Académique Documents

Professionnel Documents

Culture Documents

WP Gear Oil Specifications

Transféré par

mannajoe7Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WP Gear Oil Specifications

Transféré par

mannajoe7Droits d'auteur :

Formats disponibles

White Paper

Common industrial gear oil specifications

This brief overview explains a few of the standards used in the gear oil industry

that affect your oil selection

The first step in identifying the proper gear oil to use is to follow OEM recommendations.

This quick overview explains a few of the standards used in the gear oil industry to simplify gear oil specification.

Often, specifying a gear oil for an end user is as simple as

following an OEM recommendation. This should always be the

first step in identifying the proper gear oil to use. This information

will either be found directly on a nameplate of the gearbox or

contained in a lubrication chart in the maintenance manual/

user guide for the respective make and model of the gearbox.

OEMs use several standards to define the desired performance

characteristics and the type of the oil for a given application,

temperature range or operating condition. The following is a

brief overview to explain a few of the standards used in the gear

oil industry.

ISO VG

Viscosity of a gear oil is one of the most important physical

characteristics to be considered. With so many different For gearboxes operating at a given temperature range or operating condition,

OEMs use several standards to define the required gear oil type and

international standards defining viscosity requirements, the performance characteristics.

International Standards Organization Viscosity Grade (ISO VG)

was developed with input from all international organizations.

This ISO system is used to minimize confusion between AGMA Specification

equipment manufacturers, end users and lubricant suppliers

by standardizing the different viscosity grades of an oil. The The latest version of the American Gear Manufacturers

ISO VG is defined as the base oils viscosity expressed in the Association (AGMA) specification for the lubrication of enclosed

unit centistoke (cSt), which is also equal to mm2/s at a standard gear drives is ANSI/AGMA 9005-F16. This document provides

temperature of 40C. There is an allowable tolerance of +/- 10% both end-users and equipment manufacturers lubrication

of that standard viscosity grade. For example the viscosity of an guidelines for open and enclosed gearing. The standard defines

ISO VG 460 oil is acceptable at a minimum of 414cSt at 40C and several recommended test requirements for various viscosity

a maximum of 506cSt at 40C. ISO viscosity grades can vary grades and various oil types. Previous versions of the document

from an ISO VG 2 up to ISO VG 3200 and are defined in standard used designations for the different viscosity grades (4EP, 5EP,

steps in between. etc.). The current version of the document has standardized on

ISO viscosity grades and oil types (i.e. Antiwear/Antiscuff EP,

etc.). There are still gearboxes in industry that will specify the

White Paper Gear Oil Specs

16.12 Edition KLUSA

White Paper

Common industrial gear oil specifications

This brief explains a few of the standards used in the gear oil industry

that affect your oil selection.

use of a 5EP oil. If this is the case, check with your local Kluber API Specification

representative or old versions of the AGMA document to cross

to a current viscosity grade and type. In the past, anti-scuff The API specification is written by the Lubricants Group of

lubricants were referred to as extreme pressure or EP. The latest the American Petroleum Institute and is developed to assist

release of this standard has transitioned away from the generic automotive manufacturers and end users in the proper selection

term of EP and is now referring to these oils as anti-scuff or AS. of transmissions, transaxles and axle lubricants. The test

The FE8 bearing test has now been added as a requirement requirements are defined by ASTM D7560 and ASTM D7450.

to the anti-scuff lubricant table. There has also been an added While the API designation is primarily focused on automotive

section on enhanced lubricant characteristics to discuss the products, there still are a few OEMs that will use this for industrial

importance of temperature performance, enhanced wear applications. Currently there are only three API designations that

protection, foam behavior and efficiency. are used. These are API GL-4, API GL-5, and API GL MT-1.

API GL-4: Intended for use in applications with spiral bevel gear

CLP Gear Oils sets that operate under moderate to severe conditions.

The CLP rating is a German oil standard, similar to AGMA API GL-5: Intended to be used in hypoid gears that are

specifications, and is defined by DIN 51517-3. This document operating under high speeds and shock loading, or under

outlines the minimum physical test requirements to meet the low speed and high-torque conditions. This is defined in

CLP specification. It covers petroleum based gear lubricants that ASTM D7450.

contain additives to improve rust protection, oxidation resistance

API MT-1: Denotes lubricants that are intended for use in

and EP protection. Often, a gear manufacturer will specify a

non-synchronized manual transmissions. They are specifically

CLP oil and an oil type; for example CLP HC 220, is an ISO VG

designed to perform under the operating conditions and on the

220 PAO gear oil that meets CLP specifications.

components in a manual transmission. This is specifically true

CLP is typically a CLP mineral oil for the compatibility of sealing materials.

CLP HC is typically a CLP synthetic (SHC, PAO, POE) oil

API GL-1, API GL-2, API GL-3, & API GL-6: These four

CLP PG is typically a CLP polyglycol PAG oil designations are all not currently in use due to the ever-changing

application and test requirements. They may still be listed by

a manufacturer or OEM, but in the situation, they are the API

Designation document should be checked to provide a current

and accurate lubricant recommendation.

For more information, please contact Klber Lubrication at

marketing@us.kluber.com.

Klber Lubrication NA LP / 32 Industrial Drive / Londonderry, NH 03053 / Toll Free: 1-800-447-2238 / Phone: 603-647-4104 / Fax: 603-647-4106

Innovative tribological solutions are our passion. Through personal contact and consultation, we help our customers to be successful worldwide, in all industries and markets. With our ambitious

technical concepts and experienced, competent staff we have been fulfilling increasingly demanding requirements by manufacturing efficient high-performance lubricants for more than 80 years.

Vous aimerez peut-être aussi

- Hydraulic System Trainer AS-10Document13 pagesHydraulic System Trainer AS-10Tanlets Gery100% (1)

- Mobil GuideDocument19 pagesMobil GuidemademanPas encore d'évaluation

- Industrial Grease Lubricant Application GuideDocument2 pagesIndustrial Grease Lubricant Application GuideOscar Cruz100% (2)

- OEM Engine Oil Lubricant Specifications: White PaperDocument4 pagesOEM Engine Oil Lubricant Specifications: White Papermohamed100% (1)

- Mobil Serv Lubricants Analysis Guide 2 PDFDocument20 pagesMobil Serv Lubricants Analysis Guide 2 PDFFajar EkoPas encore d'évaluation

- SHELL Product Data Guide Industry 2013Document78 pagesSHELL Product Data Guide Industry 2013Edgar Real ViúlaPas encore d'évaluation

- ATF LubricantDocument35 pagesATF LubricantTung NguyenPas encore d'évaluation

- Engine Oil: Operation and Maintenance ManualDocument5 pagesEngine Oil: Operation and Maintenance ManualАлександр БудзинскийPas encore d'évaluation

- Industrial GreaseDocument6 pagesIndustrial GreaseNurHadi S WibowoPas encore d'évaluation

- 5354 Greases 2010 03Document6 pages5354 Greases 2010 03Gajendra SorenPas encore d'évaluation

- What You Need To Know When Selecting Gear OilsDocument5 pagesWhat You Need To Know When Selecting Gear OilsmarciofelipessantosPas encore d'évaluation

- Grease Analysis: Wouahbi Fatima Zahra/Lubricant SpecialistDocument18 pagesGrease Analysis: Wouahbi Fatima Zahra/Lubricant SpecialistYasir Khan100% (1)

- Transmission Oils For Transport MiningDocument37 pagesTransmission Oils For Transport MiningJuan Luis Rojas100% (1)

- Engine Oil MythsDocument2 pagesEngine Oil Mythshpss77Pas encore d'évaluation

- BROCHURE Premium Greases Guide TNRDocument7 pagesBROCHURE Premium Greases Guide TNRRezhaPas encore d'évaluation

- CetvelDocument17 pagesCetvelmehmetaliozgur100% (1)

- General Discussions On Lubricating OilsDocument59 pagesGeneral Discussions On Lubricating OilsHari PurwadiPas encore d'évaluation

- FUCHS RENOLIN Industrial Gear OilsDocument18 pagesFUCHS RENOLIN Industrial Gear OilsfajarfrankyPas encore d'évaluation

- M-630 Material Data Sheets For PipingDocument85 pagesM-630 Material Data Sheets For Pipingsun2meltPas encore d'évaluation

- Límites Condenatorios CATDocument2 662 pagesLímites Condenatorios CATHECTORPas encore d'évaluation

- Austempered Ductile Cast IronDocument10 pagesAustempered Ductile Cast Ironhrk100Pas encore d'évaluation

- BPL Equiv Chart PDFDocument1 pageBPL Equiv Chart PDFmannajoe7Pas encore d'évaluation

- BPL Equiv Chart PDFDocument1 pageBPL Equiv Chart PDFmannajoe7Pas encore d'évaluation

- Food Grade Lube From Each BrandDocument6 pagesFood Grade Lube From Each BrandCindy OrangePas encore d'évaluation

- Api Engine Oil ClassificationsDocument3 pagesApi Engine Oil ClassificationsJohn Johnson100% (1)

- Product Equivalents OIL PDFDocument5 pagesProduct Equivalents OIL PDFLucasPas encore d'évaluation

- Lubespec 2013: Lubricant Moly Base Thickner Color Ep FM Lubricant Type Iso Grade Base Oil Viscosity Nlgi GradeDocument4 pagesLubespec 2013: Lubricant Moly Base Thickner Color Ep FM Lubricant Type Iso Grade Base Oil Viscosity Nlgi GradeCara GutierrezPas encore d'évaluation

- Heavy Duty Engine Oils-Field TrialsDocument51 pagesHeavy Duty Engine Oils-Field TrialsJuan Luis RojasPas encore d'évaluation

- ASTM Reference OilsDocument25 pagesASTM Reference OilsRaghu NagarPas encore d'évaluation

- Deva - BM ENDocument24 pagesDeva - BM ENOscar CruzPas encore d'évaluation

- Rating of Hydraulic Fluids For Rexroth Hydraulic Components Re90235 - 2015-02 PDFDocument8 pagesRating of Hydraulic Fluids For Rexroth Hydraulic Components Re90235 - 2015-02 PDFDennis Huanuco CcamaPas encore d'évaluation

- ANALEX PQL Datasheet PDFDocument2 pagesANALEX PQL Datasheet PDFmaye palominoPas encore d'évaluation

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsdnoaisapsPas encore d'évaluation

- Lubricants For The Manufacturing IndustryDocument20 pagesLubricants For The Manufacturing IndustrynarenjiPas encore d'évaluation

- Viscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument39 pagesViscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoraliePas encore d'évaluation

- Lubricants For Steel Industry: CondatDocument2 pagesLubricants For Steel Industry: CondatAlstome PowerPas encore d'évaluation

- The Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?D'EverandThe Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?Pas encore d'évaluation

- 5448 Castrol Technical GuideDocument437 pages5448 Castrol Technical GuideUlyses Morata100% (1)

- Construction Lube Apps 18 Jan 16Document46 pagesConstruction Lube Apps 18 Jan 16José Cesário NetoPas encore d'évaluation

- Inf Gear PresentationDocument18 pagesInf Gear PresentationSarantos KapidakisPas encore d'évaluation

- Ubricants Brand ComparisonDocument6 pagesUbricants Brand ComparisonUtkarshPas encore d'évaluation

- Lubrizol360 Webinar PPT Template - v2 - Evaluation of Performance Properties of Slideway Lubricants - Z124Document58 pagesLubrizol360 Webinar PPT Template - v2 - Evaluation of Performance Properties of Slideway Lubricants - Z124tiến thử huỳnhPas encore d'évaluation

- FUCHS LUBRITECH Product RangeDocument76 pagesFUCHS LUBRITECH Product RangeBurak GüleşPas encore d'évaluation

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezPas encore d'évaluation

- F AdaptersDocument122 pagesF Adaptersxuanphuong2710Pas encore d'évaluation

- Classification of Engine Oil ViscosityDocument1 pageClassification of Engine Oil ViscosityRio aji RiyantoPas encore d'évaluation

- Is 13656 2002 PDFDocument24 pagesIs 13656 2002 PDFSiddharth GuptaPas encore d'évaluation

- WCTE 2018 Conference Paper Stoner FinalVerDocument7 pagesWCTE 2018 Conference Paper Stoner FinalVerMichael StonerPas encore d'évaluation

- Copia de Petrobras Marine Lubricating Oils Equivalent ListDocument5 pagesCopia de Petrobras Marine Lubricating Oils Equivalent Listeddy1588Pas encore d'évaluation

- Shell Albida EMS2Document1 pageShell Albida EMS2Muhammad Haris BaigPas encore d'évaluation

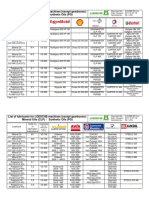

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Document8 pagesList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaPas encore d'évaluation

- Kluber-Brochure Lubrication of Various ComponentsDocument17 pagesKluber-Brochure Lubrication of Various ComponentsjalalPas encore d'évaluation

- Atf Conversion Chart - HFM & M-V Ts-As-05-112-FtDocument2 pagesAtf Conversion Chart - HFM & M-V Ts-As-05-112-FtcherokewagPas encore d'évaluation

- TDS - Total - Lubrilam Cleaner H1 - 1XQ - 201412 - enDocument1 pageTDS - Total - Lubrilam Cleaner H1 - 1XQ - 201412 - enVelibor KaranovicPas encore d'évaluation

- A Comprehensive Solution For Extreme and Specialty ApplicationsDocument7 pagesA Comprehensive Solution For Extreme and Specialty ApplicationsAmjedPas encore d'évaluation

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Document4 pagesPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbPas encore d'évaluation

- Forming Lubricants Product Portfolio PDFDocument28 pagesForming Lubricants Product Portfolio PDFceljkoPas encore d'évaluation

- EIC N 1001 0 Hydraulic FluidsDocument13 pagesEIC N 1001 0 Hydraulic FluidsCharitha LiyanagamaPas encore d'évaluation

- Design Engineer's Guide - Selecting A Lubricant For Ball ScrewsDocument10 pagesDesign Engineer's Guide - Selecting A Lubricant For Ball ScrewsDat RomanPas encore d'évaluation

- Global Industrial Gear Oil MarketDocument16 pagesGlobal Industrial Gear Oil MarketSanjay MatthewsPas encore d'évaluation

- Industrial Lubricants - Viscosities Equivalent ISO-VG GradeDocument3 pagesIndustrial Lubricants - Viscosities Equivalent ISO-VG GradeArifinPas encore d'évaluation

- PDS LZ 5703Document3 pagesPDS LZ 5703Alfredo BallonPas encore d'évaluation

- Castrol Canada Gps 2019 PDFDocument173 pagesCastrol Canada Gps 2019 PDFJeremias UtreraPas encore d'évaluation

- Truth and Reason: The Lord's SupperDocument8 pagesTruth and Reason: The Lord's Suppermannajoe7Pas encore d'évaluation

- Invoice: Khalid Saeed Al Hajri Est Production PosmsDocument1 pageInvoice: Khalid Saeed Al Hajri Est Production Posmsmannajoe7Pas encore d'évaluation

- Maratron LH 10W-40 TDS UpdatedDocument1 pageMaratron LH 10W-40 TDS Updatedmannajoe7Pas encore d'évaluation

- Syntron 5w-30 Ll01 Tds (Engine Oil)Document1 pageSyntron 5w-30 Ll01 Tds (Engine Oil)mannajoe7Pas encore d'évaluation

- Avalon Range (Hydraulic Oil) - CorrectedDocument1 pageAvalon Range (Hydraulic Oil) - Correctedmannajoe7Pas encore d'évaluation

- Product Description: Typical PropertiesDocument1 pageProduct Description: Typical Propertiesmannajoe7Pas encore d'évaluation

- Homeowners Insurance, Section IDocument23 pagesHomeowners Insurance, Section Imannajoe7Pas encore d'évaluation

- Long Life Coolant 50% L: Technical Data SheetDocument1 pageLong Life Coolant 50% L: Technical Data Sheetmannajoe7Pas encore d'évaluation

- Product Description: Brake Fluid Dot 3Document1 pageProduct Description: Brake Fluid Dot 3mannajoe7Pas encore d'évaluation

- Multigear Express API GL-5 SAE 85W-140: Technical Data SheetDocument1 pageMultigear Express API GL-5 SAE 85W-140: Technical Data Sheetmannajoe7Pas encore d'évaluation

- SAHCODocument3 pagesSAHCOmannajoe7Pas encore d'évaluation

- 050626AM - Jim NewheiserDocument3 pages050626AM - Jim Newheisermannajoe7Pas encore d'évaluation

- 08 Tintin and The King Ottokars Sceptre PDFDocument63 pages08 Tintin and The King Ottokars Sceptre PDFmannajoe7Pas encore d'évaluation

- Tintin and The Broken EarDocument63 pagesTintin and The Broken EarSteven D'souza90% (20)

- Crime Insurance and Surety BondsDocument17 pagesCrime Insurance and Surety Bondsmannajoe7Pas encore d'évaluation

- 04 Tintin and The Cigars of The Pharaoh PDFDocument63 pages04 Tintin and The Cigars of The Pharaoh PDFmannajoe7Pas encore d'évaluation

- Service Manual MIL-9000 and MIL-12000: Electric WinchesDocument29 pagesService Manual MIL-9000 and MIL-12000: Electric WinchesGlen C. ChadwickPas encore d'évaluation

- Installation Instructions: MazdaDocument3 pagesInstallation Instructions: MazdaMickael FernánPas encore d'évaluation

- MTO Indowater 2019Document5 pagesMTO Indowater 2019Muhammad Ilham Al FaizPas encore d'évaluation

- Physics Problem Solving ExampleDocument3 pagesPhysics Problem Solving Examplenathaniel borlazaPas encore d'évaluation

- Ec PDFDocument1 232 pagesEc PDFАндрей НадточийPas encore d'évaluation

- Flow Types: - Base of SpillwayDocument6 pagesFlow Types: - Base of Spillwaygizem cenikPas encore d'évaluation

- Istr Fibo300-Fibo400 GBDocument12 pagesIstr Fibo300-Fibo400 GBFrankie Abdul JimPas encore d'évaluation

- Pump Primer 2 AssDocument33 pagesPump Primer 2 AssGkou DojkuPas encore d'évaluation

- Course Plan HMTDocument3 pagesCourse Plan HMTparameshPas encore d'évaluation

- 6115-Article Text-19834-2-10-20200803 PDFDocument29 pages6115-Article Text-19834-2-10-20200803 PDFAshaari Cha-ePas encore d'évaluation

- Waves WorksheetDocument4 pagesWaves WorksheetSajjan BalasubramanyanPas encore d'évaluation

- Structural Analysis Jan 2023Document11 pagesStructural Analysis Jan 2023harshavenna04Pas encore d'évaluation

- Diesel Cycle AnalysisDocument16 pagesDiesel Cycle AnalysisSarah AsgharPas encore d'évaluation

- Öhlins Ka049 Zxr750r 91-94Document2 pagesÖhlins Ka049 Zxr750r 91-94sasaPas encore d'évaluation

- Modeling and Simulation of Multiphase/Multicomponent FlowsDocument150 pagesModeling and Simulation of Multiphase/Multicomponent FlowsSasank KomarlaPas encore d'évaluation

- 160 Kva MangrolDocument6 pages160 Kva MangrolrajendranrajendranPas encore d'évaluation

- 15P701Document4 pages15P701rajakrishnanPas encore d'évaluation

- Manual Wedge Action Grips - 2716-01X-02X and 2736-01XDocument3 pagesManual Wedge Action Grips - 2716-01X-02X and 2736-01XLALO MPas encore d'évaluation

- Vent Master Cam C InjeccionDocument2 pagesVent Master Cam C InjeccionFreddy VeraPas encore d'évaluation

- BOOM Camion (165 297)Document133 pagesBOOM Camion (165 297)David BriceñoPas encore d'évaluation

- Main Bearing Desing Update Man BWDocument21 pagesMain Bearing Desing Update Man BWarunPas encore d'évaluation

- Enerpac PullerDocument14 pagesEnerpac PullerantonioPas encore d'évaluation

- Factors Affecting Comfort Air Conditioning:: A) Fan: B) Air Condition: C) Filters: D) Supply Duct and OutletDocument4 pagesFactors Affecting Comfort Air Conditioning:: A) Fan: B) Air Condition: C) Filters: D) Supply Duct and Outletbibekananda sahooPas encore d'évaluation

- Lecture 7. HumidificationDocument29 pagesLecture 7. HumidificationNOBLEMAN100% (1)

- Compax CL: Operator S ManualDocument114 pagesCompax CL: Operator S ManualPicek30Pas encore d'évaluation