Académique Documents

Professionnel Documents

Culture Documents

Jib Crane Inspection Report 04-1003736 - J1604751 - NQ5643 - PDF

Transféré par

Anonymous N2Se0bYTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Jib Crane Inspection Report 04-1003736 - J1604751 - NQ5643 - PDF

Transféré par

Anonymous N2Se0bYDroits d'auteur :

Formats disponibles

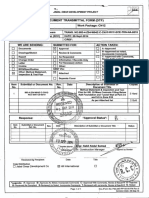

1003736 04-1003736_J

J

1C2A3NA4A5A6A7A8 C

C132 shay shay Maint Plea JJibCrane

eInspecttion

M

Maintena anceRepport

04-1003736

1300 7611 822

JobNo. J1604751

Client C1321

- Haynes Mechanical Datte 28/11/16

No. NQ5643

LibraryN Details#3 Rear Jib c/w Chain Hoist 1T Donati

CraneD RC(t) 1 EquipmentID

eOrderNo.94925

Purchase WorkOrderNo.. NA SerrviceCarriedOut 3 Monthly

ailsHMC

SiteDeta Workshop

esTake5 T5-3109

NQCrane N

NQCranesJSA Clien etyassessment Site

ntequivalentsafe Working at Heights

I/Wedecclarethattheabovvesafetyassessmentswereconductedpriortothecoommencementoftheseworks:

X

AInspecctedNoActionreq

quired,BAdjustmen

nts/RepairsMade,C

CAdditionalRepairssRequired,DUrgen

ntRepairsRequired

d,EWARNINGDO

ONOTUSE!,NANottApplicable,IImageebelow

GeneralCondition A B C D E NA Comment I

1.GeneraalConditionandCCleanliness Hoist built 1993- 22 years old. Overdue for 10 year inspection.

2.PreOpperationalLogBoook

AccessPla atformsandLaddeers A B C D E NA Comment I

3.AdequateandClean

Pendant//RadioControls A B C D E NA Comment I

4.Housinng

5.ButtonnsandSwitches

6.CableaandStrainerCablee

7.Legendds

8.EmergencyStop

CrossCate enary A B C D E NA Comment I

9.TrackssandSupports

10.Trolleys Trolleys

hit plug on catenary- recommend fitting end stops. Previously quoted. 2

11.Travelling"J"Box

12.Cabless

13.TowA Arm

Structure A B C D E NA Comment I

14.Conne ectionsBolts/Welds

17.Bufferrs

18.Guard dsandCovers

19.GenerralStructureandW Welds

20.RatedCapacity(RC)Sign nage

21.Identification(ID)Signage

22.Comp passSignage

23.Clearaance

24.LimitSStrikers

Electrics A B C D E NA Comment I

25.ElectricalSchematics

26.MainIsolatorandSign

27.AccesstoMainIsolator

28.ServicceIsolatorsandSiggns

29.ControlPanelEnclosurees

30.ContaactorsandOverloaads

31.GenerralWiring

32.Lightinng

33.WarningSirensandLigh hts

34.SoftStartersResistorsVFDrive

35.LoadIIndicator

Hoist A B C D E NA Comment I

50.GenerralCondition Very minor hoist motor fin damage 3

51.HookandSafetyCatch

52.SheavvesandPins

53.Guard ds

54.RopeorChainCondition n Chain in good condition

55.RopeChainGuides

56.RopeDrum

57.Lubriccation

58.Gearb boxandOil

59.MotorandBrake

60.DeadEndandAnchorP Point

61.ChainBucket

62.ShaftssandCouplings

63.WorkiingLimits

64.UpperrFinalLimit

65.LoadLLimiter

A.B.N.2

20060375699 www

w.nqcranes.com..au Pagee1 of3

Jib Crane Inspection

Maintenance Report

04-1003736

1300 761 822

A Inspected - No Action required, B Adjustments/Repairs Made, C Additional Repairs Required, D Urgent Repairs Required, E WARNING - DO NOT USE!, NA Not Applicable, I Image below

Trolley / Crab A B C D E NA Comment I

66. General Condition

67. Service Isolator and Signs

68. Wheels and Bearings

69. Ring Gears and Pinions

70. Anti-Derailment / Anti-Capsize

71. Lubrication

72. Gearbox and Oil

73. Motor and Brake

74. Shafts

75. Transmission Couplings and Keys

76. Limits

77. Buffers

Slew Travel A B C D E NA Comment I

94. General Condition

95. Wheels, Bearings and Bushes

96. Rings Gears and Pinions

97. Anti-Capsize

98. Lubrication

99. Gearbox and Oil

100. Motor and Brake

101. Limits and Clutches

102. Torque Arm Attachments

103. Storm Anchors

Functional Test A B C D E NA Comment I

90. Raise and Lower

92. Cross Travel

93. Swing / Slew

Comments

LSR/Hour Meter Reading: Also performed during this service (tick): Earth Continuity Check Load Test

Part No. Description Qty Store Technician Hours

Nicholas Belton

Other Equipment Used

Access Equipment 8m Scissor Supplied By Client

A.B.N. 20 060 375 699 www.nqcranes.com.au Page 2 of 3

Jib Crane Inspection

Maintenance Report

04-1003736

1300 761 822

Image 1. Image 2. Image 3.

Image 4. Image 5. Image 6.

Certificate of Test I hereby certify that any electrical installation work listed above has been tested in accordance with the prescribed procedures and that such work

complies with the requirements of Section 227 (3) Electrical Safety Regulation 2013. | Electrical Contractors License Number. 65624

The equipment has been function tested and at the time of service is in operational condition: Yes Job Complete: Yes Repairs Quote Required: No

Notes: 1. This report is made following visual inspection only of the equipment in accordance with AS2550.3-2002

2. No responsibility will be taken for unseen internal condition of components

3. Resultant repair work will only be conducted following authorization from the equipment owner

4. This docket should be kept as a record of inspection as required by government legislation

Serviced By (Name): Nick Belton Customer Name: Shayne Larcombe

X X

On completion a copy of this report will be emailed to shayne@haynesgroup.com.au Additional Email Address:

A.B.N. 20 060 375 699 www.nqcranes.com.au Page 3 of 3

Vous aimerez peut-être aussi

- Jib Crane Inspection Report 04-1003725 - J1604751 - NQC1154 - PDFDocument3 pagesJib Crane Inspection Report 04-1003725 - J1604751 - NQC1154 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Jib Crane Inspection Report 04-1005198 - J1610644 - NQ5643 - PDFDocument3 pagesJib Crane Inspection Report 04-1005198 - J1610644 - NQ5643 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Jib Crane Inspection Report 04-1005195 - J1610688 - NQC1154 - PDFDocument3 pagesJib Crane Inspection Report 04-1005195 - J1610688 - NQC1154 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Single Hoist Crane Inspection Report 02-1008027 - J1607552 - NQC1108 - PDFDocument3 pagesSingle Hoist Crane Inspection Report 02-1008027 - J1607552 - NQC1108 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Single Hoist Crane Inspection Report 02-1006877 - J1604751 - NQ5728 - PDFDocument3 pagesSingle Hoist Crane Inspection Report 02-1006877 - J1604751 - NQ5728 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Single Hoist Crane Inspection Report 02-1009223 - J1610688 - NQ5728 - PDFDocument3 pagesSingle Hoist Crane Inspection Report 02-1009223 - J1610688 - NQ5728 - PDFAnonymous N2Se0bYPas encore d'évaluation

- PMS 10.2018Document17 pagesPMS 10.2018Ocean going master Cpt. batuPas encore d'évaluation

- BK91-1310-CPF-PIP-MT-0041-5Document1 pageBK91-1310-CPF-PIP-MT-0041-5Panneer SelvamPas encore d'évaluation

- MYP-IK-FCN-6860 - B SupportDocument11 pagesMYP-IK-FCN-6860 - B SupportMohammad SaifPas encore d'évaluation

- Service Report: Specify Scope of WorkDocument3 pagesService Report: Specify Scope of WorkKevin QuijanoPas encore d'évaluation

- Susha CSDocument1 pageSusha CSPiyush VyasPas encore d'évaluation

- Section KDocument7 pagesSection KchristopherPas encore d'évaluation

- Crown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportDocument1 pageCrown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportYasar AliPas encore d'évaluation

- ® Maintenance: Ctros TelligentDocument5 pages® Maintenance: Ctros TelligentBishoo ShenoudaPas encore d'évaluation

- 6 Sigma SD Shaft Dia. VariationDocument32 pages6 Sigma SD Shaft Dia. Variationsageershaikh100% (1)

- Daily Check List For EPGDocument2 pagesDaily Check List For EPGchilamparasanPas encore d'évaluation

- HDN-CA-0034 - Calculation For External Static Pressure (ESP) Rev. 03 CommentedDocument116 pagesHDN-CA-0034 - Calculation For External Static Pressure (ESP) Rev. 03 CommentedadnanPas encore d'évaluation

- Solar OperationsDocument2 pagesSolar OperationsChanchal PathakPas encore d'évaluation

- FMEA Heat Exchanger ConnectorDocument1 pageFMEA Heat Exchanger Connectorsunny vachhaniPas encore d'évaluation

- Expansion Project Risk AssessmentDocument3 pagesExpansion Project Risk AssessmentAftab Qadir100% (1)

- S-090100-02FRM Daily Job Order (ENGINE) - SampleDocument4 pagesS-090100-02FRM Daily Job Order (ENGINE) - SampleasasasapoPas encore d'évaluation

- Concrete Vibrator Inspection ReportDocument1 pageConcrete Vibrator Inspection Reportslamet4riadiPas encore d'évaluation

- Light FittingsDocument35 pagesLight FittingsAnandu AshokanPas encore d'évaluation

- Service Report - AI-22601Document7 pagesService Report - AI-22601NinjaPas encore d'évaluation

- Cummins EngineDocument477 pagesCummins EngineMarco Antonio Bethancourt Caceres100% (1)

- Fabrication Inspection Test Plan: Barwa Commercial Avenue ProjectDocument3 pagesFabrication Inspection Test Plan: Barwa Commercial Avenue ProjectRPas encore d'évaluation

- HR RPP-40736 Freight Container Lifting Standards PDFDocument34 pagesHR RPP-40736 Freight Container Lifting Standards PDFkaniniuserPas encore d'évaluation

- Apollo Service ReportDocument1 pageApollo Service ReportPrabu RamasundaramPas encore d'évaluation

- Sacyr Ecebol Oruro 02-1-224144 Packer: FinalDocument130 pagesSacyr Ecebol Oruro 02-1-224144 Packer: FinalProgramadores & PlanificadoresPas encore d'évaluation

- Routine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeDocument3 pagesRoutine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeFL Technics DFPPas encore d'évaluation

- 80-98ME ME-C Engines MaintenaceDocument9 pages80-98ME ME-C Engines MaintenaceLeonid KolesnikovPas encore d'évaluation

- CC-F17847-KJI-ABM-001 - RevC, Structural Calculation Skimmer Tank B (Approved)Document3 pagesCC-F17847-KJI-ABM-001 - RevC, Structural Calculation Skimmer Tank B (Approved)adonara_jePas encore d'évaluation

- Om-03 Hose Handling Crane PDFDocument126 pagesOm-03 Hose Handling Crane PDFcpîndaruPas encore d'évaluation

- NDE Procedure: Leak Test and Test No. /Z 07-FiDocument4 pagesNDE Procedure: Leak Test and Test No. /Z 07-FiVũ Lê NguyênPas encore d'évaluation

- Weekly Accm CEDC 15-001Document1 pageWeekly Accm CEDC 15-001Alberto S. Cabreros IIIPas encore d'évaluation

- DOMMIESAN-Daily Self Check Control System (DSCCS)Document9 pagesDOMMIESAN-Daily Self Check Control System (DSCCS)Navindran SubramaniamPas encore d'évaluation

- Forklift Inspection ReportDocument4 pagesForklift Inspection ReportMahbubul Alam AkashPas encore d'évaluation

- Electrical Team Daily Report-230103Document2 pagesElectrical Team Daily Report-230103qutaiba.kpsPas encore d'évaluation

- National Power Corporation Corrective Maintenance RequestDocument2 pagesNational Power Corporation Corrective Maintenance RequestJasem AbdurahmanPas encore d'évaluation

- MM0905637 06Document14 pagesMM0905637 06tandy henhakkiarifin100% (1)

- Stringing near live linesDocument5 pagesStringing near live linesSujit Kumar pahiPas encore d'évaluation

- Engineering Change Order: IntentDocument2 pagesEngineering Change Order: IntentYanethPas encore d'évaluation

- HIRADocument16 pagesHIRASAMEER JAVEDPas encore d'évaluation

- Streamlined Control PlanDocument1 pageStreamlined Control PlanNatarajan RPas encore d'évaluation

- Check Sheet Improved MT Inspection Procedure Report For C-0659Document3 pagesCheck Sheet Improved MT Inspection Procedure Report For C-0659Himanyu RafiqPas encore d'évaluation

- Weekly Fleet Status Report with Vessel Technical and Crew DetailsDocument1 pageWeekly Fleet Status Report with Vessel Technical and Crew DetailsRaphael TakerubunPas encore d'évaluation

- Itp ForkliftDocument3 pagesItp ForkliftpandiPas encore d'évaluation

- G :ND A N - : I LN :!!tional J: AL "6Document3 pagesG :ND A N - : I LN :!!tional J: AL "6rayPas encore d'évaluation

- TRN 0515 B PDFDocument15 pagesTRN 0515 B PDFrayPas encore d'évaluation

- 501e4111 Infrasonic GeneratorDocument5 pages501e4111 Infrasonic GeneratorVon CrisPas encore d'évaluation

- AFA HIRA - Electrical Control PanelDocument30 pagesAFA HIRA - Electrical Control PaneljavedPas encore d'évaluation

- One Line Protection and Metering Diagram For 400v MCCS With Single Bus Bar and One IncomingDocument1 pageOne Line Protection and Metering Diagram For 400v MCCS With Single Bus Bar and One Incomingmustafa1989ocPas encore d'évaluation

- Repair Breakdown Installation Report 01-1011556 - J1606653 - NQC1108 - PDFDocument2 pagesRepair Breakdown Installation Report 01-1011556 - J1606653 - NQC1108 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Daily Activity MM ELSA 04Document7 pagesDaily Activity MM ELSA 04dindapsari1982Pas encore d'évaluation

- Service Manual: Publication NoDocument6 pagesService Manual: Publication NoTransp jaime perezPas encore d'évaluation

- 4011-REP-ABE-078-442-0001 - Rev01 - Emergency-Black Start Diesel Sizing CriteriaDocument18 pages4011-REP-ABE-078-442-0001 - Rev01 - Emergency-Black Start Diesel Sizing CriteriatskumarPas encore d'évaluation

- 240 Preventive Check Sheet of Tube Bending Machine ReDocument4 pages240 Preventive Check Sheet of Tube Bending Machine ReAjayPas encore d'évaluation

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandrePas encore d'évaluation

- M. J. NA: Glneerlng Data TransmiitalDocument23 pagesM. J. NA: Glneerlng Data TransmiitalMohamed AtefPas encore d'évaluation

- Refrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsD'EverandRefrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsÉvaluation : 3 sur 5 étoiles3/5 (2)

- HM05 Registraion PDFDocument4 pagesHM05 Registraion PDFAnonymous N2Se0bYPas encore d'évaluation

- HM06 Registration PDFDocument4 pagesHM06 Registration PDFAnonymous N2Se0bYPas encore d'évaluation

- QA-F107 Personnel Earth Leakage Register and Test Log PDFDocument6 pagesQA-F107 Personnel Earth Leakage Register and Test Log PDFAnonymous N2Se0bYPas encore d'évaluation

- Single Hoist Crane Inspection Report 02-1009223 - J1610688 - NQ5728 - PDFDocument3 pagesSingle Hoist Crane Inspection Report 02-1009223 - J1610688 - NQ5728 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Hydrant Insp 51-53 PDFDocument1 pageHydrant Insp 51-53 PDFAnonymous N2Se0bYPas encore d'évaluation

- QA-F107 Personnel Earth Leakage Register and Test Log Updated PDFDocument7 pagesQA-F107 Personnel Earth Leakage Register and Test Log Updated PDFAnonymous N2Se0bYPas encore d'évaluation

- Ext Inspection 51-53 PDFDocument3 pagesExt Inspection 51-53 PDFAnonymous N2Se0bYPas encore d'évaluation

- Crane Safe CR008 PDFDocument1 pageCrane Safe CR008 PDFAnonymous N2Se0bYPas encore d'évaluation

- Ext Inspection 9-13 Turbo PDFDocument2 pagesExt Inspection 9-13 Turbo PDFAnonymous N2Se0bYPas encore d'évaluation

- Ext Inspection 39-41 PDFDocument2 pagesExt Inspection 39-41 PDFAnonymous N2Se0bYPas encore d'évaluation

- Hydrant Inspection 39-41 PDFDocument1 pageHydrant Inspection 39-41 PDFAnonymous N2Se0bYPas encore d'évaluation

- Porta Hoist Inspection PDFDocument2 pagesPorta Hoist Inspection PDFAnonymous N2Se0bYPas encore d'évaluation

- Repair Breakdown Installation Report 01-1011556 - J1606653 - NQC1108 - PDFDocument2 pagesRepair Breakdown Installation Report 01-1011556 - J1606653 - NQC1108 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Repair Breakdown Installation Report 01-1010654 - J1606057 - NQC5511 - PDFDocument2 pagesRepair Breakdown Installation Report 01-1010654 - J1606057 - NQC5511 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Single Hoist Crane Inspection Report 02-1006281 - J1604752 - NQC5511 - PDFDocument3 pagesSingle Hoist Crane Inspection Report 02-1006281 - J1604752 - NQC5511 - PDFAnonymous N2Se0bYPas encore d'évaluation

- Diesel Generators 10kwDocument8 pagesDiesel Generators 10kwSAQIB AKHTARPas encore d'évaluation

- Section - III, Pipe SupportsDocument2 pagesSection - III, Pipe SupportspalluraviPas encore d'évaluation

- Slo - Ad Mod: For The Casio SK5/SK8Document10 pagesSlo - Ad Mod: For The Casio SK5/SK8spartacusleePas encore d'évaluation

- Nagpur - Soil Report - Unlocked PDFDocument56 pagesNagpur - Soil Report - Unlocked PDFANKESH SHRIVASTAVAPas encore d'évaluation

- Perkins 500P PDFDocument5 pagesPerkins 500P PDFsaleemPas encore d'évaluation

- 2017 Erzi CatalogueDocument164 pages2017 Erzi Cataloguejedelucca2013Pas encore d'évaluation

- WFP-TMP Iwp ElectricalDocument5 pagesWFP-TMP Iwp ElectricalMuthu KumaranPas encore d'évaluation

- JHA ConcretePlacingOperationDocument3 pagesJHA ConcretePlacingOperationAnonymous XJ9663C6N4Pas encore d'évaluation

- Kassa's ProposalDocument19 pagesKassa's ProposalGetachew TikuePas encore d'évaluation

- API 575 Practice QuestionsDocument32 pagesAPI 575 Practice QuestionsvamsikrishnaPas encore d'évaluation

- GGFHJDocument1 pageGGFHJanon_791172439Pas encore d'évaluation

- MWCP 2007 PDFDocument72 pagesMWCP 2007 PDFcesar luis gonzalez rodriguezPas encore d'évaluation

- Bu01c25a02 01enDocument9 pagesBu01c25a02 01enpaulPas encore d'évaluation

- Lean Technology and Waste Minimization in Construction Industry Using SPSSDocument11 pagesLean Technology and Waste Minimization in Construction Industry Using SPSSInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- LD148 Pressure Fix Wide Walk Through Swing Shut Safety Gate - BirchDocument3 pagesLD148 Pressure Fix Wide Walk Through Swing Shut Safety Gate - Birchapi-3714279Pas encore d'évaluation

- Puhz-Zrp200-250yka2 SM Och645 PDFDocument118 pagesPuhz-Zrp200-250yka2 SM Och645 PDFionagybPas encore d'évaluation

- Specification For Oil Approval Railway enDocument3 pagesSpecification For Oil Approval Railway enPeter_Phee_341Pas encore d'évaluation

- ASET NOIDA Mid-Semester Exam ScheduleDocument4 pagesASET NOIDA Mid-Semester Exam ScheduleAmbujSinghPas encore d'évaluation

- RAINWATER HARVESTING - Greenville County South CarolinaDocument10 pagesRAINWATER HARVESTING - Greenville County South CarolinaGreen Action Sustainable Technology GroupPas encore d'évaluation

- Types of FormworkDocument7 pagesTypes of FormworkNur SyahiraPas encore d'évaluation

- Recoil Offgrid - August, September 2015Document116 pagesRecoil Offgrid - August, September 2015oiii88Pas encore d'évaluation

- Sherrill Furniture 2023 Supplement - WEB - Spreads - 4-4Document1 pageSherrill Furniture 2023 Supplement - WEB - Spreads - 4-4Purchasing Inspira Padma JayaPas encore d'évaluation

- Scalable DrawingsDocument13 pagesScalable DrawingschowhkPas encore d'évaluation

- Nelson-Salmo Pennywise Aug 22 PDFDocument40 pagesNelson-Salmo Pennywise Aug 22 PDFPennywise PublishingPas encore d'évaluation

- Minh Viet HR - ProfileDocument23 pagesMinh Viet HR - ProfileAriesNhaPas encore d'évaluation

- Analysis of New Formwork Technology Adopted On A Construction Site in PuneDocument5 pagesAnalysis of New Formwork Technology Adopted On A Construction Site in PuneIJIERT-International Journal of Innovations in Engineering Research and TechnologyPas encore d'évaluation

- Bill of Materials/ Cost Estimates MobilizationDocument5 pagesBill of Materials/ Cost Estimates MobilizationMarie Holgado CarununganPas encore d'évaluation

- The Urban Network: A New Framework For Growth: by Peter CalthorpeDocument6 pagesThe Urban Network: A New Framework For Growth: by Peter CalthorpeDave LicerioPas encore d'évaluation

- 4 Ways To Measure Main Bearing Clearance of Two Stroke Marine EngineDocument24 pages4 Ways To Measure Main Bearing Clearance of Two Stroke Marine EnginemivanoPas encore d'évaluation

- Evenness Test Report Dec-2022Document26 pagesEvenness Test Report Dec-2022Md. Mamunur RashidPas encore d'évaluation