Académique Documents

Professionnel Documents

Culture Documents

CONECTIVIDAD

Transféré par

EdwinRamirezDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CONECTIVIDAD

Transféré par

EdwinRamirezDroits d'auteur :

Formats disponibles

TUBRICA

ENGINEERING UNIT HMI

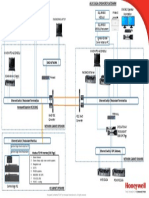

PROPOSAL - MONITORING OF THE EXTRUSION PROCESS SCADA

INTERNET

HOW IT WORKS?

We collect data from each extruder line*, using an ethernet cable, by an Industrial Network Switch.

The Network Switch is connected to a PC with OPC Server.

The OPC Server handles the communication with field devices like PLCs inside the extruders cabinet. WEB SERVER

The OPC fetch or send data to each PLC, which it then transfers to the OPC client (which is in the same PC).

The HMI SCADA fetch data from the OPC Client and shows it, via a graphical user interface, allowing

the monitoring and analyzing of the extrusion process in real-time. That information can also being OPC

SERVER/CLIENT

displayed on any computer or device with internet access by a web server.

*: Each extruder should be able to share data of the operating conditions to an OPC Server. The table of variables

required are listed below

INDUSTRIAL ETHERNET SWITCH

TCP/IP PROTOCOL

TCP/IP PROTOCOL TCP/IP PROTOCOL

TCP/IP PROTOCOL TCP/IP PROTOCOL

TCP/IP PROTOCOL TCP/IP PROTOCOL

TCP/IP PROTOCOL TCP/IP

PROTOCOLO

PLC PLC PLC PLC PLC

S7 1200 SIEMENS PLC PLC

X20 B&R AUTOMATION CONTROL C6 GEFRAN GEFRAN PLC GEFRAN

X20 B&R AUTOMATION GEFRAN

CONTROL C5 X20 B&R AUTOMATION CONTROL C5

EXTRUSION LINE 1 EXTRUSION LINE 2 EXTRUSION LINE 3 EXTRUSION LINE 4 EXTRUSION LINE 6 EXTRUSION LINE 7 EXTRUSION LINE 8

EXTRUSION LINE 5

KRAUSS MAFFEI BAUSANO CMT92 BAUSANO KRAUSS MAFFEI BAUSANO BAUSANO

KRAUSS MAFFEI

KMD 108-36 (Double) MT 4523 MT 2688AEQ KMD 75-36 MT 2704AEQ MT 2696AEQ

KMD 75-36

YEAR: 2016 YEAR: 2016 YEAR: 2012 YEAR: 2011 YEAR: 2012 YEAR: 2012

YEAR: 2011

Vous aimerez peut-être aussi

- 7 PLC PDFDocument112 pages7 PLC PDFBayu RafliPas encore d'évaluation

- Ddeserver E1Document2 pagesDdeserver E1FiveStarPas encore d'évaluation

- ONGC Enterprise Wide Scada Success Story 31 Mar 06Document21 pagesONGC Enterprise Wide Scada Success Story 31 Mar 06Dilip SagarPas encore d'évaluation

- PLCNEW (Compatibility Mode)Document56 pagesPLCNEW (Compatibility Mode)shubhamp746Pas encore d'évaluation

- Elite 500: High-Precision, Multiple Communication, TFT DisplayDocument4 pagesElite 500: High-Precision, Multiple Communication, TFT DisplayTeguh WaluyoPas encore d'évaluation

- UOGx ECEg4233 Chapter2xDocument141 pagesUOGx ECEg4233 Chapter2xYayachew MandefroPas encore d'évaluation

- Briefing Ucc4 To Uc32Document3 pagesBriefing Ucc4 To Uc32张小Pas encore d'évaluation

- Gearless Mill Drive - Operation and Maintenance: 800xa Control SystemDocument15 pagesGearless Mill Drive - Operation and Maintenance: 800xa Control SystemIrving Dirzo CarrilloPas encore d'évaluation

- Delta DVP Series CatalogDocument52 pagesDelta DVP Series CatalogAlfonso Lopez toroPas encore d'évaluation

- Ethernet To MPI DP PPI Converter For SIMATIC S7®Document2 pagesEthernet To MPI DP PPI Converter For SIMATIC S7®SyariefPas encore d'évaluation

- Unit 3 PLC (Programmable Logic Controller)Document66 pagesUnit 3 PLC (Programmable Logic Controller)hicinobPas encore d'évaluation

- Delta Programmable Logic Controller DVP Series: Automation For A Changing WorldDocument52 pagesDelta Programmable Logic Controller DVP Series: Automation For A Changing Worlddetroja tusharPas encore d'évaluation

- BR RTU en PDFDocument16 pagesBR RTU en PDF1meander23Pas encore d'évaluation

- Zenon OPC Driver ListDocument7 pagesZenon OPC Driver ListTrần Minh HùngPas encore d'évaluation

- Elite 500Document4 pagesElite 500Hari HaranPas encore d'évaluation

- AC2000 Morpho BioBridge InterfaceDocument3 pagesAC2000 Morpho BioBridge InterfaceMoises ConcepcionPas encore d'évaluation

- Cisco Profinet-White-PaperDocument6 pagesCisco Profinet-White-Paperpatel_rajendraPas encore d'évaluation

- Tutorial PLCDocument13 pagesTutorial PLCvio furqonPas encore d'évaluation

- EdgeLink Driver List 2Document11 pagesEdgeLink Driver List 2danaherzxPas encore d'évaluation

- Siemens PLCDocument14 pagesSiemens PLCAdetunji TaiwoPas encore d'évaluation

- Motor Speed Control Using VFD and PLC Programming - Ladder LogicDocument13 pagesMotor Speed Control Using VFD and PLC Programming - Ladder LogicJemerald MagtanongPas encore d'évaluation

- Bro ibaPDA-PLC-Xplorer enDocument4 pagesBro ibaPDA-PLC-Xplorer enSergioPas encore d'évaluation

- Visio-OCC For Solar Power Rev2Document1 pageVisio-OCC For Solar Power Rev2Phạm Văn HânPas encore d'évaluation

- Delta Ia-Plc DVP TP C en 20210916Document52 pagesDelta Ia-Plc DVP TP C en 20210916jesus vicuñaPas encore d'évaluation

- Twincat eDocument26 pagesTwincat ecristiPas encore d'évaluation

- Flyer Software MotoLogix E 02.2019Document4 pagesFlyer Software MotoLogix E 02.2019ALSAMAD V MPas encore d'évaluation

- Delta Ia-Plc DVP TP C en 20190517 WebDocument52 pagesDelta Ia-Plc DVP TP C en 20190517 WebKashif ZakaPas encore d'évaluation

- PosterDocument1 pagePosterMichelle VilemaPas encore d'évaluation

- RC Datasheet ISCOM5508Document5 pagesRC Datasheet ISCOM5508Muhammad WildanPas encore d'évaluation

- 3BSE062980 en L Compact Product Suite Product CatalogDocument88 pages3BSE062980 en L Compact Product Suite Product CatalogRômulo AguiarPas encore d'évaluation

- 3BSE062980 en M Compact Product Suite - Product CatalogDocument88 pages3BSE062980 en M Compact Product Suite - Product CatalogBlake CislowskiPas encore d'évaluation

- LC700 Overview March2000 EaiDocument101 pagesLC700 Overview March2000 EaiCezardeBarrosPas encore d'évaluation

- RCP/HIL FPGA-Based Real-Time SimulatorDocument2 pagesRCP/HIL FPGA-Based Real-Time Simulatorjose_jose_jose_89Pas encore d'évaluation

- Delta Ia-Plc DVP TP C en 20220906 PDFDocument52 pagesDelta Ia-Plc DVP TP C en 20220906 PDFSrirangaraj KesavarajuluPas encore d'évaluation

- Modbus Client DriverDocument9 pagesModbus Client DriverHéctor VelásquezPas encore d'évaluation

- Motor Protection and Control REM615Document8 pagesMotor Protection and Control REM615edg 3434Pas encore d'évaluation

- Gs50a01a11-01en 002Document9 pagesGs50a01a11-01en 002Dhirender DagarPas encore d'évaluation

- Bro ibaPDA-PLC-Xplorer v1.7 enDocument4 pagesBro ibaPDA-PLC-Xplorer v1.7 enhajhdjPas encore d'évaluation

- Training CourseDocument376 pagesTraining CourseHuynh DuongPas encore d'évaluation

- Data Transfer Using PLCCDocument4 pagesData Transfer Using PLCCashikPas encore d'évaluation

- Logix 3000MD Series: Technical BulletinDocument16 pagesLogix 3000MD Series: Technical BulletinSathishkumar VeluPas encore d'évaluation

- KR BECON HVACSolution Individual Global MFL61741651 Nov.2023Document49 pagesKR BECON HVACSolution Individual Global MFL61741651 Nov.2023Adan Rodríguez SoaresPas encore d'évaluation

- 4 Basic Cnet IO ProductDocument18 pages4 Basic Cnet IO ProductJefferson CastrillonPas encore d'évaluation

- ZKBioAccessIVS V3.0.1 R Brochure 20200910Document2 pagesZKBioAccessIVS V3.0.1 R Brochure 20200910Gabriel SilvaPas encore d'évaluation

- List of ProgramsDocument1 pageList of ProgramsPrawoto SoemeruPas encore d'évaluation

- TDS Profile Catalog TDSDocument28 pagesTDS Profile Catalog TDSวิระศักดิ์ วัตถุPas encore d'évaluation

- System Architecture For AUX SCADADocument1 pageSystem Architecture For AUX SCADAEngr. Nabeel Ahmad KhanPas encore d'évaluation

- LTE Access Transport Network Dimensioning ISSUE 1.02Document40 pagesLTE Access Transport Network Dimensioning ISSUE 1.02fatehmePas encore d'évaluation

- MS Course DetailsDocument2 pagesMS Course DetailsZulfiqar AhmedPas encore d'évaluation

- Cae Cilt Day 4Document66 pagesCae Cilt Day 4venkifx2000Pas encore d'évaluation

- Emc SCADA PresentationDocument36 pagesEmc SCADA Presentationerode els erodePas encore d'évaluation

- Pic Based PLCDocument21 pagesPic Based PLCWaqas Maqsud100% (1)

- VCL-TP - Teleprotection Over IP MPLSDocument4 pagesVCL-TP - Teleprotection Over IP MPLSjuandvbPas encore d'évaluation

- Controlling TM Robot by Rockwell PLC Via EtherNetIP - A Simple Integration ApplicationDocument6 pagesControlling TM Robot by Rockwell PLC Via EtherNetIP - A Simple Integration ApplicationDG RobertoPas encore d'évaluation

- XINJE Catalogue 2016Document36 pagesXINJE Catalogue 2016Emir AzharPas encore d'évaluation

- Transformer Protection and Control RET615Document8 pagesTransformer Protection and Control RET615maruf048Pas encore d'évaluation

- Basic PLC Training Material - Part2Document50 pagesBasic PLC Training Material - Part2ruchikaporwal2018Pas encore d'évaluation

- 1264 SNAP PID ModuleDocument7 pages1264 SNAP PID ModuleAlexander Charry GiraldoPas encore d'évaluation

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingD'EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingÉvaluation : 4 sur 5 étoiles4/5 (1)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosD'EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosÉvaluation : 5 sur 5 étoiles5/5 (1)

- Chapter 1 Operating SystemsDocument13 pagesChapter 1 Operating SystemsWeb MentalistPas encore d'évaluation

- VMWare Hol 2111 91 SDC - PDF - enDocument36 pagesVMWare Hol 2111 91 SDC - PDF - enmurad muslehPas encore d'évaluation

- PiggybackingDocument4 pagesPiggybackingUsama JavedPas encore d'évaluation

- Low Delay MPEG DASH Streaming Over The WebRTC Data Channel PDFDocument6 pagesLow Delay MPEG DASH Streaming Over The WebRTC Data Channel PDFRexa Mei BellaPas encore d'évaluation

- Documentacion GestioIP EnglishDocument109 pagesDocumentacion GestioIP EnglishAhmad SyahmiPas encore d'évaluation

- Com7 Act 2.3Document2 pagesCom7 Act 2.3Dhine LimbagaPas encore d'évaluation

- HP ProLiant DL560 Gen8 - Data SheetDocument4 pagesHP ProLiant DL560 Gen8 - Data SheetJohari Yovera DelgadoPas encore d'évaluation

- User Datagram Program (UDP) : TCP/IP Protocol SuiteDocument46 pagesUser Datagram Program (UDP) : TCP/IP Protocol Suitenabeel hasanPas encore d'évaluation

- Lec. 1 Computer Organization and Architecture (CPE343)Document18 pagesLec. 1 Computer Organization and Architecture (CPE343)Abu Bakar DogarPas encore d'évaluation

- Client Server Application Based On TCP-IP & UDP - Case StudyDocument8 pagesClient Server Application Based On TCP-IP & UDP - Case StudyDharmesh AcharyaPas encore d'évaluation

- Computer Components Luis RojasDocument3 pagesComputer Components Luis Rojasapi-330834419Pas encore d'évaluation

- Siemens ET200M Systems ManualDocument240 pagesSiemens ET200M Systems ManualAndrey ZimnitskiyPas encore d'évaluation

- Fortios v7.0.0 Release NotesDocument99 pagesFortios v7.0.0 Release NotesCesar Augusto Jaramillo PossoPas encore d'évaluation

- MVI56E MCMMCMXT User Manual PDFDocument199 pagesMVI56E MCMMCMXT User Manual PDFCarlos Andres Porras NinoPas encore d'évaluation

- AS400 Review Audit Work ProgramDocument12 pagesAS400 Review Audit Work ProgramKirby C. LoberizaPas encore d'évaluation

- Intel D845EPT2 Manual PDFDocument78 pagesIntel D845EPT2 Manual PDFLangllyPas encore d'évaluation

- SatLink VSAT User Guide - 0Document183 pagesSatLink VSAT User Guide - 0Marco Antônio de Castro0% (1)

- Loader - 25436 - 06 21 23 - 15 33 06Document3 pagesLoader - 25436 - 06 21 23 - 15 33 06AravindPas encore d'évaluation

- 50 Real Time Azure SQL DBA Interview QuestionsDocument3 pages50 Real Time Azure SQL DBA Interview QuestionsiamsouravkumarsPas encore d'évaluation

- Introduction To Programming 01Document23 pagesIntroduction To Programming 01Zarrar SadatPas encore d'évaluation

- Microcontroller Chapter1Document13 pagesMicrocontroller Chapter1Neelam KapoorPas encore d'évaluation

- UntitledDocument8 pagesUntitledNur suci RamadaniPas encore d'évaluation

- Vmware Validated Design: For Software-Defined Data Center 2.0Document1 pageVmware Validated Design: For Software-Defined Data Center 2.0xyz4uPas encore d'évaluation

- ECE3073 P4 Bus Interfacing Answers PDFDocument3 pagesECE3073 P4 Bus Interfacing Answers PDFkewancamPas encore d'évaluation

- TP-H26416DVD 4.8.16 Channel DVRDocument1 pageTP-H26416DVD 4.8.16 Channel DVRcloudysunPas encore d'évaluation

- Snapshots ActivosDocument10 pagesSnapshots ActivosJUAN SEBASTIAN MURCIA LAVERDEPas encore d'évaluation

- Arduinoio UgDocument296 pagesArduinoio UgmahmoudzezoglalPas encore d'évaluation

- 04 Quiz 1 - ARG OPERATING SYSTEMSDocument2 pages04 Quiz 1 - ARG OPERATING SYSTEMSrenzsantos0825Pas encore d'évaluation

- SLM License File InstallationDocument3 pagesSLM License File InstallationJaviera Aburto UlloaPas encore d'évaluation

- Yealink SIP Phones Relese Note of Version72Document37 pagesYealink SIP Phones Relese Note of Version72Luis Toledo LopezPas encore d'évaluation