Académique Documents

Professionnel Documents

Culture Documents

22.1 Itp Rot 001 PDF

Transféré par

Adades Safede EfdTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

22.1 Itp Rot 001 PDF

Transféré par

Adades Safede EfdDroits d'auteur :

Formats disponibles

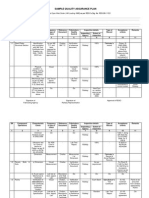

Inspection And Test Plan

for

Centrifugal Pump

HPCL, Vishakhaptnam TOYO ENGINEERING INDIA LTD.

ISSUED : 10/10/2008 JOB NO. : 6261

DOC.NO. HGU PROJECT Page 1 of 3

CLIENT : HPCL, VISHAKHAPATNAM

TEIL JOB NO. : 6261 APPLICABLE CODE : As per PR, PS

ITEM NO. /

PO. NO. :

COMMODITY : CETRIFUGAL PUMP

INSPECTION BY

S. NO. DESCRIPTION OF ACTIVITY EPCC / PMC / RECORD

TPIA

VENDOR OWNER

01 Detailed Inspection & Test Plan after issue of P A A* X

PO/PR/PS including for all auxiliaries of the Pump

skid like Pump driver, Lube oil console, API Plan,

Instrumentation, Piping etc.

02 Inspection & Test Procedures like NDT, Hydro test, P A R** X

Performance test, Mechanical run test, Painting etc.

03 Pre inspection meeting, after issue of PO/PR/PS, P H X

agenda to be prepared by VENDOR

04 Summary of all supplementary requirements as P A X

specified in the PO/PR/PS

05 Sub order verification for Bought out items like P R X

Drivers, API Plan, LO Console, Piping etc.

06 Inspection of Bought out items at Sub vendors W H X

works for Drivers, API Plan, LO Console, Piping

etc.

07 Welding Procedure Specification & Procedure P A X

Qualification Records Pressure retaining

components of the Pump, API plan, Piping etc.

08 Material Test Certificate in accordance with A A X

EN10204 3.1 / ISO10474 3.1B & meeting the

requirements of Material specification,

PR/PS/Design code

Pump components as Casing, Stuffing box, Bearing

housing, Impellers, Shaft, Shaft sleeve, Wear rings,

any other pressure retaining part / part exposed to

process fluid. Also, oil pumps , oil filters , oil

coolers, oil tank,

09 Material Compliance Certificate for Gaskets, A A X

Fasteners, Gland Packing, Valves, Piping items, etc.

10 Mechanical Seal (Testing & certificates / reports as A A X

per API 682 including Hydro test, Air test, Material

certification)

11 Coupling (Dynamic balancing report, Compliance A A X

certificate of Manufacturer)

12 Manufacturers Test Certificate / Calibration A A X

certificate for Instruments

13 NDT Examination as per PR/PS/Design code

a. Pump components as Casing, Stuffing box, P A X

Impellers, Shaft, Wear rings etc.

b. API Plan P A X

c. Auxiliary piping, Plan piping P A X

S. NO. DESCRIPTION OF ACTIVITY INSPECTION BY RECORD

Inspection And Test Plan

for

Centrifugal Pump

HPCL, Vishakhaptnam TOYO ENGINEERING INDIA LTD.

ISSUED : 10/10/2008 JOB NO. : 6261

DOC.NO. HGU PROJECT Page 1 of 3

EPCC / PMC /

TPIA

VENDOR OWNER

14 Hydrostatic Pressure Test

a. All Pressure Casing components P H X

b. Auxiliary piping P H X

c. Plan Piping P H X

d. Cooling jacket of bearing, Stuffing box P H X

e Pressure vessels. P H X

f Heat Exchangers P H X

g Filters P H X

h Other applicable items P H X

15 Dynamic balancing (including for Spares)

a. Individual Impellers P H X

b. Rotor assembly (as per PR/PS/Design code) P H X

16 Mechanical & Electrical run out of Shaft P R X

17 Lube Oil Console at sub vendor place

a. Pressure test W H X

b. Cleanliness check W H X

c. Mechanical running for 4 hours & Operation check W H X

d. Review of Material test certificates A A X

e. Review of Manufacturers Test certificates & A A X

Reports for Motor, Pump, Instruments etc.

f Contract Drivers, & Instruments W A X

g Check changeover valves W A X

h Check Auto- Start, Running and stop of stand-by W A X

pumps

i Check controls and all instrument functions W A X

18 API Plan Vessels, Coolers etc.

a. WPS / PQR A A X

b. NDT as per PR/PS/Design code A A X

c. Pressure test W H X

d. Visual & Dimensional check W H X

e. Review of Material test certificates A A X

19 Assembled Pump :

a. Performance Test as per PR/PS/Design code (with P H H** X

Mech run test) including Spare Rotar.

b. NPSH Test as per PR/PS/Design code P H H** X

c. Vibration measurement as per PR/PS/Design code P H X

d. Sound level measurement P H X

e. Mechanical running for 4 hours minimum (after P H H** X

stabilizing of Bearing temperature), with Bearing

housing resonance test

f. Bearing temperature rise as per PR/PS/Design code : P H X

Bearing and lube oil.

g. Strip test (Visual check & Wear ring clearance P H X

check)

20 Complete unit Test / String Test (can be done with P H H** X

Performance / Mech Run test). Note-9

With all Job accessories : Motor / HPRT, coupling,

seal, LO Console, Instruments, vibration/temp.

probes , if required as per PR/PS/Design code

Inspection And Test Plan

for

Centrifugal Pump

HPCL, Vishakhaptnam TOYO ENGINEERING INDIA LTD.

ISSUED : 10/10/2008 JOB NO. : 6261

DOC.NO. HGU PROJECT Page 1 of 3

21 Surface preparation & painting P A X

22 Final inspection of Complete Unit

a. Visual check for completeness & appearance P H

b. Dimensional check P H X

c. DFT check of final painting P H X

23 Review of final documents, minimum as marked in P H H** X

the column for RECORDS

24 Final stamping & issue of Inspection release H H X

certificate.

LEGEND 1) VENDOR, 2) TPAI THIRD PARTY INSPECTION AGENCY APPOINTED BY VENDOR ( LLOYDS, DNV & BVIS )

3) PMC - TOYO ENGINEERING INDIA LIMITED, 4) OWNER HPCL, VAISAKH 5) H HOLD (OFFER FOR WITNESS

& OBTAIN CLEARANCE), 6) W - WITNESS, 7) RN - RANDOM WITNESS, 8) A REVIEW & APPROVE,

9) R REVIEW ONLY, 10) P PERFORM, 11) X REQUIREMENT OF RECORD.

NOTE 1) THIS IS ONLY A INDICATIVE ITP AND VENDOR SHALL PREPARE A DETAILED ITP IN LINE WITH ABOVE AND

SPECIFIC TECHNICAL REQUIREMENTS OF APPLICABLE PR/PS/DESIGN CODE.

2) VENDOR SHALL ENSURE THAT ALL TEST AND MEASURING INSTRUMENTS ARE DULY CALIBRATED AND

CALIBRATION SHALL BE VALID AT THE TIME OF INSPECTION. CALIBRATION PROCEDURE & RECORDS SHALL BE

REVIEWED BY TPIA

3) SUB VENDOR FOR BOUGHT OUT ITEMS SHALL BE FROM PMC / OWNER APPROVED VENDOR LIST.

4) * INDICATES FOR CATEGORY A, B ONLY & ** FOR CATEGORY A ONLY

5) PMI TEST SHALL BE PERFOMED ON ALL AS/SS PRESSURE RETAINING PUMP COMPONETS, AUXILIARY PIPING,

API PLAN ETC. AT THE TIME OF PRESSURE TESTING. PMI TEST SHALL BE WITNESS BY TPIA

6) FOUNDATION TEMPLATE, GAGE PLATE FOR BASE RING & FOUNDATION BOLTS SHALL BE SUBJECT TO A FINAL

INSPECTION BY TPIA INCLUDING VISUAL, DIMENSIONAL CHECK AND REVIEW OF TEST CERTIFICATES.

7) PUMP DRIVERS SHALL BE INSPECTED AT MANUFACTURERS SHOP AS PER RELEVENT INSPECTION & TEST PLAN

8) NO SHIPMENT OF GOODS MAY BE EFFECTED UNLESS AN INSPECTION RELEASE CERTIFICATE HAS BEEN

SUBMITTED TO SELLER.

9) PERFORMANCE TEST FOR SPARE ROTOR TO BE DONE SEPARATELY

Vous aimerez peut-être aussi

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocument2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- Pump Centrifugal Pre Commissioning ITPDocument10 pagesPump Centrifugal Pre Commissioning ITPMohamad IbrahimPas encore d'évaluation

- DI Pipe Handling and Storage ProcedureDocument8 pagesDI Pipe Handling and Storage ProcedureFrancis DhanarajPas encore d'évaluation

- CR QapDocument2 pagesCR QapSimbu ArasanPas encore d'évaluation

- 6 MM TCDocument1 page6 MM TCpranesh kadamPas encore d'évaluation

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDocument3 pagesSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarPas encore d'évaluation

- Inspection and Test Plan For Silos and HoppersDocument15 pagesInspection and Test Plan For Silos and HoppersHOMAYOUN KHADIVIPas encore d'évaluation

- Screw Conveyors Pre Commissioning ITPDocument9 pagesScrew Conveyors Pre Commissioning ITPdidi sudiartoPas encore d'évaluation

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDocument14 pagesPPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqPas encore d'évaluation

- Method Statement For Pre-Fabrication and Erection of PipingDocument10 pagesMethod Statement For Pre-Fabrication and Erection of PipingMohamedPas encore d'évaluation

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaPas encore d'évaluation

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Expansion Joint Inspection and Test Plan Task Vendor TPI Inspection ClientDocument2 pagesExpansion Joint Inspection and Test Plan Task Vendor TPI Inspection ClientMussab Salih100% (1)

- 1 Gala Bronze Y-Strainer Fig 7654 SMDocument1 page1 Gala Bronze Y-Strainer Fig 7654 SMNon Etabas GadnatamPas encore d'évaluation

- Itp and Test Plan Rubber Fender Rev. 0Document5 pagesItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- Check List - Puff Test of FM 200 PipingDocument1 pageCheck List - Puff Test of FM 200 PipingAneesh ConstantinePas encore d'évaluation

- ITP - (Pressure Testing Piping) PDFDocument3 pagesITP - (Pressure Testing Piping) PDFSUNNY BOSS100% (1)

- A.9.02 - CPCL Itp For Utility Boiler PackageDocument3 pagesA.9.02 - CPCL Itp For Utility Boiler PackageGanesh EshwarPas encore d'évaluation

- Check List For DI Pipe InstallationDocument1 pageCheck List For DI Pipe InstallationSaifur Rahman0% (1)

- WWW .Abs Fir E.it: Vertical Foam Bladder TankDocument4 pagesWWW .Abs Fir E.it: Vertical Foam Bladder TankJorge InostrozaPas encore d'évaluation

- Testing and Commissioning of Water Supply Piping System Network PDFDocument4 pagesTesting and Commissioning of Water Supply Piping System Network PDFHumaid ShaikhPas encore d'évaluation

- (API 610-10th) Centrifugal Pump - SI UnitsDocument2 pages(API 610-10th) Centrifugal Pump - SI UnitsParaschiv AlexandruPas encore d'évaluation

- ITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFDocument3 pagesITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFGordon LongforganPas encore d'évaluation

- Inspection Release NoteDocument1 pageInspection Release NoteNur WijiantoPas encore d'évaluation

- Duct Works ChecklistDocument1 pageDuct Works Checklistmd azmathPas encore d'évaluation

- SOP-10 Pre Commissioning and Commissioning ActivitiesDocument14 pagesSOP-10 Pre Commissioning and Commissioning ActivitiesVineet AgrawalPas encore d'évaluation

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pages13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Commissioning Procedure Vagen Screw Conveyor With Check ListDocument3 pagesCommissioning Procedure Vagen Screw Conveyor With Check Listrahmankhan823100% (1)

- Inspection and Test Report For Concrete Work ITP: IKCP0-YYB-G-05-006Document1 pageInspection and Test Report For Concrete Work ITP: IKCP0-YYB-G-05-006Rangga GautamaPas encore d'évaluation

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198Pas encore d'évaluation

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 page4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- Tie in Procedure Rev. BDocument8 pagesTie in Procedure Rev. BgenjiPas encore d'évaluation

- Itp For Installation of Pressurization UnitDocument1 pageItp For Installation of Pressurization UnitvictorPas encore d'évaluation

- Hoist Monorail Pre Commissioning ITPDocument7 pagesHoist Monorail Pre Commissioning ITPmetroroadPas encore d'évaluation

- Compliance Sheet: SL No Specific Comments Reply Mechanical: AANDocument1 pageCompliance Sheet: SL No Specific Comments Reply Mechanical: AANJaren SobremisanaPas encore d'évaluation

- ACHE - Installation, Erection, Start Up & Commissioning Check ListDocument2 pagesACHE - Installation, Erection, Start Up & Commissioning Check Listrahim_335162856100% (1)

- Hydro Test FormatDocument2 pagesHydro Test FormatMuralitclPas encore d'évaluation

- Endorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPCDocument33 pagesEndorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPCEzhil Vendhan Palanisamy100% (1)

- Inspection & Test Plan (ITP) For Simple Package EquipmentDocument2 pagesInspection & Test Plan (ITP) For Simple Package Equipmentxajo50% (2)

- Conduit Installation GuideDocument10 pagesConduit Installation GuidelaxmandohanPas encore d'évaluation

- Blowers Fans Supply Verification ITPDocument7 pagesBlowers Fans Supply Verification ITPgauravamberkarPas encore d'évaluation

- Method & ITP Replacing Belt C4 With Hot SplicingDocument16 pagesMethod & ITP Replacing Belt C4 With Hot SplicingPed KapedPas encore d'évaluation

- MS For Tank Installation - R1Document6 pagesMS For Tank Installation - R1alvinchuan100% (1)

- Mixing Devices Mixers Agitators Etc Supply Verification ITPDocument8 pagesMixing Devices Mixers Agitators Etc Supply Verification ITPVarun Malhotra100% (1)

- A1.2.3 Method Statement 4a Redacted Version2Document98 pagesA1.2.3 Method Statement 4a Redacted Version2ChanelPas encore d'évaluation

- SOLENOID VALVE ASCO LowPower - Gseries - R8 PDFDocument14 pagesSOLENOID VALVE ASCO LowPower - Gseries - R8 PDFNUR AFIFAHPas encore d'évaluation

- FQP 16.11.18 Vol-I - BoilerDocument90 pagesFQP 16.11.18 Vol-I - Boilerashis chatterjeePas encore d'évaluation

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafPas encore d'évaluation

- Inspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistDocument2 pagesInspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistAdades Safede EfdPas encore d'évaluation

- Erection Tolerances S.No. Description ToleranceDocument2 pagesErection Tolerances S.No. Description ToleranceRajaram JayaramanPas encore d'évaluation

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasPas encore d'évaluation

- Lifting & Installation Pipes Plan - Romp 05Document6 pagesLifting & Installation Pipes Plan - Romp 05syed khaja misbhuddinPas encore d'évaluation

- KSB Etanorm LDocument40 pagesKSB Etanorm LhaseitoPas encore d'évaluation

- J08-Alarm Trip Set Point ListDocument2 pagesJ08-Alarm Trip Set Point ListSEPIRTUSPas encore d'évaluation

- CC ITP Sample PDFDocument4 pagesCC ITP Sample PDFMRezaPas encore d'évaluation

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Document2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Suraj ShettyPas encore d'évaluation

- Inspection and Test Plan Itp No.: Itp/Sta/007Document3 pagesInspection and Test Plan Itp No.: Itp/Sta/007sumit kumarPas encore d'évaluation

- Itp For ValvesDocument2 pagesItp For ValvesSuraj ShettyPas encore d'évaluation

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Document2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Suraj ShettyPas encore d'évaluation

- Annexure 4 - Indicative Inspection Test PlanDocument2 pagesAnnexure 4 - Indicative Inspection Test PlanClaudio PataniaPas encore d'évaluation

- Storage Tank Erection Procedure PDFDocument6 pagesStorage Tank Erection Procedure PDFEko Kurniawan89% (19)

- Volvo94 142kva enDocument2 pagesVolvo94 142kva enAdades Safede EfdPas encore d'évaluation

- Automatic Back-Flushing Filter Autofilt Rf10Document8 pagesAutomatic Back-Flushing Filter Autofilt Rf10Adades Safede EfdPas encore d'évaluation

- 521B1331 - APP Pumps - UK - 11.2016Document42 pages521B1331 - APP Pumps - UK - 11.2016Adades Safede EfdPas encore d'évaluation

- Automatic Back-Flushing Filter Autofilt Rf10Document8 pagesAutomatic Back-Flushing Filter Autofilt Rf10Adades Safede EfdPas encore d'évaluation

- QM-Tank Specifications (NMWD)Document43 pagesQM-Tank Specifications (NMWD)narutothunderjet216Pas encore d'évaluation

- Samples ITPDocument4 pagesSamples ITPHassan SajidPas encore d'évaluation

- ITP For Centrifugal Pump4Document1 pageITP For Centrifugal Pump4Adades Safede EfdPas encore d'évaluation

- Inspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistDocument2 pagesInspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistAdades Safede EfdPas encore d'évaluation

- Design and Construction ManualDocument17 pagesDesign and Construction ManualYaser A. Al-BustanjiPas encore d'évaluation

- BioContainer 18-200 m3 DailyDocument2 pagesBioContainer 18-200 m3 DailycurlyjockeyPas encore d'évaluation

- Sysvrf 252 Air Evo HP RDocument4 pagesSysvrf 252 Air Evo HP RAdades Safede EfdPas encore d'évaluation

- Samples ITPDocument4 pagesSamples ITPHassan SajidPas encore d'évaluation

- Inspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistDocument2 pagesInspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistAdades Safede EfdPas encore d'évaluation

- Marley Cooling TowerDocument16 pagesMarley Cooling TowerAdades Safede EfdPas encore d'évaluation

- BioContainer 18-200 m3 DailyDocument2 pagesBioContainer 18-200 m3 DailycurlyjockeyPas encore d'évaluation

- Containerized Water Treatment SystemsDocument2 pagesContainerized Water Treatment SystemsAdades Safede EfdPas encore d'évaluation

- Han S 2gbDocument32 pagesHan S 2gbAdades Safede EfdPas encore d'évaluation

- Modular Sample DrawingDocument1 pageModular Sample DrawingAdades Safede EfdPas encore d'évaluation

- Superloc Sample DrawingDocument1 pageSuperloc Sample DrawingAdades Safede EfdPas encore d'évaluation

- The Sileo Generation 8 2014Document32 pagesThe Sileo Generation 8 2014Adades Safede EfdPas encore d'évaluation

- Syscontrol Ahu 10hp SDocument12 pagesSyscontrol Ahu 10hp SAdades Safede EfdPas encore d'évaluation

- VH S 2gbDocument24 pagesVH S 2gbAdades Safede EfdPas encore d'évaluation

- Modular Sample Drawing PDFDocument1 pageModular Sample Drawing PDFAdades Safede EfdPas encore d'évaluation

- Sysvrf 500 Air Evo HP RDocument3 pagesSysvrf 500 Air Evo HP RAdades Safede EfdPas encore d'évaluation

- Technical Features - SYSVRF AIR EVO HP - 2016Document1 pageTechnical Features - SYSVRF AIR EVO HP - 2016Adades Safede EfdPas encore d'évaluation

- Sample QAP of Steel Bridge GirderDocument5 pagesSample QAP of Steel Bridge Girderuday64668Pas encore d'évaluation

- VAV DamperDocument7 pagesVAV DamperAdades Safede EfdPas encore d'évaluation

- VAV DamperDocument7 pagesVAV DamperAdades Safede EfdPas encore d'évaluation

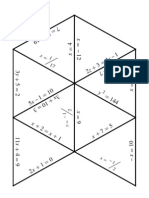

- Algebra1 Review PuzzleDocument3 pagesAlgebra1 Review PuzzleNicholas Yates100% (1)

- Ad 9915Document47 pagesAd 9915Jime nitaPas encore d'évaluation

- Digital Signal Processing Lab ManualDocument61 pagesDigital Signal Processing Lab ManualOmer Sheikh100% (6)

- AS400 RPG400 BasicsDocument148 pagesAS400 RPG400 Basicscharaviz84100% (1)

- The Aerodynamics of ParachutesDocument78 pagesThe Aerodynamics of Parachutesstevehuppert50% (2)

- Canadian-Solar Datasheet Inverter 3ph 75-100KDocument2 pagesCanadian-Solar Datasheet Inverter 3ph 75-100KItaloPas encore d'évaluation

- Viva 15jun2008Document347 pagesViva 15jun2008garth.whitakerPas encore d'évaluation

- Enterpreneurship Assignment 2Document8 pagesEnterpreneurship Assignment 2Khusbu JaiswalPas encore d'évaluation

- 1:100 Scale: SPACE-X "Crew Dragon 2" Demo Mission-1 CapsuleDocument9 pages1:100 Scale: SPACE-X "Crew Dragon 2" Demo Mission-1 CapsuleBearium YTPas encore d'évaluation

- NIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationDocument6 pagesNIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationKshitija100% (1)

- Python - Data EngineeringDocument34 pagesPython - Data EngineeringChetan PatilPas encore d'évaluation

- PienaDocument1 pagePienaMika Flores PedroPas encore d'évaluation

- Yanmar Graafmachines SV17 PDFDocument10 pagesYanmar Graafmachines SV17 PDFAleksandar PetkovicPas encore d'évaluation

- Formal Report Expt 5Document6 pagesFormal Report Expt 5AnonymouscatPas encore d'évaluation

- Full TextDocument167 pagesFull Textjon minanPas encore d'évaluation

- Evolution of Media INDUSTRIAL ERADocument16 pagesEvolution of Media INDUSTRIAL ERAAlec Ruht MasulaPas encore d'évaluation

- 3-Storeyed 31-3-2015-Schedule PDFDocument1 page3-Storeyed 31-3-2015-Schedule PDFSi Thu AungPas encore d'évaluation

- Relations Between Lean Management and Organizational StructuresDocument12 pagesRelations Between Lean Management and Organizational StructuresRENE JAVIER PACHECO SALASPas encore d'évaluation

- H&M Case Study AssignmentDocument7 pagesH&M Case Study AssignmentwqvyakPas encore d'évaluation

- Report Writing: IBS HyderabadDocument35 pagesReport Writing: IBS HyderabadHarita SudhirPas encore d'évaluation

- PreNav - Pitch - Customers Wind SiDocument20 pagesPreNav - Pitch - Customers Wind SiKaterinaLiPas encore d'évaluation

- Cocoon 8002 PDFDocument24 pagesCocoon 8002 PDFaxisPas encore d'évaluation

- Sect. 4 Tech Docum PC7 AutoLube - 1209 PDFDocument46 pagesSect. 4 Tech Docum PC7 AutoLube - 1209 PDFAlexis MikePas encore d'évaluation

- ZTE V4 RNC Commissioning and Integration TrainingDocument2 pagesZTE V4 RNC Commissioning and Integration TrainingBeena SinghPas encore d'évaluation

- Analisa AgriculturalDocument6 pagesAnalisa AgriculturalFEBRINA SARLINDA, STPas encore d'évaluation

- A Brief Tutorial On Studio MonitorsDocument18 pagesA Brief Tutorial On Studio MonitorsCurtis O'BrienPas encore d'évaluation

- Week 8: Spread-Spectrum Modulation - Direct Sequence Spread SpectrumDocument79 pagesWeek 8: Spread-Spectrum Modulation - Direct Sequence Spread SpectrumAmir MustakimPas encore d'évaluation

- Framework For A Digital Twin in Manufacturing Scope and RequirementsDocument3 pagesFramework For A Digital Twin in Manufacturing Scope and RequirementsJoão Vitor100% (1)

- 2021 3 AbstractsDocument168 pages2021 3 AbstractsLong An ĐỗPas encore d'évaluation

- Building SpecificationsDocument222 pagesBuilding SpecificationsdinaquaPas encore d'évaluation