2012 Simulations of A Low Boom Axisymmetric External Compression InletDocument22 pagesCoyne Et Al 2012 Simulations of A Low Boom Axisymmetric External Compression InletVishnu RamPas encore d'évaluation

- Pipeline Buckling Caused by Axial Loads PDFDocument9 pagesPipeline Buckling Caused by Axial Loads PDFWan Ah-LunPas encore d'évaluation

- Hydraulic Engineering: Proceedings of The 1989 National Conference On Hydraulic EngineeringDocument4 pagesHydraulic Engineering: Proceedings of The 1989 National Conference On Hydraulic EngineeringpicottPas encore d'évaluation

- Charts For Determining Size of Surge SuppressorsDocument3 pagesCharts For Determining Size of Surge Suppressorsnikolai.ortizPas encore d'évaluation

- The Transonic Flow Through A Plane Turbine Cascade As Measured in Four European Wind TunnelsDocument10 pagesThe Transonic Flow Through A Plane Turbine Cascade As Measured in Four European Wind TunnelsHamida HamidaPas encore d'évaluation

- DTW TrainingPresentation DesignOfTeruvianIntakeDocument21 pagesDTW TrainingPresentation DesignOfTeruvianIntakePrincess AnnPas encore d'évaluation

- MSIGDocument1 pageMSIGwpsbPas encore d'évaluation

- Surge Arresters: Storm Trapper H.E. (High Energy) Low Voltage Distribution Class MOV Surge ArresterDocument6 pagesSurge Arresters: Storm Trapper H.E. (High Energy) Low Voltage Distribution Class MOV Surge ArresterRodrigo RamirezPas encore d'évaluation

- Plumbing system design for restaurant tenantDocument1 pagePlumbing system design for restaurant tenantssarangPas encore d'évaluation

- Components of Hydropower Projects DesignsDocument127 pagesComponents of Hydropower Projects DesignsNoli CorralPas encore d'évaluation

- Case Studies in Pipeline Free Span FatigueDocument10 pagesCase Studies in Pipeline Free Span FatiguejoaogularPas encore d'évaluation

- Experiences in Buckling Design of Pipelines Laid on Very Irregular Seabed - Knut TornesDocument15 pagesExperiences in Buckling Design of Pipelines Laid on Very Irregular Seabed - Knut TornesDavid LimPas encore d'évaluation

- Loh & Wu (1996) Identification of Fei-Tsui Arch Dam From Both Ambient and Seismic Response DataDocument19 pagesLoh & Wu (1996) Identification of Fei-Tsui Arch Dam From Both Ambient and Seismic Response DatarihongkeePas encore d'évaluation

- Browne 1995 Fluid Dyn. Res. 15 A04Document29 pagesBrowne 1995 Fluid Dyn. Res. 15 A04enrique.ovlPas encore d'évaluation

- IS 6934 - Hydraulic Design of High Ogee SpillwayDocument13 pagesIS 6934 - Hydraulic Design of High Ogee SpillwayYounis Bhat0% (1)

- Asce Plunge Pool-Puertas Et AlDocument4 pagesAsce Plunge Pool-Puertas Et AlKarina GuadalupePas encore d'évaluation

- Optimum Low-Band Antenna for Directional ReceptionDocument7 pagesOptimum Low-Band Antenna for Directional ReceptionThornblad33Pas encore d'évaluation

- Trends: Present in Surge Tank DesignDocument34 pagesTrends: Present in Surge Tank DesignashishroshanPas encore d'évaluation

- 000 - System PDFDocument38 pages000 - System PDFJUAN JOSE VESGA RUEDAPas encore d'évaluation

- IS 6934 1998 RecoDocument13 pagesIS 6934 1998 RecoJan BakosPas encore d'évaluation

- Planning of Hydropower ProjectsDocument66 pagesPlanning of Hydropower ProjectsSivaganesan S100% (1)

- Hydrodynamic Design of Planing Hulls SavitskyDocument25 pagesHydrodynamic Design of Planing Hulls SavitskyMarcelo CaliPas encore d'évaluation

- 150KL 25M 2 CommentsDocument1 page150KL 25M 2 CommentsMUKESH RAJENDRAPas encore d'évaluation

- Trend of Surge DesignDocument34 pagesTrend of Surge DesignBalkrishna ChaudharyPas encore d'évaluation

- Talzat ZachariaDocument8 pagesTalzat ZachariaArun KumarPas encore d'évaluation

- Consideration During Pump PipingDocument4 pagesConsideration During Pump Pipingsateesh chand100% (1)

- Ocean Engineering: A C B A ADocument14 pagesOcean Engineering: A C B A APatrick Silva OliveiraPas encore d'évaluation

- SOBEK ModellingDocument13 pagesSOBEK ModellingHarry ChaeruddinPas encore d'évaluation

- Some Features of The Unsteady Pressure Field in Transonic Airfoil BuffetingDocument8 pagesSome Features of The Unsteady Pressure Field in Transonic Airfoil BuffetingaaaaPas encore d'évaluation

- Sharma Et Al-2005-Naval Engineers JournalDocument20 pagesSharma Et Al-2005-Naval Engineers Journalthiago.the.studentPas encore d'évaluation

- A Critical Analysis of Arthur Ravenel Jr. Bridge New Cooper River BridgeDocument7 pagesA Critical Analysis of Arthur Ravenel Jr. Bridge New Cooper River BridgeHoàng LongPas encore d'évaluation

- Cross-Flow Vibrations of A Pipe Close To A Rigid Boundary: V.JacobsenDocument7 pagesCross-Flow Vibrations of A Pipe Close To A Rigid Boundary: V.Jacobsen李智Pas encore d'évaluation

- Annacis Cable-Stayed Bridge-Design For Earthquake: CBA-Buckland and Taylor, Consulting Engineers, S I T eDocument11 pagesAnnacis Cable-Stayed Bridge-Design For Earthquake: CBA-Buckland and Taylor, Consulting Engineers, S I T ewang maxPas encore d'évaluation

- CHAPTER - 1.1.3 Darcy Weisbach & Moody ChartDocument20 pagesCHAPTER - 1.1.3 Darcy Weisbach & Moody ChartSteffanny LarraPas encore d'évaluation

- Strength of Submarine Hoses in Chinese-Lantern Configuration From Hydrodynamic Loads On CALM BuoyDocument27 pagesStrength of Submarine Hoses in Chinese-Lantern Configuration From Hydrodynamic Loads On CALM BuoyIbrahim RahmatullahPas encore d'évaluation

- Peripheral Pattern Waterflood Performance PredictionDocument5 pagesPeripheral Pattern Waterflood Performance Predictionirine felaskyPas encore d'évaluation

- kim2006Document12 pageskim2006niloPas encore d'évaluation

- 79-GT-120 Sieveding The Base Pressure ProblemDocument12 pages79-GT-120 Sieveding The Base Pressure ProblemDaniel HernándezPas encore d'évaluation

- V03bt16a036 93 GT 280Document10 pagesV03bt16a036 93 GT 280FeroJanoPas encore d'évaluation

- Frequency-Domain Analysis of Otec CW Pipe and Platform DynamicsDocument12 pagesFrequency-Domain Analysis of Otec CW Pipe and Platform DynamicsYoyok SetyoPas encore d'évaluation

- Webinar FX Supartono Aerodynamic 2021-06-03Document136 pagesWebinar FX Supartono Aerodynamic 2021-06-03FX SupartonoPas encore d'évaluation

- Untitled 1Document5 pagesUntitled 1Asmaa Alaa ElDeenPas encore d'évaluation

- Resistive Damping of Pulsesensed Capacitive Position SensorsDocument4 pagesResistive Damping of Pulsesensed Capacitive Position Sensorssreedevdev007Pas encore d'évaluation

- Preliminary Determination of Basic Dimensions For An Axial Flow PumpDocument11 pagesPreliminary Determination of Basic Dimensions For An Axial Flow PumpJavier Moreno DiazPas encore d'évaluation

- Seismic Earth Pressures - A Technical Note: Merrick TaylorDocument10 pagesSeismic Earth Pressures - A Technical Note: Merrick TaylorMarco Dos Santos Neves100% (1)

- Headworks Design for Sediment ControlDocument30 pagesHeadworks Design for Sediment ControlPujan Bajracharya33% (3)

- Eceived: Nesma & Partners D CDocument1 pageEceived: Nesma & Partners D CMario R. KallabPas encore d'évaluation

- Steady Unsteady FlowDocument5 pagesSteady Unsteady FlowNKPas encore d'évaluation

- In The Name of Allah The Most Beneficent, The Most MercifulDocument65 pagesIn The Name of Allah The Most Beneficent, The Most Mercifulzarakkhan masoodPas encore d'évaluation

- 978 1 4613 0857 7 - 16 PDFDocument2 pages978 1 4613 0857 7 - 16 PDFAbay TanaPas encore d'évaluation

- The Calculation of Turbulent Boundary Layers On Spinning and Curved SurfacesDocument9 pagesThe Calculation of Turbulent Boundary Layers On Spinning and Curved Surfacesyaser AlahmadiPas encore d'évaluation

- 1 s2.0 S0038080620303590 MainDocument12 pages1 s2.0 S0038080620303590 MainvaniPas encore d'évaluation

- Electronics 1940 06Document116 pagesElectronics 1940 06Jose Luis FernandezPas encore d'évaluation

- Aerodynamic stability of cable-stayed bridges simplifiedDocument4 pagesAerodynamic stability of cable-stayed bridges simplifiedHuda AlrikabiPas encore d'évaluation

- Shear Calc-IS-456-2000Document7 pagesShear Calc-IS-456-2000Sachin AgarwalPas encore d'évaluation

- Energies: Cavitation Inception in Crossflow Hydro TurbinesDocument12 pagesEnergies: Cavitation Inception in Crossflow Hydro TurbinesarielbankiPas encore d'évaluation

- Pipe Section Technical Papers - Aug 28 2009Document8 pagesPipe Section Technical Papers - Aug 28 2009Vân Anh TrầnPas encore d'évaluation

- Vertical Axis Tidal Current Genrator Paper Salter and TaylorDocument19 pagesVertical Axis Tidal Current Genrator Paper Salter and TaylorAmit DhimanPas encore d'évaluation

- Intro To ANSYS Ncode DL 14.5 L01 Introduction PDFDocument11 pagesIntro To ANSYS Ncode DL 14.5 L01 Introduction PDFpercys99Pas encore d'évaluation

- (Report) Storage Tanks (Japan)Document179 pages(Report) Storage Tanks (Japan)RAJENDRA PRASADPas encore d'évaluation

- Chapter 01Document37 pagesChapter 01Thyago de LellysPas encore d'évaluation

- Mech AC 160 WS5c-WearDocument13 pagesMech AC 160 WS5c-Wearpercys99Pas encore d'évaluation

- 02 Analisis Pte 15m SSRDocument24 pages02 Analisis Pte 15m SSRpercys99Pas encore d'évaluation

- Ansys Ls-Dyna Mapdl 14.5 l14 SummaryDocument11 pagesAnsys Ls-Dyna Mapdl 14.5 l14 Summaryarthurs9792Pas encore d'évaluation

- Building Bridges. Connecting People.: Acrow Bridge 181 New Road, Parsippany, NJ 07054Document1 pageBuilding Bridges. Connecting People.: Acrow Bridge 181 New Road, Parsippany, NJ 07054percys99Pas encore d'évaluation

- Pages From C.E.C.T.Document1 pagePages From C.E.C.T.percys99Pas encore d'évaluation

- Ansys Ls-Dyna Mapdl 14.5 l01 IntroductionDocument24 pagesAnsys Ls-Dyna Mapdl 14.5 l01 Introductionpercys99Pas encore d'évaluation

- E3 WS3-Solver Output V12Document20 pagesE3 WS3-Solver Output V12percys99Pas encore d'évaluation

- ANSYS LS-DYNA MAPDL 14.5 L08 PostprocessingDocument16 pagesANSYS LS-DYNA MAPDL 14.5 L08 Postprocessingpercys99Pas encore d'évaluation

- Ansys Ls-Dyna Mapdl 14.5 l10 Explicit-To-implicitDocument17 pagesAnsys Ls-Dyna Mapdl 14.5 l10 Explicit-To-implicitpercys99Pas encore d'évaluation

- L10 SubmodelingDocument13 pagesL10 Submodelingpercys99Pas encore d'évaluation

- ACT UPF Extension ManualDocument17 pagesACT UPF Extension Manualpercys99Pas encore d'évaluation

- L01 MechOffshoreIntroDocument5 pagesL01 MechOffshoreIntropercys99Pas encore d'évaluation

- L02 MechIntroDocument33 pagesL02 MechIntroksangeeth2000Pas encore d'évaluation

- E1Document34 pagesE1Roberto PérezPas encore d'évaluation

- ExcelInterfaceV4 R16Document6 pagesExcelInterfaceV4 R16percys99Pas encore d'évaluation

- L01 MechOffshoreIntroDocument5 pagesL01 MechOffshoreIntropercys99Pas encore d'évaluation

- Multizone MeshingDocument16 pagesMultizone Meshingpercys99Pas encore d'évaluation

- ACT Pressure Vessels Automatic Path Creation R150 v3Document14 pagesACT Pressure Vessels Automatic Path Creation R150 v3Percy Romero MurilloPas encore d'évaluation

- Example #21 Concrete Tunnel Section Checking: Civilfem Manual of Advanced Examples - Ingeciber, S.A.Document14 pagesExample #21 Concrete Tunnel Section Checking: Civilfem Manual of Advanced Examples - Ingeciber, S.A.percys99Pas encore d'évaluation

- ANSYS Workbench Element Kill and AliveDocument6 pagesANSYS Workbench Element Kill and AlivemohitknmietPas encore d'évaluation

- Sub ModelingDocument29 pagesSub Modelingpercys99Pas encore d'évaluation

- Mech HeatTransfer 15.0 L07 TransientThermalDocument30 pagesMech HeatTransfer 15.0 L07 TransientThermalpercys99Pas encore d'évaluation

- ExcelInterfaceV4 R16Document6 pagesExcelInterfaceV4 R16percys99Pas encore d'évaluation

- Oscillating PlateDocument23 pagesOscillating Platepercys99Pas encore d'évaluation

- Analysis of A Reinforced Concrete Shear Wall Bjork - Hauksdottir.2007Document118 pagesAnalysis of A Reinforced Concrete Shear Wall Bjork - Hauksdottir.2007antiacidoPas encore d'évaluation

- Centrifugal ForceDocument11 pagesCentrifugal Forceno onePas encore d'évaluation

- Guideline Values To Be Followed by S.R.O.'S of Mangaluru TalukDocument1 pageGuideline Values To Be Followed by S.R.O.'S of Mangaluru TalukSssakala ConsultantsPas encore d'évaluation

- Emcore en 150 1 3 5 ImuDocument2 pagesEmcore en 150 1 3 5 Imuachmad fitrio spnPas encore d'évaluation

- Commutation Failure in HVDC PDFDocument2 pagesCommutation Failure in HVDC PDFCodyPas encore d'évaluation

- Salient Features of Solar Water Heating SystemDocument3 pagesSalient Features of Solar Water Heating Systemtheonebalaji100% (2)

- Gen 3 Partners - Triz Companies DatabaseDocument10 pagesGen 3 Partners - Triz Companies DatabaseTRIZtease100% (2)

- Indian Geotechnical Society: Application Form For Fellowship/Membership (For Individuals)Document8 pagesIndian Geotechnical Society: Application Form For Fellowship/Membership (For Individuals)Arul XavierPas encore d'évaluation

- Ss 500 Pfs mp1Document1 pageSs 500 Pfs mp1Ing SánchezPas encore d'évaluation

- Coaltar EpoxyDocument3 pagesCoaltar EpoxyAkhtar aliPas encore d'évaluation

- The Feasibility Study of Making Pineapple Peeling and LeavesDocument3 pagesThe Feasibility Study of Making Pineapple Peeling and LeavesKassandra VirayPas encore d'évaluation

- HSE Program Plan DAILYDocument5 pagesHSE Program Plan DAILYdefidmsp39100% (1)

- Optimizing Air Instrument KPIsDocument31 pagesOptimizing Air Instrument KPIsMindiRahayuPas encore d'évaluation

- Efficient Mould Cooling MethodsDocument48 pagesEfficient Mould Cooling MethodsVinayak Aryan100% (1)

- An Introduction to FRP Composites for ConstructionDocument77 pagesAn Introduction to FRP Composites for ConstructionMohamed KhalilPas encore d'évaluation

- WagonR - Owner - Manual PDFDocument245 pagesWagonR - Owner - Manual PDFNikhil JPas encore d'évaluation

- Orological Times PDFDocument52 pagesOrological Times PDFJose Maria SzantoPas encore d'évaluation

- Re EntryDocument3 pagesRe EntryCHEKOUFI SaidPas encore d'évaluation

- UT Dallas Syllabus For Mech3350.001.11s Taught by Wooram Park (wxp103020)Document2 pagesUT Dallas Syllabus For Mech3350.001.11s Taught by Wooram Park (wxp103020)UT Dallas Provost's Technology GroupPas encore d'évaluation

- 2004 Nissan Maxima ESMDocument7 pages2004 Nissan Maxima ESMLeonardo Guajardo0% (1)

- Diagrama Hidraulico 320d FM HarvesterDocument1 pageDiagrama Hidraulico 320d FM HarvesterMatiasPas encore d'évaluation

- Water CalculateDocument8 pagesWater CalculateLeon TanPas encore d'évaluation

- Codes, Tags and Labels-Interpreting Piping and Instrumentation Diagrams - AIChEDocument8 pagesCodes, Tags and Labels-Interpreting Piping and Instrumentation Diagrams - AIChEarchana2512100% (1)

- Trident 2 PowerscreenDocument9 pagesTrident 2 PowerscreenRomuald PogorzelczykPas encore d'évaluation

- Roof DecksDocument56 pagesRoof DecksshingkeongPas encore d'évaluation

- Value Stream MapDocument42 pagesValue Stream MapultratangoPas encore d'évaluation

- Victor Aviation BrochureDocument19 pagesVictor Aviation BrochureLucas CoelloPas encore d'évaluation

- Karnataka Building Bye-Laws 2017Document143 pagesKarnataka Building Bye-Laws 2017Ravi JainPas encore d'évaluation

- 9.6 (A) Composite MaterialsDocument16 pages9.6 (A) Composite MaterialsFidree AzizPas encore d'évaluation

- A Study of Biomass Briquette in BangladeshDocument97 pagesA Study of Biomass Briquette in BangladeshPamela Nicole ManaloPas encore d'évaluation

- Ch01-Introduction To Materials ScienceDocument42 pagesCh01-Introduction To Materials ScienceSaleem MoussaPas encore d'évaluation