Académique Documents

Professionnel Documents

Culture Documents

2017-08-11 Machinery List KDWB PK Transport

Transféré par

aristya_redmi20 évaluation0% ont trouvé ce document utile (0 vote)

13 vues1 pagemachinery list bulking weigher design

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentmachinery list bulking weigher design

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

13 vues1 page2017-08-11 Machinery List KDWB PK Transport

Transféré par

aristya_redmi2machinery list bulking weigher design

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

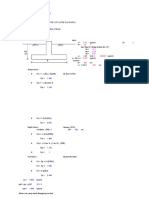

EQUIPMENT QUANTITY Installed DOCUMENT

DESCRIPTION Power REMARKS

Stand (kW) SPECIFICATION

Install Run Unit DRAWING NUMBER

by CODE NO.

A. Kernel Receiving Station

1 Kernel Receiving Screw Conveyor 2 2 0 Unit(s) - - existing equipment

2 Kernel Receiving Screw Conveyor no.3 1 1 0 Unit(s) 15 STD-M-GM-SCW.500-PB GM.06

3 Kernel Receiving Screw Conveyor no.4 1 1 0 Unit(s) 11 STD-M-GM-SCW.500-PB GM.06

4 Kernel Receiving Screw Conveyor no.5 1 1 0 Unit(s) 7.5 STD-M-GM-SCW.500-PB GM.06

5 Kernel Receiving Elevator no. 1 1 1 0 Unit(s) - - existing equipment

6 Kernel Receiving Elevator no. 2 1 1 0 Unit(s) 4 STD-M-GM-ELV.DBL GM.16

7 Double Hopper Weigher cap.15 ton PK/hour 2 2 0 Unit(s) - BS.17.01 Owner Supplied

- Rotary Feeder 2 2 0 Unit(s) 1.5 - - Owner Supplied

- Weighing System 2 2 0 Unit(s) - - Owner Supplied

8 Pneumatic Unloader 1 1 0 Unit(s) 18.5 - BS.16.01 Owner Supplied

9 Air Compressor 1 1 0 Unit(s) 5.5 - AC.01

B. Kernel Shipping Station

1 Feeding Hopper Elevator 1 1 0 Unit(s) 5.5 KDWB-DWG-M-BLS-ELV GM.16.01

2 Double Hopper Weigher cap.70 ton PK/hour 2 2 0 Unit(s) - BS.17.01 Owner Supplied

- Rotary Feeder 2 2 0 Unit(s) 1.5 - - Owner Supplied

- Weighing System 2 2 0 Unit(s) - - Owner Supplied

3 Discharge Hopper Scrapper Conveyor 1 1 0 Unit(s) 2.2 STD-M-GM-SCP.1200-BMD-8 GM.47.09

4 Discharge Hopper Elevator 1 1 0 Unit(s) 4 KDWB-DWG-M-BLS-ELV GM.16.01

C. Piping, Valves, Fitting and Insulation

1 Piping and Fitting 1 1 0 Lot - PP.01

2 Pipe Support and Hanger 1 1 0 Lot - PP.02

3 Pipe Connection 1 1 0 Lot - PP.03

4 Pipe Inspection and Test 1 1 0 Lot - PP.04

5 Valves 1 1 0 Lot - PP.05

6 Accessories 1 1 0 Lot - PP.06

D. Miscellaneous Equipment

1 Painting 1 1 0 Lot - MS.06

2 Supporting Equipment 1 1 0 Lot - MS.07

Vous aimerez peut-être aussi

- Distribusi Muatan Sumbu Terberat Kendaraan Niaga: No. Description Load Distribution Example MST (Ton)Document4 pagesDistribusi Muatan Sumbu Terberat Kendaraan Niaga: No. Description Load Distribution Example MST (Ton)aristya_redmi2Pas encore d'évaluation

- Tor LampungDocument8 pagesTor Lampungaristya_redmi2Pas encore d'évaluation

- CV Hendri Farabi - IQCSDocument5 pagesCV Hendri Farabi - IQCSaristya_redmi2Pas encore d'évaluation

- Upgrade VCT 90 MTDocument6 pagesUpgrade VCT 90 MTaristya_redmi2Pas encore d'évaluation

- Referensi - Perhitungan AnchorDocument3 pagesReferensi - Perhitungan Anchoraristya_redmi2100% (1)

- 2014-12-17 Referensi Design Warehouse LampungDocument55 pages2014-12-17 Referensi Design Warehouse Lampungaristya_redmi2Pas encore d'évaluation

- Shallow Foundation of Shell Receiving: Design LoadDocument4 pagesShallow Foundation of Shell Receiving: Design Loadaristya_redmi2Pas encore d'évaluation

- 2015-06-25 Weight List and DimensionDocument6 pages2015-06-25 Weight List and Dimensionaristya_redmi2Pas encore d'évaluation

- 00 PKWM - Repair of Loading Ramp HopperDocument1 page00 PKWM - Repair of Loading Ramp Hopperaristya_redmi2Pas encore d'évaluation

- 2015-12-03 Perhitungan Penambahan FenderDocument11 pages2015-12-03 Perhitungan Penambahan Fenderaristya_redmi2Pas encore d'évaluation

- Simulasi Perhitungan Tadah Hujan: 1. Kolam Air ExistingDocument4 pagesSimulasi Perhitungan Tadah Hujan: 1. Kolam Air Existingaristya_redmi2Pas encore d'évaluation

- Sharing Session: Pond Modeling and Material Quantity Analysis in Autocad Civil 3DDocument3 pagesSharing Session: Pond Modeling and Material Quantity Analysis in Autocad Civil 3Daristya_redmi2Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Screw Conveyor Engineering GuideDocument72 pagesScrew Conveyor Engineering GuideGOWTHAM R100% (1)

- Vogele S 1603 2 DatasheetDocument14 pagesVogele S 1603 2 DatasheethydraulicalnudumePas encore d'évaluation

- BOMAG Finisher BF 800. The Heavy Weight ChampionDocument20 pagesBOMAG Finisher BF 800. The Heavy Weight ChampionVany LunaPas encore d'évaluation

- 7 Finisoare de Asfalt Pe Senile Volvo p7820c p8820c 47543Document16 pages7 Finisoare de Asfalt Pe Senile Volvo p7820c p8820c 47543Farkas PalPas encore d'évaluation

- Dynapac Large Tracked Paver Range: SD2500C / SD2500CS / SD2550C / SD2550CSDocument20 pagesDynapac Large Tracked Paver Range: SD2500C / SD2500CS / SD2550C / SD2550CSEgika AgungPas encore d'évaluation

- John Deere 6620 Parts CatalogDocument20 pagesJohn Deere 6620 Parts Catalogkathy100% (52)

- User Manual v1 - 100Document42 pagesUser Manual v1 - 100Benoit DéryPas encore d'évaluation

- Design and Analysis of U-Shaped Ribbon Blender With Screw ConveyorDocument9 pagesDesign and Analysis of U-Shaped Ribbon Blender With Screw ConveyorPhượng NguyễnPas encore d'évaluation

- Hopper Install PDFDocument40 pagesHopper Install PDFPSKUMAR2012Pas encore d'évaluation

- Archimedys Technical Data - Metric - GB 11264 PDFDocument43 pagesArchimedys Technical Data - Metric - GB 11264 PDFAnonymous Cxriyx9HIXPas encore d'évaluation

- Screw Conveyor O&M ManualDocument20 pagesScrew Conveyor O&M Manualjay b100% (1)

- Chapter09eng LowresDocument25 pagesChapter09eng Lowresmohamed AdelPas encore d'évaluation

- Buyers Snow Plow Parts 2018Document124 pagesBuyers Snow Plow Parts 2018GregGGHPas encore d'évaluation

- Bucket Elevator Chains in OmanDocument4 pagesBucket Elevator Chains in OmanAkhil PaulPas encore d'évaluation

- John Deere Cts Parts CatalogDocument20 pagesJohn Deere Cts Parts Catalogmary100% (54)

- Capello Spartan en 2016Document8 pagesCapello Spartan en 2016Radu BarbaPas encore d'évaluation

- Design of ConveyorsDocument15 pagesDesign of ConveyorsRamachandran VenkateshPas encore d'évaluation

- Manual Erato Gp20+Ver10 enDocument46 pagesManual Erato Gp20+Ver10 enclaudiuoctPas encore d'évaluation

- P75 Commander Mixer Spec SheetDocument2 pagesP75 Commander Mixer Spec SheetPowerscreen BajioPas encore d'évaluation

- CH 7 CoveyorsDocument37 pagesCH 7 CoveyorsEbrahim Ali100% (1)

- ConveyorsDocument9 pagesConveyorsZwitsal Roslinda Auditor0% (1)

- Centrifugation: Difference Densities of The Two Liquids Small Force of Gravity WeakDocument34 pagesCentrifugation: Difference Densities of The Two Liquids Small Force of Gravity WeakLAKSHAYPas encore d'évaluation

- John Deere Combine Belts - 6600Document3 pagesJohn Deere Combine Belts - 6600Volodymyr KuruchPas encore d'évaluation

- Conveyor System Used in Coal Power PlantDocument15 pagesConveyor System Used in Coal Power PlantSalman UddinPas encore d'évaluation

- Thesis in Fluid MachineriesDocument71 pagesThesis in Fluid MachineriesSiN XPas encore d'évaluation

- Screw Conveyor.: C:/Documents and Settings/Damir/Desktop/ Kalkulacija Spirale Transportera - Screw - Conveyor PDFDocument7 pagesScrew Conveyor.: C:/Documents and Settings/Damir/Desktop/ Kalkulacija Spirale Transportera - Screw - Conveyor PDF022freePas encore d'évaluation

- INTEGRADocument24 pagesINTEGRAJhon Jairo Arango MarquezPas encore d'évaluation

- John Deere 7720 COMBINE WITH 224 RIGID PLATFORM Parts Catalog-1-31Document31 pagesJohn Deere 7720 COMBINE WITH 224 RIGID PLATFORM Parts Catalog-1-31Retro Animados100% (1)

- Perator S Anual: Snow ThrowerDocument24 pagesPerator S Anual: Snow ThrowerSaman SafdarPas encore d'évaluation