Académique Documents

Professionnel Documents

Culture Documents

Alko Case Study - Haksoz

Transféré par

Deepesh MoolchandaniDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Alko Case Study - Haksoz

Transféré par

Deepesh MoolchandaniDroits d'auteur :

Formats disponibles

Case Study: ALKO

Inputs

Holding cost, H = $ 0.15 per unit and day

TL costs from plants to DCs = $ 0.09 per unit

LTL costs from DC to customers = $ 0.10 per unit

TL costs from plants to central whse. = $ 0.05 per unit

LTL cost from central whse. to cust. = $ 0.24 per unit

Reorder Interval, T = 6 days

Lead Time, L = 5 days

Target cycle service level, CSL = 0.95

Correlation Coefficient = 0

Demand data by part and region

# of part Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 Mean, R 10 35.48 22.61 17.66 11.81 3.36 90.92 daily demand 1892.1

Part 1 SD 6.98 6.48 5.26 3.48 4.49 NA annual demand 690617

Part 3 Mean 20 2.48 4.15 6.15 6.16 7.49 26.43

Part 3 SD 3.16 6.20 6.39 6.76 3.56 NA

Part 7 Mean 70 0.48 0.73 0.80 1.94 2.54 6.49

Part 7 SD 1.98 1.42 2.39 3.76 3.98 NA

Coefficient of variation by part and region

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 0.20 0.29 0.30 0.29 1.34 NA

Part 3 1.27 1.49 1.04 1.10 0.48 NA

Part 7 4.13 1.95 2.99 1.94 1.57 NA

Demand during reorder interval and replenishment lead time

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 Mean 390.28 248.71 194.26 129.91 36.96 1000.12

Part 1 SD 23.15 21.49 17.45 11.54 14.89 NA

Part 3 Mean 27.28 45.65 67.65 67.76 82.39 290.73

Part 3 SD 10.48 20.56 21.19 22.42 11.81 NA

Part 7 Mean 5.28 8.03 8.80 21.34 27.94 71.39

Part 7 SD 6.57 4.71 7.93 12.47 13.20 NA

Outputs

Cycle stock and required safety stock by part and region Cycle stock and required safety stock by part and region in days of demand

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1Cycle Inventory 106.44 67.83 52.98 35.43 10.08 272.76 Part 1Cycle Inventory 3.00 3.00 3.00 3.00 3.00 3.00

Part 1 SS 38.08 35.35 28.70 18.98 24.49 145.60 Part 1 SS 1.07 1.56 1.62 1.61 7.29 1.60

Part 3 Cycle Inventory 7.44 12.45 18.45 18.48 22.47 79.29 Part 3 Cycle Inventory 3.00 3.00 3.00 3.00 3.00 3.00

Part 3 SS 17.24 33.82 34.86 36.88 19.42 142.22 Part 3 SS 6.95 8.15 5.67 5.99 2.59 5.38

Part 7 Cycle Inventory 1.44 2.19 2.40 5.82 7.62 19.47 Part 7 Cycle Inventory 3.00 3.00 3.00 3.00 3.00 3.00

Part 7 SS 10.80 7.75 13.04 20.51 21.71 73.81 Part 7 SS 22.50 10.61 16.30 10.57 8.55 11.37

Costs per unit by region and part

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Inventory cost $ 0.61 $ 0.68 $ 0.69 $ 0.69 $ 1.54 $ 0.69

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19

Total cost part 1 $ 0.80 $ 0.87 $ 0.88 $ 0.88 $ 1.73 $ 0.88

Inventory cost $ 1.49 $ 1.67 $ 1.30 $ 1.35 $ 0.84 $ 1.26

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19

Total cost part 3 $ 1.68 $ 1.86 $ 1.49 $ 1.54 $ 1.03 $ 1.45

Inventory cost $ 3.83 $ 2.04 $ 2.89 $ 2.04 $ 1.73 $ 2.16

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19

Total cost part 7 $ 4.02 $ 2.23 $ 3.08 $ 2.23 $ 1.92 $ 2.35

Total Annual Inventory and Distribution Cost

# of part Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 10 $103,729 $72,171 $56,964 $37,982 $21,260 $292,107

Part 3 20 $30,463 $56,425 $66,904 $69,161 $56,259 $279,213

Part 7 70 $49,246 $41,626 $63,051 $110,336 $124,747 $389,005

All Parts $183,439 $170,223 $186,920 $217,479 $202,266 $960,326

CR - 09/18/2017 15:10:24 Page 1 366233187.xlsx - Demand & Costs

Case Study: ALKO

Inputs

Holding cost, H = $ 0.15 per unit and day

TL costs from plants to DCs = $ 0.09 per unit

LTL costs from DC to customers = $ 0.10 per unit

TL costs from plants to central whse. = $ 0.05 per unit

LTL cost from central whse. to cust. = $ 0.24 per unit

Reorder Interval, T = 6.00 days

Lead Time, L = 5.00 days

Target cycle service level, CSL = 0.95

Correlation Coefficient = -

Demand data by part and region

# of part Region 1 Region 2 Region 3 Region 4 Region 5 All Regions Central

Part 1 Mean 10 35.48 22.61 17.66 11.81 3.36 90.92 90.91

Part 1 SD 6.98 6.48 5.26 3.48 4.49 NA 12.27

Part 3 Mean 20 2.48 4.15 6.15 6.16 7.49 26.43 26.43

Part 3 SD 3.16 6.20 6.39 6.76 3.56 NA 12.15

Part 7 Mean 70 0.48 0.73 0.80 1.94 2.54 6.49 6.49

Part 7 SD 1.98 1.42 2.39 3.76 3.98 NA 6.45

Demand during reorder interval and replenishment lead time

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions Central

Part 1 Mean 390.28 248.71 194.26 129.91 36.96 1000.12 1000.01

Part 1 SD 23.15 21.49 17.45 11.54 14.89 NA 40.71

Part 3 Mean 27.28 45.65 67.65 67.76 82.39 290.73 290.73

Part 3 SD 10.48 20.56 21.19 22.42 11.81 NA 40.30

Part 7 Mean 5.28 8.03 8.80 21.34 27.94 71.39 71.39

Part 7 SD 6.57 4.71 7.93 12.47 13.20 NA 21.40

Outputs

Cycle stock and required safety stock by part and region

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions Central

Part 1Cycle Inventory 106.44 67.83 52.98 35.43 10.08 272.76 272.73

Part 1 SS 38.08 35.35 28.70 18.98 24.49 145.60 66.96

Part 3 Cycle Inventory 7.44 12.45 18.45 18.48 22.47 79.29 79.29

Part 3 SS 17.24 33.82 34.86 36.88 19.42 142.22 66.28

Part 7 Cycle Inventory 1.44 2.19 2.40 5.82 7.62 19.47 19.47

Part 7 SS 10.80 7.75 13.04 20.51 21.71 73.81 35.20

Costs per unit by region and part

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions Central

Inventory cost $ 0.61 $ 0.68 $ 0.69 $ 0.69 $ 1.54 $ 0.69 $ 0.56

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.29

Total cost part 1 $ 0.80 $ 0.87 $ 0.88 $ 0.88 $ 1.73 $ 0.88 $ 0.85

Inventory cost $ 1.49 $ 1.67 $ 1.30 $ 1.35 $ 0.84 $ 1.26 $ 0.83

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.29

Total cost part 3 $ 1.68 $ 1.86 $ 1.49 $ 1.54 $ 1.03 $ 1.45 $ 1.12

Inventory cost $ 3.83 $ 2.04 $ 2.89 $ 2.04 $ 1.73 $ 2.16 $ 1.26

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.29

Total cost part 7 $ 4.02 $ 2.23 $ 3.08 $ 2.23 $ 1.92 $ 2.35 $ 1.55

Total Annual Inventory and Distribution Cost

# of part Region 1 Region 2 Region 3 Region 4 Region 5 All Regions Central Savings

Part 1 10 $103,729 $72,171 $56,964 $37,982 $21,260 $292,107 $282,208 $9,899

Part 3 20 $30,463 $56,425 $66,904 $69,161 $56,259 $279,213 $215,356 $63,857

Part 7 70 $49,246 $41,626 $63,051 $110,336 $124,747 $389,005 $257,600 $131,405

All Parts $183,439 $170,223 $186,920 $217,479 $202,266 $960,326 $755,164

Savings: $205,162

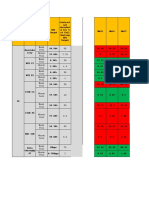

Cost Savings from Centralization as a function of the correlation coefficient and target cycle service level

All parts Correlation Cofficiant

$205,162 0.00 0.25 0.50 0.75 1.00

0.9

0.91

Target Cycle Service Level

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

Type 1 only Correlation Cofficient

$9,899 0.00 0.25 0.50 0.75 1.00

0.9

Target Cycle Service Level

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

Type 3 only Correlation Cofficient

$63,857 0.00 0.25 0.50 0.75 1.00

0.9

Target Cycle Service Level

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

Type 7 only Correlation Cofficient

$131,405 0.00 0.25 0.50 0.75 1.00

0.9

Target Cycle Service Level

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

CR - 09/18/2017 15:10:24 Page 2 366233187.xlsx - Central vs. Local

Case Study: ALKO (Part 1 is decentralized with all others centralized)

Inputs

Holding cost = $ 0.15 per unit and day daily demand at NDC 982.9

TL costs from plants to DCs = $ 0.09 per unit annual demand at NDC 358758.5

LTL costs from DC to customers = $ 0.10 per unit

TL costs from plants to central whse. = $ 0.05 per unit

LTL cost from central whse. to cust. = $ 0.24 per unit

Reorder Interval = 6 days

Lead Time = 5 days

Target cycle service level = 0.95

Correlation Coefficient = 0

Demand data by part and region

# of part Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 Mean 10 35.48 22.61 17.66 11.81 3.36 90.92

Part 1 SD 6.98 6.48 5.26 3.48 4.49 NA

Part 3 Mean 20 2.48 4.15 6.15 6.16 7.49 26.43

Part 3 SD 3.16 6.20 6.39 6.76 3.56 NA

Part 7 Mean 70 0.48 0.73 0.80 1.94 2.54 6.49

Part 7 SD 1.98 1.42 2.39 3.76 3.98 NA

Coefficient of variation by part and region

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 0.20 0.29 0.30 0.29 1.34 NA

Part 3 1.27 1.49 1.04 1.10 0.48 NA

Part 7 4.13 1.95 2.99 1.94 1.57 NA

Demand during reorder interval and replenishment lead time

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1 Mean 390.28 248.71 194.26 129.91 36.96

Part 1 SD 23.15 21.49 17.45 11.54 14.89

Part 3 Mean 290.73

Part 3 SD 40.30

Part 7 Mean 71.39

Part 7 SD 21.40

Outputs

Cycle stock and required safety stock by part and region

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1Cycle Stock 106.44 67.83 52.98 35.43 10.08

Part 1 SS 38.08 35.35 28.70 18.98 24.49

Part 3 Cycle Stock 79.29

Part 3 SS 66.28

Part 7 Cycle Stock 19.47

Part 7 SS 35.20

Costs per unit by region and part

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Inventory cost $ 0.61 $ 0.68 $ 0.69 $ 0.69 $ 1.54

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19

Total cost part 1 $ 0.80 $ 0.87 $ 0.88 $ 0.88 $ 1.73

Inventory cost $ 0.83

Transportation cost $ 0.29

Total cost part 3 $ 1.12

Inventory cost $ 1.26

Transportation cost $ 0.29

Total cost part 7 $ 1.55

Total Annual Inventory and Distribution Cost

# of part Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1 10 $103,729 $72,171 $56,964 $37,982 $21,260 $0 $292,107

Part 3 20 $215,356

Part 7 70 $257,600

All Parts $103,729 $72,171 $56,964 $37,982 $21,260 $472,956

Total logistic system: $765,064

Costs Savings

Benchmark: All parts in the field: $960,326 $195,262

All parts centralized: $755,164 -$9,899

Correlation Cofficient

$765,064 0.00 0.25 0.50 0.75 1.00

0.9

Target Cycle Service Level

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

CR - 09/18/2017 15:10:24 Page 3 366233187.xlsx - option1.0

Case Study: ALKO (Part 1,3 is decentralized with part 7 centralized)

Inputs

Holding cost, H = $ 0.15 per unit and day

TL costs from plants to DCs = $ 0.09 per unit daily demand at NDC 454.3

LTL costs from DC to customers = $ 0.10 per unit annual demand at NDC 165819.5

TL costs from plants to central whse. = $ 0.05 per unit

LTL cost from central whse. to cust. = $ 0.24 per unit

Reorder Interval, T = 6 days

Lead Time, L = 5 days

Target cycle service level, CSL = 0.95

Correlation Coefficient = 0

Demand data by part and region

# of part Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 Mean 10 35.48 22.61 17.66 11.81 3.36 90.92

Part 1 SD 6.98 6.48 5.26 3.48 4.49 NA

Part 3 Mean 20 2.48 4.15 6.15 6.16 7.49 26.43

Part 3 SD 3.16 6.20 6.39 6.76 3.56 NA

Part 7 Mean 70 0.48 0.73 0.80 1.94 2.54 6.49

Part 7 SD 1.98 1.42 2.39 3.76 3.98 NA

Coefficient of variation by part and region

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 0.20 0.29 0.30 0.29 1.34 NA

Part 3 1.27 1.49 1.04 1.10 0.48 NA

Part 7 4.13 1.95 2.99 1.94 1.57 NA

Demand during reorder interval and replenishment lead time

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1 Mean 390.28 248.71 194.26 129.91 36.96

Part 1 SD 23.15 21.49 17.45 11.54 14.89

Part 3 Mean 27.28 45.65 67.65 67.76 82.39

Part 3 SD 10.48 20.56 21.19 22.42 11.81

Part 7 Mean 71.39

Part 7 SD 21.40

Outputs

Cycle stock and required safety stock by part and region

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1Batch Stock 106.44 67.83 52.98 35.43 10.08

Part 1 SS 38.08 35.35 28.70 18.98 24.49

Part 3 Batch Stock 7.44 12.45 18.45 18.48 22.47

Part 3 SS 17.24 33.82 34.86 36.88 19.42

Part 7 Batch Stock 19.47

Part 7 SS 35.20

Costs per unit by region and part

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Inventory cost $ 0.61 $ 0.68 $ 0.69 $ 0.69 $ 1.54

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19

Total cost part 1 $ 0.80 $ 0.87 $ 0.88 $ 0.88 $ 1.73

Inventory cost $ 1.49 $ 1.67 $ 1.30 $ 1.35 $ 0.84

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.19 $ 0.19

Total cost part 3 $ 1.68 $ 1.86 $ 1.49 $ 1.54 $ 1.03

Inventory cost $ 1.26

Transportation cost $ 0.29

Total cost part 7 $ 1.55

Total Annual Inventory and Distribution Cost

# of part Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1 10 $103,729 $72,171 $56,964 $37,982 $21,260 $0

Part 3 20 $30,463 $56,425 $66,904 $69,161 $56,259 $0 $279,213

Part 7 70 $257,600

All Parts $134,192 $128,597 $123,869 $107,143 $77,519 $257,600

Total logistic system: $828,921

Costs Savings

Benchmark: All parts in the field: $960,326 $131,405

All parts centralized: $755,164 -$73,757

Correlation Cofficient

$828,921 0.00 0.25 0.50 0.75 1.00

0.9

Target Cycle Service Level

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

CR - 09/18/2017 15:10:24 Page 4 366233187.xlsx - option1.0a

Case Study: ALKO (region 5 served from region 4)

Inputs

Holding cost, H = $ 0.15 per unit and day

TL costs from plants to DCs = $ 0.09 per unit

LTL costs from DC to customers = $ 0.10 per unit

TL costs from plants to central whse. = $ 0.05 per unit

LTL cost from central whse. to cust. = $ 0.24 per unit

Reorder Interval, T = 6 days

Lead Time, L = 5 days

Target cycle service level, CSL = 0.95

Correlation Coefficient = 0

Demand data by part and region

# of partsRegion 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 Mean 10 35.48 22.61 17.66 11.81 3.36 90.92

Part 1 SD 6.98 6.48 5.26 3.48 4.49 NA

Part 3 Mean 20 2.48 4.15 6.15 6.16 7.49 26.43

Part 3 SD 3.16 6.20 6.39 6.76 3.56 NA

Part 7 Mean 70 0.48 0.73 0.80 1.94 2.54 6.49

Part 7 SD 1.98 1.42 2.39 3.76 3.98 NA

Coefficient of variation by part and region

Region 1 Region 2 Region 3 Region 4 Region 5 All Regions

Part 1 0.20 0.29 0.30 0.29 1.34 NA

Part 3 1.27 1.49 1.04 1.10 0.48 NA

Part 7 4.13 1.95 2.99 1.94 1.57 NA

Demand during reorder interval and replenishment lead time

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1 Mean 390.28 248.71 194.26 166.87 50

Part 1 SD 23.15 21.49 17.45 18.84

Part 3 Mean 290.73

Part 3 SD 40.30

Part 7 Mean 71.39

Part 7 SD 21.40

Outputs

Cycle stock and required safety stock by part and region

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1Batch Stock 106.44 67.83 52.98 35.43

Part 1 SS 38.08 35.35 28.70 30.99

Part 3 Batch Stock 79.29

Part 3 SS 66.28

Part 7 Batch Stock 19.47

Part 7 SS 35.20

Costs per unit by region and part

Region 1 Region 2 Region 3 Region 4 Region 5 Central

Inventory cost $ 0.61 $ 0.68 $ 0.69 $ 0.84

Transportation cost $ 0.19 $ 0.19 $ 0.19 $ 0.22

Total cost part 1 $ 0.80 $ 0.87 $ 0.88 $ 1.06

Inventory cost $ 0.83

Transportation cost $ 0.29

Total cost part 3 $ 1.12

Inventory cost $ 1.26

Transportation cost $ 0.29

Total cost part 7 $ 1.55

Total Annual Inventory and Distribution Cost

# of parts Region 1 Region 2 Region 3 Region 4 Region 5 Central

Part 1 10 $103,729 $72,171 $56,964 $45,892 $0

Part 3 20 $215,356

Part 7 70 $257,600

All Parts $103,729 $72,171 $56,964 $45,892 $0 $472,956

Total logistic system: $751,714

Costs Savings

Benchmark: All parts in the field: $960,326 $208,612

All parts centralized: $755,164 $3,451

CR - 09/18/2017 15:10:25 Page 5 366233187.xlsx - Option 2

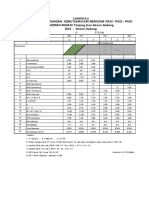

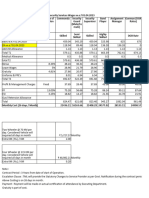

Summary of investment and annual cost for various options

Option Investment Annual Cost

Decentralize all parts in five warehouses Base Case $ 960,326

Centralize all parts at NDC $ 850,000 $ 755,164

Centralize parts 3, 7, decentralize part 1 $ 650,000 $ 765,064

Centralize part 7, decentralize parts 1, 3 $ 300,000 $ 828,921

Centralize parts 3, 7, decentralize part 1

serve region 5 part 1 from region 4 $ 600,000 $ 751,714

Savings from Base Case Rate of return

$ 205,162 24.1%

$ 195,262 30.0%

$ 131,405 43.8%

$ 208,612 34.8%

Vous aimerez peut-être aussi

- Radar Systems, Peak Detection and TrackingD'EverandRadar Systems, Peak Detection and TrackingÉvaluation : 5 sur 5 étoiles5/5 (1)

- ProjectDocument26 pagesProjectAman GuptaPas encore d'évaluation

- Managing Inventory at Alko HandoutDocument7 pagesManaging Inventory at Alko Handoutsuhani varshneyPas encore d'évaluation

- ALKO Case Final ReportDocument7 pagesALKO Case Final ReportSamarth Jain100% (1)

- Part Inspection Report: 458519100 Cover Plate 4/12/2021 NILDocument3 pagesPart Inspection Report: 458519100 Cover Plate 4/12/2021 NILRohit QualityPas encore d'évaluation

- 5 3 6-BioequivalenceDocument2 pages5 3 6-BioequivalenceHafsa AnwarePas encore d'évaluation

- Manzana InsuranceDocument5 pagesManzana InsuranceDipti BhartiPas encore d'évaluation

- Nbg-Wkmis-Aug 21Document110 pagesNbg-Wkmis-Aug 21Niraamaya RetreatsPas encore d'évaluation

- Data Produksi: PLTU IPP Lombok Timur (LED Unit 1 Dan Unit 2)Document4 pagesData Produksi: PLTU IPP Lombok Timur (LED Unit 1 Dan Unit 2)Andhy AlfharoPas encore d'évaluation

- List of Plant & Machinery: Name of The Item Qty Unit Rate Basic Price Plant & Machinery: Oil Ghani and Related PartsDocument11 pagesList of Plant & Machinery: Name of The Item Qty Unit Rate Basic Price Plant & Machinery: Oil Ghani and Related PartsAbhishek Kumar RaiPas encore d'évaluation

- ANSWER S ACME CaseDocument2 pagesANSWER S ACME CaseJiancia WangPas encore d'évaluation

- Business Research Methods AssignmentDocument8 pagesBusiness Research Methods AssignmentAnna DscribdPas encore d'évaluation

- Exercise 4: XRF Data Analysis (25 Points)Document3 pagesExercise 4: XRF Data Analysis (25 Points)Sakura ShirayukiPas encore d'évaluation

- Weekly Market RecapDocument2 pagesWeekly Market RecapmarianovePas encore d'évaluation

- To Be Processed Includes Requests-in-Process at This Step and at Upstream StepsDocument14 pagesTo Be Processed Includes Requests-in-Process at This Step and at Upstream StepsAnirudha PuranikPas encore d'évaluation

- BATERIA KY357 Batteries KEY Asia 0.10 0.016Document16 pagesBATERIA KY357 Batteries KEY Asia 0.10 0.016PushpakKumbharePas encore d'évaluation

- JPM Investment OutlookDocument2 pagesJPM Investment OutlookAcePas encore d'évaluation

- Nevi Palinsa 2020211034Document12 pagesNevi Palinsa 2020211034Ari ArdiansyahPas encore d'évaluation

- GRR MSA-4 Anova MethodDocument6 pagesGRR MSA-4 Anova MethodSead ZejnilovicPas encore d'évaluation

- 0.134 0.1082 Step 1 Cash Flow PV Factor: Problem 21-2Document5 pages0.134 0.1082 Step 1 Cash Flow PV Factor: Problem 21-2alvinPas encore d'évaluation

- Analisis Biofilm GelDocument7 pagesAnalisis Biofilm Gelinvestigacion.barrerachavezidPas encore d'évaluation

- Opreration Cycle Time (Normal Time) Sum Avg Rating B.T SAM Capacity Rate Earning 1 2 3 4 5 PC/Mint ValueDocument4 pagesOpreration Cycle Time (Normal Time) Sum Avg Rating B.T SAM Capacity Rate Earning 1 2 3 4 5 PC/Mint ValueUmairIsmailPas encore d'évaluation

- Definitions: Lab 7 Repeatability and ReproducibilityDocument9 pagesDefinitions: Lab 7 Repeatability and ReproducibilityStep ZepedaPas encore d'évaluation

- Manzana IntroDocument5 pagesManzana IntroSnehil RajPas encore d'évaluation

- Appendix: Further Discussion of The Weather Data and ResultsDocument4 pagesAppendix: Further Discussion of The Weather Data and ResultsAmin AzadPas encore d'évaluation

- REPETIBILIDAD Y REPRODUCIBILIDAD Parte 2Document6 pagesREPETIBILIDAD Y REPRODUCIBILIDAD Parte 2Juan Manuel De La CruzPas encore d'évaluation

- Project Job Number EngineerDocument1 pageProject Job Number EngineerMiriam Cristina HurtadoPas encore d'évaluation

- AREA MERIT LIST OF S.O.s / M.R.s (April 2010-Sept 2010)Document46 pagesAREA MERIT LIST OF S.O.s / M.R.s (April 2010-Sept 2010)neevneev420Pas encore d'évaluation

- Solar PlanDocument4 pagesSolar PlanAnonymous 0qBZ2tGyPas encore d'évaluation

- Power Quality DRAFT Test ReportDocument13 pagesPower Quality DRAFT Test ReportDeepak GehlotPas encore d'évaluation

- 3G FeedbackDocument3 pages3G FeedbackMark EmakhuPas encore d'évaluation

- Equity ValuationDocument26 pagesEquity ValuationAashish mishraPas encore d'évaluation

- K-2801B November 08 2023Document11 pagesK-2801B November 08 2023rizfian1927Pas encore d'évaluation

- Costing Sheet For Fabrication & Paint Calculator: Grand TotalDocument1 pageCosting Sheet For Fabrication & Paint Calculator: Grand Totalranvijaysingh2002Pas encore d'évaluation

- Mbr1060Ctl Schottky Rectifier: Sangdest Microelectronics Green ProductsDocument6 pagesMbr1060Ctl Schottky Rectifier: Sangdest Microelectronics Green ProductsManos MagicasPas encore d'évaluation

- New Flexible Design PDFDocument2 pagesNew Flexible Design PDFDe Silva Manimeldura ChandrasiriPas encore d'évaluation

- Rainfall ProjectDocument14 pagesRainfall ProjectNoor Muhamad AzimPas encore d'évaluation

- Steel Design (Track 2) Beam 9957 Check 1: Job No Sheet No RevDocument2 pagesSteel Design (Track 2) Beam 9957 Check 1: Job No Sheet No RevwaquarstrPas encore d'évaluation

- THI - BAI TAP MẪU - 2.1GRR - Xbar-R - METHOD - MSA - MANUADocument11 pagesTHI - BAI TAP MẪU - 2.1GRR - Xbar-R - METHOD - MSA - MANUAHung PhamPas encore d'évaluation

- AC Fans Static Calculation Final-1Document20 pagesAC Fans Static Calculation Final-1Hendrias A.SPas encore d'évaluation

- Business Statistics Sem 4Document9 pagesBusiness Statistics Sem 4Anna DscribdPas encore d'évaluation

- Monmouth Inc Solution 5 PDF FreeDocument12 pagesMonmouth Inc Solution 5 PDF FreePedro José ZapataPas encore d'évaluation

- Monmouth Inc Solution 5 PDF FreeDocument12 pagesMonmouth Inc Solution 5 PDF FreePedro José ZapataPas encore d'évaluation

- XLS289 XLS EngDocument8 pagesXLS289 XLS EngAnirudha PuranikPas encore d'évaluation

- GF 2Document2 pagesGF 2peuangulaPas encore d'évaluation

- HP Deskjet Printer Supply Chain: Operations ManagementDocument7 pagesHP Deskjet Printer Supply Chain: Operations ManagementTun Thu LinPas encore d'évaluation

- G+4 Labour Camp, Jabal Al Ajmi: Earth Works L B D Nos QtyDocument62 pagesG+4 Labour Camp, Jabal Al Ajmi: Earth Works L B D Nos QtykabeerPas encore d'évaluation

- Analisis 16 S BiofilmDocument5 pagesAnalisis 16 S Biofilminvestigacion.barrerachavezidPas encore d'évaluation

- Contoh Debit Kebutuhan Selama Se TahunDocument3 pagesContoh Debit Kebutuhan Selama Se TahunDafit HidayatPas encore d'évaluation

- WEN025664AWPP3D00000Document31 pagesWEN025664AWPP3D00000ballangerPas encore d'évaluation

- 3.01. Particulars Year of Operation 1 2 3 4 5: The IRR For The Project Is 27.4%, Average ROI Is 86% and Average DSCR IsDocument1 page3.01. Particulars Year of Operation 1 2 3 4 5: The IRR For The Project Is 27.4%, Average ROI Is 86% and Average DSCR Isk.g.thri moorthyPas encore d'évaluation

- ANOVADocument3 pagesANOVAChristian M. MortelPas encore d'évaluation

- Analisis 16 S Suspensión GelDocument5 pagesAnalisis 16 S Suspensión Gelinvestigacion.barrerachavezidPas encore d'évaluation

- 2019 Autumn Classic International: Ladies Short Program Judges Details Per SkaterDocument8 pages2019 Autumn Classic International: Ladies Short Program Judges Details Per SkaterAdinaPas encore d'évaluation

- SBI Press Release - SBI Q4 FY22 & Annual ResultsDocument2 pagesSBI Press Release - SBI Q4 FY22 & Annual ResultsSudarshan VaradhanPas encore d'évaluation

- Cost Sheet - Security Services - Wef 01st Apr 2023Document3 pagesCost Sheet - Security Services - Wef 01st Apr 2023abhishek kumarPas encore d'évaluation

- Processing Report Novikucakucica Merged ChunkDocument6 pagesProcessing Report Novikucakucica Merged ChunkJosip KovilićPas encore d'évaluation

- Mega Ohm Box 2022Document1 pageMega Ohm Box 2022SOURABH JAINPas encore d'évaluation

- Problem Statement: The Need of Effective Marketing For Evolving ConsumerDocument3 pagesProblem Statement: The Need of Effective Marketing For Evolving ConsumerDeepesh MoolchandaniPas encore d'évaluation

- Levine Et Al. - 2005 - Identity and Emergency Intervention How Social Group Membership and Inclusiveness of Group Boundaries Shape HelpiDocument11 pagesLevine Et Al. - 2005 - Identity and Emergency Intervention How Social Group Membership and Inclusiveness of Group Boundaries Shape HelpiDeepesh MoolchandaniPas encore d'évaluation

- Midland Energy Group A5Document3 pagesMidland Energy Group A5Deepesh Moolchandani0% (1)

- Curled Metal IncDocument1 pageCurled Metal IncDeepesh MoolchandaniPas encore d'évaluation

- The Science of Self RealizationDocument233 pagesThe Science of Self RealizationLakshmi811Pas encore d'évaluation

- Series 90 100cc Pump Parts ManualDocument152 pagesSeries 90 100cc Pump Parts ManualHernan Garcia67% (3)

- White and Yellow Reflective Thermoplastic Striping Material (Solid Form)Document2 pagesWhite and Yellow Reflective Thermoplastic Striping Material (Solid Form)FRANZ RICHARD SARDINAS MALLCOPas encore d'évaluation

- Social Media Engagement and Feedback CycleDocument10 pagesSocial Media Engagement and Feedback Cyclerichard martinPas encore d'évaluation

- Level of Life Skills Dev 5Document59 pagesLevel of Life Skills Dev 5MJ BotorPas encore d'évaluation

- Bill FormatDocument7 pagesBill FormatJay Rupchandani100% (1)

- Bill (Law) : Jump To Navigation Jump To SearchDocument9 pagesBill (Law) : Jump To Navigation Jump To SearchPunitPas encore d'évaluation

- MSA & Destructive TestDocument4 pagesMSA & Destructive Testanon_902607157100% (1)

- Parts Price ListDocument5 325 pagesParts Price ListAlva100% (1)

- Id or Class Are SimplyDocument5 pagesId or Class Are SimplyK CorPas encore d'évaluation

- FIP & CouponsDocument5 pagesFIP & CouponsKosme DamianPas encore d'évaluation

- Toyota Auris Corolla 2007 2013 Electrical Wiring DiagramDocument22 pagesToyota Auris Corolla 2007 2013 Electrical Wiring Diagrampriscillasalas040195ori100% (125)

- PDS Air CompressorDocument1 pagePDS Air Compressordhavalesh1Pas encore d'évaluation

- Ex-Capt. Harish Uppal Vs Union of India & Anr On 17 December, 2002Document20 pagesEx-Capt. Harish Uppal Vs Union of India & Anr On 17 December, 2002vivek6593Pas encore d'évaluation

- 1849 1862 Statutes at Large 601-779Document200 pages1849 1862 Statutes at Large 601-779ncwazzyPas encore d'évaluation

- Complete Governmental Structure of PakistanDocument6 pagesComplete Governmental Structure of PakistanYa seen khan0% (1)

- Cassava Starch Granule Structure-Function Properties - Influence of Time and Conditions at Harvest On Four Cultivars of Cassava StarchDocument10 pagesCassava Starch Granule Structure-Function Properties - Influence of Time and Conditions at Harvest On Four Cultivars of Cassava Starchwahyuthp43Pas encore d'évaluation

- Sworn Statement of Assets, Liabilities and Net WorthDocument2 pagesSworn Statement of Assets, Liabilities and Net WorthFaidah Palawan AlawiPas encore d'évaluation

- Marc-André Ter Stegen PES 2021 StatsDocument1 pageMarc-André Ter Stegen PES 2021 StatsSom VasnaPas encore d'évaluation

- The Application of 1,2,3-PropanetriolDocument2 pagesThe Application of 1,2,3-PropanetriolAlisameimeiPas encore d'évaluation

- Irazu EULA AgreementDocument7 pagesIrazu EULA AgreementLiqiang HePas encore d'évaluation

- Why Is Inventory Turnover Important?: ... It Measures How Hard Your Inventory Investment Is WorkingDocument6 pagesWhy Is Inventory Turnover Important?: ... It Measures How Hard Your Inventory Investment Is WorkingabhiPas encore d'évaluation

- DS TEGO Polish Additiv WE 50 e 1112Document3 pagesDS TEGO Polish Additiv WE 50 e 1112Noelia Gutiérrez CastroPas encore d'évaluation

- VMC Ballscrew 32mm Horizontal Plane ReplacementDocument11 pagesVMC Ballscrew 32mm Horizontal Plane ReplacementMarlon GeronimoPas encore d'évaluation

- BSBMGT516 Facilitate Continuous Improvement: Summative Assessment 1Document4 pagesBSBMGT516 Facilitate Continuous Improvement: Summative Assessment 1Mmc MixPas encore d'évaluation

- Fund For Local Cooperation (FLC) : Application FormDocument9 pagesFund For Local Cooperation (FLC) : Application FormsimbiroPas encore d'évaluation

- Gorlov Wind TurbineDocument3 pagesGorlov Wind TurbineDwaynePas encore d'évaluation

- Webdynpro ResumeDocument4 pagesWebdynpro ResumeAmarnath ReddyPas encore d'évaluation

- Salary Data 18092018Document5 124 pagesSalary Data 18092018pjrkrishna100% (1)

- Bit2203 Advanced Object-Oriented Programming Lectures Sep 2021Document250 pagesBit2203 Advanced Object-Oriented Programming Lectures Sep 2021Agnes MathekaPas encore d'évaluation

- Caso 1 - Tunel Sismico BoluDocument4 pagesCaso 1 - Tunel Sismico BoluCarlos Catalán CórdovaPas encore d'évaluation