Académique Documents

Professionnel Documents

Culture Documents

Assignment 2

Transféré par

Laura RobayoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assignment 2

Transféré par

Laura RobayoDroits d'auteur :

Formats disponibles

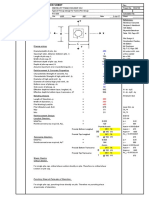

MECH 6561 Assignment 2 Due on July 19th, 2016

1. The lower yield point for a certain plain carbon steel bar is found to be 135 MPa, while a second

bar of the same composition yields at 260 MPa. Metallographic analysis shows that the average

grain diameter is 50 m in the first bar and 8 m in the second bar.

(a) Predict the grain diameter needed to cause a lower yield point of 205 MPa.

(b) If the steel could be fabricated to form a stable grain structure of 500 nm grains, what

strength would be predicted?

2. Some alloys use a combination of strain hardening and precipitation hardening to achieve

particularly high strength levels. The usual order of strengthening is solution treatment,

quenching, cold working, and finally precipitation heat treatment. Why not reverse the order of

the cold working and precipitation heat treatment steps?

3. A thin-walled pressure vessel 1.25-cm thick originally contained a small semicircular flaw (radius

0.25-cm) located at the inner surface and oriented normal to the hoop stress direction. Repeated

pressure cycling enabled the crack to grow larger. If the fracture toughness of the material is

88MPa , the yield strength equal to 825 MPa, and the hoop stress equal to 275 MPa, would the

vessel leak before it ruptured?

4. Discuss the strengthening techniques that may be used to enhance the fatigue resistance

5. A mild steel plate is subjected to constant uniaxial fatigue loads to produce stresses varying from

= 160 MPa and = -20 MPa. The static properties of the steel are = 500 MPa, Su=

1/2

600 MPa, E= 207 GPa and Kc= 100 MPa m . If the plate contains an initial through thickness

edge crack of 0.5 mm, how many fatigue cycles will be required to break the plate?

Assume the relationship between crack growth and fracture toughness to be:

Vous aimerez peut-être aussi

- Metal matrix composites: Processing and InterfacesD'EverandMetal matrix composites: Processing and InterfacesR EverettPas encore d'évaluation

- Corrosion Resistance of Cerium-Doped Zinc Calcium Phosphate Chemical Conversion Coatings On AZ31 Magnesium AlloyDocument15 pagesCorrosion Resistance of Cerium-Doped Zinc Calcium Phosphate Chemical Conversion Coatings On AZ31 Magnesium AlloyMichael Merino CrispinPas encore d'évaluation

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesD'EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesPas encore d'évaluation

- Reduction of Ferric Oxides in The Red Mud by The Aluminıothermic ProcessDocument5 pagesReduction of Ferric Oxides in The Red Mud by The Aluminıothermic Processlaurentiu_filipescuPas encore d'évaluation

- Adiabatic Shear Localization: Frontiers and AdvancesD'EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddPas encore d'évaluation

- 2 Upsetting Test of Forgeability of MetalDocument9 pages2 Upsetting Test of Forgeability of MetalJc Ong100% (1)

- ME 292 - Metallic Materials SessionalDocument39 pagesME 292 - Metallic Materials SessionalMuhammedNayeemPas encore d'évaluation

- Engineering Alloys (Non Ferrous)Document52 pagesEngineering Alloys (Non Ferrous)Sukhwinder Singh GillPas encore d'évaluation

- Lecture 5-6-Grossman and Jominy HardenabilityDocument58 pagesLecture 5-6-Grossman and Jominy Hardenabilitychristofer kevinPas encore d'évaluation

- Cast Iron DampingDocument5 pagesCast Iron Dampinggabs88Pas encore d'évaluation

- W6 Lecture 6.surface Hardening of Steel PDFDocument28 pagesW6 Lecture 6.surface Hardening of Steel PDFYota KimirePas encore d'évaluation

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuPas encore d'évaluation

- EBSD Overview NowellDocument86 pagesEBSD Overview NowellRolando Nuñez MonrroyPas encore d'évaluation

- Magnesium-Alloy Sheet and Plate: Standard Specification ForDocument6 pagesMagnesium-Alloy Sheet and Plate: Standard Specification ForDanZel DanPas encore d'évaluation

- lectut-MTN-513-pdf-Structure of Crystalline CeramicsDocument53 pageslectut-MTN-513-pdf-Structure of Crystalline CeramicsAkash AgarwalPas encore d'évaluation

- 2 Cast Iron FatigueDocument47 pages2 Cast Iron FatigueBruno BrepohlPas encore d'évaluation

- Danes HM A Nesh 2003Document6 pagesDanes HM A Nesh 2003Rina OktapianiPas encore d'évaluation

- Introduction To Materials: Prof. H. K. KhairaDocument75 pagesIntroduction To Materials: Prof. H. K. KhairaDhanush NairPas encore d'évaluation

- Chapter2 - AJMDocument13 pagesChapter2 - AJMravish kumarPas encore d'évaluation

- Common Causes of Premature Failure of MN SteelDocument3 pagesCommon Causes of Premature Failure of MN Steeldrackensohn100% (1)

- Aco HadfieldDocument22 pagesAco HadfieldFelipe ZanellaPas encore d'évaluation

- Microsoft PowerPoint - Austenitic Manganese Steel Compatibility Mode 2Document81 pagesMicrosoft PowerPoint - Austenitic Manganese Steel Compatibility Mode 2Damla Kaymakçı100% (1)

- Fenomena TWIP Dan TRIP Pada Material Dan Pengaruhnya Terhadap KetangguhanDocument2 pagesFenomena TWIP Dan TRIP Pada Material Dan Pengaruhnya Terhadap KetangguhanAtika RahmahwatiPas encore d'évaluation

- Toughness - WikipediaDocument3 pagesToughness - WikipediaaliPas encore d'évaluation

- Fe Fe3c Diagram PDFDocument2 pagesFe Fe3c Diagram PDFAmyPas encore d'évaluation

- Fracture MechanicsDocument16 pagesFracture Mechanicskamal hameed tayyPas encore d'évaluation

- Phase Diagram Study of Alloys in Iron Carbon Chromium Mo-NiDocument13 pagesPhase Diagram Study of Alloys in Iron Carbon Chromium Mo-NiRavichandran JayaprakashPas encore d'évaluation

- 2 - Ashby Method: 2.1 - Introduction To Materials SelectionDocument25 pages2 - Ashby Method: 2.1 - Introduction To Materials Selectionsgr_kansagraPas encore d'évaluation

- Metal FormingDocument80 pagesMetal Formingashok PradhanPas encore d'évaluation

- CleanSteel9 2015 CAPURRO PDFDocument11 pagesCleanSteel9 2015 CAPURRO PDFSpark Fernando Calderon ContrerasPas encore d'évaluation

- An Investigation of The Causes That Lead To Burn-InBurn-On in Heavy PDFDocument13 pagesAn Investigation of The Causes That Lead To Burn-InBurn-On in Heavy PDFTraian TiberiuPas encore d'évaluation

- c1 Mechanical PropertiesDocument46 pagesc1 Mechanical PropertiesHusnal TaufiqPas encore d'évaluation

- Practise Question (Calculations) AnswerDocument26 pagesPractise Question (Calculations) AnswerYeo JosephPas encore d'évaluation

- Charpy Impact Test: Experiment 2Document5 pagesCharpy Impact Test: Experiment 2Utkarsh KumarPas encore d'évaluation

- Non-Ferrous Alloys: Dr. Indika de Silva Senior Lecturer Dept. of Materials Science & Engineering University of MoratuwaDocument68 pagesNon-Ferrous Alloys: Dr. Indika de Silva Senior Lecturer Dept. of Materials Science & Engineering University of MoratuwaChandima K Priyamal100% (1)

- Astm F 1295 - 01Document4 pagesAstm F 1295 - 01Marcos Verissimo Juca de PaulaPas encore d'évaluation

- Ni ResistDocument2 pagesNi ResistAslan AlpPas encore d'évaluation

- 1.0 TitleDocument10 pages1.0 TitlezackziffiPas encore d'évaluation

- Effects of Cold Work: Stress-Strain Curves For A Material With Progressively Increasing Cold WorkDocument31 pagesEffects of Cold Work: Stress-Strain Curves For A Material With Progressively Increasing Cold Workel modridistaPas encore d'évaluation

- Tungsten CarbideDocument47 pagesTungsten CarbideAmit DhekalePas encore d'évaluation

- Inverse Chill in Ductile Iron CastingsDocument2 pagesInverse Chill in Ductile Iron Castingsdemiancito06Pas encore d'évaluation

- Wettability (Kemampubasahan) (Compatibility Mode)Document38 pagesWettability (Kemampubasahan) (Compatibility Mode)Ujang Daud SeptianPas encore d'évaluation

- Mse Notes - Unit - 2Document12 pagesMse Notes - Unit - 2337-ME- KIRTHAN DEVADIGAPas encore d'évaluation

- JMATPRO Ifhtse 2008Document4 pagesJMATPRO Ifhtse 2008FahrgerustePas encore d'évaluation

- Crystals 12 00978Document9 pagesCrystals 12 00978irmaPas encore d'évaluation

- Charpy Impact TestDocument2 pagesCharpy Impact TestAnonymous QmVGKZSM100% (1)

- Ebsd (Electron Backscattered Diffraction)Document45 pagesEbsd (Electron Backscattered Diffraction)mm11_nedPas encore d'évaluation

- MartensiteDocument2 pagesMartensitemp87_ingPas encore d'évaluation

- Chapter2 Bonding and PropertiesDocument71 pagesChapter2 Bonding and PropertiesShahd AlhamaydaPas encore d'évaluation

- Chapter 3: Tensile TestingDocument10 pagesChapter 3: Tensile TestingKhairul MuzafarPas encore d'évaluation

- Heat Treatment by Quenching - DiagramsDocument20 pagesHeat Treatment by Quenching - Diagramssunilmathew4477Pas encore d'évaluation

- Lecture 10 Fracture MechanicsDocument21 pagesLecture 10 Fracture Mechanicsantoine demeire100% (3)

- MetalografiDocument40 pagesMetalografisunaryoPas encore d'évaluation

- SolidificationDocument10 pagesSolidificationAnonymous RY3dAWN9o100% (1)

- TEM Lecture CrystallineDocument30 pagesTEM Lecture CrystallineSyed Abdul AhadPas encore d'évaluation

- RMW3 20 Harata TDocument18 pagesRMW3 20 Harata TmaghfiraPas encore d'évaluation

- Characterizing Metallic Microstructure Cu-Based AlloysDocument51 pagesCharacterizing Metallic Microstructure Cu-Based AlloysjuegyiPas encore d'évaluation

- Aluminum 2024 T6Document4 pagesAluminum 2024 T6Thiru Kumaran0% (1)

- A Comparative Study of The Forming-Limit Diagram Next Term Models For Sheet SteelsDocument8 pagesA Comparative Study of The Forming-Limit Diagram Next Term Models For Sheet SteelsRaghav KhajuriaPas encore d'évaluation

- Assignment ProcessDocument2 pagesAssignment ProcessMuhammad Nazmul Hassan KhanPas encore d'évaluation

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerWael ChouchaniPas encore d'évaluation

- Truss and Gridder RoofDocument37 pagesTruss and Gridder RoofYashi GuptaPas encore d'évaluation

- Pile Cap Design OriDocument14 pagesPile Cap Design OriHoihogo Hoi100% (1)

- Technical Note of GM-GCLDocument3 pagesTechnical Note of GM-GCLAnonymous CQ4rbzLVEPas encore d'évaluation

- Gray Water SystemDocument12 pagesGray Water SystemElie HajjPas encore d'évaluation

- Astm D3163 01 2023Document2 pagesAstm D3163 01 2023Georgiy MakedonovPas encore d'évaluation

- PC2 BPDocument9 pagesPC2 BPAUNGPSPas encore d'évaluation

- TOE Theory of FailuresDocument20 pagesTOE Theory of Failuresajithkr4114Pas encore d'évaluation

- Fluid Flow OperationDocument2 pagesFluid Flow OperationShubham imtsPas encore d'évaluation

- Copper Fittings For HVACR Applications 082820Document7 pagesCopper Fittings For HVACR Applications 082820Md Saddam HossainPas encore d'évaluation

- BOQ ExcelDocument4 pagesBOQ Excelnandini100% (1)

- Price List: Supplier Cost I. Steel Unit SGIDocument4 pagesPrice List: Supplier Cost I. Steel Unit SGIBords MoralesPas encore d'évaluation

- Major Bridge Estimate (Well Found.)Document12 pagesMajor Bridge Estimate (Well Found.)Mohammed Faiz100% (1)

- SPE 76-002 (2006) Flange MaterialsDocument6 pagesSPE 76-002 (2006) Flange Materials김창배Pas encore d'évaluation

- Bahirdar Model Exam CIVILEngEXIT - 230710 - 040757Document21 pagesBahirdar Model Exam CIVILEngEXIT - 230710 - 040757Tadesse MegersaPas encore d'évaluation

- Mat FoundationDocument38 pagesMat FoundationDinarWahyuPas encore d'évaluation

- Advert - 31.10.23-1Document19 pagesAdvert - 31.10.23-1Isaac GisorePas encore d'évaluation

- Final Estimation BridgeDocument21 pagesFinal Estimation BridgeMahesh ShindePas encore d'évaluation

- Job Description Print Preview - Professor - Civil, Architectural EngineeringDocument1 pageJob Description Print Preview - Professor - Civil, Architectural EngineeringStacy JohnsonPas encore d'évaluation

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- Microstructure and Mechanical Properties of AustenDocument7 pagesMicrostructure and Mechanical Properties of AustenkarahandevrimPas encore d'évaluation

- Gherkin PresentationDocument32 pagesGherkin Presentationravi ram100% (1)

- Eigen 16Document4 pagesEigen 16Essenam GOLIPas encore d'évaluation

- Viscosity of Fluids-Newtonian and Non Newtonian Analysis As Applied To PlasticsDocument20 pagesViscosity of Fluids-Newtonian and Non Newtonian Analysis As Applied To PlasticsSushmaPas encore d'évaluation

- Indian Standard Is 456 2000 COMPILEDDocument61 pagesIndian Standard Is 456 2000 COMPILEDKalasekar M Swamy79% (14)

- The Crack Tip Opening Displacement in Elastic-Plastic Fracture Mechanics - Proceedings of The Workshop On The CTOD MethodologyDocument364 pagesThe Crack Tip Opening Displacement in Elastic-Plastic Fracture Mechanics - Proceedings of The Workshop On The CTOD Methodologyrafael.aniceto7348Pas encore d'évaluation

- Fluid Mechanics Chapter 5-Conservation of MassDocument12 pagesFluid Mechanics Chapter 5-Conservation of MassFirdaus OthmanPas encore d'évaluation

- QuickSelection AppliedProducts PDFDocument40 pagesQuickSelection AppliedProducts PDFPrinces Katherine VergaraPas encore d'évaluation

- Flow of Incompressible Fluids in Conduits & Thin LayersDocument22 pagesFlow of Incompressible Fluids in Conduits & Thin LayerssaimaabdulrasheedPas encore d'évaluation

- Building Works - Piling WorkDocument5 pagesBuilding Works - Piling WorkArup DebnathPas encore d'évaluation

- A Welder’s Handbook to Robotic ProgrammingD'EverandA Welder’s Handbook to Robotic ProgrammingÉvaluation : 5 sur 5 étoiles5/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.D'EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Évaluation : 4 sur 5 étoiles4/5 (5)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!D'EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Évaluation : 4 sur 5 étoiles4/5 (3)

- Digital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSD'EverandDigital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSPas encore d'évaluation

- Artificial You: AI and the Future of Your MindD'EverandArtificial You: AI and the Future of Your MindÉvaluation : 4 sur 5 étoiles4/5 (3)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsD'EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Practical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)D'EverandPractical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)Pas encore d'évaluation

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityD'EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Building with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksD'EverandBuilding with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksPas encore d'évaluation

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildD'EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildÉvaluation : 5 sur 5 étoiles5/5 (5)

- ChatGPT: The Future of Intelligent ConversationD'EverandChatGPT: The Future of Intelligent ConversationÉvaluation : 3.5 sur 5 étoiles3.5/5 (8)

- Artificial Intelligence: From Medieval Robots to Neural NetworksD'EverandArtificial Intelligence: From Medieval Robots to Neural NetworksÉvaluation : 4 sur 5 étoiles4/5 (4)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessD'EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessPas encore d'évaluation

- Artificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesD'EverandArtificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesÉvaluation : 5 sur 5 étoiles5/5 (2)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesD'EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesÉvaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Collection of Raspberry Pi ProjectsD'EverandCollection of Raspberry Pi ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceD'EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceÉvaluation : 5 sur 5 étoiles5/5 (9)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkD'EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkÉvaluation : 5 sur 5 étoiles5/5 (1)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionD'EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionÉvaluation : 3.5 sur 5 étoiles3.5/5 (129)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsD'EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsPas encore d'évaluation