Académique Documents

Professionnel Documents

Culture Documents

M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by Description

Transféré par

AJAY1381Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by Description

Transféré par

AJAY1381Droits d'auteur :

Formats disponibles

M-01-DS-0003

Specification Sheet

Project Name HVFO/HFO Tank and Associated

System design

Client HNG FLOAT GLASS LTD

Document Number MCR-01-V-001

Document Revision 01

Document Title Process Datasheet for Tanker Unloading

Pump Filter

Project Number P160001

Document type Datasheet

Tag No 100-T-001 A/B

8-Jun-16 01 ISSUED FOR REVIEW RA AT AT

Prepared Checked Approved

DATE REV Description

By By By

NOTE : After approval on this document it will be submitted to vendor(s), further vendor document document will be submitted along with this data to

client.

NO. DATE BY CK SECT DESCRIPTION Project HVFO/HFO Tank and Associated System design

0 8-Jun-16 PS AT AT FOR Review Location Halol Gujarat

Service Heavy Fuel Oil

Classification Class 1, Div 2, Gr D, T3

OPERATING CHARACTERISTICS

Item No. 100-F-101 A/B

Quantity 2 (1 working + 1 standby)

Manufacturer Vessel Model Number

Fluid Heavy Fuel Oil

Vapor, Molecular Weight

3

Normal Nm /h 5

3

Flow Maximum Nm /h 15

3

Design Nm /h 17

Operating Pressure brag NORMAL: 2.6

Temperature C NORMAL: 20-55 MAXIMUM: 75

Max. Differential Pressure (P) brag CLEAN: 0.21 DIRTY: 0.5

Loading at Inlet wt% Liquid

3

Liquid Density kg/m 1010

Viscosity at Operating Temp. cP 385

Solids, content of Rust, pipe scale and other materials

Entrained Liquid ppm

Quality (solids) %

Total Solids EXPECTED TO BE NIL, (NOTE 2)

Droplet and % Size microns

Particle Removal 90 % Size 10 microns

Efficiency 99.5 % Size 15 microns

DESIGN CHARACTERISTICS

Design Pressure brag 6.0

Design Temperature C 110

Max. P Across Clean Kpa (SEE P REQUIREMENTS ABOVE)

Filter Element Fouled Kpa (SEE P REQUIREMENTS ABOVE)

Filter Housing Dimensions(dia x overall length)/ Orientation (NOTE 1)

Sump Dimensions (NOTE 1)

Corrosion Allowance mm

Code Requirements ASME SECTION VIII, DIV. 1

Inlet Diameter in 6

Outlet Diameter in 6

Connections Rating 150# - RFWN

Orientation

Drain Diameter in 1

Vent Diameter in 1

Shell / Housing (NOTE 8)

Materials Internals ASTM MATERIALS

Gaskets (NOTE 1)

Type Cartridges

Filter Number / Dimensions / Surface Area (NOTE 1)

Element Material (NOTE 1)

Mfr. Model No. (NOTE 1)

Skirt Required (NOTE 1,8)

Supports Required

Level Gauge Connection None

Insulation / personnel protection, mm None

Notes:

1. Bidder to specify for MWE approval.

2. Solids are abrasive.

3. Filter shall be designed for continuous operation excluding filter cartridge changeouts due to high DP from particulate accumulation.

4. Filter shall be cleaned before transportation.

5. Manufacturer shall provide closure with Lifting device (davit, spring balance, etc.) when weight of cover exceeds 15 kg.

6. All swing bolts (eye bolts) shall be one-piece construction without welding. Hinge pins shall be solid (not rolled)

and of the same material as the bolts.

7. Grounding clips are required.

8. All part shall be CS

9. Filter shall be located outdoors.

HNG FLOAT GLASS LTD SHEET OF PROJECT NUMBER

100-F-101 A/B 1 1 160001

Tanker Unloading Pump Filter DOCUMENT NUMBER REV

DS-P-100-004 01

DS-P-01-001 F-101 A&B, Separation Equipment DS Printed: 6/10/2016

Vous aimerez peut-être aussi

- Statistics for Process Control Engineers: A Practical ApproachD'EverandStatistics for Process Control Engineers: A Practical ApproachPas encore d'évaluation

- DJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADocument3 pagesDJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADIANTOROPas encore d'évaluation

- Steam Condensate Pot SizingDocument1 pageSteam Condensate Pot SizingmaniazharPas encore d'évaluation

- RT PDFDocument2 pagesRT PDFsri9987Pas encore d'évaluation

- Tank Pressure During Pump OutDocument1 pageTank Pressure During Pump OutRexx MexxPas encore d'évaluation

- Three Phase Separator Sizing Overflow WeirDocument3 pagesThree Phase Separator Sizing Overflow WeirDazzy 265Pas encore d'évaluation

- Steam CoilDocument6 pagesSteam CoilMyung Ho SynPas encore d'évaluation

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801Pas encore d'évaluation

- RD 810Document73 pagesRD 810Ashish MishraPas encore d'évaluation

-  Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)Document16 pages Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)KalpeshJadhavPas encore d'évaluation

- Spreadsheet To Design SeparatorsDocument21 pagesSpreadsheet To Design SeparatorsreninbabaskiPas encore d'évaluation

- Calculation Sheet - Working Volume - Piping UpdateDocument4 pagesCalculation Sheet - Working Volume - Piping UpdateamiyachemPas encore d'évaluation

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 pagesSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierPas encore d'évaluation

- ΔP criteria ΔP criteria ρV ρVDocument3 pagesΔP criteria ΔP criteria ρV ρVjenish parekhPas encore d'évaluation

- Colum Specification SheetDocument6 pagesColum Specification SheetEddy RainPas encore d'évaluation

- P RefStd - 4043 - v091130 - EN - LOPADocument18 pagesP RefStd - 4043 - v091130 - EN - LOPAlucianduPas encore d'évaluation

- Distillation Theoretical Stages CalculatorDocument1 557 pagesDistillation Theoretical Stages Calculatorgautam_96948069Pas encore d'évaluation

- R1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0ADocument4 pagesR1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0AAHMED AMIRAPas encore d'évaluation

- Process Engineer - PSV SizingDocument3 pagesProcess Engineer - PSV SizingLaorenciaPas encore d'évaluation

- Pump CalcDocument1 pagePump CalcMoch WildanPas encore d'évaluation

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFDocument4 pagesVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezPas encore d'évaluation

- Two Phase Horizontal Separator - Design ProcedureDocument24 pagesTwo Phase Horizontal Separator - Design Procedurekennethmsoriano100% (1)

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanPas encore d'évaluation

- PSV D-103Document24 pagesPSV D-103DIANTOROPas encore d'évaluation

- Specification For Air Compressors and Air Dryer PackagesDocument21 pagesSpecification For Air Compressors and Air Dryer PackagesSudjono BroPas encore d'évaluation

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolawePas encore d'évaluation

- Relief and Blowdown Report: Page 1 of 21Document21 pagesRelief and Blowdown Report: Page 1 of 21TarekPas encore d'évaluation

- Fdocuments - in Separator Sizing SpreadsheetDocument31 pagesFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaPas encore d'évaluation

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14Pas encore d'évaluation

- GPSA - Methanol Inhibition Rate RevisedDocument11 pagesGPSA - Methanol Inhibition Rate RevisedrmaganPas encore d'évaluation

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document15 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Mustafa AhsanPas encore d'évaluation

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuPas encore d'évaluation

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiPas encore d'évaluation

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPPas encore d'évaluation

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1Pas encore d'évaluation

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006Pas encore d'évaluation

- 8-0241-4503-Flare System Design PDFDocument8 pages8-0241-4503-Flare System Design PDFVinothrajaPas encore d'évaluation

- Volume 3-The Origins of ProtreatDocument2 pagesVolume 3-The Origins of ProtreatIbhar Santos MumentheyPas encore d'évaluation

- Cvts - Tag No. Mpt-tv-4161Document2 pagesCvts - Tag No. Mpt-tv-4161biswasdipankar05Pas encore d'évaluation

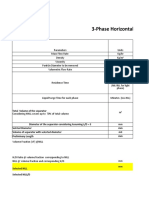

- 3-Phase Sparator Sizing (Vertical and Horizontal)Document30 pages3-Phase Sparator Sizing (Vertical and Horizontal)WickyPas encore d'évaluation

- 00000-Jds-003 (Level Trans DS) Rev 0Document4 pages00000-Jds-003 (Level Trans DS) Rev 0sithulibraPas encore d'évaluation

- Dokumen - Tips - Gpsa 13 Ed Separation PDFDocument48 pagesDokumen - Tips - Gpsa 13 Ed Separation PDFNovi WulansariPas encore d'évaluation

- BDVDocument3 pagesBDVJason ThomasPas encore d'évaluation

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiPas encore d'évaluation

- DDG-T-P-03310 Condensate StripperDocument11 pagesDDG-T-P-03310 Condensate StripperCristinaPas encore d'évaluation

- DJM MBA PCS CA 011 de Butanizer Accumulator REV 1Document6 pagesDJM MBA PCS CA 011 de Butanizer Accumulator REV 1DIANTOROPas encore d'évaluation

- DJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDocument6 pagesDJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDIANTOROPas encore d'évaluation

- Macro: This Worksheets Use Visual Basic Module Regarding ToDocument56 pagesMacro: This Worksheets Use Visual Basic Module Regarding ToOlumuyiwa FasehunPas encore d'évaluation

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171Pas encore d'évaluation

- Unlock Separator SizingDocument42 pagesUnlock Separator SizingmortezasabetiPas encore d'évaluation

- Validation Report On The 2 Phase Line Sizing 3 PDFDocument18 pagesValidation Report On The 2 Phase Line Sizing 3 PDFJoseph MedinaPas encore d'évaluation

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuPas encore d'évaluation

- Tank Venting Capacity-Fire CaseDocument1 pageTank Venting Capacity-Fire CaseAjay TiwariPas encore d'évaluation

- Sizing Hydrocracking ReactorDocument2 pagesSizing Hydrocracking ReactorMeidinaSekarNadistiPas encore d'évaluation

- 1055 Crude Stailization Systems-SperoidsDocument0 page1055 Crude Stailization Systems-SperoidsgshdavidPas encore d'évaluation

- Level Transmitter MSPLDocument6 pagesLevel Transmitter MSPLPratap ShettyPas encore d'évaluation

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomPas encore d'évaluation

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomPas encore d'évaluation

- A3080 6040 Dat MC 142 eDocument11 pagesA3080 6040 Dat MC 142 erameshqcPas encore d'évaluation

- 2 Phase Vertical Separator Sizing Calculation-AUHDocument26 pages2 Phase Vertical Separator Sizing Calculation-AUHMike Dukas100% (1)

- EFS P&ID DetailsDocument2 pagesEFS P&ID DetailsAJAY1381Pas encore d'évaluation

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381Pas encore d'évaluation

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381Pas encore d'évaluation

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381Pas encore d'évaluation

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381Pas encore d'évaluation

- Vijay Resignation LetterDocument1 pageVijay Resignation LetterAJAY1381Pas encore d'évaluation

- ASME U StampDocument2 pagesASME U StampAJAY1381Pas encore d'évaluation

- Select Your Seat and Web Checkin Online - IndiGoDocument2 pagesSelect Your Seat and Web Checkin Online - IndiGoAJAY1381Pas encore d'évaluation

- 10% Torispherical Dished Ends: Di/Do MM Ri MM Ri MM THK Min Max Hi MM Vol LitresDocument1 page10% Torispherical Dished Ends: Di/Do MM Ri MM Ri MM THK Min Max Hi MM Vol LitresAJAY1381Pas encore d'évaluation

- Study Facilitation Capability FlyerDocument1 pageStudy Facilitation Capability FlyerAJAY1381Pas encore d'évaluation

- Beer ProcessDocument251 pagesBeer ProcessAJAY1381100% (2)

- More Issues With LOPA-From The Originators-WebsiteDocument23 pagesMore Issues With LOPA-From The Originators-WebsiteAJAY1381Pas encore d'évaluation

- Pump Calculation Basic Pump DataDocument2 pagesPump Calculation Basic Pump DataAJAY1381Pas encore d'évaluation

- ML Tank-Horizontal Tank Sizing Rev 0Document1 pageML Tank-Horizontal Tank Sizing Rev 0AJAY1381Pas encore d'évaluation

- Sr. No. Parameter Unit: ML Treatment Tank Cynauric Chloride Pasting VesselDocument1 pageSr. No. Parameter Unit: ML Treatment Tank Cynauric Chloride Pasting VesselAJAY1381Pas encore d'évaluation

- Synopsis - Randstad - Revised VersionDocument3 pagesSynopsis - Randstad - Revised VersionAJAY1381Pas encore d'évaluation

- SDS-01-M-01 Heavy Fuel Oil HeaterDocument2 pagesSDS-01-M-01 Heavy Fuel Oil HeaterAJAY1381Pas encore d'évaluation

- Chem Brouchure PDFDocument16 pagesChem Brouchure PDFPirpasha UjedePas encore d'évaluation

- Bernoulli Venturi NozzleDocument4 pagesBernoulli Venturi NozzleFrank PingolPas encore d'évaluation

- Chapter ThreeDocument53 pagesChapter ThreeESRAEL GETUPas encore d'évaluation

- First Internal Question PaperDocument2 pagesFirst Internal Question PaperVenkitaraj K PPas encore d'évaluation

- Application of Spiral Heat Exchangers in Heavy Oil Service External PDFDocument27 pagesApplication of Spiral Heat Exchangers in Heavy Oil Service External PDFProcess EngineerPas encore d'évaluation

- Lecture 4 - Rate Law and StoichiometryDocument32 pagesLecture 4 - Rate Law and StoichiometryNizam JumadiPas encore d'évaluation

- Spe 8025 MS PDFDocument36 pagesSpe 8025 MS PDFvictory cvsgPas encore d'évaluation

- High-Velocity Oxygent Fuel (HVOF) Metal SprayDocument16 pagesHigh-Velocity Oxygent Fuel (HVOF) Metal SprayEdy SuprayitnoPas encore d'évaluation

- Dynamic Simulation of Naphtha Stabilizer - Draft4Document76 pagesDynamic Simulation of Naphtha Stabilizer - Draft4G Vengat VinayagamPas encore d'évaluation

- Department of Education: Learning Activity SheetDocument4 pagesDepartment of Education: Learning Activity SheetKaren May UrlandaPas encore d'évaluation

- Assignment Excel ProbDocument2 pagesAssignment Excel ProbUsman HasanPas encore d'évaluation

- Group 7Document13 pagesGroup 7Alhaj Massoud100% (1)

- Referencias BibliograficasDocument2 pagesReferencias BibliograficasRafael VictoriaPas encore d'évaluation

- Geotechnical Engineering-IIDocument1 pageGeotechnical Engineering-IISubhadip GhosalPas encore d'évaluation

- Thermodynamic II PDFDocument33 pagesThermodynamic II PDFحيدر محمدPas encore d'évaluation

- ETP Drawing - SL - FMS12MAR2021 - Option - 1Document1 pageETP Drawing - SL - FMS12MAR2021 - Option - 1muhammad saqib IlyasPas encore d'évaluation

- Asfdhj PDFDocument130 pagesAsfdhj PDFDilin Dinesh MEPas encore d'évaluation

- 4095 - Stulz MRD 552 PDFDocument114 pages4095 - Stulz MRD 552 PDFxuyen tranPas encore d'évaluation

- Nuflo Orifice PlatesDocument8 pagesNuflo Orifice PlatesnwabukingzPas encore d'évaluation

- Introduce: Expansion Production Change) (Pressure Ility) Compressib (Total Volume) (Pore - Time RateDocument3 pagesIntroduce: Expansion Production Change) (Pressure Ility) Compressib (Total Volume) (Pore - Time RateariPas encore d'évaluation

- Fluid MechanicsDocument19 pagesFluid MechanicsPangerwati OzukumPas encore d'évaluation

- Chemical Reaction EngineeringDocument93 pagesChemical Reaction EngineeringGuru Raj BhattPas encore d'évaluation

- Mer - We - db3120 - Domestic Hot Water Produc DiagramDocument6 pagesMer - We - db3120 - Domestic Hot Water Produc DiagramtienlamPas encore d'évaluation

- Spaix V2 Database Update: Release 2017-04-12Document3 pagesSpaix V2 Database Update: Release 2017-04-12Diego PobletePas encore d'évaluation

- Esquema Hidraulico Rbb1-1127Document2 pagesEsquema Hidraulico Rbb1-1127David TurpoPas encore d'évaluation

- NFPA 25 2011 Sprinkler Inspection TableDocument2 pagesNFPA 25 2011 Sprinkler Inspection TableHermes VacaPas encore d'évaluation

- Daftar Kebutuhan Gas Medis IcuDocument4 pagesDaftar Kebutuhan Gas Medis IcuGamerBro IDPas encore d'évaluation

- Heat T ch1Document30 pagesHeat T ch1Fira tubePas encore d'évaluation

- An Evaluation of Ablation Mechanisms For The Apollo Heat Shield MaterialDocument7 pagesAn Evaluation of Ablation Mechanisms For The Apollo Heat Shield MaterialKanishka LankatillakePas encore d'évaluation