Académique Documents

Professionnel Documents

Culture Documents

Refri Removing&Replacing Compressors

Transféré par

manonpom0 évaluation0% ont trouvé ce document utile (0 vote)

4 vues1 pagehvac

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documenthvac

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

4 vues1 pageRefri Removing&Replacing Compressors

Transféré par

manonpomhvac

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

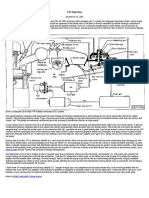

REMOVING and REPLACING COMPRESSORS

1. Remove ALL refrigerant by using an approved method (EPA).

2. Determine if failure caused refrigerant and/or lubricating oil to be contaminated.

a) Check color of refrigerant and/or oil. The oil can be tested using an oil test kit.

3. Flushing agents are NOT recommended. Use nitrogen to flush or purge system

as necessary.

4. Use a torch and purge with nitrogen to remove piping and compressor as

necessary.

a) The use of a low pressure nitrogen flow (in an open system to prevent

pressure buildup) during the compressor removal will prevent a black film to

form inside the piping and compressor, contaminating the system.

5. Install new compressor using the nitrogen purging process to prevent

contamination buildup.

6. Using nitrogen (high pressure) - check for leaks.

7. If no leaks are found, purge the system with nitrogen for a few minutes.

8. Evacuate system using a vacuum pump with clean oil.

a) Pull the vacuum to 500 microns for two hours. The micron reading should be

down to 200 microns after two hours.

9. Wire compressor following the factory wiring schematic.

10. Add the proper refrigerant charge following the factory specifications.

11. Start unit,

a) Check for amperage reading (not to exceed factory specification)

b) Check inlet vs discharge temperatures at the indoor unit. The temperature

difference should approximately 22F to 25F in coo ling.

Cleanup work site and repack tools JOB WELL DONE!

Vous aimerez peut-être aussi

- Caution: CCN: 80440142 Rev. ADocument5 pagesCaution: CCN: 80440142 Rev. AGustavo HuertasPas encore d'évaluation

- Clean Up Procedure for Compressor BurnoutsDocument11 pagesClean Up Procedure for Compressor Burnoutsmahmoud mohamedPas encore d'évaluation

- Leak-Test-VacuumDocument1 pageLeak-Test-Vacuumdarby1028Pas encore d'évaluation

- 150 FX 4 ElectriDocument646 pages150 FX 4 ElectrilefontPas encore d'évaluation

- Air Conditioning SystemDocument1 pageAir Conditioning Systemjohn karl lapePas encore d'évaluation

- ImpregnationDocument9 pagesImpregnationsivamettPas encore d'évaluation

- .Archivetempsection 15 - StorageDocument6 pages.Archivetempsection 15 - StorageFernando MirandaPas encore d'évaluation

- Aftercooler - Test PDFDocument6 pagesAftercooler - Test PDFDaniel Castillo Peña100% (1)

- APDD 339A Sierra Long Term StorageDocument4 pagesAPDD 339A Sierra Long Term StorageCesar HernandezPas encore d'évaluation

- Mini Galaxy e 050600Document19 pagesMini Galaxy e 050600Роман ПрокопчукPas encore d'évaluation

- Pegasys Manual Inst Oper MantDocument12 pagesPegasys Manual Inst Oper MantDaniel LagosPas encore d'évaluation

- HS-150 Steam Sterilizer ANDROID SYSTEM ManualDocument49 pagesHS-150 Steam Sterilizer ANDROID SYSTEM Manualbayu hendrawanPas encore d'évaluation

- All in One Class4 OralsDocument33 pagesAll in One Class4 OralsSantharam Mariner100% (2)

- Maintance ReportDocument6 pagesMaintance ReportUncle WaynePas encore d'évaluation

- Galaxy S User ManualDocument18 pagesGalaxy S User ManualBen ColesPas encore d'évaluation

- Aftercooler - Test: Testing and AdjustingDocument6 pagesAftercooler - Test: Testing and AdjustingAbdoulaye Boua BERTHEPas encore d'évaluation

- Basic AC guidelinesDocument3 pagesBasic AC guidelinesRian SethrashPas encore d'évaluation

- Working Condition and Specification Machine ParametersDocument12 pagesWorking Condition and Specification Machine ParametersMobin AhmedPas encore d'évaluation

- Galaxy S CO2 Incubator User ManualDocument18 pagesGalaxy S CO2 Incubator User ManualEvelynPas encore d'évaluation

- Alkali Boil OutDocument4 pagesAlkali Boil OutAnsuman Sen SharmaPas encore d'évaluation

- Manual de Toyota 2nz..Document50 pagesManual de Toyota 2nz..francisco iman sosaPas encore d'évaluation

- Bristol CompresoresDocument31 pagesBristol CompresoresBairon jaramilloPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- PQ Sterile TunnelDocument10 pagesPQ Sterile TunnelReza JafariPas encore d'évaluation

- Oprating Manual For Cloud & Pour PointDocument5 pagesOprating Manual For Cloud & Pour PointChaitanya Kamthe100% (1)

- Biomist - Operating ManualDocument28 pagesBiomist - Operating ManualArturo Millán GuadarramaPas encore d'évaluation

- Eco İng.a5Document35 pagesEco İng.a5Edgar Nicolás Paricela VergarayPas encore d'évaluation

- SOP For FlushingDocument5 pagesSOP For Flushingmoms2Pas encore d'évaluation

- Performance Qualification of Autoclave Cum Bung ProcessorDocument17 pagesPerformance Qualification of Autoclave Cum Bung ProcessorĐức LinhPas encore d'évaluation

- AE 250DS ManualDocument13 pagesAE 250DS ManualLuis SalazarPas encore d'évaluation

- Bristol H2234643DBLADocument10 pagesBristol H2234643DBLAvickersPas encore d'évaluation

- Maintenance Working Hours Flow For Gas TurbineDocument7 pagesMaintenance Working Hours Flow For Gas TurbineHilmi HanoinPas encore d'évaluation

- Testing of Engines - 0Document12 pagesTesting of Engines - 0S lenkaPas encore d'évaluation

- A/C Compressor & Magnetic Clutch Installation Instructions: General Service Information and RequirementsDocument10 pagesA/C Compressor & Magnetic Clutch Installation Instructions: General Service Information and RequirementsJose A. Basanta H.Pas encore d'évaluation

- Furnace Manual 120v Updated 2013Document21 pagesFurnace Manual 120v Updated 2013api-251989125Pas encore d'évaluation

- Removal of Moisture From Systems by Vacuum PumpDocument4 pagesRemoval of Moisture From Systems by Vacuum PumpSaravana KarthikeyanPas encore d'évaluation

- Refrigerant LeakguidelinesDocument6 pagesRefrigerant Leakguidelinessumanth.n nPas encore d'évaluation

- Radiator FlushDocument7 pagesRadiator FlushmichaelguzziPas encore d'évaluation

- Mep March 2023Document17 pagesMep March 2023Subham SamantarayPas encore d'évaluation

- Types of Coating PansDocument46 pagesTypes of Coating Pansعبدالعزيز بدرPas encore d'évaluation

- Manual For GASBOARD-6010 Opacity Meter Components Smoke HeadDocument10 pagesManual For GASBOARD-6010 Opacity Meter Components Smoke HeadJOSEPH CAJOTEPas encore d'évaluation

- FTS004 Deep Fat FryersDocument3 pagesFTS004 Deep Fat FryersWissam JarmakPas encore d'évaluation

- 81 LP XZngs FLDocument15 pages81 LP XZngs FLSteven Belduma AriasPas encore d'évaluation

- Chemical Cleaning of BoilerDocument27 pagesChemical Cleaning of BoilerlrpatraPas encore d'évaluation

- Manual Hota STAR LIGHT HA-260SS/HA-260WHDocument48 pagesManual Hota STAR LIGHT HA-260SS/HA-260WHegozenoviePas encore d'évaluation

- Heat Transfer System FlushingDocument2 pagesHeat Transfer System FlushingDANIEL ZORROPas encore d'évaluation

- Oil ViscocityDocument11 pagesOil ViscocityLouie Dupaya100% (1)

- 8 Servicio en AA Con HC PDFDocument14 pages8 Servicio en AA Con HC PDFAnel ValdesPas encore d'évaluation

- O2 SafetyDocument3 pagesO2 Safetyrajpatil0007Pas encore d'évaluation

- Cartridge Filter Type Spray Booth Instructions v1.1Document21 pagesCartridge Filter Type Spray Booth Instructions v1.1AnnPas encore d'évaluation

- AN ManualDocument142 pagesAN ManualAhmed Said ElrouiePas encore d'évaluation

- Horno RftoDocument31 pagesHorno Rftojulio RCPas encore d'évaluation

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsDocument11 pagesDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshPas encore d'évaluation

- Manual - Filter Oil Test Rig -ISO 1 & 3Document5 pagesManual - Filter Oil Test Rig -ISO 1 & 3Rudra QMS SolutionPas encore d'évaluation

- Evaluation AnswerDocument7 pagesEvaluation AnswerAdam HaziqPas encore d'évaluation

- Gas Oven Operation ManualDocument14 pagesGas Oven Operation Manualsharklink blackPas encore d'évaluation

- 1kr Fe CoolingDocument128 pages1kr Fe Coolingfguij100% (1)

- CorrosionboxDocument4 pagesCorrosionboxmankari.kamal.18022963Pas encore d'évaluation

- Dive ScubaPro - S600 Schema ' Americain Philips (#38) Head Screw'new Balanced ChamberDocument1 pageDive ScubaPro - S600 Schema ' Americain Philips (#38) Head Screw'new Balanced ChambermanonpomPas encore d'évaluation

- Dive Scubapro ' RSA'conditio-of-saleDocument1 pageDive Scubapro ' RSA'conditio-of-salemanonpomPas encore d'évaluation

- MB + EGR ' Via Vacuu EGR-Valv'testDocument1 pageMB + EGR ' Via Vacuu EGR-Valv'testmanonpomPas encore d'évaluation

- CIS InjectionDocument1 pageCIS InjectionmanonpomPas encore d'évaluation

- Refri-Syst Copeland-Emerson ' CPS' - CO2 Ps-TestDocument2 pagesRefri-Syst Copeland-Emerson ' CPS' - CO2 Ps-TestmanonpomPas encore d'évaluation

- Refri CO2 - SafetyDocument12 pagesRefri CO2 - SafetymanonpomPas encore d'évaluation

- Automotiv - MG Midget ' Morris Garage'series TC - Safety Fast ! - Trim ColoursDocument10 pagesAutomotiv - MG Midget ' Morris Garage'series TC - Safety Fast ! - Trim ColoursmanonpomPas encore d'évaluation

- Mercedes-Benz W123 and R107 DIY: Mercedes Vacuum DiagramDocument3 pagesMercedes-Benz W123 and R107 DIY: Mercedes Vacuum DiagrammanonpomPas encore d'évaluation

- Automotiv - MG Midget ' Morris Garage'series TC - Safety Fast ! - MOTORING-GUILD OWNERS - 1960Document7 pagesAutomotiv - MG Midget ' Morris Garage'series TC - Safety Fast ! - MOTORING-GUILD OWNERS - 1960manonpomPas encore d'évaluation

- Cycles (Steerer ' Cadre'&Fourch ' Fork'CARBON) EddyMerckx - Com - StradaDocument2 pagesCycles (Steerer ' Cadre'&Fourch ' Fork'CARBON) EddyMerckx - Com - StradamanonpomPas encore d'évaluation

- SCUBAPRO Washer Addition BulletinDocument1 pageSCUBAPRO Washer Addition BulletinmanonpomPas encore d'évaluation

- Dive Cps + MONOPHASE DUAL-capa (400microF:300V Start&60microF:450V Run) Elec-Motor ' Alu Housing'model ML100L-2 (2poles, 220V:50Hz, S1, 3Kw, 2800rpm, Form B3 ' Feet'IMB3) 23KgDocument1 pageDive Cps + MONOPHASE DUAL-capa (400microF:300V Start&60microF:450V Run) Elec-Motor ' Alu Housing'model ML100L-2 (2poles, 220V:50Hz, S1, 3Kw, 2800rpm, Form B3 ' Feet'IMB3) 23KgmanonpomPas encore d'évaluation

- Dive Scubapro - Nova 850 Lumens - Wide ' Night'Document1 pageDive Scubapro - Nova 850 Lumens - Wide ' Night'manonpomPas encore d'évaluation

- Refri Removing&Replacing CompressorsDocument1 pageRefri Removing&Replacing CompressorsmanonpomPas encore d'évaluation

- Dive Cps - Bauer + Hongma@hongmamotor - Com:hongmamotor@188.com - 3Kw, 2800rpm, Type-Of-Constructio B3 - ML (YL) Serie - ML100L-2 - 220V:50Hz, SINGLE-Phase, 25KgDocument1 pageDive Cps - Bauer + Hongma@hongmamotor - Com:hongmamotor@188.com - 3Kw, 2800rpm, Type-Of-Constructio B3 - ML (YL) Serie - ML100L-2 - 220V:50Hz, SINGLE-Phase, 25KgmanonpomPas encore d'évaluation

- Refri-Syst Copeland-Emerson ' CPS' - CO2 Ps-TestDocument2 pagesRefri-Syst Copeland-Emerson ' CPS' - CO2 Ps-TestmanonpomPas encore d'évaluation

- Dive Mru - Cps-Operator STDDocument2 pagesDive Mru - Cps-Operator STDmanonpomPas encore d'évaluation

- Automotiv MGTC DistributionDocument1 pageAutomotiv MGTC DistributionmanonpomPas encore d'évaluation

- Removal of Moisture From Systems by Vacuum PumpDocument4 pagesRemoval of Moisture From Systems by Vacuum PumpSaravana KarthikeyanPas encore d'évaluation

- Dive CCR - Revo Checklist - CtMassFlow CMF - OverPsValv OPV - BailOutValv BOVDocument2 pagesDive CCR - Revo Checklist - CtMassFlow CMF - OverPsValv OPV - BailOutValv BOVmanonpomPas encore d'évaluation

- Dive CCR ' Revo'Air-diluent ProceduresDocument8 pagesDive CCR ' Revo'Air-diluent ProceduresmanonpomPas encore d'évaluation

- Automotiv MGTC DistributionDocument1 pageAutomotiv MGTC DistributionmanonpomPas encore d'évaluation

- Dive Scubapro - Nova 850 Lumens - Wide ' Night'Document1 pageDive Scubapro - Nova 850 Lumens - Wide ' Night'manonpomPas encore d'évaluation

- Dive Scubapro D400 Maintenance ProcedureDocument5 pagesDive Scubapro D400 Maintenance ProceduremanonpomPas encore d'évaluation

- Refri - Coca-Cola R290 P-T ChartDocument4 pagesRefri - Coca-Cola R290 P-T ChartmanonpomPas encore d'évaluation

- Refri CO2 Boc-Linde - How To Spot@Gas LeakDocument2 pagesRefri CO2 Boc-Linde - How To Spot@Gas LeakmanonpomPas encore d'évaluation

- Dive CCR ' Revo'Air-diluent ProceduresDocument8 pagesDive CCR ' Revo'Air-diluent ProceduresmanonpomPas encore d'évaluation

- Dive Scubapro - Air2 3rd - Maintenance ProcedureDocument5 pagesDive Scubapro - Air2 3rd - Maintenance Proceduremanonpom100% (1)

- Macos Sierra - Level 1 OutlineDocument4 pagesMacos Sierra - Level 1 OutlinemanonpomPas encore d'évaluation

- Dive Scubapro - Mk2+, Mk2 - Maintenance ProcedureDocument4 pagesDive Scubapro - Mk2+, Mk2 - Maintenance ProceduremanonpomPas encore d'évaluation