Académique Documents

Professionnel Documents

Culture Documents

Prosper 2222

Transféré par

aliCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Prosper 2222

Transféré par

aliDroits d'auteur :

Formats disponibles

Examples Guide 726

Select | File | Exit | Main and this completes the exercise.

3.1.4 Tutorial 03: Modelling an oil well with black oil PVT matching

File: ~/samples/PROSPER/T03_OilWellPVTMatching.OUT

The main objectives of this example are to show:

How to set up a PROSPER model for an oil producing well

How to match calibrate the black oil correlations against actual PVT lab

measurements

How to enter the IPR data

How to describe the down hole equipment

How to perform a system calculation (VLP + IPR) to estimate the well flow

rate for a given WHFP.

How to generate a well performance curve

How to generate and export lift curves to GAP/MBAL/REVEAL or any third

party software (Eclipse, VIP, etc)

3.1.4.1 Statement Of The Problem

A well is to be drilled to produce oil from an oil reservoir.

Fluid data (PVT), reservoir data (IPR) and down hole equipment description (VLP) are

provided.

© 1990-2010 Petroleum Experts Limited

727 PROSPER

It is required to:

- Build a PROSPER well model for an oil producing well

- Calibrate the black oil correlations against lab data

- Use the model to estimate the initial flow rate against a well head flowing pressure of

250 psig

- Generate a well performance curve (Rate vs. well head flowing pressure)

- Generate lift curves to be utilised by a simulator (Reveal, GAP, MBAL, Eclipse, VIP,

etc)

3.1.4.2 PVT Input Data

The basic available PVT data are:

Parameter Value

Solution GOR: 400 scf/stb

Oil Gravity: 30 API

Gas gravity: 0.75 (Air =1)

Water salinity: 80000 ppm

Impurities (CO2, N2, H2S): None

Bubble point pressure: 2500 psig at 200 degF

Further PVT data are given in tabular form below at 200 degF:

Pressure in psig Gas Oil Ratio in scf/ Oil FVF in rb/stb Oil Viscosity in

stb centipoises

1500 237 1.138 1.34

2000 324 1.178 1.15

2500 400 1.214 1.01

3000 400 1.207 1.05

4000 400 1.198 1.11

3.1.4.3 System Equipment Input Data

The system equipment input section is sub-divided into 5 sub-sections:

- Deviation survey

- Surface equipment

- Down hole equipment

- Geothermal gradient and

- Average heat capacities

3.1.4.3.1 Deviation survey

In PROSPER, the deviation survey can have its origin anywhere: well head, sea-bed,

platform, RKB etc.

The key thing is to describe all the equipment in the well in a manner consistent with the

origin selected.

The well head depth does not have to coincide with the origin of the deviation survey.

PROSPER Manual January, 2010

Examples Guide 728

Measured Depth in ft True Vertical Depth in ft

0 0

8000 8000

3.1.4.3.2 Surface Equipment

All equipment located downstream of the well head are part of the surface equipment.

The surface equipment can include: well head chokes, risers, flow lines, fittings, and so

on.

In this example the surface equipment will not be modelled.

3.1.4.3.3 Down hole Equipment

The down hole equipment include the tubings, casings, nipples, Sub-surface Safety

valves and so on.

Equipment Measured Internal Roughness in Rate multiplier

type depth in ft diameter in inches

(down to) inches

Xmas Tree (Well0 N/A N/A N/A

Head)

Tubing 7800 3.992 0.0018 1

Casing 8000 8.3 0.0018 1

3.1.4.3.4 Static Geothermal Gradient

The geothermal gradient expresses the rate of increase in temperature per unit depth.

The geothermal gradient is independent of the well flow rate.

When using the rough approximation temperature prediction method, the geothermal

gradient is entered versus measured depth. PROSPER internally converts the

measured depth into true vertical depth. It is the temperature gradient based upon the

true vertical depth that is used during the calculation.

Measured Depth in ft Static temperature in deg F

0 70

8000 200

The overall heat transfer coefficient is 8 btu/h/ft2/F.

Note: The overall heat transfer (also called U value) is a composite number that

captures the different heat transfer mechanisms taking place: conduction, convection

and radiation. It can be thought of as the inverse of the thermal resistance in the

surroundings of the wellbore.

© 1990-2010 Petroleum Experts Limited

729 PROSPER

3.1.4.3.5 Average Heat Capacities

Here are the default average heat capacities that will be used:

Phase Heat Capacity in btu/lb/F

Oil: 0.53

Gas: 0.51

Water: 1

3.1.4.4 Reservoir Input Data

PROSPER has more than 20 different inflow models for oil wells. The IPR model

selection depends upon the purpose of the study, the suitability of the particular model

and the data available for the study.

IPR model: Darcy / Enter Skin by hand

Static Reservoir Pressure: 4000 psig

Reservoir Temperature: 200 degF

Water Cut: 0%

Total GOR: 400 scf/stb

Compaction Permeability Reduction No

model:

Relative Permeability: No

Reservoir Permeability: 150 mD

Reservoir Thickness (True stratigraphic 100 ft

thickness) :

Drainage Area: 340 acres

Dietz shape factor: 31.6

Well bore radius (Drill bit radius): 0.354 ft

Mechanical skin: +2

3.1.4.5 Step by Step

The following pages provide a step-by-step procedure that will lead to the solution of the

problem:

- Build a PROSPER well model for an oil producing well

- Calibrate the black oil correlations against lab data

- Use the model to estimate the initial flow rate against a well head flowing pressure of

250 psig

- Generate a well performance curve (Rate vs. well head flowing pressure)

- Generate lift curves to be utilised by a simulator (Reveal, GAP, MBAL, Eclipse, VIP,

etc)

PROSPER Manual January, 2010

Examples Guide 730

3.1.4.5.1 System Options

Simply select | File | New if a PROSPER file is already open.

Otherwise, select | Options | Options and make the following choices:

Fluid: Oil and Water. All other settings can be left to their defaults options.

Select | Done to complete this step.

3.1.4.5.2 PVT data Input

In order to enter the PVT data, simply select | PVT | Input Data and populate the screen

as shown below:

© 1990-2010 Petroleum Experts Limited

731 PROSPER

Parameter Value

Solution GOR: 400 scf/stb

Oil Gravity: 30 API

Gas gravity: 0.75 (Air =1)

Water salinity: 80000 ppm

Impurities (CO2, N2, H2S): None

In order to enter the lab measurements at different pressures, select the | Match Data

button and populate the table as follow:

PROSPER Manual January, 2010

Examples Guide 732

Select | Done to get back to the PVT input screen

PVT regression

Now select |Regression | Match All to kick the non-linear regression algorithm. The

following screen will confirm when the regression is completed.

© 1990-2010 Petroleum Experts Limited

733 PROSPER

In order to quality-check the regression, select | OK | Parameters and this is what can be

seen:

Please consult the online help to get the details about the regression algorithm.

Ideally, Parameter 1, which is a multiplier, should be close to unity whereas the shift

(Parameter 2) is expected to be around nil.

On the basis of the results obtained here, we will proceed with the combination Glaso /

Petrosky.

For this, select | Done | Done and choose the appropriate black oil correlations as per

screen-shot below:

PROSPER Manual January, 2010

Examples Guide 734

Select | Done and this complete this step.

3.1.4.5.3 Saving the file

Like working with any other computer program, it is good practice to save the file

frequently in order to avoid data loss in case the computer crashes.

To save a file, simply select | File | Save as.

Afterwards, simply browse to the place where the file is to be saved.

It is suggested to save the file as *.OUT file.

© 1990-2010 Petroleum Experts Limited

735 PROSPER

The rest is self-explanatory.

3.1.4.5.4 System Equipment Description

In order to describe the system equipment (i.e the hardware in and around the well

bore), simply select | System | Equipment (Tubing etc) | All

PROSPER Manual January, 2010

Examples Guide 736

Now by selecting | Edit, the software will take the user through all the screens necessary

to input the equipment data starting with the deviation survey

3.1.4.5.4.1 Deviation Survey

Here are the data:

Measured Depth in ft True Vertical Depth in ft

0 0

8000 8000

© 1990-2010 Petroleum Experts Limited

737 PROSPER

Note: It is possible to input or import a large deviation survey table into PROSPER. A

filtering algorithm is implemented that will select up to 20 of the most relevant data

points describing the well trajectory.

For this, the | Filter button located on the top right of this screen is to be used.

Select | Done and the screen labelled Surface Equipment will follow.

3.1.4.5.4.2 Surface Equipment

This model will not include any surface equipment.

PROSPER Manual January, 2010

Examples Guide 738

Selecting the "Cancel" button located on the top left of the screen will take the user to

the next screen: the down hole equipment description screen.

3.1.4.5.4.3 Down Hole Equipment

The down hole equipment includes the tubings, casings, nipples, Sub-surface Safety

valves and so on.

Equipment Measured Internal Roughness in Rate multiplier

type depth in ft diameter in inches

(down to) inches

Xmas Tree (Well0 N/A N/A N/A

Head)

Tubing 7800 3.992 0.0018 1

Casing 8000 8.3 0.0018 1

© 1990-2010 Petroleum Experts Limited

739 PROSPER

The deepest entry in the down hole equipment section is the datum depth for the

static reservoir pressure that will be entered in the IPR section.

It is recommended to take the top perforation as the reference depth for the static

reservoir pressure. This implies that the down hole equipment description must stop at

the top of the perforation. This is also true for multiple-zone completion because the

pressure drop between the zones will be taken into account by the appropriate Inflow

model (multi-layer IPR model with dP or multilateral IPR model).

Select | Done to proceed to the next screen: the geothermal gradient.

3.1.4.5.4.4 Geothermal gradient

The data available are:

Measured Depth in ft Static temperature in deg F

0 70

8000 200

PROSPER Manual January, 2010

Examples Guide 740

The overall heat transfer coefficient is 8 btu/h/ft2/F.

Select | Done to proceed to the average heat capacity screen.

3.1.4.5.4.5 Average Heat Capacities

The default average heat capacity values will be used for this example.

© 1990-2010 Petroleum Experts Limited

741 PROSPER

Note: The | Default button will reset any user-entered values.

With | Done the entry screen of the Equipment data section will be accessed:

3.1.4.5.4.6 Equipment Summary

From the Equipment Data screen, one can generate a sketch of the well bore with |

Summary and this is what would appear:

PROSPER Manual January, 2010

Examples Guide 742

If one then selects | Draw Down hole this is the sketch of the well bore that appears:

© 1990-2010 Petroleum Experts Limited

743 PROSPER

Select | Main to exit the screen.

3.1.4.5.4.7 Saving the PROSPER file

It is recommended to save / overwrite the file at this stage.

To save the file, simply select | File | Save and then simply answer YES to overwriting

the file.

3.1.4.5.5 Inflow Performance Relation (IPR)

To select the IPR model, simply select | System | Inflow Performance and make the

appropriate choices as follows:

IPR model selection

IPR model: Darcy

Static Reservoir Pressure: 4000 psig

Reservoir Temperature: 200 degF

Water Cut: 0%

Total GOR: 400 scf/stb

Compaction Permeability ReductionNo

model:

Relative Permeability correction: No

PROSPER Manual January, 2010

Examples Guide 744

Skin model: Enter skin by hand

To proceed, simply select the Input Data button (red if invalid) in the top right corner of

the screen above:

IPR data entry

Reservoir Permeability: 150 mD

Reservoir Thickness (True stratigraphic 100 ft

thickness) :

Drainage Area: 340 acres

Dietz shape factor: 31.6

Well bore radius (Drill bit radius): 0.354 ft

© 1990-2010 Petroleum Experts Limited

745 PROSPER

From the screen above, select the the tab "Mech/Geom Skin" at the bottom left corner

of the screen to enter the mechanical skin:

IPR : Skin value entry

Mechanical skin: +2

PROSPER Manual January, 2010

Examples Guide 746

IPR : Generating an IPR plot

Once the IPR data input is completed, it is a good practice to create an IPR plot to verify

that everything makes sense. For this, simply select | Calculate and the software will

create and display the following plot:

© 1990-2010 Petroleum Experts Limited

747 PROSPER

Please select | Main and then save the PROSPER file with | File | Save to secure all

changes made so far.

3.1.4.5.6 Estimation of the well flow rate

The response of a well bore combines fluid properties (PVT), reservoir data (IPR) and

tubing response (VLP).

The fluid properties are used to compute the reservoir response (IPR) and the tubing

response (VLP).

For a given set of boundary conditions (given reservoir pressure and well head flowing

pressure), the well flow rate is the intersection between the IPR curve and the VLP

curve.

In order to compute this intersection point with PROSPER, simply select | Calculation |

System | 3 Variables as per screen-shot below:

PROSPER Manual January, 2010

Examples Guide 748

After selecting the system calculation, one needs to enter the well head flowing pressure

as per screen-shot below:

© 1990-2010 Petroleum Experts Limited

749 PROSPER

The top node pressure is the pressure downstream of the system. Since here there is

no pipeline in this PROSPER model, the top node pressure is the well head flow

pressure.

The parameters Water Cut and GOR were entered earlier on the IPR screen. For the

fluid description, there was also a need to enter the GOR on the PVT screen.

However, during the life of a well either parameter may change. Therefore, this screen

allow the user to sensitize both.

When sensitizing on the water cut and / or the GOR, PROSPER will use the new

sensitivity values for the calculations It will no longer use the GOR and the water cut

values entered on the IPR screen or the GOR from the PVT screen. The same principle

applies to all sensitivity variables specified elsewhere.

Surface Equipment Correlation: This applies to any pipeline in the model. Since this

PROSPER Manual January, 2010

Examples Guide 750

model does not include any pipeline, the choice of a pipeline correlation is irrelevant.

Vertical Lift Correlation: Petroleum Experts 2.

Solution Node: Bottom Node

Rate Method: Automatic - Linear

Left-Hand Intersection: DisAllow

One can proceed with | Continue | Continue and Calculate with the following results:

One can read an oil rate of 10 500 stb/d as solution rate. The corresponding BHFP

reads: 2584 psig.

If one selects | Plot | System Plot, the system plot (VLP + IPR plot) is displayed as

follow:

© 1990-2010 Petroleum Experts Limited

751 PROSPER

Select | Main to get back to the main PROSPER screen and save the file to secure all

changes made so far.

3.1.4.5.7 Well Performance Curve Generation

A well performance is a plot of flow rate versus well head pressure at a given reservoir

pressure.

Therefore, generating a well performance simply means running sensitivities on the well

head flowing pressure, from a very low well head pressure to the highest possible well

pressure that will shut-in the well.

In this example, we will vary the well head flowing pressure from 50 psig to 1200 psig.

For this, simply select | Calculation | System (IPR VLP) | 3 Variables | Continue and here

select the sensitivity variable "First Node Pressure":

PROSPER Manual January, 2010

Examples Guide 752

One can manually populate the cells with the desired values or generate them

automatically with | Generate. Afterwards, one needs to enter the first value, the last

value, the number of values and the sequencing algorithm:

© 1990-2010 Petroleum Experts Limited

753 PROSPER

To complete the process, simply select | Generate and then the input cells are

populated accordingly:

One can see that on this screen up to 3 variables can be sensitized on simultaneously. It

is generally possibly to sensitize on any number of parameters.

With | Continue | Calculate, ten (10) sets of VLP and IPR are computed.

To visualise a plot of the solution rate versus first node pressure, select | Sensitivity.

This is the plot of the Bottom Hole Flowing Pressure versus First Node pressure, the

first node being the well head.

PROSPER Manual January, 2010

Examples Guide 754

In order to plot the oil flow rate versus the first node pressure, one simply needs to select

| Variables and then | Gas Rate for the Y axis variable:

With | Done, the well performance curve appears as follow:

© 1990-2010 Petroleum Experts Limited

755 PROSPER

This completes this section.

Select | Main to return to the main screen of PROSPER.

3.1.4.5.8 Lift Curve generation for other applications

3.1.4.5.8.1 Introduction

Lift curves express the pressure drop across a tubing for a given set of variables.

Different software providers use different formats and acronyms for lift curves.

The most common acronyms are:

- VLP for Vertical Lift Performance

- TPD for Tubing Performance Data

- TPC for Tubing Performance Curves

- VFP for Vertical Flow Performance and so on.

For naturally flowing oil wells, the variables involved in lift curve generation are:

- liquid rate

- Well Head flowing pressure (= first node pressure)

- Water Cut and

PROSPER Manual January, 2010

Examples Guide 756

- GOR

Even though in this case, four (4) variables will change, the lift curves are referred to as

3-Variables VLP. The rate variable is taken for granted as one cannot calculate

pressure drop without flow rate.

The 3 VLP variables for a naturally flowing oil well are: WHFP, GOR & Water Cut.

Recommendation:

In this example, we will demonstrate how to generate lift curves with PROSPER since lift

curve generation is a key task that PROSPER is used to perform. However, if a project

involves the generation of lift curves for multiple wells, a more efficient approach would

involve the use of GAP, the network modelling and optimisation tool developed by

Petroleum Experts.

Here are the reasons why:

- GAP will instruct PROSPER to generate the lift curves using the very same PROSPER

well model created by the user and linked to the well icon in GAP

- GAP uses PROSPER to generate and save lift curve for any number of wells in batch-

mode. This can be done overnight for instance to save time.

- GAP will ask for the right VLP variables input depending upon the well type. The

variable selection for lift curves can sometimes be delicate because different simulators

use different names for the same quantity (example gas lift injection rate versus. GLR

injected).

3.1.4.5.8.2 Steps

In order to generate wells' VLP, one first needs to work out the variables involved. Here

these variables are liquid rate, WHFP, GOR and Water Cut.

The second step is to choose values for the variables in such a manner that the host

application (GAP, MBAL, REVEAL, Eclipse, etc) can reasonably interpolate between

them to find the solution needed. Extrapolation and very large variable spacing are to be

avoided.

In this example, the following values will be used:

Liquid Rate: from 100 stb/d to 15 000 stb/d. The performance curve generated earlier

shows that the well can produce a maximum of 12 000 stb/d without artificial lift.

WHFP: from 50 psig to 1500 psig; Those values will cover the following situations:

from nearly fully open well to the full shut-in (see performance curve generated earlier).

Water cut: from 0 to 100%.

GOR: From 300 scf/stb to 15000 scf/stb.

In order to enter the data for the lift curve generation , select | Calculation | VLP (Tubing

Curves) | 3 Variables

© 1990-2010 Petroleum Experts Limited

757 PROSPER

The next screen shot can be used to enter the range of rates to use:

PROSPER Manual January, 2010

Examples Guide 758

A few notes:

The values for top node pressure, water cut and GOR will be overwritten through the

sensitivity variables.

One should make sure that the right VLP correlation is selected. Here, the Petroleum

Experts 2 correlation will be used.

The "User Selected" rate method gives control to the user to enter the rates he /she

think will best describe the expected operating ranges of the well.

One should also ensure that the first and last node are correctly selected.

© 1990-2010 Petroleum Experts Limited

759 PROSPER

In order to proceed, simply select | Continue, select the relevant variables and populate

the entries as per screen-shot below:

Now simply select | Continue to proceed.

The lift curve calculation is triggered with | Calculate.

PROSPER Manual January, 2010

Examples Guide 760

Be patient as this might take a while!

At the end, a message will confirm that the calculation has completed.

It is always a good practice to plot and visualise the lift curves before exporting them.

In this example, simply select | Plot and this is what appears:

© 1990-2010 Petroleum Experts Limited

761 PROSPER

One can see that the lift curves do all have the right shape (J -curve) and look smooth.

One can return to the previous screen with | Finish.

In order to export the lift curve, simply select the button "Export Lift Curve".

PROSPER Manual January, 2010

Examples Guide 762

The following screen will appear where one has to select the format for the host

application (here Eclipse):

© 1990-2010 Petroleum Experts Limited

763 PROSPER

The process is completed with | Continue | Save and the file is saved and edited

automatically for viewing:

Select | File | Exit | Main and this completes the exercise.

3.1.5 Tutorial 04: Modelling an horizontal oil well

File: ~/samples/PROSPER/T04_HorizontalOilWell.out

The main objectives of this example are to show:

How to set up a PROSPER model for a horizontal oil well

How to enter basic black oil PVT data

How to enter the IPR data

How to describe the down hole equipment

How to perform a system calculation (VLP + IPR) to estimate the well flow

rate for a given WHFP of 250 psig.

PROSPER Manual January, 2010

Examples Guide 764

How to generate a well performance curve

How to generate and export lift curves to GAP/MBAL/REVEAL or any third

party software (Eclipse, VIP, an so on)

3.1.5.1 Statement Of The Problem

A horizontal well is to be drilled to produce oil.

Fluid data (PVT), reservoir data (IPR) and down hole equipment description (VLP) are

provided.

It is required to:

- Estimate the initial oil rate against a well head flowing pressure of 250 psig

- Perform sensitivity runs on the horizontal well length for 500 ft, 1000 ft, 1500 ft, 2000 ft,

2500 ft and 3000 ft.

- Sensitize simultaneously on water cut of 0 %. 10%, 20%, 30%, 40% and 50%.

3.1.5.2 PVT Input Data

The basic available PVT data are:

Parameter Value

Solution GOR: 400 scf/stb

Oil Gravity: 30 API

Gas gravity: 0.75 (Air =1)

Water salinity: 80000 ppm

Impurities (CO2, N2, H2S): None

Bubble point pressure: 2500 psig at 200 degF

Further PVT data are given in tabular form below at 200 degF:

Pressure in psig Gas Oil Ratio in scf/ Oil FVF in rb/stb Oil Viscosity in

stb centipoises

1500 237 1.138 1.34

2000 324 1.178 1.15

2500 400 1.214 1.01

3000 400 1.207 1.05

4000 400 1.198 1.11

3.1.5.3 System Equipment Input Data

The system equipment input section is sub-divided into 5 sub-sections:

- Deviation survey

- Surface equipment

- Down hole equipment

© 1990-2010 Petroleum Experts Limited

Vous aimerez peut-être aussi

- Tutorial Prosper 08Document6 pagesTutorial Prosper 08FernandoChauque100% (1)

- Prosper® Tutorial 09: Modelling A Water Injection WellDocument49 pagesProsper® Tutorial 09: Modelling A Water Injection WellPedro MarquezPas encore d'évaluation

- PtrE 521 - Lecture 3 - Other Artificial Lift TechnologiesDocument144 pagesPtrE 521 - Lecture 3 - Other Artificial Lift TechnologiesGhoulemEllah Haithem IfrenePas encore d'évaluation

- Prosper 444 PDFDocument27 pagesProsper 444 PDFaliPas encore d'évaluation

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsD'EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsPas encore d'évaluation

- Bottomholemodaloil PCDocument6 pagesBottomholemodaloil PCKimiko ShopPas encore d'évaluation

- Multilateral Oil Well DeliverabilityDocument8 pagesMultilateral Oil Well DeliverabilityPuppy Ayu JatmikoPas encore d'évaluation

- 1ntroduction To Petroleum Production SystemDocument12 pages1ntroduction To Petroleum Production SystemHadi Bapir SlemanPas encore d'évaluation

- Prosper® Tutorial 08: Modelling A Gas Well With Connected PipelineDocument9 pagesProsper® Tutorial 08: Modelling A Gas Well With Connected PipelinePedro MarquezPas encore d'évaluation

- Initial Oil in PlaceDocument21 pagesInitial Oil in PlacehamougPas encore d'évaluation

- Sucker Rod Pumping Flow Rate&PowerDocument4 pagesSucker Rod Pumping Flow Rate&PowerDian Handayani PratiwiPas encore d'évaluation

- Inflow Performace: Petroleum Engineering ProductionDocument16 pagesInflow Performace: Petroleum Engineering Productionكهلان البريهيPas encore d'évaluation

- Poettmann Carpenter BHPDocument5 pagesPoettmann Carpenter BHPPablo GnzgaPas encore d'évaluation

- M SC Petroleum Engineer 2Document3 pagesM SC Petroleum Engineer 2anouari2014Pas encore d'évaluation

- Pipesim Modelado AvancadoDocument62 pagesPipesim Modelado Avancadoluis alberto godinez villaPas encore d'évaluation

- SKPP3513 Assignment 3Document5 pagesSKPP3513 Assignment 3Zul AtfiPas encore d'évaluation

- PlungerliftDocument6 pagesPlungerliftAndreina MonasteriosPas encore d'évaluation

- Answer Key PE 2016Document20 pagesAnswer Key PE 2016Rahul Sharma100% (1)

- PEG 4102 - Sucker Rod Pump Project PresentationDocument22 pagesPEG 4102 - Sucker Rod Pump Project PresentationAlex StollPas encore d'évaluation

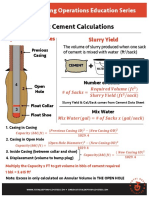

- Basic Cement CalculationsDocument1 pageBasic Cement Calculationsابوالحروف العربي ابوالحروفPas encore d'évaluation

- Well Test Analysis PDFDocument23 pagesWell Test Analysis PDFJaime Alberto Aranibar CabreraPas encore d'évaluation

- Enhanced Oil Recovery (Eor) Eor Screening Using Eorgui SoftwareDocument13 pagesEnhanced Oil Recovery (Eor) Eor Screening Using Eorgui SoftwareMohanad HussienPas encore d'évaluation

- NTZ Pump SpecsDocument4 pagesNTZ Pump SpecsMaxPas encore d'évaluation

- PetroquizDocument2 pagesPetroquizRia Jain100% (2)

- Buckley and Leverett (1942) : Reservoir Engineering HandbookDocument32 pagesBuckley and Leverett (1942) : Reservoir Engineering Handbookحسين رامي كريم A 12Pas encore d'évaluation

- Final Module 5 - GEO Technical OrderDocument18 pagesFinal Module 5 - GEO Technical OrderNayeem SheikPas encore d'évaluation

- Nodal Analysis GasDocument12 pagesNodal Analysis GasFebry Putra Wangsa JayaPas encore d'évaluation

- Introduction To Reservoir EngineeringDocument82 pagesIntroduction To Reservoir Engineeringweldsv50% (2)

- Report of BuzurganDocument10 pagesReport of Buzurgankazm0% (1)

- Assignment 1Document2 pagesAssignment 1Fizz MartinPas encore d'évaluation

- Water Drive Oil ReservoirDocument2 pagesWater Drive Oil ReservoirJoseph YepezPas encore d'évaluation

- Tarea 1Document7 pagesTarea 1Carlos Alberto MHPas encore d'évaluation

- University of Tripoli Faculty of Engineering Petroleum EngineeringDocument8 pagesUniversity of Tripoli Faculty of Engineering Petroleum EngineeringRoba SaidPas encore d'évaluation

- Production 2Document22 pagesProduction 2Ramy MaamounPas encore d'évaluation

- Feb 8 WeekDocument51 pagesFeb 8 WeekMohammad Iqbal Mahamad Amir100% (2)

- PIPESIM 2019: Steady-State Multiphase Flow SimulatorDocument32 pagesPIPESIM 2019: Steady-State Multiphase Flow SimulatorHafiz AkhtarPas encore d'évaluation

- Well Head NodalDocument7 pagesWell Head Nodalmath62210Pas encore d'évaluation

- Suckerrodpumpingflowrate&Power - XLS: TF To TiDocument4 pagesSuckerrodpumpingflowrate&Power - XLS: TF To TiyoleidacrPas encore d'évaluation

- Drainage RadiusDocument33 pagesDrainage RadiusAngela rismaPas encore d'évaluation

- Advanced Reservoir Sheet 1,2Document7 pagesAdvanced Reservoir Sheet 1,2Abdelazim MohamedPas encore d'évaluation

- Artificial Lift MethodsDocument7 pagesArtificial Lift MethodsusmanPas encore d'évaluation

- 10.1 Wte-Lect. No.10 (2SPP)Document10 pages10.1 Wte-Lect. No.10 (2SPP)Omer IkhlasPas encore d'évaluation

- Petroleum Engineering SoftwareDocument1 pagePetroleum Engineering SoftwareMikhailPas encore d'évaluation

- Final Project PDFDocument56 pagesFinal Project PDFAbbas AlkhudafiPas encore d'évaluation

- PCP PDFDocument14 pagesPCP PDFRizwan Farid100% (1)

- Pe 04025 Reservoir IDocument9 pagesPe 04025 Reservoir ISona SithPas encore d'évaluation

- Pvtsim Technical Overview 2016 Download v3Document16 pagesPvtsim Technical Overview 2016 Download v3Jorge Vásquez CarreñoPas encore d'évaluation

- Topic: Mathematical Modelling of Liquid Loading in Natural Gas ReservoirDocument14 pagesTopic: Mathematical Modelling of Liquid Loading in Natural Gas ReservoirAkashShuklaPas encore d'évaluation

- Assignment 2 MBEDocument3 pagesAssignment 2 MBEBadut SarkasPas encore d'évaluation

- Artificial Lift Technology Quizzes Questions: Lecture # 1 Sept 3, 2020Document21 pagesArtificial Lift Technology Quizzes Questions: Lecture # 1 Sept 3, 2020Jhon Hery T.R. Harahap100% (2)

- Van Everdingen Hurst AquifersDocument21 pagesVan Everdingen Hurst Aquifers13670319100% (1)

- The General Material Balance EquationDocument12 pagesThe General Material Balance EquationArrofi NurmidaPas encore d'évaluation

- Microbial Enhancement of Oil Recovery - Recent AdvancesD'EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesPas encore d'évaluation

- Fundamentals and Applications of Bionic Drilling FluidsD'EverandFundamentals and Applications of Bionic Drilling FluidsPas encore d'évaluation

- Introduction to Enhanced Recovery Methods for Heavy Oil and Tar SandsD'EverandIntroduction to Enhanced Recovery Methods for Heavy Oil and Tar SandsPas encore d'évaluation

- Practical Petroleum Geochemistry for Exploration and ProductionD'EverandPractical Petroleum Geochemistry for Exploration and ProductionPas encore d'évaluation

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyD'EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyPas encore d'évaluation

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeD'EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeÉvaluation : 4 sur 5 étoiles4/5 (2)

- Running Casing (Drillers) : Cormorant Alpha Drilling Operations GuideDocument21 pagesRunning Casing (Drillers) : Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- 101 IntroPVTsimDocument9 pages101 IntroPVTsimaliPas encore d'évaluation

- Production Data Analysis To Aid Reservoir CharacterizationDocument8 pagesProduction Data Analysis To Aid Reservoir CharacterizationaliPas encore d'évaluation

- KDP Well Test Procedures ManualDocument77 pagesKDP Well Test Procedures ManualJacob Keemink100% (2)

- Reeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuideDocument5 pagesReeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- 107 Fluid SamplingDocument33 pages107 Fluid SamplingaliPas encore d'évaluation

- Racking Back The Kelly: Cormorant Alpha Drilling Operations GuideDocument3 pagesRacking Back The Kelly: Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- Sec1 07Document14 pagesSec1 07aliPas encore d'évaluation

- Laying Down Pipe (Floorman) : Cormorant Alpha Drilling Operations GuideDocument9 pagesLaying Down Pipe (Floorman) : Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- Bha Handling (Driller) : 1) Elevators. 2) Slips. 3) Bowls. 4) Dog Collars (Safety Clamps) - 5) Drill Collars. 5) Subs. 6)Document17 pagesBha Handling (Driller) : 1) Elevators. 2) Slips. 3) Bowls. 4) Dog Collars (Safety Clamps) - 5) Drill Collars. 5) Subs. 6)aliPas encore d'évaluation

- Pulling Pipe (Driller) : Cormorant Alpha Drilling Operations GuideDocument10 pagesPulling Pipe (Driller) : Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- Registration Certificate: Dem 0 Page 1 of 3 Issue 1 July 1996Document3 pagesRegistration Certificate: Dem 0 Page 1 of 3 Issue 1 July 1996aliPas encore d'évaluation

- Picking Up Pipe (Floorman) : Cormorant Alpha Drilling Operations GuideDocument9 pagesPicking Up Pipe (Floorman) : Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- Making Connections With The Kelly: Cormorant Alpha Drilling Operations GuideDocument10 pagesMaking Connections With The Kelly: Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- Polymers Chemistry 5Document16 pagesPolymers Chemistry 5aliPas encore d'évaluation

- Stuck Pipe Exercise-8Document1 pageStuck Pipe Exercise-8aliPas encore d'évaluation

- Stuck Pipe ChartDocument1 pageStuck Pipe ChartaliPas encore d'évaluation

- Composition of Mud-2Document12 pagesComposition of Mud-2aliPas encore d'évaluation

- Basic Filtration 03Document9 pagesBasic Filtration 03aliPas encore d'évaluation

- WBM Systems 6Document19 pagesWBM Systems 6aliPas encore d'évaluation

- Basic Rheology 4Document17 pagesBasic Rheology 4aliPas encore d'évaluation

- Leader in Drilling Systems & Controls: Active Heave DrawworksDocument20 pagesLeader in Drilling Systems & Controls: Active Heave DrawworksaliPas encore d'évaluation

- 3 PDFDocument62 pages3 PDFaliPas encore d'évaluation

- Drilling Fluid Functions-1Document14 pagesDrilling Fluid Functions-1aliPas encore d'évaluation

- Sands and Sandstones Matrix Permeability: Flow Chart To Select Non-Damaging Horizontal Drill-In FluidDocument9 pagesSands and Sandstones Matrix Permeability: Flow Chart To Select Non-Damaging Horizontal Drill-In FluidaliPas encore d'évaluation

- Picking Up The Kelly: Cormorant Alpha Drilling Operations GuideDocument3 pagesPicking Up The Kelly: Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- Overview of The Manual: Dem 1 Page 1 of 6 Issue 1 July 1996Document6 pagesOverview of The Manual: Dem 1 Page 1 of 6 Issue 1 July 1996aliPas encore d'évaluation

- Exxon Mud BookDocument366 pagesExxon Mud BookOrlando PalaciosPas encore d'évaluation

- Drawwork Control: Cormorant Alpha Drilling Operations GuideDocument7 pagesDrawwork Control: Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- Sec03 PDFDocument85 pagesSec03 PDFaliPas encore d'évaluation

- TEST-13 (ME) Fluid Mechanics (FM01) Ies MasterDocument22 pagesTEST-13 (ME) Fluid Mechanics (FM01) Ies MasterBrijesh KumarPas encore d'évaluation

- Physics FormulasDocument20 pagesPhysics Formulasbrandon100% (1)

- Q PapersDocument53 pagesQ PapersTanu RdPas encore d'évaluation

- 7MF4033 1ga10 2ab6 Za01Document222 pages7MF4033 1ga10 2ab6 Za01DangolPas encore d'évaluation

- Banlaw Sales Brochures RailDocument6 pagesBanlaw Sales Brochures Railapi-3752216Pas encore d'évaluation

- Uniform Costing Model User's Guide: Prepared For The Texas Water Development BoardDocument105 pagesUniform Costing Model User's Guide: Prepared For The Texas Water Development Boardועדת איכות הסביבה חייםPas encore d'évaluation

- Tutorial 10 FluidsDocument2 pagesTutorial 10 Fluidsapi-3827354Pas encore d'évaluation

- Lab 1Document6 pagesLab 1aminsubriPas encore d'évaluation

- Thermodynamic Steam TrapDocument8 pagesThermodynamic Steam TrapMallela Sampath KumarPas encore d'évaluation

- Fma 1967Document45 pagesFma 1967John LingPas encore d'évaluation

- Investigation On Conveyance Motion Using CFD and Structural AnalysisDocument14 pagesInvestigation On Conveyance Motion Using CFD and Structural AnalysisAndrew PeterPas encore d'évaluation

- Dryspell Plus Manual 1Document67 pagesDryspell Plus Manual 1Reuel TacayPas encore d'évaluation

- CAT 01 Hydraulic Fundamental Student GuideDocument106 pagesCAT 01 Hydraulic Fundamental Student Guidewarshipvn100% (6)

- Chapter 13, GasesDocument24 pagesChapter 13, GasesTeza Nur FirlyansyahPas encore d'évaluation

- O Gage Atm 97 KpaDocument4 pagesO Gage Atm 97 Kpayeng botzPas encore d'évaluation

- Test Ch#3 1st YearDocument3 pagesTest Ch#3 1st YearRashid Jalal100% (1)

- Hall YarboroughDocument8 pagesHall YarboroughLawrence MbahPas encore d'évaluation

- ENGINEERING DESIGN GUIDELINES Relief Valves Sizing and Selection Rev WebDocument31 pagesENGINEERING DESIGN GUIDELINES Relief Valves Sizing and Selection Rev Webjr_satish6965Pas encore d'évaluation

- CIE - O Level - Physics Syllabus - 2020-2021Document40 pagesCIE - O Level - Physics Syllabus - 2020-2021astargroupPas encore d'évaluation

- US ARMY Gates and Valves PDFDocument58 pagesUS ARMY Gates and Valves PDFJonathan ColePas encore d'évaluation

- Compiled Property Calculation (30C) PDFDocument66 pagesCompiled Property Calculation (30C) PDFcryptic postPas encore d'évaluation

- Determination of Natural Gas Recovery Factors: JC.p/66:"'D3Document15 pagesDetermination of Natural Gas Recovery Factors: JC.p/66:"'D3Hector MarzanaPas encore d'évaluation

- Practice Problem Turbine Fans and Blower and CompressorDocument3 pagesPractice Problem Turbine Fans and Blower and CompressorRey Regaspi Tuyay50% (2)

- Production LoggingDocument70 pagesProduction Loggingjdaksh204Pas encore d'évaluation

- In-Breathing, Out-Breathing Tank Vapor Vents OriginalDocument8 pagesIn-Breathing, Out-Breathing Tank Vapor Vents OriginalPatricio G. ArrienPas encore d'évaluation

- Drilling Calculation SummaryDocument3 pagesDrilling Calculation SummaryBerat HasolliPas encore d'évaluation

- Spectraa 240Document58 pagesSpectraa 240JESUS ABAD100% (1)

- 11 Fluids SDocument26 pages11 Fluids SapocalypticPas encore d'évaluation

- Boyle's Law Questions PDFDocument3 pagesBoyle's Law Questions PDFamvijayagopal100% (1)