Académique Documents

Professionnel Documents

Culture Documents

Astm F 477 - 02 PDF

Transféré par

Raul Humberto Mora VillamizarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Astm F 477 - 02 PDF

Transféré par

Raul Humberto Mora VillamizarDroits d'auteur :

Formats disponibles

An American National Standard

Designation: F 477 02e1

Standard Specification for

Elastomeric Seals (Gaskets) for Joining Plastic Pipe1

This standard is issued under the fixed designation F 477; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e1 NOTETable 2 was editorially updated in October 2002.

1. Scope D 883 Terminology Relating to Plastics3

1.1 This specification covers elastomeric seals (gaskets) D 1149 Test Method for Rubber DeteriorationSurface

used to seal the joints of plastic pipe used for gravity, Ozone Cracking in a Chamber2

low-pressure, and high-pressure applications. This refers to D 1229 Test Method for Rubber PropertyCompression

push-on joints which require no internal or external pressure to Set at Low Temperatures2

effect the initial seal. D 1349 Practice for RubberStandard Temperatures for

1.2 Requirements are given for natural or synthetic rubber Testing4

gaskets, or a combination of both. D 1414 Test Methods for Rubber O-Rings5

D 1415 Test Method for Rubber PropertyInternational

NOTE 1Oil-resistant gaskets are available for those applications Hardness2

where exposure to solvents or oil may occur. The user should contact the

gasket manufacturer for recommendations.

D 1566 Terminology Relating to Rubber4

D 2240 Test Method for Rubber PropertyDurometer

1.3 The text of this specification references notes, footnotes, Hardness2

and appendixes which provide explanatory material. These F 913 Specification for Thermoplastic Elastomeric Seals

notes and footnotes (excluding those in tables and figures) shall (Gaskets) for Joining Plastic Pipe6

not be considered as requirements of the specification. 2.2 NSF Standards:

1.4 The following precautionary caveat pertains only to the Standard No. 14 for Plastic Piping Components and Related

test method portion, Section 7, of this specification: This Materials7

standard does not purport to address all of the safety concerns, Standard No. 61 for Drinking Water Systems Components-

if any, associated with its use. It is the responsibility of the user Health Effects7

of this standard to consult and establish appropriate safety and

health practices and determine the applicability of regulatory 3. Terminology

limitations prior to use. 3.1 DefinitionsTerms relating to rubber or elastomer shall

be as defined in Terminology D 1566. Terms relating to plastics

2. Referenced Documents

shall be as defined in Terminology D 883.

2.1 ASTM Standards:

D 395 Test Methods for Rubber PropertyCompression 4. Composition and Manufacture

Set2 4.1 All gaskets shall be extruded or molded in such a

D 412 Test Methods for Vulcanized Rubber and Thermo- manner that any cross section will be dense, homogeneous, and

plastic ElastometersTension2 free of porosity, blisters, pitting, or other imperfections. The

D 471 Test Method for Rubber PropertyEffect of Liq- gasket shall be fabricated from a high-grade elastomer mate-

uids2 rial. The basic polymer shall be natural rubber, synthetic

D 518 Test Method for Rubber DeteriorationSurface rubber, a blend of both, or a thermoplastic elastomer, meeting

Cracking2 the requirements prescribed in Sections 5 and 6.

--`,``,,,,,``,`,```,``,`,,,````-`-`,,`,,`,`,,`---

D 573 Test Method for RubberDeterioration in an Air 4.2 Where a splice is used in the manufacture of the gasket,

Oven2

3

Annual Book of ASTM Standards, Vol 08.01.

1 4

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Annual Book of ASTM Standards, Vols 09.01.

5

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. Annual Book of ASTM Standards, Vol 09.02.

6

Current edition approved May 10, 2002. Published July 2002. Originally Annual Book of ASTM Standards, Vol 08.04.

7

published as F 477 76. Last previous edition F 477 99. Available from the National Sanitation Foundation, P.O. Box 1468, Ann Arbor,

2

Annual Book of ASTM Standards, Vol 09.01. MI 48106.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Valencia, Hugh

No reproduction or networking permitted without license from IHS Not for Resale, 02/03/2007 13:06:38 MST

F 477 02e1

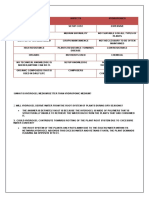

the strength shall be such that the gasket shall withstand 100 % TABLE 2 Physical Requirements for Thermoplastic Elastomeric

elongation over the part of the gasket which includes the splice Seals for Plastic Pipe

with no visible separation of the splice. While in a stretched

Low-Head High-Head

position the gasket shall be rotated in the spliced area a Application Application

minimum of 180 in each direction in order to inspect for (Below 150 (150 kPa or

separation. In addition, any portion of the splice shall be kPa or 50-ft 50-ft Head

Head) and Above)

capable of passing a bend test without visible separation. The

Original Properties:

bend test for circular gaskets is defined as wrapping the portion Tensile strength, min, MPa (psi) 3.0 (435) 3.5 (500)

of the unstretched gasket containing the splice a minimum of 100 % modulus, min, MPa (psi) 1.4 (200) 1.9 (280)

180 and a maximum of 270 around a rod of a diameter equal Elongation, min, % 350 350

Hardness, Type A durometer 40 to 70 40 to 70

to the cross section diameter of the gasket. Low-temperature hardness, Type A 10 10

durometer, max increase, points

5. Dimensions and Tolerances Compression set, max % 25 20

5.1 When in its final assembled position, the gasket shall not Ozone resistance no cracks no cracks

Accelerated Aging (Air Oven Test):

be stretched more than 30 % of its original circumference. Decrease in tensile strength, max % of 15 15

original

NOTE 2Excessive stretch may have deleterious effect on rubber Decrease in elongation, max % of original 15 15

gaskets, the minimum stretch compatible with the proper performance of Hardness, Type A durometer, max change, 5 5

the gasket should be used at all times. points

After Water Immersion:

5.2 The gaskets shall conform to the dimensions specified Change in volume max % 4 4

by the manufacturer of the pipe or fittings, with which the Force Decay 40 50

Remaining stress, min,%

gaskets are to be used, with a Rubber Manufacturers Associa-

tion Class 3 tolerance on all cross section dimensions, and

61 % on all diametrical dimensions, unless otherwise agreed NOTE 4The gasket manufacturer should be assured that materials

used for retaining or reinforcement, or both, do not encroach upon the

--`,``,,,,,``,`,```,``,`,,,````-`-`,,`,,`,`,,`---

upon by the pipe or fitting manufacturer and the purchaser.

5.3 For molded gaskets or gasket material, the permissible sealing surfaces of the gasket, and have physical properties which ensure

adequate longevity for the anticipated usage.

flash shall be a maximum of +0.80 mm (0.032 in.). Maximum

mold mismatch shall not exceed 0.25 mm (0.010 in.). 6.1.1 HardnessThe Type A durometer average hardness

specified by the manufacturer shall be within the range given in

6. Physical Requirements Table 1 for thermoset elastomers or Table 2 for thermoplastic

6.1 The sealing portion of the gaskets shall comply with the elastomers. Gaskets are required to have the Type A durometer

physical requirements listed in Table 1 for thermoset elas- hardness specified, 6 5 points.

tomers or Table 2 for thermoplastic elastomers, when tested in 6.2 Elastomer compounds must be non-crazing to pipe. The

accordance with the methods in Section 7. gasket in the cured state shall not cause craze marks, pits, or

blisters when in contact with the plastic pipe. Staining of the

NOTE 3Some gaskets incorporate a high durometer elastomeric or

nonelastomeric, that is, metal or plastic material, as a reinforcement or plastic pipe in the area of gasket contact is acceptable. Test in

retaining feature, or both. These materials do not alter the physical accordance with 7.9 to qualify elastomer compound for pipe

properties of the sealing portion of the gasket and should not be tested as made from the plastic polymer in question.

such, or expected to meet the material requirements listed in Table 1. 6.3 Where the particular joint design utilizing a rubber

gasket dictates the use of a lubricant to facilitate assembly, the

TABLE 1 Physical Requirements for Elastomeric Seals for lubricant shall be of such composition which will in no way

Plastic Pipe

damage the gasket or pipe due to prolonged exposure.

Low-Head High-Head 7. Test Methods

Application Application

Tests (Below 150 (150 kPa or 7.1 Perform laboratory tests to determine the physical prop-

kPa or 50-ft 50-ft Head erties of the gaskets to be furnished under this specification on:

Head) and Above)

(1) the finished product as supplied, ( 2) test specimens taken

Original Properties: from the finished product, or ( 3) from specimens of fabrication

Tensile strength, min, MPa (psi) 8.3 (1200) 13.8 (2000)A

Elongation, min, % 325 400 of the same elastomeric compound, and in accordance with the

Hardness, Type A durometer 40 to 60 40 to 60 appropriate ASTM standard. (See Practice D 1349.)

Low-temperature hardness, Type A duro- 15 15 7.2 Tensile Strength and ElongationDetermine tensile

meter, max increase, points

Compression set, max % 25 20 strength, 100 % modulus, and elongation in accordance with

Ozone resistance no cracks no cracks Test Methods D 412 or D 1414 for O-rings.

Accelerated Aging (Air Oven Test):

Decrease in tensile strength, max % of 15 15

7.3 HardnessDetermine the durometer, Type A, of the

orignal gasket in accordance with Test Method D 2240 or Test Meth-

Decrease in elongation, max % of original 20 20 ods D 1414 for O-rings. (See Test Method D 1415.)

Hardness, Type A durometer, max increase, 8 8

points

7.4 Low-Temperature HardnessMeasure the durometer,

After Water Immersion: Type A, of the gasket in accordance with Test Method D 2240

Change in volume max % 5 5 or Test Methods D 1414 for O-rings after conditioning for 22 h

A

For EPDM and nitrile seals, tensile strength min. MPa (psi) is 10.3 (1500). at 10 6 2C (+14 6 4F) to determine the change in hardness.

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Valencia, Hugh

No reproduction or networking permitted without license from IHS Not for Resale, 02/03/2007 13:06:38 MST

F 477 02e1

7.5 Compression SetDetermine the compression set in 7.9.4 Set the test apparatus up as in the compression set test

accordance with Method B of Test Methods D 395 or D 1414 in accordance with Method B of Test Methods D 395 with the

for O-rings. Test temperature and time shall be 22 h at 70 6 plastic bearing plate in place.

2C (158 6 4F), with a 25 % deflection of the test specimens. 7.9.5 Age the specimens under load for 96 h at 70 6 2C

(See Test Method D 1229.) (158 6 4F).

7.6 Accelerated AgingAge specimens for physical test in 7.9.6 Let the specimens cool in the fixture for 24 h at 21 to

accordance with Test Method D 573. (See Test Method D 518.) 25C (70 to 77F).

7.6.1 Age physical test specimens for 96 h at 70 6 2C (158 7.9.7 Upon release, inspect the plastic bearing plate surface

6 4F). that has been in contact with the elastomeric compound for

7.7 Water ImmersionDetermine the change in volume in cracks, craze marks, pits, or blisters (6.2).

accordance with Test Method D 471 or Test Methods D 1414 7.10 Stress RelaxationDetermine stress relaxation in ac-

for O-rings. cordance with thermoplastic elastomer stress relaxation test as

7.7.1 The temperature shall be 70 6 2C (1586 4F), and outlined in Specification F 913.

the immersion period shall be 48 h.

7.7.2 Immediately after removal from the water, blot the 8. Rejection

specimens, weigh, and calculate the volume increase in accor- 8.1 The rubber gaskets shall be subject to rejection when-

dance with Test Method D 471. ever they show surface checking, weathering, or other deterio-

7.8 Ozone ResistanceDetermine the gaskets resistance to ration prior to installation.

ozone in accordance with Test Method D 1149.

7.8.1 Conduct test for 72 h in 50 pphm concentration at 40 9. Certification

6 2C (104 6 4F) with specimens stressed to 20 % extension.

--`,``,,,,,``,`,```,``,`,,,````-`-`,,`,,`,`,,`---

9.1 At the option of the purchaser, certified copies of test

7.9 Determine elastomer compound effect on pipe (6.2) by

reports on the elastomer from which the shipment of gaskets

the following procedure:

was made shall be furnished by the gasket supplier.

7.9.1 The specimen shall be a gasket or a part of a gasket

that will fit within the test fixture shown in Fig. 1.

10. Storage

7.9.2 The fixture for the test shall be as described for the

compression set test in Method B of Test Methods D 395 with 10.1 The rubber gaskets shall be stored in a cool, clean,

a plate of plastic adjoining the interior surfaces of the com- shaded place. The preferred temperature is 21C (70F) or

pression plates (see Fig. 1). lower.

7.9.3 Make liner bearing plates of plastic with a minimum

wall thickness of 3.0 mm (0.120 in.) to fit the interior surfaces 11. Marking

of the fixtures compression plates. 11.1 The markings shall include the gasket manufacturers

7.9.3.1 Form the plastic bearing plate from like plastic name or symbol, gasket size, and manufacturers code to

material by cutting and pressing pipe at a workable stressre- differentiate between high- and low-head gaskets.

lieving temperature not to exceed that required to form a gasket 11.2 Any additional marking or color designation shall be as

race. agreed upon by the pipe and gasket manufacturer.

SUPPLEMENTARY REQUIREMENTS

POTABLE WATER REQUIREMENT

This requirement applies whenever a Regulatory Authority or user calls for product to be used to

FIG. 1 Device for Test of Elastomeric Compound Effect on Plastic

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Valencia, Hugh

No reproduction or networking permitted without license from IHS Not for Resale, 02/03/2007 13:06:38 MST

F 477 02e1

convey or to be in contact with potable water.

S1. Products intended for contact with potable water shall Standard No. 14 by an acceptable certifying organization when

be evaluated, tested and certified for conformance with ANSI/ required by the regulatory authority having jurisdiction.

NSF Standard No. 61 or the health effects portion of NSF

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,``,,,,,``,`,```,``,`,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Valencia, Hugh

No reproduction or networking permitted without license from IHS Not for Resale, 02/03/2007 13:06:38 MST

Vous aimerez peut-être aussi

- Astm D 4976 - 04Document7 pagesAstm D 4976 - 04Anıl ZiylanPas encore d'évaluation

- Standard Specification For Fiberglass, (Fibra de Vidrio)Document5 pagesStandard Specification For Fiberglass, (Fibra de Vidrio)coltkidPas encore d'évaluation

- Astm D-3840 - 01Document9 pagesAstm D-3840 - 01Bipin SasikumarPas encore d'évaluation

- Specification ASTM D3350 PDFDocument110 pagesSpecification ASTM D3350 PDFraja reyhanPas encore d'évaluation

- Norma Astm F794Document7 pagesNorma Astm F794WalterRamosPas encore d'évaluation

- Astm D3034 00 PDFDocument10 pagesAstm D3034 00 PDFngronau124545Pas encore d'évaluation

- BS EN 744 1996.cracked PDFDocument16 pagesBS EN 744 1996.cracked PDFHassanSoboh100% (1)

- D2412-11 Standard Test Method For Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate LoadingDocument7 pagesD2412-11 Standard Test Method For Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loadingjavier perezPas encore d'évaluation

- Guided Side Bend Evaluation of Polyethylene Pipe Butt Fusion JointDocument11 pagesGuided Side Bend Evaluation of Polyethylene Pipe Butt Fusion JointdnavarroPas encore d'évaluation

- ASTM D 6093 - 97Document3 pagesASTM D 6093 - 97shgsuhermanPas encore d'évaluation

- Iso11922 1 1997Document17 pagesIso11922 1 1997Ayman S. Ashour0% (1)

- Astm D1785 (2012) PDFDocument11 pagesAstm D1785 (2012) PDFchairul anwarPas encore d'évaluation

- Astm F477Document4 pagesAstm F477Hernando Andrés Ramírez Gil100% (1)

- F439Document7 pagesF439cenkunal100% (1)

- Astm F439Document7 pagesAstm F439Quat Le DinhPas encore d'évaluation

- ASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónDocument14 pagesASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónalexagoPas encore d'évaluation

- Astm C1103 3Document2 pagesAstm C1103 3Boz Van DuynPas encore d'évaluation

- Astm D3034-00 PDFDocument10 pagesAstm D3034-00 PDFericpardo59100% (4)

- Astm d1785 1986Document11 pagesAstm d1785 1986aymanmkPas encore d'évaluation

- Poly (Vinyl Chloride) (PVC) Large-Diameter Plastic Gravity Sewer Pipe and FittingsDocument6 pagesPoly (Vinyl Chloride) (PVC) Large-Diameter Plastic Gravity Sewer Pipe and FittingsAmar JabarPas encore d'évaluation

- ASTM D4218-15 Contenido NHDocument3 pagesASTM D4218-15 Contenido NHNelson VivancoPas encore d'évaluation

- Astm d2444 21 落锤试验机标准Document10 pagesAstm d2444 21 落锤试验机标准Avin WangPas encore d'évaluation

- 4-Csa B137.3-2009Document36 pages4-Csa B137.3-2009AhmadmasrokanPas encore d'évaluation

- Astm F441-02 PDFDocument7 pagesAstm F441-02 PDFedelvallemp93100% (2)

- Astm 2466-15 PDFDocument6 pagesAstm 2466-15 PDFDeisabel CrespoPas encore d'évaluation

- Astm2241 09 PDFDocument9 pagesAstm2241 09 PDFPaola MenaPas encore d'évaluation

- Astm F 437-99 PDFDocument4 pagesAstm F 437-99 PDFJORGE ARTURO TORIBIO HUERTAPas encore d'évaluation

- ASTM F 2164 - 02 (Reapproved 2007)Document5 pagesASTM F 2164 - 02 (Reapproved 2007)Carlos MontBlackPas encore d'évaluation

- Astm D2412-11Document7 pagesAstm D2412-11Leudy Utria100% (1)

- Astm D3311Document27 pagesAstm D3311Hernando Andrés Ramírez GilPas encore d'évaluation

- Astm D2143 - 2005 PDFDocument3 pagesAstm D2143 - 2005 PDFMiguel Martinez GuerreroPas encore d'évaluation

- Astm F714Document10 pagesAstm F714santiago barrionuevoPas encore d'évaluation

- Astm D3262-96Document8 pagesAstm D3262-96anish_am2005Pas encore d'évaluation

- D 1599 PDFDocument3 pagesD 1599 PDFrickatmanPas encore d'évaluation

- ASTM 1598 - Standard Test Method For Time-to-Failure of Plastic Pipe Under Constant Internal PressureDocument0 pageASTM 1598 - Standard Test Method For Time-to-Failure of Plastic Pipe Under Constant Internal PressureferidizacijaPas encore d'évaluation

- D 2447 - 01 - Rdi0ndctukve PDFDocument9 pagesD 2447 - 01 - Rdi0ndctukve PDFAndre CasteloPas encore d'évaluation

- Polyolefins Technical Guide: Material Types, SDR Ratings, and Pressure StandardsDocument1 pagePolyolefins Technical Guide: Material Types, SDR Ratings, and Pressure Standardsjacok22Pas encore d'évaluation

- F1412 16Document7 pagesF1412 16masoud132Pas encore d'évaluation

- Astm F 679-03Document6 pagesAstm F 679-03JORGE ARTURO TORIBIO HUERTA100% (1)

- D3517Document11 pagesD3517Cristhian AndresPas encore d'évaluation

- D2444 PDFDocument8 pagesD2444 PDFDavid Solis0% (1)

- Astm D3212.380331 1Document3 pagesAstm D3212.380331 1anish_am2005Pas encore d'évaluation

- ASTM F336 Enveloped Gaskets Desing-ConstructionDocument4 pagesASTM F336 Enveloped Gaskets Desing-ConstructionDieguitoOmarMoralesPas encore d'évaluation

- D2444-99 (2010) Standard Test Method For DeterminatDocument9 pagesD2444-99 (2010) Standard Test Method For Determinatjavier perezPas encore d'évaluation

- Astm d4101Document17 pagesAstm d4101asdrecvPas encore d'évaluation

- Astm-F 2164Document5 pagesAstm-F 2164damithPas encore d'évaluation

- Polyethylene (PE) Plastic Pipe (DR-PR) Based On Outside DiameterDocument12 pagesPolyethylene (PE) Plastic Pipe (DR-PR) Based On Outside DiameterBayron Parra100% (2)

- Contact-Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Corrosion Resistant Pipe and FittingsDocument7 pagesContact-Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Corrosion Resistant Pipe and Fittingshasan syukur100% (1)

- ASTM F412 12 Terminology PDFDocument18 pagesASTM F412 12 Terminology PDFBinodh DanielPas encore d'évaluation

- Awwa-C906-15 AWWA Has Published C906-15!Document1 pageAwwa-C906-15 AWWA Has Published C906-15!ToBertPas encore d'évaluation

- DIN30672 Corrosion Protection CoatingsDocument6 pagesDIN30672 Corrosion Protection CoatingsDanijela100% (1)

- D2466 PDFDocument5 pagesD2466 PDFDavid SolisPas encore d'évaluation

- Iso 4435Document28 pagesIso 4435MarwaPas encore d'évaluation

- Poly (Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120Document11 pagesPoly (Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120Flor PeraltaPas encore d'évaluation

- Astm F 477Document4 pagesAstm F 477Zahoor Ahmed MohsanPas encore d'évaluation

- ASTM D2628 (1998) - Preformed Polychloroprene Elastastomeric Joint Seals For Concrete PavingDocument3 pagesASTM D2628 (1998) - Preformed Polychloroprene Elastastomeric Joint Seals For Concrete Pavingnoto SugiartoPas encore d'évaluation

- ASTM C542-05 Standard Specification For Lock-Strip GasketsDocument5 pagesASTM C542-05 Standard Specification For Lock-Strip GasketsgustavoesanchezPas encore d'évaluation

- D 2000 - 00 - Rdiwmdatmdbfmq - PDFDocument38 pagesD 2000 - 00 - Rdiwmdatmdbfmq - PDFJohnny VargasPas encore d'évaluation

- D1056-14 - Standard Specification For Flexible Cellular Materials - Sponge or Expanded RubberDocument15 pagesD1056-14 - Standard Specification For Flexible Cellular Materials - Sponge or Expanded RubberFrancoPas encore d'évaluation

- D 3771 - 03 - Rdm3nzeDocument4 pagesD 3771 - 03 - Rdm3nzeCasey RybackPas encore d'évaluation

- Pressure Vessels RuptureDocument6 pagesPressure Vessels RuptureronfrendPas encore d'évaluation

- Piping InspectionDocument6 pagesPiping InspectionRaul2307Pas encore d'évaluation

- Chain Rule - Higher DerivativesDocument4 pagesChain Rule - Higher Derivativesakirank1Pas encore d'évaluation

- Algunas Derivadas TrigonométricasDocument4 pagesAlgunas Derivadas TrigonométricasRaul Humberto Mora VillamizarPas encore d'évaluation

- THE Computation of Derivatives: Cálculos de DerivadasDocument5 pagesTHE Computation of Derivatives: Cálculos de DerivadasRaul Humberto Mora VillamizarPas encore d'évaluation

- Derivatives of Products, Quotients, Sine, CosineDocument5 pagesDerivatives of Products, Quotients, Sine, Cosineakirank1Pas encore d'évaluation

- Selecting the Right PEC Probe for Cable Wall ThicknessDocument2 pagesSelecting the Right PEC Probe for Cable Wall ThicknessRodrigo Civetta MartinezPas encore d'évaluation

- Implicit Functions and DerivativesDocument3 pagesImplicit Functions and DerivativesRaul Humberto Mora VillamizarPas encore d'évaluation

- Visual Inspection For CUIDocument5 pagesVisual Inspection For CUIRaul Humberto Mora VillamizarPas encore d'évaluation

- Selecting the Right PEC Probe for Cable Wall ThicknessDocument2 pagesSelecting the Right PEC Probe for Cable Wall ThicknessRodrigo Civetta MartinezPas encore d'évaluation

- Elbow Components in Lyft 1.2 Software WorkflowDocument1 pageElbow Components in Lyft 1.2 Software WorkflowRaul Humberto Mora VillamizarPas encore d'évaluation

- Funciones Compuestas y Regla de La CadenaDocument4 pagesFunciones Compuestas y Regla de La CadenaRaul Humberto Mora VillamizarPas encore d'évaluation

- DNV-RP-F116 Integrity Management of Submarine Pipeline Systems, 2009Document62 pagesDNV-RP-F116 Integrity Management of Submarine Pipeline Systems, 2009jeremyg998100% (2)

- Tasas de Cambio Relacionadas: Related RatesDocument4 pagesTasas de Cambio Relacionadas: Related RatesRaul Humberto Mora VillamizarPas encore d'évaluation

- Regla Del Cociente y ProductoDocument4 pagesRegla Del Cociente y ProductoRaul Humberto Mora VillamizarPas encore d'évaluation

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- More Maximumminimum Problems. Reflection and RefractionDocument6 pagesMore Maximumminimum Problems. Reflection and RefractionRaul Humberto Mora VillamizarPas encore d'évaluation

- Método de Newton para Cáculo de RaícesDocument3 pagesMétodo de Newton para Cáculo de RaícesRaul Humberto Mora VillamizarPas encore d'évaluation

- ASME IX Changes 2003 PDFDocument5 pagesASME IX Changes 2003 PDFRaul Humberto Mora VillamizarPas encore d'évaluation

- Managin Piping 1 PDFDocument8 pagesManagin Piping 1 PDFRaul Humberto Mora VillamizarPas encore d'évaluation

- Development of Pipeline Integrity Management System (PIMS) - Asle Venas - tcm144-482444Document36 pagesDevelopment of Pipeline Integrity Management System (PIMS) - Asle Venas - tcm144-482444Natraji100% (3)

- Fillet Weld Gauges: Phased Array Technology Writing WpssDocument44 pagesFillet Weld Gauges: Phased Array Technology Writing WpssKenshin HimuraPas encore d'évaluation

- Maple 11 TutorialDocument40 pagesMaple 11 TutorialAlfianInziaFusiariPas encore d'évaluation

- B31.1 2016Document32 pagesB31.1 2016Raul Humberto Mora VillamizarPas encore d'évaluation

- Paper MateDocument3 pagesPaper MateRaul Humberto Mora VillamizarPas encore d'évaluation

- Cswip 3.1 New BookDocument342 pagesCswip 3.1 New BookMohsin Rasul90% (52)

- Risknis Rbireport RgeDocument53 pagesRisknis Rbireport RgeDavid RodriguesPas encore d'évaluation

- Aws A5.4Document39 pagesAws A5.4Raul Humberto Mora VillamizarPas encore d'évaluation

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionslram70100% (20)

- CQE_160 Actual Test QuestionsDocument48 pagesCQE_160 Actual Test QuestionsMazin Alahmadi100% (2)

- PT14 Engine Monitor 1Document2 pagesPT14 Engine Monitor 1BJ DixPas encore d'évaluation

- Steam Turbine ManualDocument211 pagesSteam Turbine ManualDani Alberto Romero Villalba100% (2)

- Brosura - Micom A300 GTW - 2011 (En)Document2 pagesBrosura - Micom A300 GTW - 2011 (En)Cata CatalinPas encore d'évaluation

- Modular FixturesDocument2 pagesModular FixturesBhishman DesaiPas encore d'évaluation

- ASCE2011Madhu ManderDocument4 pagesASCE2011Madhu ManderNattalia RomeroPas encore d'évaluation

- C 34367Document19 pagesC 34367Loan LePas encore d'évaluation

- Bibiyana 300-450 MW CCPP Vol I.pdf - BPDBDocument118 pagesBibiyana 300-450 MW CCPP Vol I.pdf - BPDBhumayan kabirPas encore d'évaluation

- Electronics Illustrated 1963 01Document118 pagesElectronics Illustrated 1963 01ontmeth50% (2)

- CK 800-EU Pump StationDocument30 pagesCK 800-EU Pump Stationtiago calderPas encore d'évaluation

- CH 27Document5 pagesCH 27onlydlonly0% (1)

- HEB2016 50HzDocument11 pagesHEB2016 50HzMarco Godoy AstorgaPas encore d'évaluation

- BD2F Parts Wo Engine OptDocument154 pagesBD2F Parts Wo Engine Optali4299100% (1)

- Sony Klv-32v400a klv-32v400b Chassis Eg1l 987299403 Rev.3Document80 pagesSony Klv-32v400a klv-32v400b Chassis Eg1l 987299403 Rev.3بوند بوندPas encore d'évaluation

- Motor Starting Analysis ImpactsDocument2 pagesMotor Starting Analysis ImpactsBhavik PrajapatiPas encore d'évaluation

- Vertical Multistage Centrifugal PumpsDocument32 pagesVertical Multistage Centrifugal Pumpsfirda8587Pas encore d'évaluation

- Vane Pump1Document1 pageVane Pump1Romy MPas encore d'évaluation

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentRameshLoganathanPas encore d'évaluation

- Have ST DoneDocument2 pagesHave ST DoneBeatriz LGPas encore d'évaluation

- Data Sheet - Carrier ChillerDocument4 pagesData Sheet - Carrier Chillercalvin.bloodaxe4478Pas encore d'évaluation

- @code of Site Supervision, 2005Document104 pages@code of Site Supervision, 2005cyong7788Pas encore d'évaluation

- Diagnostic Trouble Codes (Text)Document7 pagesDiagnostic Trouble Codes (Text)talyerautoshop5432Pas encore d'évaluation

- OilfieldDocument4 pagesOilfieldSig BahaPas encore d'évaluation

- Ba Battery Tester MBT 101 enDocument8 pagesBa Battery Tester MBT 101 enDamian FediukPas encore d'évaluation

- Knuckle JointDocument32 pagesKnuckle JointThirumalaimuthukumaranMohanPas encore d'évaluation

- Adel Resume.Document4 pagesAdel Resume.adelsamhanPas encore d'évaluation

- Kitchen Equipment Boq PDFDocument82 pagesKitchen Equipment Boq PDFAnonymous qOBFvIPas encore d'évaluation

- Energy-Related Essay MESC TahriziDocument2 pagesEnergy-Related Essay MESC TahriziTahrizi AndanaPas encore d'évaluation

- Stainless Steel Hand Pallet: Material Handling and LiftingDocument1 pageStainless Steel Hand Pallet: Material Handling and LiftingAULIAPas encore d'évaluation

- Premium Protection Synthetic Motor Oils (AMO & ARO)Document2 pagesPremium Protection Synthetic Motor Oils (AMO & ARO)brian5786Pas encore d'évaluation

- Power System Analysis Cover 3Document2 pagesPower System Analysis Cover 3DanielPas encore d'évaluation