Académique Documents

Professionnel Documents

Culture Documents

Technical - Info MTU 20V4000L62

Transféré par

Marvin Tejerina GarfiasTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical - Info MTU 20V4000L62

Transféré par

Marvin Tejerina GarfiasDroits d'auteur :

Formats disponibles

TB 46218 e 50

OAGD - 26.05.2011

Technical Description

GB

Genset without heat recovery box

AoE 20V4000L62 (robust)

1 Ratings and Emissions

For operation on NATURAL GAS

Methane number MZ 80

Low heat value (LHV) Hu = 8,0-11,5 kWh/mn

Cooling water temperature 90 / 78 C

Genset with synchronous generator

3Ph, 50Hz

for generating

Intake air temperature 30 - 40 C

Gas mixture cooler, intern

integrated

(1st stage HT)

Gas mixture cooler, extern

53 C

(2nd stage LT)

NOx < 500 mg/mn3

1.1 Continuous Operating Data in Grid Parallel Mode

8 % tolerance for thermal outputs and 5 % for total energy input listed. Performance data in accordance with ISO 3046. All data apply to grid

parallel operation. Data for site operating conditions other than those mentioned, available on demand. Max. reactive power in kVA, resp. nominal

current acc. to nominal output of the generator.

GB1948N5 GB1948N5 GB1950N5 GB1948N5 GB1948N5

Generator voltage 400 415 6300 10500 11000 V

Electrical output of generator

1948 1948 1950 1948 1948 kW el

(no overload capacity)

Thermal output

1244 kW th

(Engine cooling / lube oil / 1st stage HT mixture cooler)

Thermal output

99 kW th

(2nd stage LT mixture cooling)

Total energy input 4843 kW

1.2 Part Load Data in Grid Parallel Mode (75 %)

Generator voltage 400 415 6300 10500 11000 V

Electrical output of generator 1461 1463 1463 1460 1460 kW el

Thermal output

922 kW th

(Engine cooling / lube oil / 1st stage HT mixture cooler)

Thermal output

72 kW th

(2nd stage LT mixture cooling)

Total energy input 3713 kW

1.3 Part Load Data in Grid Parallel Mode (50 %)

Generator voltage 400 415 6300 10500 11000 V

Electrical output of generator 972 971 971 969 968 kW el

Thermal output

650 kW th

(Engine cooling / lube oil / 1st stage HT mixture cooler)

Thermal output

49 kW th

(2nd stage LT mixture cooling)

Total energy input 2600 kW

1.4 Continuous Operating Data in Isolated Mode

Generator voltage 400 415 6300 10500 11000 V

Electrical output of generator 1771 1771 1773 1771 1771 kW el

AoE 20V4000L62 /1500/12,1:1/80/9078/omKat/500/

TVU 2010-09-09 / TA 734661e 734657e Seite/Sheet 1 von/of 7

TB 46218 e 50

OAGD - 26.05.2011

Technical Description

GB

1.5 Pollutant Emissions

Emission values related to dry exhaust gas with 5 % O2. (For exhaust gas volume flow see 3.5)

NOx, stated as NO2 < 500 mg/mn3

CO, without catalyst < 1000 mg/mn3

Formaldehyde, without catalyst < 140 mg/mn3

CO, with catalyst

< 300 mg/mn3

(optional, delivered loose)

Formaldehyde, with catalyst

< 60 mg/mn3

(optional, delivered loose)

2 Design Principles / Scope of Supply

Engine and flange-mounted alternator (SAE 00 housing) are connected via a torsionally resilient coupling and resiliently mounted to a

rigid, welded steel base frame.

Standby heater

Lube oil pump for draining the oil sump (incl. two solenoid valves).

The base frame is installed on vibration dampers

2.1 Engine plus Accessories

Otto-Gas-Engine MTU 20V4000L62

Cyl. arrangement, no. of cyl. V 20

Bore / stroke 170 / 210 mm

Volume 95,33 Litre

Speed 1500 1/min

Mean piston speed 10,5 m/s

Compression ratio 12,1:1

Mean effective pressure 16,8 bar

Standard power acc. to ISO 3046,

2000 kW mech

(no overload capacity)

Specific full-load consumption (tolerance 5 %) 2,42 kWh/kWhmech

Gas consumption (based on LHV = 10,03 kWh/m3n) 482,9 m3/h

Lube oil consumption

0,3 g/kWhmech

(not guaranteed, at rated load and after 1000 Oh)

Basic Engine

Monobloc grey cast crankcase with inspection ports, flywheel housing SAE 00, flywheel 21 cast iron oil pan

Forged crankshaft

Forged connecting rods

Four-valve, individual cylinder heads with central pre-chamber armoured valves with Rotocap rotators

Light-metal solid-skirt pistons with oil cooling duct, piston cooling via oil spray nozzles

Mixture Formation

Air intake via dry-type engine-mounted air filters

Venturi type air-gas mixer with gas supply via electronically controlled gas metering valve

Turbocharging

Turbocharger for gas-air mixture compression

Two-stage mixture cooling

Throttles between mixture coolers and intake manifold

Exhaust System

Dry-type, insulated exhaust manifolds in the engine Vee

Lube Oil System

Lube oil circulation pump with safety valve for forced-feed lubrication and piston cooling

Engine mounted heat exchanger

Lube oil filters with replaceable filter elements

Engine-mounted device for automatic oil level control

Oil dipstick

Closed crankcase venting system with oil separator connected to mixture piping before turbo charger

Connections for oil refill and oil draining

AoE 20V4000L62 /1500/12,1:1/80/9078/omKat/500/

TVU 2010-09-09 / TA 734661e 734657e Seite/Sheet 2 von/of 7

TB 46218 e 50

OAGD - 26.05.2011

Technical Description

GB

Cooling System (2-circuit)

High temperature circuit for lube oil cooling, 1st stage of mixture cooling and engine jacket

Connections with counter-flanges for external cooling- or heat recovery system

Integrated cooling preheating unit

Starting System

Electric starter (2x 9 kW, 24 VDC)

Ignition System

Microprocessor-controlled high-voltage spark-ignition system with low voltage distribution, no moving parts, no wear

Automatic control for ignition energy adjustment

Variable timing control

Timing sensors at camshaft and crankshaft

One ignition coil per cylinder

Industrial spark plugs

2.2 Generator

Self-regulating, brushless revolving-field synchronous generator with built-in exciter, voltage and cos regulator, designed to VDE 0530, radio

interference class N, low-harmonic design.

Generatorspannung 400 415 6300 10500 11000 V

Rating (F) 2560 2560 2744 2711 2840 kVA

Insulation class H H F F F

Temperature-rise rating F F F F F

Cos 1,0 - 0,8 1,0 - 0,8 1,0 - 0,8 1,0 - 0,8 1,0 - 0,8

Frequency 50 Hz

Speed 1500 1/min

Efficiency (100 % load) at cos 1 97,4 97,4 97,5 97,4 97,4 %

Stator connection Star

Voltage tolerance 5 %

Frequency tolerance 5 %

Max. ambient temperature. 40 C

Installation altitude max. 1000 m

Type of protection IP 23

*) Cos-phi must be over the whole power range in the defined range. Only inductive reactive power admissible (over-erected).

In case of nominal mains voltage variations by 2 %, an automatic voltage adjustment must be used.

2.3 Gas Supply

Gas regulation lines delivered loose, components approved per Directive for Gas Components 90/356/EWG

Gas Regulation Line

Gas filter

two solenoid valves (or double solenoid valve)

Low pressure regulator

valve leakage monitor

flexible stainless steel hose

2.4 Controller of Genset

MMC

Operation and visualization

Control of auxiliary drives (cogeneration unit / extern)

Connection / seperation of the generator to/from the grid

Control of generator and grid protection functions, see separate description "Technical Description MMC 4000 control"

ECU7

Speed governing

Air / Fuel ratio control via engine characteristic map

Engine start / stop sequence

Emergency stop sequence

Engine monitoring (temperatures, pressures, speed, etc.)

EMU7

Single exhaust temperature monitoring (cylinderhead)

AoE 20V4000L62 /1500/12,1:1/80/9078/omKat/500/

TVU 2010-09-09 / TA 734661e 734657e Seite/Sheet 3 von/of 7

TB 46218 e 50

OAGD - 26.05.2011

Technical Description

GB

SAM

Providing CANopen interface

Lube oil make up

Monitoring of minimum load

Ignition

Electronic ignition system

Ignition time setting

Speed monitoring

Knocking monitoring AKR

Acoustic knocking monitoring system

Individual ignition timing adjustment per cylinder

3 Technical Data Design / Operation

3.1 Operating Media

The binding specifications for cooling water, fuel, lube oil, exhaust condensate and heating water are stipulated in the relevant MTU operating

media regulations.

Values for cooling / heating water are based on water without antifrost and corrosions additives.

Admissible antifrost and corrosions additives see operating media. Values in brackets [ ] refer to 35 % Glycol.

3.2 Filling Quantities

Lube oil quantity (first filling) 378 Liter

Lube oil quantity (consecutive oil changes) 350 Liter

Engine cooling water, HT 310 Liter

Mixture cooling water, LT

23 Liter

(without recooler and pipes)

3.3 Heat Generation

Engine Cooling (engine block with lube oil and 1st stage HT mixture cooling)

Thermal output (8 % tolerance) 1244 kW

Cooling water temperature, in- / outlet 78 / 90 C

Cooling water volume flow 94 [101 ] m/h

Pressure loss 2,6 [3,0 ] bar

System pressure permitted max. 6,0 bar

Cooling water temperature, min. 40 C

Mixture Cooling (2nd stage LT)

Thermal output (8 % tolerance) 99 kW

Mixture cooling water volume flow (8 % tolerance) 30 m3/h

Inlet temperature mixture cooling water max. 52 C

Outlet temperature mixture cooling water max. 55 C

Max. permissible pressure loss outside the heat recovery 0,5 bar

System pressure permitted max. 6,0 bar

Note information pressure control valve.

AoE 20V4000L62 /1500/12,1:1/80/9078/omKat/500/

TVU 2010-09-09 / TA 734661e 734657e Seite/Sheet 4 von/of 7

TB 46218 e 50

OAGD - 26.05.2011

Technical Description

GB

3.4 Combustion Air / Ventilation

Heat radiated from the genset

126 kW

(engine and generator without adjoining pipes)

Engine room ventilation

Minimum intake air volume flow for engine room cooling.

(The engine room ventilation has to be calculated and

adjusted according to the requirements for gaseous fuels

48237 m3/h

valid at the installation site)

Ventilation air volume flow 39443 m3/h

Combustion air volume flow 8067 mn3/h

Intake air temperature min.

(for other temperatures the limit values must be adapted 30 C

after consultation)

Temperature difference intake / ventilation max. < 10 K

max. permissible intake negative pressure at inlet air filter 3 mbar

3.5 Exhaust Gas (Exhaust gas heat exchanger not included in scope of supply, optional)

Thermal output by 120 C (8 % tolerance) 1089 kW

Exhaust temperature

444 C

(turbocharger outlet)

Exhaust gas mass flow, dry 10027 kg/h

Exhaust gas mass flow, moist 10788 kg/h

Exhaust gas volume flow, dry

7607 mn3/h

(0 C, 1013 mbar)

Exhaust gas volume flow, moist

8498 mn3/h

(0 C, 1013 mbar)

Permissible back-pressure downstream of engine

30 / 60 mbar

min. / max.

In multi-genset systems, separate exhaust piping for each genset is recommended.

If a common exhaust header system is installed, exhaust flow back into any non-operationing gensets must be avoided by use of a 100 % gas-

tight exhaust shut-off flap.

In the range of partial load the exhaustive temperature rises up to 550 C. In case of use of catalyzers, due to the exothermic reaction the

exhaustive temperature may increase up to 600 C.

AoE 20V4000L62 /1500/12,1:1/80/9078/omKat/500/

TVU 2010-09-09 / TA 734661e 734657e Seite/Sheet 5 von/of 7

TB 46218 e 50

OAGD - 26.05.2011

Technical Description

GB

3.6 Sound Levels

Engine surface noise emitted by the genset

(distance 1 m, free field measurement, Tolerance +5 dB for single 1/3-octave band, +2 db(A) for total A-weighted level)

Frequency (Hz) Sound pressure levels (dB)

12,5

16

20

25 67,6

31,5 64,6

40 67,4

50 71,5

63 77,7

80 80,9

100 82,8

125 95,4

160 83,3

200 87,0

250 83,8

315 87,4

400 95,7

500 90,8

630 88,5

800 88,5

1000 89,6

1250 87,7

1600 86,8

2000 84,9

2500 83,3

3150 82,6

4000 80,5

5000 82,2

6300 100,4

8000 83,9

10k 77,9

Lin dB dB (A)

Sum of sound pressure levels (dB) 104,1 102,4

Sound power levels dB (A) 122,6

undampened Exhaust noise

(distance of 1 m from outlet, Tolerance +5 dB for single 1/3-octave band, +3 db(A) for total A-weighted level)

Frequency (Hz) Sound pressure levels (dB)

12,5

16

20 78,8

25 83,9

31,5 83,3

40 90,5

50 95,1

63 105,1

80 106,4

100 103,2

125 107,8

160 103,8

200 101,2

250 95,0

315 100,0

400 95,7

500 92,7

630 89,1

800 87,6

1000 85,2

1250 89,4

1600 85,2

2000 83,7

2500 83,8

3150 83,2

4000 77,8

5000 72,8

6300 69,5

8000 66,7

10k 65,2

Lin dB dB (A)

Sum of sound pressure levels (dB) 113,4 101,1

Sound power levels dB (A) 113,1

AoE 20V4000L62 /1500/12,1:1/80/9078/omKat/500/

TVU 2010-09-09 / TA 734661e 734657e Seite/Sheet 6 von/of 7

TB 46218 e 50

OAGD - 26.05.2011

Technical Description

GB

3.7 Connections

Unless stated otherwise, the connecting flanges are to DIN 2501.

Nominal diameters and pressures are as follows:

Safety gas line * DN100 / PN16

Exhaust gas outlet (expansion joint) 2x DN250 / PN6

Cooling water in- / outlet DN100 / PN16

Mixture cooling water in- / outlet DN50 / PN16

Lube oil flow and return: Tube connection to DIN 3861 d = 22

*) Dimension depending on gas pressure and gas quality

3.8 Paints, Dimensions and Weights of the Genset

Engine and Generator RAL 9006

Frame RAL 5002

Length 5900 mm

Width 1700 mm

Height 2600 mm

Genset (dry weight) 400 V 17700 kg

Genset (service weight) 18400 kg

For binding dimensions please refer to drawing.

Dimensions and weight may vary according to the alternator type (voltage rating)

Data are subject to change without notice in the interest of further development.

AoE 20V4000L62 /1500/12,1:1/80/9078/omKat/500/

TVU 2010-09-09 / TA 734661e 734657e Seite/Sheet 7 von/of 7

Vous aimerez peut-être aussi

- Installation Conditions: Gas Engine-Generator Sets With Series 400, Series 500, and Series 4000 EnginesDocument62 pagesInstallation Conditions: Gas Engine-Generator Sets With Series 400, Series 500, and Series 4000 EnginesBen ZithaPas encore d'évaluation

- Spec Sheet Mtu 12v4000 Ds1750 NeaDocument6 pagesSpec Sheet Mtu 12v4000 Ds1750 NeaTri Hudami WibowoPas encore d'évaluation

- MTU Solution Guide Marine Oct 2022Document59 pagesMTU Solution Guide Marine Oct 2022TwinPas encore d'évaluation

- Mtu 12v4000 Spec Sheet PDFDocument6 pagesMtu 12v4000 Spec Sheet PDFSomadbsiPas encore d'évaluation

- MTU 4000 With MIP v1.8Document23 pagesMTU 4000 With MIP v1.8Aurelio Serrano100% (2)

- Мануал L33 - new - MS50199 - 01EDocument16 pagesМануал L33 - new - MS50199 - 01EAleksey100% (1)

- Mtu - Oil & Gas Sales ProgramDocument63 pagesMtu - Oil & Gas Sales Programalamen ZayidPas encore d'évaluation

- Series 8000 Diesel Engines For Marine ApplicationsDocument3 pagesSeries 8000 Diesel Engines For Marine ApplicationsMaurizioPas encore d'évaluation

- Technical Sales Document: - Product DataDocument27 pagesTechnical Sales Document: - Product DataLuis AyalaPas encore d'évaluation

- 20v4000enDocument266 pages20v4000enMario MartinezPas encore d'évaluation

- MTU 12V4000 Diesel EngineDocument2 pagesMTU 12V4000 Diesel Enginenastyn-1Pas encore d'évaluation

- Diesel Engines 8V 4000 M53/M63 SpecsDocument2 pagesDiesel Engines 8V 4000 M53/M63 Specsroberttv374Pas encore d'évaluation

- 1600 Series Parts and OverviewDocument94 pages1600 Series Parts and OverviewJorge Eraldo Albarran PoleoPas encore d'évaluation

- Natural gas and biogas generator frequency and emissionsDocument2 pagesNatural gas and biogas generator frequency and emissionsjosuelino2002Pas encore d'évaluation

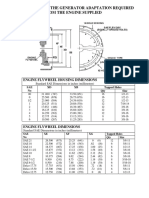

- Determining The Generator Adaptation Required From The Engine SuppliedDocument2 pagesDetermining The Generator Adaptation Required From The Engine SuppliedolumidePas encore d'évaluation

- Diesel Engines 20V 4000 M93/M93L: For Vessels With Low Load Factors (1DS)Document3 pagesDiesel Engines 20V 4000 M93/M93L: For Vessels With Low Load Factors (1DS)Alberto100% (1)

- 16V4000G83 3D en ConsumptionDocument9 pages16V4000G83 3D en ConsumptionmsahbkPas encore d'évaluation

- 3012Tag3A 3000 Series: Diesel Engine - ElectropakDocument2 pages3012Tag3A 3000 Series: Diesel Engine - ElectropakMounir Yousfi100% (1)

- 16V2000G65 536113080 enDocument181 pages16V2000G65 536113080 enAndré AntunesPas encore d'évaluation

- Operating Instructions: Gas Engine 20 V 4000 L32 FBDocument214 pagesOperating Instructions: Gas Engine 20 V 4000 L32 FBNico FajRiPas encore d'évaluation

- Maintenance ScheduleDocument22 pagesMaintenance ScheduleDen100% (2)

- IMS Industrial & Marine Services GmbH Provides Maintenance QuoteDocument6 pagesIMS Industrial & Marine Services GmbH Provides Maintenance QuoteNoui BouzidPas encore d'évaluation

- Gas Control Systems & IgnitionDocument44 pagesGas Control Systems & Ignitionaaakengyahoo.comPas encore d'évaluation

- MTU Friedrichshafen GmbH Stationary Power Generation Accessories Price ListDocument7 pagesMTU Friedrichshafen GmbH Stationary Power Generation Accessories Price ListGerman O.Pas encore d'évaluation

- Siemens industrial diesel and gas engines & generator setsDocument2 pagesSiemens industrial diesel and gas engines & generator setsAlejandro SanchezPas encore d'évaluation

- Operating Instructions: Diesel Engine 12 V 4000 T94, T94LDocument197 pagesOperating Instructions: Diesel Engine 12 V 4000 T94, T94LCristian A.Pas encore d'évaluation

- 001a HM02316 - 00 Engine SpecificationsDocument92 pages001a HM02316 - 00 Engine SpecificationsBruno VenturaPas encore d'évaluation

- Operating Instructions: Diesel Engine 8 V 4000 M40A 8 V 4000 M40B Application Group 3BDocument170 pagesOperating Instructions: Diesel Engine 8 V 4000 M40A 8 V 4000 M40B Application Group 3BNerjan PetitPas encore d'évaluation

- MTU 1600-EPC-12V1600 Parts CatalogueDocument43 pagesMTU 1600-EPC-12V1600 Parts CatalogueJ Pramono100% (1)

- MTU General WhitePaper EngineManagement 2014Document4 pagesMTU General WhitePaper EngineManagement 2014Pankaj KamblePas encore d'évaluation

- MTU CI Ag Mining SalesProgramDocument37 pagesMTU CI Ag Mining SalesProgramMarcial MilitantePas encore d'évaluation

- Operating Instructions: Downloaded From Manuals Search EngineDocument155 pagesOperating Instructions: Downloaded From Manuals Search EngineRis Wati100% (1)

- 16 V 4000Document4 pages16 V 4000aup0% (1)

- 3A Maintenance M050733 - 06EDocument10 pages3A Maintenance M050733 - 06ELiya Mahagama100% (1)

- MS15018 01eDocument162 pagesMS15018 01eاشرينكيل مسونكيلPas encore d'évaluation

- 1100 Series PerkinsDocument2 pages1100 Series PerkinsGilberto Diaz CastilloPas encore d'évaluation

- GasEngines&Gensets PDFDocument4 pagesGasEngines&Gensets PDFShakhowath Chowdhury100% (1)

- Generac - Motor MTU 18V2000G85Document26 pagesGenerac - Motor MTU 18V2000G85July E. Maldonado M.100% (1)

- 6R160010F Parts CatalogueDocument104 pages6R160010F Parts Catalogueniceashwin79Pas encore d'évaluation

- Installation and Commissioning Instructions: Electronic Control System Engine Interface (EIM) Application: MarineDocument114 pagesInstallation and Commissioning Instructions: Electronic Control System Engine Interface (EIM) Application: MarineWilliam PeelePas encore d'évaluation

- X20CM0985 1 Eng - V1.42Document72 pagesX20CM0985 1 Eng - V1.42rushaPas encore d'évaluation

- 3306 164-200KW PRDocument4 pages3306 164-200KW PRvanaselvan vpPas encore d'évaluation

- Mtu Diesel Engine MS150068 - 01eDocument287 pagesMtu Diesel Engine MS150068 - 01eM Nuraga Lazuardy Ramadhan100% (1)

- MTU 16V 2000 M93 Brochure SpecificationDocument2 pagesMTU 16V 2000 M93 Brochure SpecificationPedro Mas0% (1)

- Operating Instruction - Motores DieselDocument254 pagesOperating Instruction - Motores DieselAlbertoPas encore d'évaluation

- ACS Analogue Control Systems eDocument12 pagesACS Analogue Control Systems eKhaled KamelPas encore d'évaluation

- Operating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3ADocument155 pagesOperating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3APetrus GunturPas encore d'évaluation

- Mitsubishi Diesel Engine - S16R-Y2PTAW2Document2 pagesMitsubishi Diesel Engine - S16R-Y2PTAW2Christian Rivera FloverPas encore d'évaluation

- Mtu Reach SVHC 2018-10-29 enDocument75 pagesMtu Reach SVHC 2018-10-29 enalawi50% (2)

- QSK19G PerformanceDocument5 pagesQSK19G PerformancetroyPas encore d'évaluation

- B2-Lehe4748-01 - Emcp3.3Document8 pagesB2-Lehe4748-01 - Emcp3.3Ali H. Al-ZowayedPas encore d'évaluation

- Engine AlarmsDocument27 pagesEngine AlarmsaupPas encore d'évaluation

- 6125HF070CDocument2 pages6125HF070ClilirenePas encore d'évaluation

- Peter Barr: Technical Specification and Scope of Supply MTU 20V4000 GS GG20V4000A1Document27 pagesPeter Barr: Technical Specification and Scope of Supply MTU 20V4000 GS GG20V4000A1Milad KerramatiPas encore d'évaluation

- 16V2000G65 3B Consumption AC EnglishDocument9 pages16V2000G65 3B Consumption AC Englishepicenterrulez100% (1)

- Operating InstructionsDocument161 pagesOperating Instructionsfares bellPas encore d'évaluation

- Technical DescriptionDocument9 pagesTechnical Descriptionpezhman arazpoorPas encore d'évaluation

- 40 kVA Specification SheetDocument2 pages40 kVA Specification SheetAlex MohanPas encore d'évaluation

- CHP Unit TEDOM Cento T160 SPDocument4 pagesCHP Unit TEDOM Cento T160 SPHernan GiorgettiPas encore d'évaluation

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishPaola NoMás DicenPas encore d'évaluation

- H L G - 1 5 0 H: 150W Constant Voltage + Constant Current LED DriverDocument10 pagesH L G - 1 5 0 H: 150W Constant Voltage + Constant Current LED DriverMarvin Tejerina GarfiasPas encore d'évaluation

- Catalogo de Cond CordeiroDocument3 pagesCatalogo de Cond CordeiroMarvin Tejerina GarfiasPas encore d'évaluation

- Circuito Electrico Volqueta de Bajo Perfil DuxDocument1 pageCircuito Electrico Volqueta de Bajo Perfil DuxMarvin Tejerina GarfiasPas encore d'évaluation

- Colorpage-Sf600: Portable Image/Document/E-Mail/Bcr Sheetfed ScannerDocument5 pagesColorpage-Sf600: Portable Image/Document/E-Mail/Bcr Sheetfed ScannerMarvin Tejerina GarfiasPas encore d'évaluation

- Essential Ledtube 1200mm 18w840 t8 AP IDocument2 pagesEssential Ledtube 1200mm 18w840 t8 AP IMarvin Tejerina GarfiasPas encore d'évaluation

- Compresora Kaeser M26Document2 pagesCompresora Kaeser M26Marvin Tejerina GarfiasPas encore d'évaluation

- 12-113 Series C Molded Case Circuit Breakers 70 - 400 AmperesDocument1 page12-113 Series C Molded Case Circuit Breakers 70 - 400 AmperesMarvin Tejerina GarfiasPas encore d'évaluation

- Circuito Hidráulico 1 DuxDocument1 pageCircuito Hidráulico 1 DuxMarvin Tejerina GarfiasPas encore d'évaluation

- Compresora Kaeser M26Document2 pagesCompresora Kaeser M26Marvin Tejerina GarfiasPas encore d'évaluation

- FICHA TECNICA LUMINARIA SmartForm LED BCS460Document4 pagesFICHA TECNICA LUMINARIA SmartForm LED BCS460Marvin Tejerina Garfias0% (1)

- Luminaria RC160VDocument4 pagesLuminaria RC160VMarvin Tejerina GarfiasPas encore d'évaluation

- Test JP PrintDocument1 pageTest JP PrintMarvin Tejerina GarfiasPas encore d'évaluation

- Ups 2200va 230v Apcsua2200xliDocument5 pagesUps 2200va 230v Apcsua2200xliMarvin Tejerina GarfiasPas encore d'évaluation

- Experimental TCU As Built DataDocument2 pagesExperimental TCU As Built DataRola PolaPas encore d'évaluation

- Cold Room SavingsDocument2 pagesCold Room Savingsimran MohammadPas encore d'évaluation

- SGE550 Data SheetDocument1 pageSGE550 Data SheetmohamedkhalifehPas encore d'évaluation

- Hitachi Mild Hybrid Press ReleaseDocument4 pagesHitachi Mild Hybrid Press ReleaseRafa SilesPas encore d'évaluation

- 6 Lecture (Regenerative Rankine Cycle - CFWH)Document16 pages6 Lecture (Regenerative Rankine Cycle - CFWH)Ali Haider RizviPas encore d'évaluation

- Service News: Click The Following List Then Service News Files Will OpenDocument1 pageService News: Click The Following List Then Service News Files Will OpenNarendra niranjan MathiyarasuPas encore d'évaluation

- ECBC Implementation Experience - A Case Study on UPERC BuildingDocument21 pagesECBC Implementation Experience - A Case Study on UPERC BuildingAanchal MishraPas encore d'évaluation

- X Minerals Part IiDocument4 pagesX Minerals Part IiShree jegan Kumar B SPas encore d'évaluation

- Catalogo Interuptor 220 KVDocument2 pagesCatalogo Interuptor 220 KVRommel Augusto Arnica AguedoPas encore d'évaluation

- Energy and Buildings enDocument2 pagesEnergy and Buildings enSufiPas encore d'évaluation

- Switchgear Application Book Interlocking SystemsDocument29 pagesSwitchgear Application Book Interlocking Systemsrobertspiteri7Pas encore d'évaluation

- Feasibility of Small Hydropower in KurdistanDocument78 pagesFeasibility of Small Hydropower in KurdistanmimahmoudPas encore d'évaluation

- Comparison Between SiC - and Si-Based Inverters ForDocument11 pagesComparison Between SiC - and Si-Based Inverters Forvenktesh22Pas encore d'évaluation

- Embedded Power Critical ContinuityDocument1 pageEmbedded Power Critical ContinuityrepropPas encore d'évaluation

- 10 General Plot Plan Original 1 Rev 1Document1 page10 General Plot Plan Original 1 Rev 1andrieysyah2525Pas encore d'évaluation

- Cost Effective Tools For Finding The Fault Faster and Reducing Outage DurationDocument2 pagesCost Effective Tools For Finding The Fault Faster and Reducing Outage DurationNguyen Anh TuPas encore d'évaluation

- Coek - Info - Performance Testing of Supercapacitors Important IDocument14 pagesCoek - Info - Performance Testing of Supercapacitors Important ICazimir BostanPas encore d'évaluation

- Vacuum Contactor SpecDocument5 pagesVacuum Contactor SpecAkhilesh AnandPas encore d'évaluation

- SB6000TL 21 Den1420wDocument2 pagesSB6000TL 21 Den1420wEliana CostaPas encore d'évaluation

- Bana Barn PDFDocument4 pagesBana Barn PDFRajesh SinghPas encore d'évaluation

- R. Buckminster Fuller - Critical Path PDFDocument510 pagesR. Buckminster Fuller - Critical Path PDFbhardin441196% (57)

- 04 GTP-M-PCE Part4Document67 pages04 GTP-M-PCE Part4Ramesh-NairPas encore d'évaluation

- BPDB TariffDocument10 pagesBPDB TariffAshiqur Rahman ZituPas encore d'évaluation

- Petrosil Glycerine ReportDocument8 pagesPetrosil Glycerine Reportvishi.segalPas encore d'évaluation

- Smart StairsDocument1 pageSmart StairsAshish KumarPas encore d'évaluation

- River Valley High School JC2 Preliminary Exam Physics PaperDocument18 pagesRiver Valley High School JC2 Preliminary Exam Physics PaperfaratPas encore d'évaluation

- BEYONDSUN - BiDrive-Max-Series-TSBHM-144HVG-535-545Document2 pagesBEYONDSUN - BiDrive-Max-Series-TSBHM-144HVG-535-545EletriSul Instalações ElétricasPas encore d'évaluation

- Assignment - 1 - Pu SystemsDocument3 pagesAssignment - 1 - Pu SystemsDeepak ThapaPas encore d'évaluation

- Austa 3P121518K1GDocument1 pageAusta 3P121518K1GIgor MatijevićPas encore d'évaluation

- Energy Transfers 3 QPDocument14 pagesEnergy Transfers 3 QPApdiweli AliPas encore d'évaluation